Transcription

CHEMICALRESISTANCE GUIDEFROM SPEC TO PROTECTprotectiveemea.sherwin-williams.com

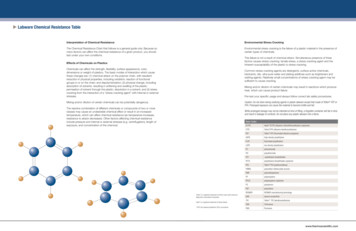

TANK LININGS CHEMICAL RESISTANCE GUIDE APRIL 2021This list has been abbreviated please contact us if you do not see the required chemical.CONTENTS:Specific notes 3Chemical resistance list 4–32Notes 33–34Sherwin-Williams protective coatings produce the most versatile range of chemically resistant linings on the market.This guide is intended to provide a summary of the capabilities of the Sherwin-Williams linings offer. It does not containall the linings in the Sherwin-Williams offer and the chemicals listed are not the limit of chemicals to which SherwinWilliams linings are resistant.2Sherwin-Williams supply linings suitable for a wide varietyof applications including, but not limited to: internal lining ofabove and below ground storage tanks, internal lining forprocess vessels and piping, external lining of buried tanks,vessels and equipment.Sherwin-Williams aim to provide the highest levels of service inselecting, specifying and applying the linings systems. Please donot hesitate to contact us with any enquiries or problems youhave and we will provide you the best solution to satisfy yourrequirements.Sherwin-Williams also provide a range of linings suitablefor use onto concrete surfaces which protect againstchemical, abrasion and impact attack. Specialised systemsare available which can provide crack bridging solutions forapplications where concrete movement is expected.If any training or support is required for the actual application ofthe lining, Sherwin-Williams have specialists who can support thelocal Technical Service Representatives if this is necessary.This document is intended for guidance purposes only,please contact Sherwin-Williams for confirmation of productperformance.

TANK LININGS CHEMICAL RESISTANCE GUIDESPECIFIC NOTESIntroductionTank cleaningAn explanation of the notations against each product is as follows:Sherwin-Williams do not advise on methods of tank cleaning, except where cleaningmethods may cause damage to the coating. Please contact your local Sherwin-Williamstechnical representative before carrying out any cleaning protocols which may berequired as part of an inspection or process.Note storage of product subject to the conditions of the specific Chemicalnotes itemised.1, 4 Recommended provided the requirements of Notes 1 and 4 are met.NR Not recommended for this service.MixturesNT Testing is required to determine if this product is suitable for this service.For mixtures of materials it may not simply be a case of the chemical resistance guidefor the components.LR Acceptable for short term immersion such as secondary containment, sumps etc.Recommendations are based on laboratory test data, field service and / or practicalexperience.Performance is subject to application and cure in strict accordance with the ProductData Sheets and specification – use of non-approved primers or fillers may have anegative impact upon performance.The chemical resistance information included in this document is for materials curedunder normal ambient conditions. Post-curing can in some cases improve the chemicalresistance of certain linings (and also reduce any risk of contamination in some criticalchemicals). Consult your local Sherwin-Williams.All concentrations listed are aqueous, unless otherwise noted.Substrates and primersThe resistance quoted in the guide refers to the coating system being applied directly tomild steel that has been prepared to the standard quoted on the product data sheet orover an approved primer. Application to alternative primers and substrates is possible.Product storage temperatureChemical resistance is recorded as the maximum continuous storage temperature(loading temperatures may be up to 10 C higher than the storage temperature).In certain circumstances some products have been demonstrated to be suitable for hightemperature service and the recorded value may be increased subject to confirmation ofthe conditions – please consult your regional linings technical representative.Care should be taken when storing high temperature aqueous chemicals. Where largetemperature differentials exist between the Chemicals and external tank wall there is adanger of the tank coating system being adversely affected due to cold wall thermalshock. If temperature differences are in excess of 30 C (54ºF), it is recommended thatthe tank is insulated to reduce thermal gradient.Mixtures can behave differently to the sum of their components. Please consult SherwinWilliams to confirm suitability of lining schemes for chemical blends.Typical thicknessesPerformance is subject to application and cure in strict accordance with the ProductData Sheets and specification. Excessive film thicknesses may have a negative impactupon the performance of a lining.Change in servicePlease consult your local Sherwin-Williams technical representative to confirm whetherit is advisable to switch service to another cargo.

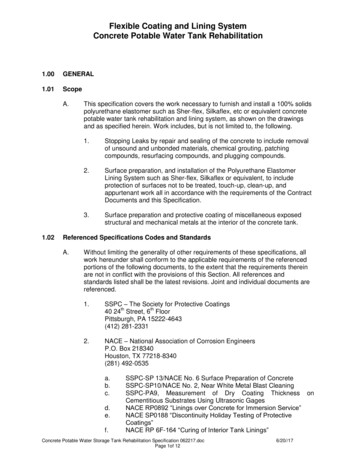

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration (%)Phenicon HSDura-Plate UHSIM (ºC)SCIM (ºC)SCSCSCSCR40 CR40 CR40 CR40 CRNRNRNRNRNRNRNRNRNRNRNRNR60 CRAcetic Acid 100% Glacial AceticNRNRNRNRNRNRNRNRNRNR40 CRAcetic Acid 15%NRNRNRNRNTNTNRNRNRNR60 CRAcetic Acid 2%; Formic Acid 2%NRNRNRNRNRNRNRNRNRNR60 CRAcetic Acid 25%NRNRNRNRNRNTNRNRNRNR50 CRAcetic Acid 40%NRNRNRNRNRNTNRNRNRNR50 CRAcetic Acid 50%NRNRNRNRNRNTNRNRNRNR50 CRAcetic Acid 75%NRAcetic Acid Vapors 1%NTNRNRNRNRNRNRNRNRNR40 CRNTNTNTNTNTNRNRNTNT50 CRAcetic AnhydrideNRNRNRNRNRNRNRNRNRNRNRRAcetone NTNRNRNTNTNRNRAcid Sulfite pH 1-2NTNTNTNTNTNTNRNRNTNT60 CR40 CR40 CR40 CRNTNTNTNT60 CRAdipic Acid 23%NRNRNRNRNRNRNRNRNRNR50 CRAdipic Acid 25%NRNRNRNRNRNRNRNRNRNR50 CRAlkyl Benzene Sulfate Acid 92%NRNRNRNRNRNRNRNRNTNT60 CR50 CR50 CR50 CR50 CR50 CR40 CRNTNTNRNRNTNTNTNTNTNT27 CR10Alpha Methylstyrene40 CR40 CR40 CR40 CR40 CR40 CR12Alpha Oleum SulfatesNTNTNTNTNTNTNTNTNTNT50 CRAluminum Bromide40 CR40 CR40 CRNTNT50 CR60 CRAluminum Chloride 30%40 CR40 CR40 CRNTNT50 CR27 CRAluminum Chloride, All40 CR40 CR40 CRNTNT50 CR60 CRAluminum Nitrate 10%40 CR40 CR40 CRNTNT50 CR60 CRAluminum Nitrate 50%40 CR40 CR40 CRNTNT50 CR60 CR40 CAcetic Acid 10%Activated Carbon BedsAlkyl Benzene, LinearAllyl Chloride, All4121212NR Non resistantNotes12R ResistantNT Not testedNotesMagnalux 41V2IM (ºC)2, 4-Toluene DiisocyanateNotesNova-Plate 325IM (ºC)SCNotesNova-Plate 360IM (ºC)IMNotesNova-Plate UHS12IM ImmersionNotesSC Secondary Containment

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration (%)Phenicon HSIM (ºC)SCSCNTNTNTNT60 CR60 CRAluminum Sulfate 50%60 CR60 CAluminum Sulfate, All60 CRAmmonia 10%NTAmmonia Vapors, Wet GasNova-Plate 360IM (ºC)SCSCNTNTNT50 C60 CRNTNTR60 CRNT60 CR60 CRNTNTNTNTNTNTNTNTAmmonium Bicarbonate 10%40 CRNTAmmonium Bicarbonate 50%40 CRNTNTAluminum Sulfate 10%Aluminum Nitrate, SaturatedAmmonium Bisulfite (Black Liquor)NotesNotesNova-Plate 325IM (ºC)SCNotesNova-Plate UHSIM (ºC)IMNotesDura-Plate UHSNotesMagnalux 41V2IM (ºC)SCR60 CR50 CR60 CRNT50 CR60 CRNTNT50 CR60 CRNTNTNTNTNTNRNRNTNTNTNTNTNTNRNRNT40 CRNTNTNTNT60 CRNT40 CRNTNTNTNT60 CRNTNTNTNTNTNTNTNT50 CR60 CRAmmonium Carbonate 25%40 CRNTNT40 CRNTNTNTNT60 CRAmmonium Carbonate, All40 CRNTNT40 CRNTNTNTNT60 CRAmmonium Hydroxide 1%40 CR40 CR40 CR40 CRNTNTNTRAmmonium Hydroxide 10%27 CRNRR27 CRNTNT40 CRNRRAmmonium Hydroxide 20%27 CRNRR27 CRNTNT40 CRNRRAmmonium Hydroxide 30%27 CRNRR27 CRNTNT40 CRNRRAmmonium Hydroxide 40%NTNTNTNTNTNTNTNT40 CRNRRAmmonium Hydroxide 5%40 CR40 CR40 CR40 CR40 CRNTRNTNTNTNTNTNTNTNTNTNT60 CRAmmonium Lauryl Sulfate 30%Ammonium Nitrate 5%60 CR50 CR50 CRNTNT50 CR60 CRAmmonium Nitrate 50%60 CR50 CR50 CRNTNT50 CR60 CRAmmonium Nitrate 65%60 CR50 CR50 CRNTNT50 CR60 CRAmmonium Nitrate 83%60 CR50 CR50 CRNTNT50 CR60 CRAmmonium Nitrate, SaturatedNTNTNTNTNTNTNTNT50 CR60 CRAmmonium Perchlorate 10%40 CR40 CR40 CRNTNTNTNT60 CRAmmonium Persulfate 10%40 CR40 CR40 CRNTNT50 CR60 CRAmmonium Phosphate 40%60 CR50 CR50 CRNTNTNTNT60 CRAmmonium Phosphate 50%60 CR50 CR50 CRNTNTNTNT60 CR5NR Non resistantR ResistantNT Not testedIM ImmersionNotesSC Secondary Containment

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration (%)Phenicon HSDura-Plate UHSIM (ºC)SCIM (ºC)SCSCSCSCR50 CR60 CRNTNTNTNT60 CR60 CR50 CR60 CRNTNTNTNT60 CRAmmonium Sulfate 8%60 CR50 CR60 CRNTNTNTNT60 CRAmmonium Sulfate Dry60 CR50 CR60 CRNTNTNTNT60 CRNTNTNTNTNTNTNTNT50 CR60 CRAmmonium Sulfide 24%40 CR40 CR40 CRNTNT50 CR60 CRAmmonium Sulfide 45%40 CR40 CR40 CRNTNT50 CR60 CRNTNTNTNTNTNTNTNTNTNT60 CR40 CRNTNT40 CR40 CRNTNTNTNT60 CRNTNTNTNTNTNTNTNT60 CRAmyl Acetate40 CR40 CR40 CRNRNRNTNT40 CRAmyl Alcohol66 CR50 CR50 CR40 CR50 CR50 CRAniline 100%NRNRNRNRNRNRNRNRNRNTNRNRArsenic Acid 50%NRNTNRNTNRNTNRNRNTNT40 CRArsenic Acid, AllNRNTNRNTNRNTNRNRNTNT40 CRArsenious Acid 19 BENRNTNRNTNRNTNRNRNTNT40 CRArsenous AcidNRNTNRNTNRNTNRNRNTNT50 CR50 CR50 CR50 CR50 CRNTNT40 CR60 CAmmonium Sulfate 65%Ammonium Sulfide (Bisulfide)Ammonium SulfiteAmmonium Sulfite 50%Ammonium Sulfite, SaturatedAviation Fuel JP 4Axle Grease Lubricant555Notes5NotesMagnalux 41V2IM (ºC)Ammonium Sulfate 6%NotesNova-Plate 325IM (ºC)SCNotesNova-Plate 360IM (ºC)IMNotesNova-Plate UHS5NTNTNTNTNTNTNTNTNTNTNRRBanvel Herbicide40 CR40 CR40 CRNTNTNTNTNTNTBarium Carbonate, All40 CR40 CR40 CR40 CR50 CR60 CRBarium Chloride 50%40 CR40 CR40 CR40 CR50 CR60 CRBarium Chloride, All40 CR40 CR40 CR40 CR50 CR60 CRBarium Cyanide, All40 CR40 CR40 CR40 CR40 CR40 CRBenzene (Benzol)40 CR40 CR40 CR40 CR50 CR40 CRBenzene Sulfonic Acid 100%NTNTNTNTNTNTNRNRNTNT60 CRBenzene Sulfonic Acid 25%NTNTNTNTNTNTNRNRNTNT60 CR6NR Non resistantR ResistantNT Not testedIM ImmersionNotes105SC Secondary Containment

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration (%)Phenicon HSDura-Plate UHSIM (ºC)SCIM (ºC)SCSCNTNTNTNTSCNRNTNT60 CR40 CR40 CR40 CR40 CR40 CRBenzoic Acid, SaturatedNTNTNRNRNRNRNTNT60 CRBenzoyl Benzoic AcidNTNTNRNRNRNRNTNT60 CRBenzyl Alcohol 100%NTNTNTNTNTNTNTNT27 CR10Benzyl Chloride 100%NRNRNRNRNTNTNTNT27 CR10R60 CR60 CR60 CR60 CR60 CRNTNTNTNTNTNTNTNT50 CR50 CRNTNTNTNTNTNTNRNR40 CR60 CRBrake Fluid HD 55740 CRNTNT40 CRNTNT40 CR60 CRBrine Mixture60 CR50 CR60 CR60 CR50 CR60 CRBrine, Saturated50 CR50 CR60 CR60 CR50 CR60 CRNTNTNTNTNTNTNTNTNTNT60 CRButadiene Gas40 CR40 CR40 CR40 CR40 CR40 CRButanediol82 CR82 CR60 CR82 CR50 CR60 CRButanol50 CR50 CR50 CR40 CR50 CR40 CRNTNTNTNTNTNTNRNRNTNT40 CRBenzene:Ethylbenzene 1/3 - 2/3BiodieselBlack Liquor, Pulp MillNTNR40 CRNRNRNRNRNTNTNRNR60 CNotesNotesMagnalux 41V2IM (ºC)NTNotesNova-Plate 325IM (ºC)Benzene Sulfonic Acid 50%SCSCNotesNova-Plate 360IM (ºC)IMNotesNova-Plate UHSNotesBleach (see Sodium Hypochlorite)Boric Acid, All (Borax,sodium borate)Bromine Water 5%ButoxyethanolNTNTButyl AcetateButoxyethoxyethanol40 CRNTNT40 CRNTNT40 CRButyl AcrylateNTNTNRNTNTButyl Alcohol (Butanol)50 CR50 CRButyl Benzyl Phthalate 100%40 CR40 CButyl CarbitolNTNTButyl Carbitol AcetateNTButyl Carbitol Diethyl Glycol 100%Butyl Cellosolve7NRNRNTNT40 CRNRNR50 CR1NRNRNTNRNR50 CR1NRNR50 CR40 CR50 CR40 CRR40 CR40 CR40 CR60 CRNRNRNRNRNRNRNTNT40 CRNTNRNRNRNRNRNRNTNTNRNRNTNTNTNTNTNTNTNTNTNT40 CRNRNRNRNRNRNRNRNRNTNT50 CR111NR Non resistantR ResistantNT Not testedIM Immersion10SC Secondary Containment

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration (%)Phenicon HSIM (ºC)SCSCNTNRNRNTNTNTNTNTButyl Oxitol40 CRNRButylene Glycol82 CRButylene OxideNTButyraldehydeNova-Plate 360IM (ºC)SCSCSCNTNRNRNTNTNTNTNTNTNTNTNTNT27 CRR40 CRNTNTNTNTNTNT50 CR82 CR82 CRNTNT40 tyric Acid 100%NRNRNRNRNRNRNRNRNRNR50 CRButyric Acid 25%NRNRNRNRNRNRNRNRNRNR50 CRButyric Acid 5%NRButyric Acid 50%NRNRNRNRNRNRNRNRNRNR50 CRNRNRNRNRNRNRNRNRNR50 CRCalcium Bisulfite, AllNTNTNTNTNTNTNTNT50 CR60 CRCalcium Bromide 10%40 CR40 CR40 CR40 CR50 CR60 CRCalcium Carbonate, All50 CR50 CR50 CR50 CR50 CR60 CRCalcium Carbonate, Dry50 CR50 CR50 CR50 CR50 CR60 CRCalcium Carbonate, Saturated50 CR50 CR50 CR50 CR50 CR60 CRNTNTNTNTNTNTNTNTNTNT60 CRCalcium Chloride40 CR40 CR40 CR50 CR50 CR60 CRCalcium Chloride 40%40 CR40 CR40 CR50 CR50 CR60 CRNTButyl EtherCalcium Chlorate, AllNotesNotesMagnalux 41V2IM (ºC)Butyl Cellosolve AcetateNotesNova-Plate 325IM (ºC)SCNotesNova-Plate UHSIM (ºC)IMNotesDura-Plate UHSCalcium Chloride 50%40 CR40 CR40 CR50 CR50 CR60 CRCalcium Chloride, Saturated40 CR40 CR40 CR50 CR50 CR60 CRCalcium Hydroxide 10%60 CR40 CR60 CR40 CR50 CRNRNRCalcium Hydroxide 15%60 CR40 CR60 CR40 CR50 CRNRNRCalcium Hydroxide 25%60 CR40 CR60 CR40 CR50 CRNRNRCalcium Hydroxide 5%NTNT40 CR40 CR40 CR50 CRNRNRCalcium Hydroxide 50%60 CR40 CR60 CR40 CR50 CRNRNRCalcium Hypochlorite 1%NRNRNRNRNRNRNTNTNTNTNRNRCalcium Hypochlorite 15%NRNRNRNRNRNRNTNTNTNTNRNR8NR Non resistantR ResistantNT Not testedIM ImmersionNotesSC Secondary Containment

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration (%)Phenicon HSDura-Plate UHSIM (ºC)SCSCNTNTNTNT40 CR40 CRNTNTNTNT40 CR40 CRCalcium Sulfate, SlurryNTNTNTCalcium Sulfite, AllNTNTCarbon TetrachlorideNTCarbon Tetrachloride 90%; Chloroform 10%NTCalcium LignosulfonateCalcium Nitrate, AllCalcium OxideSCSCNTNTNT50 C40 CRNTNTNTNTNT40 CRNTNTNTNTNTNTNTNTNT2NotesSCRNRNRNTNT50 CRNT50 CR60 CRNTNT40 CR60 CRNTNTNT50 CR60 CRNTNTNTNTNTNT60 ux 41V2IM (ºC)2NotesNova-Plate 325IM (ºC)SCNotesNova-Plate 360IM (ºC)Calcium Hypochlorite 5%IM (ºC)IMNotesNova-Plate UHSCastor Oil40 CR40 CR50 CR40 CR40 CR60 CRCellosolveNTNTNTNTNTNTNRNRNTNT250 CRCellosolve AcetateNTNTNTNTNTNTNRNRNTRNRNRChlorinated Brine pH 2.5NRNRNRNRNRNRNTNTNTNT60 CRChlorinated Brine pH 9.0NRNRNRNRNRNRNTNTNTNT60 CRChlorinated Brine pH 2.5 - 9.0NRNRNRNRNRNRNTNTNTNTNRRChlorinated PulpNRNRNRNRNRNRNTNTNTNT60 CRChlorinated Wax, AllNRNRNRNRNRNRNTNTNTNT60 CRChlorination WasherNRNRNRNRNRNRNTNTNTNT60 CRChlorine Dioxide GeneratorNRNTNRNTNRNTNTNTNTNT60 CRChlorine Dioxide ScrubberNRNTNRNTNRNTNTNTNTNT60 CRChlorine Dioxide, Chlorine BleachNRNTNRNTNRNTNTNTNTNT60 CRChlorine Dioxide, Wet, SaturatedNRNTNRNTNRNTNTNTNTNT60 CRChlorine Water pH 2.5NRNTNRNTNRNTNTNTNTNT60 CRChlorine Water pH 9.0NRNTNRNTNRNTNTNTNTNT60 CRChlorine Water pH 2.5 - 9.0NRNTNRNTNRNTNTNTNTNTNTRChlorine, Dry Gas (fumes only)NTNTNTNTNTNTNTNTNRRNTRChlorine, Wet Gas (fumes only)NTNTNTNTNTNTNTNT50 CRNTRChloroacetic Acid 25%NRNRNRNRNRNRNRNRNRNR40 CR9NR Non resistantR ResistantNT Not testedIM ImmersionNotes210SC Secondary Containment

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration (%)Phenicon HSIM (ºC)SCSCRNRRNRNRRNRRChloroacetic Acid 86% - 100%NRRNRChlorobenzeneNTNTChlorobenzene (Mono)NTChlorobutaneNova-Plate 360IM TNTChloroethene SM 111-TriNTNTNTChloroformNTNTNTChloroacetic Acid 26% - 50%NRChloroacetic Acid 51% - 85%NotesNotesNova-Plate 325IM (ºC)SCNotesNova-Plate UHSIM (ºC)IMNotesDura-Plate UHSNotesMagnalux 41V2IM (ºC)SCNotesR40 CR10NRRNTNTNRNRRNRNRNTNT50 CRNRNRNTNTNTNTNTNRNRNTNTNTNT50 CR50 CNRNTNTNTNTNTNTNTNRNRNTNTNTNTNT50 lueneNTNTNTNTNTNTNTNTNTNTNRRChrome Bath, 19% Chromic Acid with SodiumFluosilicate and SulfateNRNRNRNRNRNRNRNRNRNRNRRChromic Acid 10%NTNTNRRNRNTNRNRNTNTNRRChromic Acid 20%NRNTNRNTNRNTNRNRNTNTNRNRChromic Acid 25%NRNTNRNTNRNTNRNRNTNTNRRChromic Acid 30%NRNTNRNTNRNTNRNRNTNTNRRChromic Acid 40%NRNTNRNTNRNTNRNRNTNTNRNRChromic Acid 41% - 75%NRNTNRNTNRNTNRNRNRRNRNRChromic Acid 5%NRNTNRRNRNTNRNRNTRNRNRChromic ChlorideNRNTNTNTNTNTNRNRNTNT60 CRChromium Acid/Sulfuric Acid Mix 10%NRNRNRNRNRNRNRNRNRNRNTNTChromium PlateNRNRNRNRNRNRNRNRNRNR60 CRChromium Sulfate, AllNRNRNRNRNRNRNTNTNRNR60 CRCitric Acid 10%40 CR40 CR40 CRNTNT50 CR60 CRCitric Acid 25%40 CR40 CR40 CRNTNT50 CR60 CRCitric Acid 35%40 CR40 CR40 CRNTNT50 CR60 CRCitric Acid 40%40 CR40 CR40 CRNTNT50 CR60 CRCitric Acid 5%40 CR40 CR40 CRNTNT50 CR60 CR10NR Non resistantR ResistantNT Not testedIM Immersion6SC Secondary Containment

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration (%)Phenicon HSDura-Plate UHSIM (ºC)SCIM (ºC)SCSCSCSCR40 CR40 CRNTNT50 CR60 CR40 CR40 CR40 CRNTNTNTNT60 CRCoconut Oil, All50 CR250 CR250 CR250 CR240 CR260 CR2Cod Liver Oil50 CR250 CR250 CR250 CR240 CR227 CR2Copper Chloride 50%40 CR40 CR40 CR40 CR50 CR60 CRCopper Chloride, All40 CR40 CR40 CR40 CR50 CR60 CRNTNTNTNTNTNTNTNTNTNT27 CRCopper Cyanide, All40 CRNTNT40 CRNTNT50 CR60 CRCopper Cyanide, Potassium40 CNRRNTNT40 CRRNRRNRRNTNT50 CR60 CRNRNRNTNT60 CR40 CRNTNT40 CRNTNT50 CR60 CRCopper Plating, AcidNRNTNRNTNRNTNRNRNTNT50 CRCopper Plating, CyanideNRNTNRNTNRNTNTNTNTNT50 CRCopper Sulfate, All40 CRNTNT40 CR40 CR50 CR60 CRCorn Oil40 CR40 CR50 CR50 CR50 CR60 CRCorn StarchNTNTNTNTNTNTNTNTNTNT60 CRCorn Steep LiquorNTNTNTNTNTNTNTNTNTNT60 CRCorn Syrup60 CR560 CR60 CR5NTNTNTNT60 CR5Cottonseed Oil40 CR240 CR50 CR250 CRNTNT60 CR2NRRNRRNRRNRNRNRRNRNRCrude Oil (IMO Synthetic - Water Free)93 CR82 CR93 CR93 CR1593 CR1582 CRCrude Oil and Water50 CR50 CR82 CR93 CR1593 C15NTNTCrude Oil, Sour121 CR66 CR137 CR1593 CR15177 CR1593 CRCrude Oil, Sweet121 CR66 CR137 CR1593 CR15177 CR1593 CRCumene50 CR50 CR50 CR50 CR50 CR40 CRCupric and Cuprous ChlorideNTNTNTNTNTNTNTNTNTNT60 CRCupric and Cuprous CyanideNTNTNTNTNTNTNTNTNTNT60 CR40 CClay, SaturatedCopper Chromate Arsenic 4%Copper Matte, 30% FeCl3, 19% HCLCopper Nitrate, AllCresol (Cresylic Acid)1125215NR Non resistantNotesR ResistantNT Not testedNotesMagnalux 41V2IM (ºC)Citric Acid 50%NotesNova-Plate 325IM (ºC)SCNotesNova-Plate 360IM (ºC)IMNotesNova-Plate UHS22IM ImmersionNotes2SC Secondary Containment

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration ineCymeneDecanoic Acid, AllDecanol 100%Phenicon HSDura-Plate UHSIM (ºC)SCIM (ºC)SCSCR50 CR50 CR50 CNTNTNRNRNRNR40 CR40 CR40 CNRNRNRNR50 CR50 CNRNR66 CRSC50 CNotesNova-Plate 360IM (ºC)IMNotesNova-Plate UHSNotesNotesNova-Plate 325IM (ºC)SCR50 CNRNRR40 CNRNRR50 CNRNR50 CRNotesMagnalux 41V2IM (ºC)SCR50 CRNRNRNTNTR40 CRNTNTNRNRNTNTNRNRR50 CR40 CR50 CRNRNRNRNRNRNR50 CR50 CR40 CR50 CR50 CRDecyl Alcohol (1-Decanol)66 CR50 CR50 CR40 CR50 CR50 CRDesmophen 670-9060 CR60 CR60 CR40 CRNTNTNTNTDesmophen 80060 CR60 CR60 CR40 CRNTNTNTNTDextrose Solution40 CR40 CR40 CRNTNT40 CR60 CRDiallyl Phthalate40 CR40 CR40 CR40 CR40 CR60 CRDibutyl CarbitolNTNTNRNRNTNTNRNRNTNTNTNTDibutyl EtherNTNTNRNRNTNTNRNRNTNTNTNTDibutyl Phthalate40 CR40 CR40 CR40 CR50 CR50 CRDibutyl Sebacate, All40 CR40 CR40 CR40 CR40 CR60 l Fuel66 CR60 CR82 CR82 CR82 CR82 CRDiesel Fuel/Water 50:50 V/V50 CR50 CR50 CR60 CR50 CNT60 CRDiesel Oil, #2, #366 CR50 CR50 CR82 CR50 CR66 CRDiethanolamine40 CRNTNT82 CR50 CRNTNTNTNTNTNTNTNT82 CR82 CRNTNTNTNT40 CR40 CR40 CRNTNTNTNTNRNRDiethyl EtherNTNTNRNRNTNTNTNTNTNTNRNRDiethyl FormamideNRNRNRNRNRNRNRNRNRNRNRNRDiethyl Ketone40 CR40 CR40 CRNRNRNTNTNRNRDiethyl SulfateNTNTNTNTNTNTNTNTNTNT40 CRDiethanolamine 25% in WaterDiethyl Carbonate12NR Non resistantR ResistantNT Not testedIM ImmersionNotes5SC Secondary Containment

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration (%)Phenicon HSDura-Plate UHSIM (ºC)SCIM (ºC)SCSCSCR50 CR50 CR50 CR50 C50 CR50 CR50 CR50 CRDiethylene Glycol Monobutyl iethylhexyl Phosphoric Acid 20%NRNRNRNRNRDiglycol Amine (DGA)NRNRNRNRDiglycol Amine (DGA) 50% in WaterNTNTNT40 CR40 CDiethylbenzene50 CDiethylene Glycol DEG)Diisobutyl KetoneNotesNotesNova-Plate 325IM (ºC)SCNotesNova-Plate 360IM (ºC)IMNotesNova-Plate UHSNotesMagnalux 41V2IM (ºC)SCR27 CRNTNT66 CRNRNTNTNTNTNRNRNTNTNTNTNRNRNRNTNT60 CRNRRNRRNTNTNTNTNT82 CR82 CRNTNTNTNTR40 CRNRNR40 CR40 CRDiisobutyl Phthalate40 CR40 CR40 CR40 CR50 CR60 CRDiisobutylene40 CR40 CR40 CR40 CR40 CR40 CRDilute Caustic (Sodium Hydroxide)50 CR50 CR50 CR50 CRNTNTNTNTDimethyl AnilineNRNRNRNRNRNRNRNRNRNR40 CRDimethyl FormamideNTNTNRNRNRNRNRNRNTNTNRRDimethyl MorpholineNTNTNRNRNRNRNRNRNTNT40 CR40 CR40 CR40 CR40 CR50 CR50 CRDimethyl SulfideNTNTNRNRNRNRNTNTNTNTNRNRDimethyl SulfoxideNTNTNTNTNTNTNTNTNTNTNRNRDimethyl ThiazolidineNTNTNTNTNTNTNTNTNTNT60 CRDimethyl TNTNRNRDioctyl PhthalateNTNTNTNTNTNTNTNTNTNT40 CRDipotassium Phosphate 50%NTNTNTNTNTNTNTNTNTNT40 CR82 CR60 CR82 CR82 CRNTNT60 CRNTNTNTNTNTNTNTNTNTNT40 CRDodecanol (Lauryl Alco)66 CR50 CR50 CR40 CR50 CR60 CRDodecene40 CR40 CR40 CR40 CRNTNT60 CRDodecyl Alcohol (Lauryl)40 CR40 CR40 CR40 CR40 CNT50 CRNTNTNTNTNTNTNRNRNTNT60 CRDipropylene GlycolDivinylbenzeneDodecyl Benzene Sulfonic Acid13555NR Non resistant5R ResistantNT Not testedIM ImmersionNotes1010SC Secondary Containment

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration (%)Phenicon HSDura-Plate UHSIM (ºC)SCIM (ºC)SCSCSCR50 CR50 CR50 CR50 CNTNTNRNRNTNTNTNTDowanol EB Glycol EtherNTNTNRNRNTNTNTDowanol PM Glycol ed Soybean OilNTNTNRNREsters, Fatty Acid40 CR40 CEthanol 10%66 CRNT50 CDowanol DB Glycol EtherDodecylbenzeneIM (ºC)SCR40 CRNTNT40 CRNTNTNT40 CRNTNTNTNTNTNRNTNTNTNTNTNTRNTNTNTNTNTNT60 CRR40 CR40 CR50 CR60 CRR50 CRNTR50 CR50 CR66 CR50 CR50 CR40 CR50 CR40 CR66 CRNTRNTRNTR50 CR50 CREthanol 50%66 CRNTRNTRNTR50 CR40 CREthanol 95%66 CRNTRNTR40 CR50 CR40 CREthanolamine (MEA)NTNTNTNT50 CRNRNRNTNT27 CREthanolamine (MEA) 25% in waterNTNTNRNR82 CR82 CRNTNTNTNTEthoxyl EthanolNTNTNTNTNTNTNRNRNTNTNTNTEthyl AcetateNTNTNRNRNTNTNRNRNTNTNRNREthyl AcrylateNTNTNTNTNTNTNRNRNTNTNRNR66 CR50 CR50 CR40 CR50 CR40 CR1311NotesEthanol 100%131NotesMagnalux 41V2Ethanol 20%Ethyl Alcohol, Liquor (see Ethanol)1NotesNova-Plate 325IM (ºC)SCNotesNova-Plate 360IM (ºC)IMNotesNova-Plate UHS1Ethyl Amine 20%NTNTNTNTNTNTNTNTNTNTNRNREthyl ChlorideNRNRNRNRNRNRNRNRNTRNRNREthyl ChloroformateNRNRNRNRNRNRNRNRNTNTNRNREthyl Ether (Diethylether)NTNTNTNTNTNTNRNRNTNTNTNTEthyl Hexyl AcrylateNTNTNTNTNTNTNRNRNTNTNTNT40 CR40 CR40 CRNTNT40 CRNTNTEthyl SulfateNTNTNTNTNTNTNTNT50 CR40 CREthyl ThiochloroformateNRNRNRNRNRNRNRNRNTNTNTNT50 CR50 CR50 CR50 CR50 CNT40 CREthyl Hexyl NitrateEthylbenzene14NR Non resistantR ResistantNT Not testedIM ImmersionNotes110SC Secondary Containment

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration (%)Phenicon HSDura-Plate UHSIM (ºC)SCIM (ºC)SCR50 CR50 CNTNTNRNREthylene Glycol82 CR60 CREthylene Glycol Monoethyl Ether40 CRNREthylene OxideNTNTEucalyptus OilNTNTFatty Acids, Saturated40 CRFatty Acids, Unsaturated40 CRFatty EsterEthylbenzene: Benzene 2/3:1/3Ethylene ChlorideIMSC50 CNotesNova-Plate 360IM (ºC)SCR50 CNTNT82 CRNR40 CNTNTNT225NotesNova-Plate UHSIM (ºC)SCR50 CNRNR82 CRRNRNTNTNTNTNT40 CR50 CR40 CR50 CR5NotesSCNT40 CRNTNTNRNR50 CR60 CRNRNTNTNTNTNRNRNTNTNRNRNTNTNTNT60 CR250 CRNTNT60 CR250 CR50 CR60 CR5NotesMagnalux 41V2IM (ºC)5NotesNova-Plate 3255240 CR40 CR40 CR40 CR40 CR40 CRFerric Acetate, SaturatedNTNTNTNTNTNTNTNTNTNT60 CRFerric Ammoniom Citrate SolutionNTNTNTNTNTNTNTNTNTNTNTNTFerric Chloride 38%40 CR740 CR740 CR740 CR740 CR60 CRFerric Chloride10%50 CR740 CR740 CR840 CR7NTNTNTNTFerric Sulfate 12%40 CR740 CR740 CR740 CR740 CR760 CRFerrous Chloride, All40 CR740 CR740 CR740 CR740 CR760 CRFertilizer (Liquid Urea)40 CR640 CR640 CR640 CR740 CR6NTNTFertilizer, URAN40 CR640 CR640 CR640 CR740 CR660 CRFish OilNTNTNTNTNTNTNTNTNTNT60 CR7Fly Ash, SlurryNRRNRRNRRNTNTNTNT60 CRFormaldehyde 44%NTNTNRRNTNTNRNRNTNT60 CRFormaldehyde, AllNTNTNTNTNTNTNRNRNTNT60 CRFormic Acid 10%NRNRNRNRNRNRNRNRNRNR60 CRFormic Acid 98%NRNRNRNRNRNRNRNRNRNR27 CRFuel Oil - No. 160 CR60 CR82 CR82 CR82 CR60 CRFuel Oil - No. 260 CR60 CR82 CR82 CR82 CR60 CRFuel Oil - No. 6 (Bunker C)60 CR60 CR82 CR82 CR82 CR60 CRFuel Oil, Heating Oil60 CR60 CR82 CR82 CR82 CR60 CR15NR Non resistantR ResistantNT Not testedIM ImmersionNotes5210SC Secondary Containment

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration (%)Phenicon HSDura-Plate UHSIM (ºC)SCNRNRNRNRNTNTGasoline (White)50 CRGasoline (White) 50% Unleaded Ethanol 50%50 CRGasoline (White) 50% Unleaded, 50% Tapwater50 CRGasoline (White) 80% Unleaded Methanol 20%NTNT50 CRIMSCFurfural 100%NRFurfural to 10%Furfuryl Alcohol 100%Gasoline (White) 90% Unleaded Ethanol 10%NotesIM (ºC)SCNRNRNRNRNRNR50 CRNR666NotesNova-Plate UHSNova-Plate 360NotesIM (ºC)SCNRNRNRNRNRNR650 CRR640 C50 CR6NTNT50 CRNotesNova-Plate 325IM (ºC)SCNRNRNRNRNRNR650 CRR650 C50 CR66NTNT650 CRNotesMagnalux 41V2IM (ºC)SCNRNRNRNRNRNRNRNTNTNRNR650 CR50 CRR6NTNTNTNT50 CR650 CR6NTNT6NTNT650 CR6NTNT650 CR6NTNTNTNT6Gasoline (White) 90% Unleaded, 10% Methanol40 CR6NRNR6NRNR650 CR650 CR6NTNTGasoline (White) 90% Unleaded, 10% MTBE50 CR650 CR650 CR650 CR650 CR6NTNTGasoline E8550 CR640 CR650 CR650 CR650 CR6NTNTGasoline Reference Fuel C50 CR650 CR650 CR650 CR650 CR640 CRGasoline, Aviation50 CR550 CR550 CR550 CR550 CR560 CRGasoline, Commercial50 CR50 CR50 CR50 CR50 CR40 CRGasoline, Diesel 50%, 50% Tapwater50 CR50 CR50 CR50 CR82 CR50 CRGasoline, Jet Fuel JP450 CR50 CR50 CR50 CR50 CR60 CRGasoline, Leaded50 CR50 CR50 CR50 CR50 CR60 CRGasoline, Premium Unleaded50 CR50 CR50 CR50 CR50 CR60 CRGasoline, Regular Unleaded555550 CR50 CR50 CR50 CR50 CR60 CRGlacial Acetic Acid (see Acetic Acid 100%)NRNRNRNRNRNRNRNRNRNR40 CNRGlucoseNTNTNTNTNTNTNRNRNTNT66 CRGlutaraldehyde 50%NRNRNRNRNRNRNRNRNRNR40 CNRGlutaric Acid 50%NRNRNRNRNRNRNRNRNRNR40 CRGlycerin40 CR40 CR40 CR82 CR50 CR60 CRGlycerol40 CR40 CR40 CRNTNT50 CR40 CRGlycol82 CR60 CR82 CR82 CR50 CR60 CRNRNRNRNRNRNRNRNRNRNR27 CRGlycolic Acid 70%16555NR Non resistant55R ResistantNT Not tested5IM ImmersionNotes55SC Secondary Containment

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration (%)Phenicon HSDura-Plate UHSIM (ºC)SCIM RRNR50 CR50 CR50 CRHeptanoic etramine 40%NRNRNR50 CR50 CGlyconic Acid 50%NRGlyoxal 40%Green Liquor, AllHeptaneHexaneNotesNotesNova-Plate 325IM (ºC)SCNotesNova-Plate 360IM (ºC)IMNotesNova-Plate UHSIM (ºC)SCNR40 CRNRNR40 CRNR50 CR40 CR50 CR50 CR60 CRRNRNRNTNT40 CRNRNRNRNRNRNRNRRNRNRNRNRNRNRNR40 CRR50 CR50 CR50 CR60 CRNotesHexylene Glycol82 CR560 CR582 CR582 CRNTNT60 CRHydraulic Fluid60 CR660 CR660 CR6NTNTNTNT60 CRHydrazineNTNTNTNTNTNTNRNRNTNTNRNRHydrazine 35%NRNRNRNRNRNRNRNRNRNRNRNRHydrazine HydrateNRNRNRNRNRNRNRNRNRNRNRNRHydrobromic Acid 20%NRNRNRNRNRNRNRNRNTNT40 CR7Hydrobromic Acid 25%NRNRNRNRNRNRNRNRNTNT40 CR7Hydrobromic Acid 50%NRNRNRNRNRNRNRNRNTNT40 CR7Hydrobromic Acid 62%NRNRNRNRNRNRNRNRNTNTNTR7Hydrochloric Acid 1%NTNT40 CR40 CR40 CRNTNTNTNT75NotesMagnalux 41V276Hydrochloric Acid 10%NRNRNRNRNRNRNRNR27 CR750 CR7Hydrochloric Acid 15%NRNRNRNRNRNRNRNR27 CR750 CR7Hydrochloric Acid 20%NRNRNRNRNRNRNRNR27 CR750 CR7Hydrochloric Acid 30%NRNRNRNRNRNRNRNR27 CR740 CR7Hydrochloric Acid 37%NRNRNRNRNRNRNRNR27 CR740 CR7Hydrochloric Acid 5%NRNRNRR40 CRNRNR27 CR750 CR7Hydrocyanic Acid, AllNRNRNRNRNRNRNRNRNRNR60 CR7Hydroflouric Acid 35%NRNRNRNRNRNRNRNRNRNTNRNRHydrofluoric Acid 10%NRNRNRNRNRNRNRNRNRNTNRNR17NR Non resistantR ResistantNT Not testedIM ImmersionSC Secondary Containment

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration (%)Phenicon HSIM (ºC)SCSCNRNRNRNRNRNRNRNRHydrofluoric Acid 50%NRNRNRHydrofluoric Acid 70%NRNRHydrofluosilicic Acid 10%NRHydrofluosilicic Acid 25%Nova-Plate 360IM RNRNRNRHydrofluosilicic Acid 30%NRNRNRHydrofluosilicic Acid 35%NTNTNTHydrofluoric Acid 20%NRHydrofluoric Acid 35%NotesNotesNova-Plate 325IM (ºC)SCNotesNova-Plate UHSIM (ºC)IMNotesDura-Plate UHSNotesMagnalux 41V2IM RNTNTNRNRNotesHydrogen Peroxide 10%NTNTNTNTNTNTNTNTNTNT40 CRHydrogen Peroxide 30%NRNRNRNRNRNRNTNTNTNT40 CRHydrogen Peroxide 5%NTNTNTNTNTNTNTNTNTNT40 CRHydrogen Peroxide 50%NTNTNTNTNTNTNTNTNTNTNRNRHydrogen Sulfide 5%40 CR40 CR40 CR40 CR40 CR60 CRHydrogen Sulfide GasNTNTNTNT40 CR40 CRNTNT60 CRHydrogen Sulfide, WetNTNTNTNT40 CR40 CRNTNT60 CRHydroiodic Acid 20%NRNRNRNRNRNRNRNRNTNT40 CR7Hydroiodic Acid 40%NRNRNRNRNRNRNRNRNTNT40 CR7Hydrosulfite Bleach, AqueousNRRNRRNRRNRNRNTNT60 CRHydroxyacetic Acid 70% (see Glycolic Acid)NRRNRRNRRNRNRNTNT27 CRHypochlorous Acid 10%NRNTNRRNRRNRNRNRNT60 CRHypophosphorous Acid 50%NRRNRRNRRNRNRNRNT40 CRIodine VaporNRNRNRNRNRNRNTNTNTNT50 CRIodine, CrystalsNTNTNTNTNTNTNTNTNTNT50 CRIron and Steel Cleaning BathNRNRNRNRNRNRNRNRNTNT60 CRIron Plating SolutionNRNRNRNRNRNRNRNRNTNT60 CRIso Butane40 CR40 CR40 CR40 CRNTNT50 CRIsoamyl Alcohol50 CR50 CR50 CR40 CRNTNT60 CR18NR Non resistantR ResistantNT Not testedIM Immersion6SC Secondary Containment

TANK LININGS CHEMICAL RESISTANCE GUIDEChemical environment and concentration (%)Phenicon HSDura-Plate UHSIM (ºC)SCIM (ºC)SCSCSCR50 CR50 CR40 CRNT50 CR50 CR50 CR40 CRIsononyl Alcohol50 CR50 CR50 CR40 CIsooctyl Alcohol50 CR50 CR50 NRNRIsopropanol AmineNTNTNTIsopropyl AcetateNTNT40 CIsobutyl Alcohol50 CIsodecanol AlcoholIsopropyl Alcohol (Isopropanol)NotesNotesNova-Plate 325IM (ºC)SCNotesNova-Plate 360IM (ºC)IMNotesNova-Plate UHSNotesMagnalux 41V2IM (ºC)SCNT60 CRNTNT60 CRRNTNT60 CR40 CRNTNT60 CRNTNTNTNTNT50 CRNTNTNRNRNTNT40 CRNTNTNTNRNRNTNT60 CRR40 CRNRNRNTNTNRNRNotes50 CR50 CR50 CRNRNR50 CR50 CRIsopropyl AmineNRNRNRNRNRNRNRNRNRNRNRNRIsopropyl EtherNTNTNTNTNTNTNTNTNTNTNRNRIsopropyl MyristateNTNTNTNTNTNTNTNTNTNT60 CRIsopropyl PalmitateNTNTNTNTNTNTNTNTNTNT60 CRItaconic Acid 25%NRNTNRNTNRNTNRNRNTNT40 CR50 CR50 CR50 CR50 CR50 CR60 CR5Jet Turbine OilNTNTNTNTNTNT50 CRNTNT60 CR5Kaolin (Saturated China C

This list has been abbreviated please contact us if you do not see the required chemical. CONTENTS: Specific notes 3 Chemical resistance list 4-32 Notes 33-34 TANK LININGS CHEMICAL RESISTANCE GUIDE APRIL 2021 2 Sherwin-Williams protective coatings produce the most versatile range of chemically resistant linings on the market.