Transcription

JHHARDIEWINDBREAKER BOARDINSTALLATION GUIDEMAY 2019Installation GuideHardieWindbreaker Sheathing Board

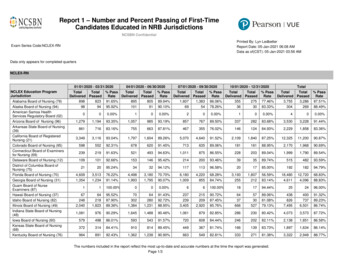

2HARDIEWINDBREAKER SHEATHING BOARDINSTALLATION GUIDEContentsGeneral5Product6Tools & 1Installation12Horizontal unsupported board edges13Vertical unsupported board edges14Boards installed vertically15Boards installed horizontally15Facade16Fire performance17Health & Safety18Warranty19Product Information203

4HARDIEWINDBREAKER SHEATHING BOARDINSTALLATION GUIDEGeneralOverviewHardieWindbreaker sheathing board is the next generation weather defence air barrier by James Hardie.It is a 9mm fibre cement board used as a sheathing layer behind ventilated rain-screen cladding.HardieWindbreaker board can be used in both new build or refurbishment projects. It can be installed onto asteel or timber frame and removes the need for a membrane to seal the building. The board has a sealerapplied on the face and edges which repels moisture rapidly and helps resist moisture penetration.MOISTURERESISTANTBuilt in waterrepellent barrier,no membraneneededFIRERESISTANTNon-combustibleA2 fire rated,offers up to60 minutesprotectionWINDRESISTANTWithstandshigh windpressures up to5800 Pa UFL*Why use HardieWindbreaker boards?With superior fire resistance, water-tightness and breathability, HardieWindbreaker sheathing helps newbuilds to battle the elements:A quicker build: early close-in avoids weather delays,A stronger building: made from engineered fibreremoving the need to reschedule trades and reducingcement, adding strength to your building.unplanned equipment hire costs. Our boards will notwarp or shrink when exposed to adverse climates,Made for extra high wind zones: our boards helpand offer a guaranteed 12 months’ exposure duringto equalise the air pressure inside the outer wallconstruction.cavity, allowing your building to stand up to extrahigh wind zones.A simpler build: offers a complete solution that islightweight, easy to cut and install due to high-speedGuaranteed & tested for peace of mind: madefixing methods.from fibre cement material that won’t crack,warp, swell or rot. Comes with a full 15 yearA more weather-tight building: provides superiorweather-tightness as our water-repellant sealantstops water getting in; the board’s breathability allowsmoisture vapour to get out.* Ulimate failure loadJames Hardie warranty.5

6HARDIEWINDBREAKER SHEATHING BOARDINSTALLATION GUIDEProductHardieWindbreaker BoardDescriptionDimensionsArticle NoDark grey coloured fibrecement sheathing board,coated with a moisturebarrier to the front faceand edges.Weight: 13.1 kg/m2Thickness: 9 mmLengthWidth2400 mm1200 mm50000212700 mm1200 mm50000223000 mm1200 mm5000023HardieBlade HardieBlade Saw BladeEspecially designed for use with James Hardie boards. Recommendedfor cutting fibre cement, the diamond tipped edges reduce dust andprevent faster blade wear. Available in Ø160, Ø190, Ø254, Ø305 mmdiameter size hole.Tools & AccessoriesScrewsHardieWindbreaker Screws for high gauge steel 0.7 mm 2 mm gaugeDesigned for the installation of fibre cement boards onto steel frame. Thethread and heads are designed to give a secure fix. Forming part of theHardieWindbreaker board system. PackagingBox of 250ColourGold colouredSize40 mm x 3.9 mmArticle No.79121Box of 500ColourGold colouredSizeArticle No.Ø160 mm20/16 mm*5300163Ø190 mm30/20 mm*5300164Ø254 mm30 mm5300165Ø305 mm30 mm5300166* Reducing washer suppliedMetal ProfilesZ-Profile, galvanised steel 3000 mmThe Z-Profile can be used in floor separation systems.HardieWindbreaker Screws for timber or steelDesigned for the installation of fibre cement boards onto timber or steelframe. The thread and heads are designed to give a secure fix. Formingpart of the HardieWindbreaker system.PackagingDiameterPackaging5 per packColourGalvanised steelSize(15 x 15 x 15 mm) x 3 m lengthArticle No.5300493h-Profile, galvanised steel 3000 mm for horizontal jointsThe h-profile can be used for unsuported horizonal board joints to offergreater stability.Size35 mm x 3.9 mm50 mm x 3.9 mmPackaging5 per packArticle No.7912079122ColourGalvanised steelSize(55 x 15 x 15 mm) x 3 m lengthArticle No.5300491HardieTape HardieTape Sealing TapeFor sealing the board joints to give an airtight seal.H-Profile, galvanised steel 3000 mm for vertical jointsThe H-profile can be used for unsuported vertical board joints to offergreater stability.ColourTranslucentSize50 mm x 25 mPackaging5 per packArticle No.6060004ColourGalvanised steelSize(55 x 15 x 35 mm) x 3 m lengthArticle No.5300492* Make sure the tape is applied flat and without any air bubbles, a suitable squeegee or roller can be used toassist with this application7

8HARDIEWINDBREAKER SHEATHING BOARDINSTALLATION GUIDEStorageHandlingStore flat and keep dry prior to installation. In storage a maximum of 4 pallets can be stacked on top of eachThe boards should always be carried by two people and on the edge. They should never be carried flat as thisother. Products stored outside should be covered with a waterproof sheet in addition to the product wrapper.will result in bending of the product.The waterproof sheet should not cover the pallet timber to ensure adequate ventilation. James Hardie is notresponsible for damage caused by improper storage and handling of the product.Store flat4 pallets MAX stacked vertically Waterproof cover and product wrapper Do not leave uncoveredCarry panels on edge 9

10 HARDIEWINDBREAKER SHEATHING BOARDINSTALLATION GUIDE 11CuttingPreparationSafetyStructureAs with all other building materials safety precautions must be taken into account. Cutting and drilling createThe structural wall to which HardieWindbreaker board is to be fixed, must be in its own right of sufficientdust, and proper precautions must be taken. Dust from fibre cement boards is characterised as mineral duststrength and stiffness to satisfy the requirements of the local building regulations, under the design dead andand EU-approved respirators can be used in conjunction with the following cutting practices to further reducelive loads. The structure may be made of timber or steel frame. James Hardie is not responsible for the designdust exposure.or performance of the subframe, if you are in doubt please consult with a structural engineer. The claddingsupport brackets (‘helping hands’) and any other load must be fixed back through the board to the timber orCutting instructionsAcceptable CuttingMethodSanding/Rebating/Drilling/Other Machiningoutdoors:Dust reducing circular saw with aIf sanding, rebating, drilling, or1. Position cutting station soCutting should always be doneHardieBlade saw blade (only useother machining is necessary,that wind will blow dust awayfor low to moderate cutting)you should always wear a dustfrom user and others in theMinimum Cutting Method (for lowrespirator in compliance withimmediate vicinity.to moderate cutting only)local requirements (e.g. EN 149,Hand saw with hardened teeth.FFP2/3) and warn others in theNever use a power saw indoors.immediate area.2. Use one of the followingmethods based on the requiredNever use a circular sawcutting rate.blade that does not carryImportant Note:the HardieBlade saw bladeFor maximum protection (lowestPreferred CuttingMethodtrademark.respirable dust production),Never use a grinder or continuousJames Hardie recommendsrim diamond blade for cutting asalways using the ’Preferred’ levelDust reducing circular sawthey produce too much dust.cutting methods where feasible.steel frame structure.Wind loadConstructionFraming/studsCentres (mm)Fixing type/ dimensionsFixing centresvertically (mm)Max windpressure (kPa)Timber Studs44 mm x 92 mmMax. 600IM360 PaslodeRingshank Nail(5 mm x 51 mm)2001.6IM45 Paslode Nail(6 mm x 35 mm)2001.6Ring/Rille Nail fixing(7 mm x 36 mm)2001.93HardieBacker boardscrew (6 mm x 32 mm)2001.86Staple fixings(38 mm)2001.4Countersunk Screw fixing(6 mm x 32 mm)2001.9Steel Air Gun Nail fixing(6 mm x 38 mm)2001.46(Minimum size)HSE approved respirators can beequipped with a HardieBlade saw blade and HEPA vacuumWhen cleaning up dust andused in conjunction with the aboveextraction.debris, Never dry sweep as itcutting practices to further reducemay excite silca dust particlesdust exposures. If concern stillinto the user’s immediate vicinity.exists about exposure levels orInstead, damp debris down with ayou do not comply with the abovefine water mist to suppress dustpractices, you should alwaysduring sweeping, or use a HEPAconsult a qualified industrialvacuum to collect particles.environmentalist or contact JamesHardie for further information.Always follow toolSteel C Studs1.2 mm x 100 mm x50 mm(Minimum size)Max. 600Note: Tested and evaluated to EAD 090062-00-0404, which replaces ETAG 034 (2)manufacturer’s safetyFor further information, refer torecommendations.our Material Safety Data Sheetavailable atwww.jameshardie.co.uk

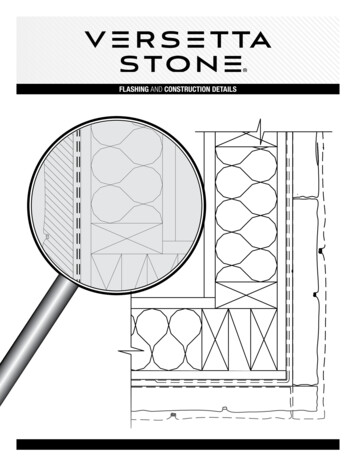

12 HARDIEWINDBREAKER SHEATHING BOARDINSTALLATION GUIDE 13InstallationThe boards are secured to the subframe profiles using either HardieWindbreaker screws, nails or staplesInstalling to horizontal unsupported board edges(depending on whether the subframe is a timber or steel subframe). Maximum fixing centres 200 mm. Maximum profile spacing 600 mm Maximum fixing centres 200 mm600 mm Minimum fixing distance from the board edge 12 mm Minimum fixing distance from the board corner (detail A) Horizontal corner 50mm Vertical corner 75mmOptional installationThe metal profiles are an optional installation. If needed the Z-profile can be used to offer additional support atthe floor separation level. The h-profile can be used to offer additional support to unsupported horizontal boardedges. The H-profile can be used to offer additional support to unsupported vertical board edges.The metal profiles are not a requirement for the fire rating.200 mm200 mmDetail A

14 HARDIEWINDBREAKER SHEATHING BOARDINSTALLATION GUIDE 15Installing to vertical unsupported board edgesSealing of board jointsHardieWindbreaker boards are installed butt-jointed and can be installed vertically or horizontally. Allboard joints are sealed with the HardieTape sealing tape. The tape is first fixed to the horizontal joints andthen overlapped on the vertical joints. All joints must be sealed to achieve the 12 month exposure time.HardieWindbreaker Tape is translucent and can thus be used in open joint cladding without the issue ofbeing visible.600 mmA suitable squeegee or roller (supplied by others) can be used to ensure that the tape is applied securely to theboard surface and without any bubbles. Always ensure the centre line of the tape is over the centre line of theboard joint.Note: sealing tape is only required for board joints and is not needed to cover fixing heads.Vertical board installation200 mm200 mmHorizontal board installation

16 HARDIEWINDBREAKER SHEATHING BOARDINSTALLATION GUIDE 17FacadeFire performanceJames Hardie has a variety of fibre cement cladding solutions for facades, including HardiePlank Construction Overviewweatherboard and HardiePanel cladding. With a complete system solution from James Hardie you ensurea long-lasting cladding solution that gives peace of mind and requires only minimal maintenance.For further information please visit www.jameshardie.co.ukFire ClassificationSystem SpecificationSteel Studs 60 min Fire Rating (EI 60) from both directions2 x 12.5 mmStandard plasterboardsStuds100 mm x 1.2@ 600 mm centres(minimum gauge 0.6)90 mm x 30 kg/m3 mineral stonewool (minimum)HardieWindbreaker board 9 mmTimber Studs 60 min Fire Rating (REI 60) from both directions2 x 12.5 mmStandard plasterboardsStuds38 x 140 mm Timber studs@ 600 mm centres195 mm x 30 kg/m3 mineral stonewool (minimum)HardieWindbreaker board 9 mmReaction to FireHardieWindbreaker sheathing board is A2, s1-d0 rated and complies with UK building regulations forexternal wall constructions.

18 HARDIEWINDBREAKER SHEATHING BOARDINSTALLATION GUIDE 19Health & SafetyWarrantyAvoid Breathing DustHardieWindbreaker board and accessories are covered by a 15 year product warranty.For further details on our warranty and terms and conditions please visit www.jameshardie.co.ukJames Hardie products contain crystaline silica. This mineral is found everywhere in the world (often in theform of sand) and therefore is commonly used in many construction products (for example brick, concrete,glasswool and abrasives). The mineral itself is inert, but certain building practices such as drilling, high speedcutting and abrading can release fine particulate dust which may constitute a health hazard.Excessive or protracted inhalation of fine particle silica dust can lead to lung disease called Silicosis. Thereis also some evidence that it may increase the risk of lung cancer, if inhaled for prolonged periods. Smokingmay also exacerbate this risk. Like smoking, the risk from fine particle silica dust is time and concentrationdependent.ControlTo suppress or to reduce excessive inhalation of fine particle silica dust the following steps should be taken toprotect operatives who work with products containing silica dust:During fabrication operate outdoors or in a well ventilated space in a separate area, if available, or away anddown-wind from other operatives;Use controlled dust cutting tools, such as the HardieBlade saw blade fitted to a low dust circular sawconnected to a dust extraction HEPA filter vacuum cleaner (see James Hardie tools);When cutting, drilling or abrading always wear a FFP2/3 dust control or full face mask adjusted and fitted inconformity with regulatory recommendations and affixed with CE markings and/or fully certified to the relevantEN standards if applicable;Keep the working environment clean and remove debris as soon as possible;At the end of the operation remove dust from clothes, tools and working area with a HEPA filter vacuumcleaner or damp with water to suppress the dust before sweeping.James Hardie products are no more dangerous than many other building materials containing crystaline silicasand. We hope through this information to engage in effective education of the construction industry and buildupon the requirements of national health and safety regulations.For more information, see our installation instructions and MSDS available on www.jameshardie.co.uk or callJames Hardie on 0121 311 3480.

20 HARDIEWINDBREAKER SHEATHING BOARDINSTALLATION GUIDE 21Product InformationDimension (nominal)Hydrothermal propertiesThickness9.0mmWater absorption (24 hrs 105 C, 24 hrs in water, EN12467)24.9%Width1200mmMoisture movement0.5mm/mLength2400/2700/3000mmWater impermeability (EN12467)No dropVisualThickness /-0.9mmVapour transmission resistance (Z-value)0.79GPa m² s/kgWidth /-3.6mmVapour transmission resistance5786s/mLength /-5.0mmVapour diffusion equivalent air layer thickness0.16Sd (m)Vapour resistivity87MN s/(gm)Vapour resistance factor (μ/value)17.43μVapour resistance0.79MN s/gDimension tolerance (EN 12467, Level 1)Water vapour transmission properties (EN12572-C)Physical propertiesDensity, dry, minimum (EN12467) 1300Kg/m³Density, dry, average (EN12467)1350Kg/m³Weight average (incl. 5% moisture)13.1Kg/m²Fire performanceMoisture content (on dispatch ex works, ASTM C1185)5-8%Reaction to fireA2-s1, d0EN13501Air permeability (EN12114)0.0 (Panel only)0.0103 (taped, butt joint)m³/m²h PaFire protection classification (rating)K1 10EN13501-2Other propertiesMechanical properties (EN12467) – Bending modulus of elasticity (MOE)E-module along grain, ambient3.19GPaE-module across grain, ambient4.23GPaAlong grain, ambient11.14MPaAcross grain, ambient15.87MPaCoefficient of thermal expansion4.0 x 10-⁶/ Cmm/m CThermal conductivity (ISO 8301, EN 12667)0.263λ10 W/(mK)Bending strength (EN12467) – Bending moment of rupture (MOR)Thermal propertiesAverage racking strengthWindloads – for details on wind loading please see page 11Contact us for further details

22 HARDIEWINDBREAKER SHEATHING BOARDNotesINSTALLATION GUIDE 23

2019 James Hardie Europe GmbH. TM and denoteregistered and unregistered trademarks of James HardieTechnology Ltd and James Hardie Europe GmbH.A James Hardie warranty applies to all our fibre cementproducts. Please see www.jameshardie.co.uk/warranty forterms and conditions.James Hardie Building Products Ltd7 The PrioryOld London RdSutton Coldfield B75 5SHCustomer serviceTel0121 311 3480E-mail -00009/IB/05.19

4 HARDIEWINDBREAKER SHEATHING ARD INSTALLATION 5 General Overview HardieWindbreaker sheathing board is the next generation weather defence air barrier by James Hardie. It is a 9mm fibre cement board used as a sheathing layer behind ventilated rain-screen cladding. HardieWindbreaker board can be used in both new build or refurbishment projects.