Transcription

Hansen P4Hansen M4ACCPowerful solutions for cooling towers and aircooled condensersSolutions performantes pour aéroréfrigérantset condensateurs à airLeistungsstarke Lösungen für Kühltürme undLuftkondensatorenPotentes soluciones para torres de refrigeracióny condensadores de aire604 EFDS gKatalog 991228 EN/FR/DE/ES 10/2019

ggMWCCCOOOMMPPPLLLEEETTTEEE AAANNNDDD PPPOOOWWEEERRRFFFUUULLLMPPLLEETTEE AANNDD PPOOWWEERRFFUULLCCOOMSSSOOOLLLUUUTTTI IIOOONNNSSS FUULLCCOOOLMPLETEANDEDOLINGTOWEOLINGTOWC O O L I N G T O W ERRRSSSCOOLINGTOWERSCOOLINGTOWERSSSOOLLUUTTI IOONNSS FFOORRWEERRSSCCOOOOLLI INNGG TTOOWMPPLLEETTEE AANNDD coolingtowerfandrives,HansenoncoolingtowerfanCOLLI OTTOOWRRSS lyIndustrial Transmissions’drives are hstandexactingoperatingIndustrial onditions,whilestillareusinga mcreates flexibleandwhileservicesflexibleunits iblegeargearunitsthatcancanbe kingthesecanbe adaptedto vicesflexiblegearunits that canbe nbe rd.standard.created a rangeof smissionscreatedThisway smissionsdesigns,createsandfor the cancanbeProof offlexiblethe products’reliabilityis yisisthefor ngadaptedspecificrequirements.ISO thenents,ofofweoffera rangeof gear sServicesCentres.Usingstandardcompocustomisedto thespecificneedsof lications.applications.industryggcccc oooo llll iiii nnggoooonnggcc oo oo ll ii nn gg HHAANNSSEENN PP44: ::AALL GGEEAARR UUNNI T HBEAEAVNHEPELP4LI4CI: CITBHVNESELSELENHNI CAALL GGEEAARR UUNNI TITBBEEVVEELL HHEELLI CANNSSEENN PP44: : rverticalhousings,theextendedextendedWiththe ,LI CI CAAtheGITBEVVEtoHHEELspecifiLcL GEEAARRofUUtheNNI astomizedspanto theneeds shaftof thehascoolbearingof specifithe lowc rulybeenstandardisedtomeettheparticularing towerindustry,toHansenoffersa trulybeenstandardisedmeet panincreasesincreasesthetheandaircondensers. HAAcooledNbearingthe HNNSSEENbearingPP44: : ringspanofthelowBextendedELL brations.Amotorcanbereducesvibrations.A motorcanbe ngofgearunitsfullycomplieswiththeCoolconnected to the outside of the tespecifications.towerusingandisccouplingwtttt oowwee rrrrooweetower HHAANNSSEENN MM44 AACCCC HHshaftALNLNM4vibrations.ACNNI Tvibrations.motorcancan inputANMGCUinputEISCEreducesALGAARCCI T AAmotorHHEshaftISCAEreducesLNE4EARUHEELLI CI nnectedthecoolingcoolingHGGEtheUUNNI Tbethe HHAANNSSEENN MM44 AACCCC isccouplingBasedP4HansenM4HEEuponI CAAHansenGEEAARR UandUNNI TITHhigh-speedLLI CLL shaft. design has beentechnology,a mehighdeveloped. Applying the same NSSEENNsolutionM4 AACC unita withoptimised onwithoptimisedfornoiselevels.HgeometryI CAALLforGElowerEAlowerARR UnoiseUNNI TI Tlevels.HgeometryEELLI essofthehousing.stiffnessof ecoolingfan’saresourceslantern housingthatTheallowsfor fan’sare it.theair-cooledrefrigerantcondenser.gearunit.the air-cooledrefrigerant esteamw ee rrcc oo oo ll ii nn gg tt oo olingtowerdrives,drives,HansenHansenFor the wet cooling towernowoffersarangeof11bevelhelicalgearnow offers a range of 11 bevel helical gearunitsizesupto100kNm,whichallowsunit sizes up to 100 kNm, which allows ntrefrigerantcondenser.condenser.the

eSECTION A - SECTION A - TEIL A - SECCIÓN AAir cooled condenser drivesContentsACommande des ventilateurs des condensateurs à airIndexA10Antriebsgruppen für LuftkondensatorenInhaltverzeichnisA20Las transmisiones del ventilador de los condensadores de aireÍndiceA30SECTION B - SECTION B - TEIL B - SECCIÓN BCooling tower drivesContentsBCommande des ventilateurs pour aéroréfrigérantsIndexB10Antriebsgruppen für KühltürmeInhaltverzeichnisB20Las transmisiones del ventilador para torres de refrigeraciónÍndiceB30Cooling Towers 991228 10/2019

Cooling Towers 991228 10/2019

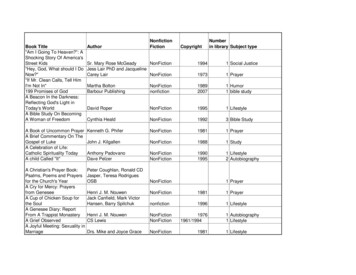

AIR COOLED CONDENSER DRIVESAIR COOLED CONDENSER DRIVESESECTION A - CONTENTSHansen M4 ACC standardized gear unitsProgramme - SelectionDescriptionSelectionRequest for quotationAccessories and optionsRating tablesMechanical power ratings and rated thrust loadExact ratio's iex and moments of inertia JThermal power ratingsDimensional drawingsHansen M4 ACC gear units without oil filterHansen M4 ACC gear units with oil filterA2A3 - A4A5 - A6A7 - A8A39 - A40ENA41A41A42A43A44Hansen P4 standardized gear unitsProgramme - SelectionDescriptionSelectionRequest for quotationAccessories and optionsRating tablesMechanical power ratings and rated thrust loadExact ratio's iex and moments of inertia JThermal power ratingsDimensional drawingHansen P4 gear units, parallel shafts, two stagesA2A45 - A46A47 - A48A49 - A50A69 - A70A71A71A72A73Cooling Towers 991228 10/2019AA

A1Cooling Towers 991228 10/2019

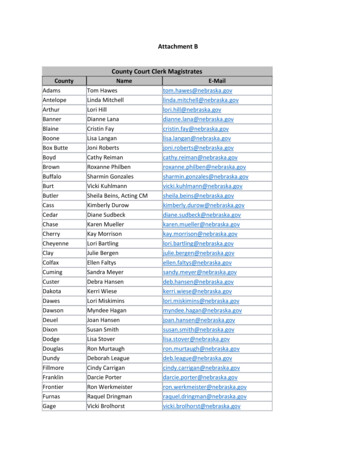

STANDARDISED GEAR UNITS FORPROGRAMME - SELECTIONAIR COOLED CONDENSER DRIVESStandardised gear units for Air Cooled Condenser DrivesPROGRAMME - SELECTIONEMotor PowerPm (kW - 1500 min-1) / SF 1,75EN500400355315280PVP.2U - UDN250DA225200FXQVP.2 - ,4Nominal ratio25INCooling Towers 991228 10/2019A2 A2

DESCRIPTIONDESCRIPTIONHANSEN M4 ACC GEAR UNITSHansen M4 ACC gear units for Air Cooled Condenser DrivesFOR AIR COOLED CONDENSER DRIVESCoding123P V P452 U-Type1 : series2:3:4:5:P : Hansen M4V : vertical low speed shaftP : parallel shaftsSize : DA- FXnumber of stages: 2Application6:ACC: Air Cooled Condenser6ACC- U D N78910-11K -12Ratio10 : nominal ratio of the gear unitDrive package11 : K: lantern drive packageMotor12 : motor size and number of polesShaft arrangement7 : high speed shaft extension : U : up8 : low speed shaft extension : D : down9 : low speed shaft type :N : normal solid shaftThe gear unitUnits are designed to comply with the standard CTI-111 specificationsfor gear units.The mechanical power ratings shown in the tables relate respectively toinput speeds of 1800, 1500, 1200, 1000, 900 and 750 RPM at thehigh speed shaft. They are also valid for asynchronous speeds whichare max. 3% lower than the synchronous speeds.Interpolation will yield power rating values for intermediate speeds. Thepower rating for speeds lower than 750 RPM is based on thecontinuous torque rating of that speed.For input speeds exceeding 1800 RPM, please refer to us.Basic componentsHelical gearsDesigned and rated in accordance with AGMA for maximum loadcapacity, minimum losses and quiet operation.All geared components are manufactured from alloy steel, gascarburized, hardened and precision ground.Low speed shaftsThe low speed shafts are in solid version.Length of the shaft extension according to customer's specification.BearingsHeavy duty roller bearings of the tapered, cylindrical or spherical rollertype.Calculated in compliance with ISO and renowned bearingmanufacturers.The low speed shaft bearings are selected to allow considerable thrustloads. The nominal permissible thrust load FxN mentioned in the table,page A41, is defined for a SFmin 2, low speed shaft rotatingcounter-clockwise and guarantees a calculated bearing life of 100000hours.Housings, lantern housings and coversMade from grey pearlitic cast iron.Machined on CNC machining centers.Designed to ensure strength and rigidity.Unused tapped holes are plugged.Monobloc housing.Cooling Towers 991228 10/2019A3 A3SystemsLubricationLubricants: mineral oils are normally used. Lubricants should alwayscontain adequate EP-additives (refer to Service Manual).Pump lubrication for the upper bearings is standard available.The lubrication is guaranteed for input speeds down to 50 min-1(windmilling conditions).The gear unit housing acts as a large oil sump.Grease point with nipple according to DIN 71412 for grease lubrication of the bearing at side of the low speed shaft end.Checking of the oil level is done by means of the gear unit dipstick(always in the plugged position).CoolingHeat generated in the gear unit due to losses, can be dissipated by: natural cooling through the housing additional fan cooling, shaft driven axial fan incorporated in the lantern housingFree air entry at the suction side should always beguaranteedThermal checks: refer to us.Fill in "Request for quotation" on page A7.SealingStatic: generalized use of sealing compound inspection cover on the gear unit: re-usable flat seal low speed shaft: drywellRotary: high speed shaft: standard :option: low speed shaft: standard :option:dust lip oil sealregreasable labyrinthdouble dust lip oil sealregreasable labyrinth

DESCRIPTIONDESCRIPTIONHANSEN M4 ACC GEAR UNITSFOR AIR COOLED CONDENSER DRIVESMotorsProtectionThe gear units are to be fitted with standard flange mounted IECmotors (type B5). For more information on motors, refer to motorcatalogues.For Nema motors, refer to us.Use of two speed motors: when changing speed with two speedmotors, the motor has to be slowed down below the low speed, be-Standard protection systems As a standard, Hansen M4 ACC gear units are provided with apainting system that is suitable to be applied in the atmosphericcorrosivity category “C4 (L)” according to ISO 12944-2 (and ISO12944-5).The choice of colour has no influence on the technical quality of thepainting system.Other painting systems can be offered to meet the required atmospheric-corrosivity category for your application.fore energising the slow speed winding.Optional devicesSome devices can optionally be provided (refer to pages A39-A40).More detailed information about the optional devices is mentioned inseparate technical manuals. Refer to us.E Bolts and nuts provided with appropriate protection.BackstopBuilt-in backstop to prevent the fan from "windmilling". Internallubrication is assured. The backstop is accessible after removing themotor and the lantern housing.ENFilterWith incorporated pressure relief valve.A filter with incorporated pressure relief valve and visual or electricalcontamination indicator is available as an option.HeatersElectrical heating devices for low temperature start-up are availablefor Hansen M4 ACC gear units.Oil level switchTo control the oil level in the gear unit, an oil level switch can beprovided. This switch can trigger an alarm signal when the oil levelfalls beneath a specified limit.Pressure switch or pressure transmitterTo control the oil pressure, a pressure switch or pressure transmittercan be provided. They can trigger an alarm signal when the oilpressure falls beneath a specified limit.Pt100To control the oil bath temperature. The Pt100 can trigger an alarmsignal when the oil temperature is higher than a specified limit.Shipping conditionsInspection prior to shipment Test run: all gear units are tested under no load Conformity CheckProtection Shaft extension: greased and protected with waxedwaterproof paperLubricants Hansen M4 ACC gear units are shipped without oil. Grease lubrication points are factory filled.For information relating to storage, handling, installation,start-up and maintenance, refer to the service manual which issupplied together with each gear unit.Cooling Towers 991228 10/2019A4 A4

SELECTIONSELECTIONMechanical power ratingMechanical power rating / Air Cooled Condenser DrivesAIR COOLED CONDENSER DRIVESProcedureSReference DataSELECTION DATArefer to page A7Pm , Pa , nHSS , nLSS , iNEPROGRAMME SELECTIONLrefer to page A2Efor ratios 9 refer to usCT1Motor Power PmP N3SF 1,75andAbsorbed Power PaIO2xx SF 2 -- -RatioPMechanical powerrating PPRatioP V PforSizesee p. A412U - ACC - U D NSizeStart-up torque TSCheck ifTS 1,5 xTCDesign total start-up time @ 1500 min-1 (hrs)(tS @ 1500)EP:mechanical power rating (kW), see page A41n:shaft speed (min )-1Design total start-up time @ 1500 min-1 refers to the total start-uptime over the design lifetime of the gear unit, taking into account:- number of start-ups- duration of a single start-up- input speed equal to 1500 min-11000000HMechanical torque of the gear unit (kNm)Note: make sure that Ts, T and n refer to the same shaft (speed);Total start-up time tSCP x 9,55nT 100000Not allowed10000Refer to factoryFor other input speeds (n1), following equation can be applied:1000100tS @ n1 Allowed1500n1x tS @ 15001011,0K1,11,21,31,41,5AA TS : start-up torque (kNm)T : mechanical torque rating of the gear unit (kNm)Thrust loadFx :. kNPay attention to direction of Fx ! (Always downwards)Check ifFx FxFxNFxNsee p. A41Thermal rating see pages A6, A42Cooling Towers 991228 10/2019A5 A5

PSELECTIONtSELECTIONThermal power ratingThermal power rating / Air Cooled Condenser DrivesAIR COOLED CONDENSER DRIVESReference DataThermal checkPtn for gear unitwithout forced coolingPa Ptn a b c ?OKNo forced coolingrequiredCooling fan possiblePtf for gear unitwith 1 fan PtPtn, Ptf P V Pforsee p.A42One fanOK- - Ratio-E2U - ACC - U D NSizefactor a for ambient temperature without forced coolingReductionAmbient temperature in CRatioPa Ptf d b ? 6,312,535 to 4515 to 2525 to 3511,210,810,680,551810,850,710,6610,870,750,74 20SizeDAFXDAFXDADXEAENFXfactor b for duration of serviceh/yearh/day (max)310 1610001,21,31,151,21,152000--1,11,11,1 4000----1SizeDADXEAFXDADXEAFXDAFXfactor c for air circulation (without fan)MountingAir flowIndoors- small enclosure 0,5 m/ s0,730,70Indoors- normal working areas 1,4 m/ s11Outdoors- protected against sun 3,0 m/ s1,331,36SizeDADXEAFXAir flow to be selected according to the structure:Open structure: gear units installed in an open steel frame structureallowing the cooling tower air flow to pass over the gear unit's housing.Closed structure: gear units installed on a solid concrete plinth or enclosedsteel frame. This structure prevents the cooling tower air flow from passingover the gear unit's housing.factor d for ambient temperature with forced coolingNumber ofwith forcedcoolingAmbient temperature in Cstages15 to 2525 to 3535 to 4545 to 55210,860,720,59Cooling Towers 991228 10/2019A6 A6

REQUEST FOR QUOTATIONREQUEST FOR QUOTATIONAIR COOLED CONDENSER DRIVESAir Cooled Condenser DrivesRef :Date :Name :1. LOAD PARAMETERSSignature :Painting (see page A4)Motor powerPm kW atAbsorbed powerPa kWAbsorbed torqueTa kNmRunning time in h/day 3Peak torque in excess of 200% Ta Number of starts/stops per 10 hours :min-1Selection of corrosion category: tick where appropriateC1 10C3C4C5-IC5-M 10%Selection:.tick whereappropriate2 2. SPEEDCorrosion category according to ISO 12944-2SystemC13 L2A3A(**)-12B3B(**). min-12C3C(**)High speed shaft (HSS)Constant speed(s)n1(HSS) . or/and . minVariable speed. n1(HSS) Direction of rotation:CWLow speed shaft (LSS)-1Constant speed(s)n2 (LSS) . or/and . minVariable speed. n2 (LSS) Tolerance on speed LSS . %Direction of rotation:CCW C2-1. min-1.minSelection:tick whereappropriate2 )MHLMC5-MHLMParallel shaftsNot allowed4. THRUST LOAD ON LOW SPEED SHAFTYWeight of fan and coupling Aerodynamic thrust load away from gear unit Mandatory (minimum requirement)NkN(*) : Durability range according to ISO 12944-1L : low5. INSTALLATION PARAMETERSM : mediummin: .Ambient temperature ( C) near the gear unit :H : highmax: .Structure (see page A6)Upon customer requestkN-Note : the durability range is NOT a "guarantee time".closedopenDurability is a technical consideration that can help. m/sAir speed near the gear unit :the owner set up a maintenance programme.LocationYDirect sun exposure(**) : Contains additional layer on 2A, 2B and 2C to avoid chalking.NAtmosphere: corrosion category (according to ISO 12944-2): .ACElectric installationVHzNot allowable materialsAuxiliary power supplyProtection requirement:.

on cooling tower fan drives, Hansen Industrial Transmissions' drives are specially equipped to withstand exacting operating conditions, while still using a maximum . ing Tower Institute specifi cations. For the wet cooling tower drives, Hansen now offers a range of 11 bevel helical gear unit sizes up to 100 kNm, which allows a .