Transcription

CHEMICAL GLOVE RESISTANCE GUIDE

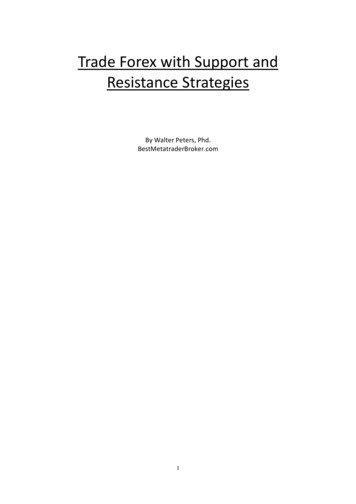

When reviewing the following recommendations, remember that testsAnsell’s ASTM standard permeation and degradation are presented on theare conducted under laboratory conditions, and that actual workplacefollowing pages as an aid in determining the general suitability of variousconditions usually dictate a combination of performance capabilities.products for use with specific chemicals. Because the conditions of ultimateA product’s resistance to cuts, punctures, and abrasion must also betaken into account as a critical usage factor. A glove with excellentpermeation resistance may not be adequate it if tears or punctures easily.Always factor in the physical performance requirements of the job orapplication when selecting a chemical-resistant glove.use are beyond our control, and because we cannot run permeation tests inall possible work environments and across all combinations of chemicalsand solutions, these recommendations are advisory only.THE SUITABILITY OF THE PRODUCT FOR A SPECIFIC JOBMUST BE DETERMINED BY TESTING BY THE PURCHASER.DEFINITION OF KEY TERMSPermeation is a process by which a chemical can pass through aprotective film without going through pinholes, pores, or other visibleopenings. Individual molecules of the chemical enter the film and “squirm”through by passing between the molecules of the glove compound orfilm. In many cases the permeated material may appear unchanged to thehuman eye.Chemical permeation can be describedin simple terms by comparing it towhat happens to the air in a balloonafter several hours. Although there areno holes or defects, and the balloon istightly sealed, the air gradually passesthrough (permeates) its walls andescapes. This simple example uses gaspermeation, but the principle is thesame with liquids or chemicals.Permeation data is presented in two ways: Breakthrough time and Colorcode. Breakthrough times (min.) are the times observed from the start ofthe test to first detection of the chemical on the other side of the sample(see test chamber setup). These times represent how long a glove can beexpected to provide effective permeation resistance when totally immersedin the test chemical.The color code provides direction on the glove’s acceptance against thechemical. Green reflects the glove will work well against the chemicalversus red suggesting the glove should not be recommended. The colors inbetween reflect protection acceptance based on the exposure time.Degradation is a reduction in one or more physical properties of a glovematerial due to contact with a chemical. Certain glove materials maybecome hard, stiff, or brittle, or they may grow softer, weaker, and swell toseveral times their original size. If a chemical has a significant impact onthe physical properties of a glove material, its permeation resistanceis quickly impaired.Please note, however, that permeation and degradation do notalways correlate.

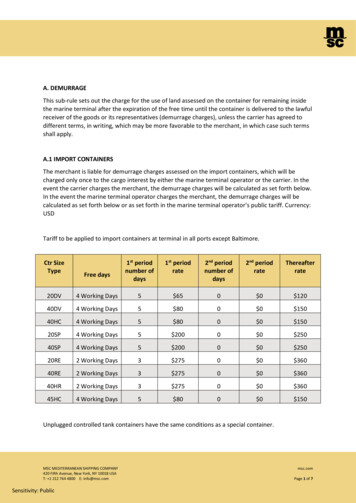

Degradation and Permeation Breakthrough TimesMaterialButylThickness (mil)14Product Name / eopreneNeopreneNitrileNitrile2.52718551118Barrier Chemical nameLLDPE 02-100Chemi-Pro 87-224PDPNeoprenePDPSolvex 08-35208-35429-865DScorpio 37-145DPPPVC37.570PVASnorkelAlphaTec 58-435DPolyvinylAlcoholD 15-554PDG 120-240' NRViton Butyl12 04-414ChemTek 38-612PDPDP 10'F10-30'DD 480'sgl64-19-7Acetic acid, glacial100E 480'E120-240'E60-120'E 480'E 480'G30-60'sgl67-64-1Acetone100E240-480'E 480'G 10'G 10'G 10'NR 10'NR 10'P60-120' NR 10'DD 120-240'sgl75-05-8Acetonitrile100E 480'E 480'E10-30'E10-30'E10-30'F 10'F10-30'E60-120' NR 10'DDsgl79-10-7Acrylic Acid100– 480'– 480'E60-120'E 480'E 480'G30-60'G30-60'NR 10'NR30-60'– 480'sglNRAcrylonitrile100E240-480'E 480'– 10'–30-60'–30-60'– 10'– 10'E 480'– 10'E240-480'sgl107-18-6Allyl alcohol100E 480'E 480'E10-30'E240-480'E240-480'F30-60'F60-120'P 10'P60-120'E120-240'sgl1336-21-6Ammonium Hydroxide25E 480'E10-30'E10-30'E 480'E 480'E120-240'E 480'NR 10'E10-30'E 480'sgl71-43-2Benzene100P 10'E 480'NR 10'NR 10'NR 10'P 10'P30-60'E 480'NR 10'E240-480'sgl98-88-4Benzoylchloride100– 10'– 480'– 10'– 10'– 10'– 10'–10-30'– 480'– 10'––sgl80-05-7Bisphenol A100E 480'E 480'E 480'E 480'E 480'E 480'E 480'E240-480'E 480'E 480'sgl590-92-1Bromopropionic acid100– 480'– 480'– 480'– 480'– 480'– 480'– 480'– 10'–120-240'– 480'sgl111-76-22-Butoxyethanol100E 480'E 480'E30-60'E 480'E 480'E240-480'E240-480'E120-240'P 10'E 480'sgl123-86-4Butyl acetate100E60-120'E 480'NR10-30'NR 10'NR 10'F10-30'F60-120'G 480'NR 10'DD 10'sgl71-36-3Butyl alcohol100E 480'E 480'E120-240'E 480'E 480'E 480'E 480'F60-120'G120-240'E 480'sgl75-15-0Carbon disulfide100P 10'E 480'NR 10'NR 10'NR 10'G10-30'G10-30'E 480'NR 10'E120-240'sgl56-23-5Carbon Tetrachloride100F10-30'–240-480' NR 10'NR 10'NR 10'G240-480'E 480'F10-30'–60-120'sgl67-66-3Chloroform100P 10'E10-30'NR 10'NR 10'NR 10'NR 10'E 480'NR 10'E120-240'G 240-480'NR 10' 480'sgl8007-45-2Coal Tar100– 10'– 480'–10-30'–60-120'–60-120'– 480'– 480'– 480'–10-30'– 480'sgl68308-34-9 Crude oil100P 10'E 480'P10-30'E60-120'E60-120'E 480'E 480'G 480'NR10-30'E 480'E10-30'E240-480'E240-480'E 480'E 480'G 480'E240-480'E 480'120-240'sgl108-93-0Cyclohexanol100E 480'E 480'sgl108-94-1Cyclohexanone100E 480'E 480'P30-60'P30-60'P60-120'F10-30'F30-60'E 480'NR30-60'Psgl84-74-2Dibutyl Phtalate100– 480'– 480'G10-30'F60-120'F60-120'G 480'G 480'E 480'NR 60-120'––100P 10'E 480'P30-60'E60-120'E60-120'E 480'E 480'G 480'NR30-60'E 480'10-30'F10-30'NR 10'NR10-30'NR10-30'10-30'NR10-30'NR10-30'DD 480' 10'NR 10'DD 480'sgl68334-30-5 Diesel fuelsgl109-89-7Diethylamine100F 10'E 480'NR 10'P 10'P 10'Fsgl68-12-2Dimethylformamide (DMFA)100E 480'E 480'E30-60'E30-60'E30-60'NR10-30'NRsgl67-68-5100E 480'E 480'E 480'E 480'E 480'E120-240'E100P 10'E 480'P10-30'E60-120'E60-120'E 480'E 480'G 480'NR10-30'E 480'100E240-480'E 480'E30-60'E240-480'E240-480'E240-480'E 480'NR 10'G60-120'E 480'sglsglDimethyl Sulfoxide (DMSO)(petroleum),64742-47-8 Distillatehydrotreated light64-17-5Ethanol240-480' NRD Degradation P PermeationSee legend at the end for degradation ratings.1

Degradation and Permeation Breakthrough TimesMaterialButylThickness (mil)14Product Name / opreneNeopreneNitrileNitrile2.52718551118Barrier Chemical nameLLDPE 02-100Chemi-Pro 87-224DPDPDNeopreneScorpio 08-35208-35429-865PDSolvex PD c 58-435PD 15-554PDViton Butyl12 04-414ChemTek 38-612PDPDP10-30'sgl141-78-6Ethyl acetate100E30-60'E 480'F 10'F10-30'F10-30'NR10-30'NR10-30'F 480'NR 10'DDsgl75-04-7Ethylamine100– 480'– 20'–240-480'– 10'——sgl110-80-5Ethyl Glycol100E 480'E 480'E10-30'E240-480'E240-480'G120-240'G 120-240'E60-120'P10-30'E60-120'sgl107-21-1Ethylene Glycol100– 480'E 480'E 480'E 480'E 480'E 480'E 480'F120-240'E 480'– 480'sgl111-15-9Ethylglycol acetate100E 480'E 480'E10-30'G30-60'G30-60'F60-120'F60-120'E 0'– 480'– 480'– 480'– 480'– 480'– 480'– 10'– 480'– 480'sgl64-18-6Formic acid100E240-480'E 480'E60-120'E 480'E 480'F10-30'F30-60'NR 10'–120-240'–240-480'E 480'E 480'G240-480' NR 10'–– 10'NR10-30'E120-240' NR 10'E 480'sgl76-13-1Freon TF100– 10'––NR 10'E240-480'E240-480'sgl96-48-0Gamma Butyrolactone100E 480'E 480'E240-480'E120-240'E120-240' NRsgl8006-61-9100F10-30'E 480'NR 10'NR30-60'NR30-60'E120-240'E240-480'G 480'P60-120'E 480'sgl111-30-850E 480'E 480'E 480'E 480'E 480'E 480'E 480'NR 10'E 480'E 480'sgl142-82-5GasolineGlutaraldehyde,aquous solutionHeptane100P 10'E 480'P 10'E120-240'E120-240'E 480'E 480'E 480'NR 10'E 480'sgl999-97-3Hexamethyldisilazane100E240-480'E 480'F60-120'E 480'E 480'E 480'E 480'G 480'P60-120'E240-480'sgl110-54-3Hexane100P 10'E 480'P 10'E30-60'E30-60'E 480'E 480'G 480'NR 10'E 480'sgl7647-01-0Hydrochloric acid37– 480'E 480'E 480'E 480'E 480'E 480'E 480'NR 10'E 480'– 480'sgl7664-39-3Hydrofluoric acid48E 480'E 480'– 480'E 480'E 480'E30-60'E120-240' NR 10'E 480'E 480'sgl7722-84-1Hydrogen Peroxide30E 480'E 480'G 480'E 480'E 480'E 480'E 480'NR 10'E 480'E 480'sgl540-84-1Iso-octane100P30-60'E 480'P30-60'E 480'E 480'E 480'E 480'E 480'P30-60'E 480'sgl78-59-1Isophorone100– 480'– -480'– 480'– 10'––67-63-0Isopropanol100E 480'E 480'E120-240'E 480'E 480'E 480'E 480'NR60-120'G120-240'E 480'100P 10'E 480'P10-30'E 480'E 480'E 480'E 480'G 480'NR10-30'E 480'sglsgl64742-81-0 Kerosenesgl110-16-7Maleic acid, aquous solution50E 480'E 480'E 480'E 480'E 480'E 480'E 480'NR 10'G 480'E–sgl67-56-1Methanol100E 480'E 480'E30-60'E120-240'E240-480'E30-60'E60-120'NR 10'G30-60'DD �� -480'– pylacetate100– 480'– 480'– 10'–10-30'–10-30'–120-240'–120-240'– 480'– 10'–10-30'sgl96-33-3Methyl acrylate100–60-120'– 480'– 10'– 10'– 10'– 10'–10-30'– 480'– 10'– 10'sgl78-93-3Methyl ethyl ketone100E60-120'E 480'P 10'P 10'P 10'NR 10'NR 10'F30-60'NR 10'DD10-30'sgl108-10-1Methyl Isobutyl Ketone100–120-240'– 480'– 10'–10-30'–10-30'– 10'–10-30'–60-120'– 10'–10-30'D Degradation P PermeationSee legend at the end for degradation ratings.2

Degradation and Permeation Breakthrough TimesMaterialButylThickness (mil)14Product Name / opreneNeopreneNitrileNitrile2.52718551118Barrier Chemical nameLLDPE 02-100Chemi-Pro 87-224DPDPDNeopreneScorpio 08-35208-35429-865Solvex 37-145PolyvinylAlcoholPVC37.570PVASnorkelAlphaTec 58-435 15-554PDPDPDPDPViton Butyl12 04-414DPDChemTek 38-612PDP 10'sgl1634-04-4Methyl tert-Butyl Ether100G10-30'E 480'NR 10'P30-60'P30-60'E 480'E 480'G 480'NR 10'–sgl74-89-5Methylamine, aquous solution40E 480'E 480'E10-30'E 480'E 480'E 480'E 480'NR 10'E60-120'E–sgl75-09-2Methylenechloride100G 10'E10-30'NR 10'R 10'NR 10'NR 10'NR 10'G 480'NR 10'E30-60'sgl80-62-6Methylmethacrylate100E30-60'E 480'NR 10'NR 10'NR 10'P10-30'P10-30'G 10'DD 10'sgl8012-95-1Mineral Oil100P 10'E 480'P10-30'E60-120'E60-120'E 480'E 480'G10-30'E 480'sgl108-90-7Monochlorobenzene100P 10'E 480'NR 10'NR 10'NR 10'NR 10'NR10-30'sgl141-43-5100– 480'– 480'E 480'E 480'E 480'E 480'E 480'100P 10'E 480'P10-30'E60-120'E60-120'E 480'E100P 10'E 480'P10-30'E60-120'E60-120'E 480'100P 10'E 480'P10-30'E60-120'E60-120'E 480'sglMonoethanolamine(petroleum),64742-82-1 Napthahydrodesulfurized heavypetroleum,64742-49-0 Naphtha,hydrotreated light8030-30-6 Naphta VM&Psgl7697-37-2Nitric acid70– 480'E 480'sgl98-95-3Nitrobenzene100E 480'E 480'sgl872-50-4N-methyl-2-pyrrolidone100E ctyl alcohol100E 480'sgl144-62-7Oxalic acid, aquous solution99E 480'sgl79-21-0Peracetic 2Phenol100sglsglNR 120-240'240-480' NR 480'NRE 480'NR 10'F 480'E60-120'E 480'E240-480' 480'G 480'NR10-30'E 480'E 480'G 480'NR10-30'E 480'E 480'G 480'NR10-30'E 480'NR30-60'E 480'E 480'NR30-60'NR 10'F30-60'––F 10'NR 10'NR 10'NR60-120' NR 60-120'G 480'NR 10'E 480' 480'F10-30'NR10-30'NR10-30'NR10-30'NR10-30'NR 10'NR 10' 480'P30-60'E120-240'E120-240'E 480'E 480'G 480'NR 10'E 480'E 480'E 480'E 480'E 480'E 480'E 480'G240-480'F240-480'E 480'E 480'E 480'E 480'E 480'E 480'E 480'NR 10'E 480'E 480' 480'– 480'–60-120'– 480'– 480'–120-240'–60-120'– 10'–120-240'– 480'P 10'E 480'NR10-30'NR 10'NR 10'G120-240'G 240-480'E 480'NR 10'E 480'E 480'E 480'E120-240'E 480'E 480'NR60-120' NR 60-120'F 480'G120-240'E 480'DD 60-120'sgl7664-38-2Phosphoric acid85– 480'E 480'G 480'G 480'G 480'E 480'E 480'NR 10'G 480'– 480'sgl110-85-0Piperazine100E 480'E 480'E 480'E 480'E 480'E 480'E 480'E 480'E 480'E 480'sgl71-23-8Propanol100E 480'E 480'E120-240'E 480'E 480'E 480'E 480'P60-120'F120-240'E 480'sgl107-12-0Propionitrile100– 480'– 480'– 10'–60-120'–60-120'– 10'–10-30'– 480'– 10'– 10'sgl109-60-4Propylacetate100E60-120'E 480'P 10'P 10'P 10'F10-30'F10-30'G 480'NR 10'DD 10'sgl57-55-6Propylene Glycol100– 480'– 480'– 480'– 480'– 480'– 480'– 480'– 480'– 480'– 480'sgl110-86-1Pyridine100E60-120'E 480'P10-30'NR 10'NR 10'NR10-30'NR10-30'G 10'NR 10'DD30-60'sgl1310-73-2Sodium Hydroxide50E 480'E 480'E 480'E 480'E 480'E 480'E 480'NR 10'G 480'E 480'D Degradation P PermeationSee legend at the end for degradation ratings.3

Degradation and Permeation Breakthrough TimesMaterialButylThickness (mil)14Product Name / opreneNeopreneNitrileNitrile2.52718551118Barrier Chemical nameLLDPE02-100DChemi-Pro 87-224PDPNeoprenePDPSolvex 08-35208-35429-865DScorpio 37-145DPDPVC37.570PVASnorkelAlphaTec 58-435PPolyvinylAlcoholD 15-554Viton Butyl12 04-414PDPChemTek 38-612DPDPsgl8052-41-3Stoddard Solvent100P 10'E 480'G10-30'E60-120'E60-120'E 480'E 480'G 480'F10-30'E 480'sgl100-42-5Styrene100P10-30'E 480'NR 10'NR 10'NR 10'NR10-30'NR10-30'G 480'NR10-30'E 480'sgl7664-93-9Sulphuric acid96E240-480'E 480'NR 120-240'F240-480'F240-480' NR30-60'NR 120-240' NR 10'G30-60'E 480'sgl109-99-9Tetrahydrofuran100F 10'E 480'NR 10'NR 10'NR 10'NR 10'NR10-30'P30-60'NR 10'DD 10'sgl110-01-0Tetrahydrothiophene100– 480'– 480'–10-30'– 10'– 10'–10-30'–30-60'– ��60-120'–120-240'– 10'– 10'– 10'– 10'– 10'–120-240'– 10'––sgl108-88-3Toluene100P 10'E 480'NR 10'NR 10'NR 10'F10-30'F10-30'G 480'NR 10'E 480'sgl79-01-6Trichloroethylene100NR 10'E 480'NR 10'NR 10'NR 10'NR10-30'NR10-30'E 480'NR 10'sgl1330-78-5Tricresyl Phosphate100E 480'– 480'E 480'F 480'F 480'E 480'E 480'G 480'F 480'DD 120-240'E 480'sgl102-71-6Triethanolamine100– 480'– 480'–240-480'E 480'E 480'E240-480'E 480'G240-480'E 480'–240-480'sgl121-44-8Triethylamine100– 10'– 480'– 10'– 10'– 10'– 480'– 480'– 480'– 10'–240-480'sgl64742-88-7 White Spirit100P 10'E 480'P10-30'E60-120'E60-120'E 480'E 480'G 480'NR10-30'E 480'sgl1330-20-7100P10-30'E 480'NR 10'NR10-30'NR10-30'F10-30'G30-60'E 480'NR 10'E 480'XyleneLegendPermeation Breakthrough Times (min) 10Not Recommended10-30Splash Protection30-60Splash Protection60-120Medium Protection120-240Medium Protection240-480Good Protection 480Good ProtectionDegradation RatingsDDDelamination of Outer LayerNRNot RecommendedPPoorFFairGGoodEExcellentIf a specific Ansell glove or chemical is not found on this chart, please contact yourAnsell representative or call us at 800-800-0444 to conduct a Chemical Guardian.The permeation breakthrough times presented in this chart were evaluated according to theASTM F739 standard. The letters used in this chart correspond to the degradation ratings, whereas the colors represent the permeation breakthrough levels (see legend for more information). and are registered trademarks owned by Ansell Limited or one of its affiliates.US Patented and US and non-US Patents Pending: www.ansell.com/patentmarking 2016 Ansell Limited. All Rights Reserved.DisclaimerRecommendations are based on extrapolations from laboratory test results and information regarding the composition of chemicals and may notadequately represent specific conditions of end use. Synergistic effects of mixing chemicals have not been accounted for. For these reasons, andbecause Ansell has no detailed knowledge of or control over the conditions of end use, any recommendations must be advisory only and Ansellfully disclaims any liability including warranties related to any statement contained ce

and solutions, these recommendations are advisory only. THE SUITABILITY OF THE PRODUCT FOR A SPECIFIC JOB MUST BE DETERMINED BY TESTING BY THE PURCHASER. 1 D P D P D P D P D P D P D P D P D P D P sgl 64-19-7 Acetic acid, glacial 100 E 480' E 120-240' E 60-120' E 480' E 480' G 30-60' G 120-240' NR 10' F 10-30' DD 480'