Transcription

GE MarineProductSelection Guide2014/2015GE imagination at work

Table of ContentsAbout GE MarineAbout GE Marine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3GE Marine’s family of medium-speed diesel engines includes its L250A History of Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4inline engine as well as its V250 and V228 engine model platforms. TheL250 IMO Tier II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6engines deliver continuous power, ranging from 1,308 kW to 4,650 kWL250 IMO Tier II Engine Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6V250 IMO Tier II. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8(1,754 hp to 6,235 hp) and can be configured to meet U.S. EPA Tier 3 andEPA Tier 4i as well as IMO MARPOL Annex VI Tier II and Tier III emissionslevels. Each engine features high-capacity turbochargers, efficientV250 IMO Tier II Engine Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8combustion design, electronic fuel injection (EFI) or Common Rail (CR)V228 IMO Tier II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10and can be integrated into marine and stationary systems to meet strictV228 IMO Tier II Engine Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12emissions levels. Currently operating in some of the most challengingV228 IMO Tier II Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14industrial environments worldwide, GE’s engines are dependable, long-L250 EPA Tier 3/IMO Tier II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17lasting, durable and efficient.L250 EPA Tier 3/IMO Tier II Engine Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18L250 EPA Tier 3/IMO Tier II Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20L/V250 EPA Tier 4i/IMO Tier III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24L250 EPA Tier 4i/IMO Tier III Engine Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26L250 EPA Tier 4i/IMO Tier III Engine Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27V250 EPA Tier 4i/IMO Tier III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29V250 EPA Tier 4i/IMO Tier III Engine Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29V250 EPA Tier 4i/IMO Tier III Engine Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30Marine Gensets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32Stationary Gensets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34Global Distribution Network for Servicing Worldwide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4123

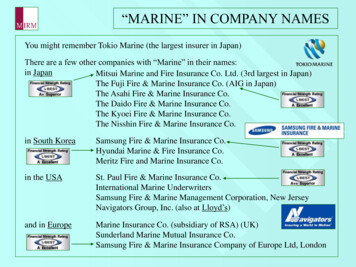

A History of PerformanceGE Transportation has been serving the transportation industry for moreGE’s Emissions Paththan a century. For more than 40 years, we have designed and built2012high-performance diesel engines and have become one of the largest2013U.S. EPAmanufacturers of marine products that help tackle the most importantL/V250Along with the L250 engine, GE’s family of medium-speed enginesincludes 8-, 12- and 16-cylinder V configurations that can be configuredto meet IMO Tier II, EPA Tier 3 as well as EPA Tier 4i and IMO Tier III, in-IMO Marpolsolutions, breakthrough technologies and process innovations. You cansucceed.2016EPA Tier 4EPA Tier 2EPA Tier 4i 2,000 KW8L250 and 12/16V250challenges facing the marine industry today through integratedrely on GE’s experience, innovation and proven performance to help you2015EPA Tier 3 2,000 KW6L250, 8L250manufacturers of medium-speed engines in the world.GE Marine, a division of GE Transportation, is one of the world’s leading2014L/V250V228IMO/MARPOL Tier IIIMO Tier II/IIIIMO/MARPOL Tier IIIMO Tier III takes effect on January 1, 2016 in NOx Emission Control Areas (NECA’s).engine without need for SCR after-treatment or urea injection.With more than 15,000 engines operatingworldwide in some of the mostchallenging industrial environments,GE’s medium-speed engines aredependable, long-lasting, durableand efficient. From tugboats in Turkeyand fishing vessels in Peru to offshoreconstruction vessels in Norway andferries in Texas, GE’s marine engines aresupported by an extensive global partsdistribution and service network.45

L250 IMO Tier IIL250 IMO Tier IIEngine SpecificationsEngine SpecificationsEngine dataEngine dimensionsNumber of cylindersStroke cycleCylinder arrangement6L2508L25068Length44Width1,950 mm (77 in)1,950 mm (77 in)inlineinlineHeight2,962 mm (116 in)2,962 mm (116 in)Crankshaft center lineto sump940 mm (37 in)940 mm (37 in)Crankshaft center lineto mounting feet308 mm (12 in)308 mm (12 in)Exhaust diameter457 mm (18 in)457 mm (18 in)Bore250 mm (9.84 in)250 mm (9.84 in)Stroke320 mm (12.60 in)320 mm (12.60 in)16.8:116.8:1Compression ratio6L250900 rpmContinuous1Max21,050 rpm121,498 kW (2,009 hp) 1,998 kW (2,679 hp)1,648 kW (2,210 hp)2,198 kW (2,947 hp)Continuous1,664 kW (2,232 hp)2,219 kW (2,976 hp)Max11,000 rpm8L2501,831 kW (2,455 hp)2,441 kW (3,274 hp)Continuous11,748 kW (2,344 hp)2,330 kW (3,125 hp)Max1,922 kW (2,578 hp)2,564 kW (3,438 hp)22Dry weight6L2508L2505,138 mm (202 in)5,949 mm (234 in)17,295 kg (38,129 lbs) 20,856 kg (45,980 lbs)Dimensions and weights are approximate and include all on-engine accessories.At standard reference conditions per ISO 3046-1:2002E, ISO 8665One hour per 12-hour period67

V250 IMO Tier IIV250 IMO Tier IIEngine SpecificationsEngine SpecificationsEngine dataEngine dimensionsNumber of cylinders16Length12V25016V2504,808 mm (189 in)5,684 mm (224 in)44Width2,468 mm (97 in)2,468 mm (97 in)Cylinder arrangementVVHeight3,190 mm (126 in)3,275 mm (129 in)Bore250 mm (9.8 in)250 mm (9.8 in)Stroke320 mm (12.6 in)320 mm (12.6 in)Crankshaft center lineto sump1,077 mm (42 in)1,162 mm (46 in)16.8:116.8:1Crankshaft center lineto mounting feet536 mm (21 in)536 mm (21 in)610 mm (24 in)610 mm (24 in)900 rpm12V25016V250Continuous12,726 kW (3,655 hp)3,632 kW (4,870 hp)Max22,998 kW (4,021 hp)3,995 kW (5,357 hp)Continuous3,028 kW (4,060 hp) 4,038 kW (5,415 hp)Max23,330 kW (4,466 hp) 4,442 kW (5,957 hp)11,000 rpmContinuous3,180 kW (4,265 hp)4,239 kW (5,685 hp)Max23,499 kW (4,692 hp)4,664 kW (6,254 hp)11,050 rpm216V25012Stroke cycleCompression ratio112V250Exhaust diameterDry weight23,400 kg (51,600 lbs) 30,844 kg (68,000 lbs)Dimensions and weights are approximate and include all on-engine accessories.At standard reference conditions per ISO 3046-1:2002E, ISO 8665One hour per 12-hour period89

V228 IMO Tier II EngineDependable, long-lasting marine powerGE has been designing and buildinghigh-performance diesel engines formore than 40 years. Today, we areone of the leading manufacturersof medium-speed engines inThey work harder.GE’s V228 Series Engines are high-compression, four-stroke, mediumspeed, turbocharged, electronically fuel injected, class-approved enginesdesigned and built for rigorous marine applications. Our medium-speedengines are proven reliable, with more than 150 million hours of service.They are among the most fuel-efficient engines in their class.the world. Our V228 SeriesThey go longer.Engines produce continuousWith rugged construction and quality-assured parts, V228 enginespower from 1,305 kW to 3,357are capable of operating cost effectively for more than 20 years. MostkW (1,750 hp to 4,500 hp).components can go without overhaul for up to 40,000 hours on a typicalWith exceptional reliabilitymarine duty cycle. Among medium-speed engines on the market, V228and operating costs amongengines offer one of the lowest life-cycle costs.the lowest in their class,V228 engines from GE are the rightchoice for dependable, efficient power.They run smarter.A high-capacity turbocharger, electronic fuel injection and efficientcombustion management come together in V228 engines to make fuelGE’s V228 Series Engines are designed to power workboats, tugs,and lube oil consumption, as well as emissions, among the lowest in theoffshore supply vessels, ferries, dredges, fishing vessels and otherindustry.marine transport applications. Dependable and durable, these mediumspeed engines are among the best in their class for fuel efficiency andlow life-cycle costs. Engines are available in 8-, 12- and 16-cylinderconfigurations meeting IMO Tier II emissions.The easy-to-maintain engine.The modularized construction of our V228 engines improvesmaintainability. Among the features that make maintenance easier arelarge access doors on the engine mainframe to reach bearings and othercrankcase components. The segmented camshaft, sectional exhaustmanifold and utilized power assembly are features that simplify removaland replacement of components.1011

V228 IMO Tier IIV228 IMO Tier IIEngine SpecificationsEngine SpecificationsEngine dataEngine dimensions8V22812V22816V2288V22812V22816V228Number of cylinders81216HeightStroke cycle4442,766 mm(109 in)2,734 mm(108 in)3,010 mm(118 in)45-degree V45-degree V45-degree VLength3,955 mm(156 in)4,687 mm(185 in)5,560 mm(219 in)Bore228.6 mm(9 in)228.6 mm(9 in)228.6 mm(9 in)Width2,040 mm(80 in)2,121 mm(84 in)2,200 mm(87 in)Stroke266.7 mm(10.5 in)266.7 mm(10.5 in)266.7 mm(10.5 in)Crank center line to sump978 mm(39 in)950 mm(37 in)1,221 mm(48 in)15.7:115.7:115.7:1Crank center line tomounting feet480 mm(19 in)480 mm(19 in)480 mm(19 in)Exhaust diameter457 mm(18 in)508 mm(20 in)610 mm(24 in)13,668 kg(30,135 lbs)18,942 kg(41,760 lbs)22,038 kg(48,585 lbs)Cylinder arrangementCompression ratio8V22812V22816V228Continuous11,307 kW(1,753 hp)1,961 kW(2,630 hp)2,614 kW(3,506 hp)Max21,438 kW(1,928 hp)2,157 kW(2,893 hp)2,876 kW(3,857 hp)1,453 kW(1,948 hp)2,179 kW(2,922 hp)2,905 kW(3,896 hp)Max21,598 kW(2,143 hp)2,397 kW(3,214 hp)3,196 kW(4,286 hp)Continuous11,525 kW(2,045 hp)2,289 kW(3,070 hp)3,057 kW(4,100 hp)Max21,678 kW(2,250 hp)2,518 kW(3,375 hp)3,363 kW(4,510 hp)900 rpmContinuous11,000 rpm1,050 rpm12Dry weightDimensions and weights are approximate and include all on-engine accessories.At standard reference conditions per ISO 3046-1:2002E, ISO 8665One hour per 12-hour period1213

V228 IMO Tier IIEngine ComponentsDesigned for high reliability and low life-cycle costsRigid cast mainframeElectronic fuel injection (EFI)The V228 engine mainframe features high-Our EFI systems ensure compliance to all major regulatory standards.strength, monobloc cast-iron construction.Precise fuel management and control also yield fuel savings. TheAll water, fuel and exhaust piping is externallyreliability and performance of electronic fuel injection technology frommounted, eliminating the potential for internalGE has been proven with more than 150 million hours of engine servicecontamination. Large access doors allow forfor more than 15 years.easier maintenance, and generous casing andribbed cross-members dampen vibration.High-strength pistonsForged steel crowns with forced oilHigh-performance turbochargerlubrication and cooling promote heatGE’s expertise in gas turbine technologyreduction for longer life. A three-ringcontributes to an industry-leading designarrangement, which distributes pressure morefor performance in the turbocharger. A high-evenly, and a cutback design decrease lube oilcompression ratio improves efficiency across theconsumption. A lightweight aluminum skirt offersload range. Dual modular pulse piping preserveshigh heat resistance. The master and articulated rod share a commonexhaust pulse energy for maximal thermaljournal, minimizing engine length while maximizing bearing width.efficiency and the stainless dual exhaust pipesexhibits long component life.Segmented camshaftThe camshaft in a V228 engine isUnitized power assemblyarranged in individual sections forFour-bolt mounting makes assembly removal fast andeasy inspection and maintenance.easy. Electron-beam welding of the steel liner to theForged and hardened camshaftforged head prevents leakage. Stainless steel valvelobes reduce wear. Oversized endseats, inconel exhaust, chromed intake valves and valvebearings decrease loads for longerrotators extend overhaul intervals and component life.camshaft life.1415

V228 IMO Tier IIEngine ComponentsHeavy-duty crankshaftThe engine’s one-piece crankshaft is forged from high-quality steel,nitride-hardened for long life. Hefty journals and crank pins minimizesurface loads, and large radii fillet welded counterweights reduce stressfor longer crankshaft life.Tolerant tri-metal main bearingsThe main bearings are oversized to reduce pressure while providingexceptional oil-wedge formation for low wear. A sacrificial run in overlaypromotes rapid conformity at start up. A nickel barrier ensures superiorheat resistance, while a lead tin overlay serves as a high-tolerancecontaminant trap for particles and degraded oil.L250 EPA Tier 3/IMO Tier II EngineClean, lean marineGE’s L250 Series Inline Diesel Engine offers a streamline design that isfuel-efficient and delivers continuous power from 1,518 to 1,999 kW.The L250 is specifically engineered for marine applications with itsaccessories mounted on the engine for maintenance ease and offersa full-power PTO option.The L250 is marine-class compliant and meets U.S. EPA Tier 3 emissionrequirements, a proactive approach to fuel savings and emissionsreduction natural to GE. Depending on the application and duty cycle,the L250 offers an average 12% fuel savings when compared to the V228engine.The engine, available in 6- and 8-cylinder models, also offers ease ofre-power as its narrow inline footprint takes in mind marine engine roomconstraints where space is at a premium. The narrower frame uses asimilar footprint as competitive engines for minimum design change.GE designed the L250 engine based on the successful V250 engineplatform using the Six Sigma Quality design process. Together, withflexible installation and maintenance options, proven parts performanceand support from GE’s worldwide distribution network, the L250 offerscustomers reliability and limited downtime.1617

L250 EPA Tier 3/IMO Tier IIL250 EPA Tier 3/IMO Tier IIEngine SpecificationsEngine SpecificationsEngine dataEngine dimensionsNumber of cylindersStroke cycle6L2508L2506L2508L25068Length4,674 mm (184 in)5,564 mm (219 in)Width1,950 mm (77 in)1,950 mm (77 in)Height including sump2,827 mm (111 in)2,931 mm (115 in)Crankshaft center line tosump940 mm (37 in)940 mm (37 in)Crankshaft center line tomounting feet308 mm (12 in)308 mm (12 in)Exhaust diameter256 mm (10 in)310 mm (12 in)Weightdry 17,295 kg(38,129 lbs)wet 18,411 kg(40,589 lbs)dry 19,897 kg(43,865 lbs)wet 21,267 kg(46,885 lbs)44inlineinlineBore250 mm (9.84 in)250 mm (9.84 in)Stroke320 mm (12.60 in)320 mm (12.60 in)16.8:116.8:1Cylinder arrangementCompression ratio6L2508L250Maximum continuousrating*Maximum continuousrating*900 rpm1,517 kW (2,035 hp)1,998 kW (2,679 hp)1,000 rpm1,686 kW (2,261 hp)N/A1,050 rpm1,770 kW (2,374 hp)N/A* Maximum speed and load conditions at which the engine is capable of operatingDimensions and weights are approximate and include all on-engine accessories.continuously for an unlimited number of hours per year; between the normalmaintenance intervals stated by GE, under standard ambient conditions and withthe maintenance prescribed by GE having been carried out. Engine overload islimited for U.S EPA Tier 3 (40CFR Part 1042) regulations.1819

L250 EPA Tier 3/IMO Tier IIEngine ComponentsMarine class, inline designSturdy mainframeExhaust manifoldThe L250’s mainframe is a rugged one-pieceThe exhaust manifold provides increased transient response and betteriron casting which provides excellent vibration-efficiency under pulse and constant pressure operation. It is modularizeddampening characteristics and long-term stabilitywith identical piping and bellows sections for all of the immediateto minimize line bore distortion. Further strength andcylinder assemblies. The bellows sections help lower the thermal andrigidity are added by bolting main bearing caps bothvibration-induced stresses on the exhaust system.vertically and horizontally. The lube-oil gallery and passages are cast orfrilled into the frame to provide lubrication to all vital engine areas withno pipe or hose connections within the frame, helping eliminate leaks orpossible loss of lubrication.Intercooler and air-intake manifoldThe L250’s combustion air-intake system includes one intercoolermounted on the mainframe between the turbo outlet and air manifoldinlet. This allows for lower fuel consumption, emissions and exhaustTurbochargertemperatures. For servicing, the intercooler can be removed withoutThe L250 uses a new, high-efficiency, radial flow and water-cooleddismantling other engine components.turbocharger to achieve EPA Tier 3 emissions without sacrificing engineperformance. Depending on duty cycle and application, response timeand fuel efficiency have improved over the L250 Tier 2 engines and fuelconsumption has improved 5% to 6%.One-piece linersThe stiff, one-piece, mid-stop liner has an integral externalwater jacket that removes the possibility of water leaks.An anti-polishing ring provides a durable running surface,Crankshaft and engine drive trainimproving lube oil consumption and liner life. The top one-The crankshaft is press-forged, high-quality alloy steel. Oil passagesthird of the liner is cooled.drilled in the crankshaft allow oil delivery to connecting rod bearings andpistons. A flywheel with ring gear for the starting motor is bolted directlyto the crankshaft flange.2021

L250 EPA Tier 3/IMO Tier IIEngine ComponentsMarine class, inline designPower assembliesCamshaftsThe L250’s power assemblies are designed to meet theThe camshafts on the L250 are made of sectional carbonhigh-pressure demands of the engine while adhering tosteel forgings joined by dowel-bolted flanges, a design thatstrict reliability requirements and an easy-to-maintainsimplifies component removal and replacement. Individualassembly concept. Unitized cylinder assembly enables quicksections of the camshaft, rather than the entire camshaft,change-outs and increased engine uptime. Each assemblycan be serviced or replaced.is mounted directly to the mainframe and includes linerassembly, cylinder head, intake and exhaust valves, valvelinkage and a high-pressure fuel-injection pump and nozzle.This design enables excellent flow paths for combustion,lower fuel consumption and reduced emissions. Design improvementswill result in a significant reduction in lube oil consumption over L250 Tier2 engines.PistonsOur pistons are ruggedly designed to accommodate the high-peak firingpressure requirements of L250 engines. The pin and skirt componentsalso are designed to yield better piston lubrication and guidance as ittravels within the liner. The design helps minimize oil consumption andblow-by as well as lengthen oil life.22Connecting rod assemblyThe forged-steel connecting rods are exceptionally strong and exhibithigh stiffness, which is beneficial during the engine’s lifetime. Largebearing widths with optimized oil grooves also helpimprove oil-film thickness and pressure, allowing foroptimum performance and lower friction losses.Advanced EFIDesigned for greater efficiency at varying speeds and loads, the L250’selectronic fuel injection features precise fuel control, increased pressurecapability and refined timing. Optimization of the cam profile, injectionstart, injection volumes and flows and control algorithms have produceda relatively simple system, proven reliable through extensive validation.23

L/V250 EPA Tier 4i/IMO Tier III EnginesL/V250 EPA Tier 4i/IMO Tier III EnginesGE Marine’s non-SCR dieseltechnology requires no after-treatmentDiesel engine innovation meets EPA Tier 4iand IMO Tier III emissions standardsAs a global leader in emissions-reducing solutions, GE Marine again isKey benefitsat the forefront with its breakthrough non-SCR diesel technology that requires no urea-based after-treatment. This advanced technologyreduces key emissions by more than 70% and enables in-enginecompliance with EPA Tier 4i and IMO Tier III emissions standards.ranging from 1700kW to 4650kW Eliminates urea use and storage to preserve cargo and tank space Requires no supplemental equipment or fluids, reducing capital andThis innovative non-SCR diesel engine technology is available onGE Marine’s L250 and V250 Series Diesel Engines and is the result ofoperating expenditures an eight-year investment to help businesses worldwide comply withEPA and IMO emission regulations.Available on GE Marine’s L250 and V250 Series Diesel EnginesEngines supported by an extensive global parts, distribution andservice network Reducing ship design complexity and shipyard installation timeand cost2425

L250 EPA Tier 4i/IMO Tier IIIL250 EPA Tier 4i/IMO Tier IIIEngine SpecificationsMCR RatingsEngine data6L250 MDCNumber of cylindersStroke cycleCylinder arrangement6L250 MDC8L250 MDC6844inlineinlineBore250 mm (9.84 in)250 mm (9.84 in)Stroke320 mm (12.60 in)320 mm (12.60 in)15.0:115.0:1Compression ratioRated speedMCRRated speedEngine dimensions8L250 MDCHeight w/ deep sump2,809 mm (110.6 in)2,809 mm (110.6 in)Length4,691 mm (184.7 in)5,580 mm (219.7 in)Width2,006 mm (79 in)2,006 mm (79 in)Crankshaft center linemarine sump940 mm (37 in)940 mm (37 in)Crankshaft center lineto mounting feet308 mm (12.13 in)308 mm (12.13 in)260 mm (10.2 in)260 mm (10.2 in)Exhaust diameterDry 0kW2,2502,500hp3,0173,3538L250 MDCMCR6L250 MDCRpmMaximum continuous rating (MCR)Maximum speed and load conditions at which the engine is capableof operating continuously for an unlimited number of hours per year;between the normal maintenance intervals stated by GE, under statedambient conditions and with the maintenance prescribed by GE havingbeen carried out.19,944 kg (43,876 lbs) 23,356 kg (51,491 lbs)27

L250 EPA Tier 4i/IMO Tier IIIV250 EPA Tier 4i/IMO Tier IIIRecommended Match PointsEngine PP/EPP-CS6L250 MDCRated speedMatch pointMatch pointMatch pointMatch ,2802,548Rpm9001,000HeightkW2,0502,250Length5,284 mm (208 in)6,285 mm (247 in)hp2,7493,017Width2,693 mm (106.3 in)2,693 mm (106.3 in)Crankshaft center linemarine sump1,077 mm (42.4 in)1,161 mm (45.8 in)Crankshaft center lineto mounting feet536 mm (21.1 in)536 mm (21.1 in)610 mm (24 in)610 mm (24 in)Number of cylindersRated speedFPPMatch pointFPP-HTMatch pointCPP/EPP-VSMatch pointMatch pointFPP Fixed pitch propellerFPP-HT Fixed pitch propeller– high ,353kW2,2502,500hp3,0173,35312V25016V2501216Stroke cycle44Cylinder arrangementVVBore250 mm (9.8 in)250 mm (9.8 in)Stroke320 mm (12.6 in)320 mm (12.6 in)15.0:115.0:1Compression ratioEngine dimensions8L250 MDCApplicationtypesCPP/EPP-CSEngine dataRpmExhaust diameterDry weight12V25016V2503,636 mm (143 in)3,721 mm (147 in)25,545 kg (56,317 lbs) 31,840 kg (70,195 lbs)CPP/EPP-VS Variable speed CPP or gen setCPP/EPP-CS Constant speed CPP or gen setDefinitions for application types are found on page 31.2829

V250 EPA Tier 4i/IMO Tier IIIV250 EPA Tier 4i/IMO Tier IIIMCR RatingsRecommended Match Points12V250 MDCRated speed16V250 ,2244,6945,6326,249Maximum continuous rating (MCR)ApplicationtypesRated speedFPPMatch pointFPP-HTMatch pointCPP/EPP-VSMatch pointCPP/EPP-CSMatch pointMaximum speed and load conditions at which the engine is capableof operating continuously for an unlimited number of hours per year;between the normal maintenance intervals stated by GE, under statedambient conditions and with the maintenance prescribed by GE havingbeen carried out.12V250 MDC16V250 PA vessel where the engine powers a fixed pitch propeller.Examples: tug boats, cargo vesselsFPP-HTA vessel where the engine powers a fixed pitch propeller which demandsextended maximum engine torque.Examples: river push boats, tow boats, dredge pumpsCPP/EPP-VSA vessel where the engine operates at a variable speed to power acontrollable pitch or an electrically powered propellerCPP/EPP-CSA vessel where the engine operates at a constant speed to power acontrollable pitch or an electrically powered propeller3031

GE Marine’s GensetsDrawing on our experience as a leader in medium-speed engine designand manufacturing, we offer marine genset solutions that provideefficient, cost-effective service in some of the world’s harshest operatingenvironments.Powering these products are our reliable V250 and V228 Series Engines,offering high fuel efficiency and low life-cycle costs, in 8-, 12- and16-cylinder configurations and L250 Series Engines in 6- and 8-cylinderGenset modelsSpeed, RPMIMO Tier IIElec. freq.HzEPA Tier 4i/IMO Tier IIIContinuous power (ekW)12V250GSU96.5% line configurations. Power solutions range from 1.5 to 4.5 mW with16V250GSUgeneration of voltage up to 13.8 kV- 50/60 Hz. We also maintain a global1,000503,897network of service centers that provide packaging, installation and900603,505commission, spare parts and service support.8V228GSU96.5% efficiencyN/A4,487N/A4,05396.0% 2,092900601,88412V228GSU96.0% efficiency16V228GSUN/AN/AN/AN/A96.5% 01,597900601,4386L250GSU96.0% efficiency8L250GSU32EPA Tier 31,620N/A1,457N/A96.0% 33

GE Stationary’s GensetsFor more than 40 years, GE Transportation has designed and builthigh-performance diesel engines and today is one of the world’slargest manufacturers of medium-speed diesel engines. When used forcontinuous and standby power, these advanced engines are not onlydependable, long-lasting and efficient, they also perform in the world’smost challenging environments.The stationary genset product line includes generator drive engines,unenclosed gensets and gensets in walk-in enclosures. Powering theseproducts are our reliable V228 and L/V250 Series Engines offering highfuel efficiency and low life-cycle costs. Power solutions range from1,438 ekW to 5,065 ekW and are available with a broad range of lowand medium voltage alternators. We also maintain a global network ofservice centers that provides packaging, installation and commission,Stationary GensetEmissionsGE offers stationary gensets optimized for a variety of emissionsrequirements. For North America, U.S. EPA Tier 2 and Tier 3 configurationsare available. Fuel optimized or World Bank emissions configurations arealso available.World Bank engine configurations are capable of meeting the NOx andparticulates emissions levels specified in the World Bank EmissionsGuidelines for Small Combustion Facilities . SOx emissions vary with fuel1sulfur content. GE Transportation is unable to make any representation asto the emissions output of the facility into which the engine is installed.International Finance Corporation “Environmental, Health, and Safety (EHS)Guidelines” April 30, 20071spare parts and service support.3435

Stationary GensetGE StationaryEmissionsLesser Regulated Country Genset RatingsEPA Tier 4 2,000 KWEmergency genset 2,000kW EPA Tier 2Stationary Emissions: Prime and Continuous L/V25020122013201420152016U.S. EPAEPA Tier 3 2,000 KWL/V250EPA Tier 4EPA Tier 2LRC Fuel Opt.36L/V250Fuel optimized - lesser regulated countriesV228Fuel optimized - lesser regulated 032,52396.0% alternator efficiency1,5971,7581,4381,58296.0% alternator efficiency2,1302,3431,9182,11096.5% alternator efficiency3,2133,5062,8933,15796.5% alternator efficiency4,2874,6763,8554,20596.0% al

GE Marine's family of medium-speed diesel engines includes its L250 inline engine as well as its V250 and V228 engine model platforms. GE's V228 Series Engines are designed to power workboats, tugs, offshore supply vessels, ferries, dredges, fishing vessels and other marine transport applications.