Transcription

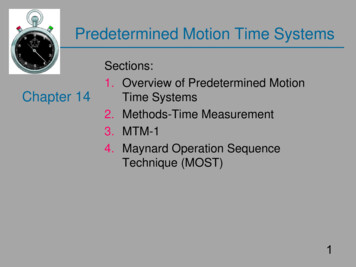

Predetermined Motion Time SystemsChapter 14Sections:1. Overview of Predetermined MotionTime Systems2. Methods-Time Measurement3. MTM-14. Maynard Operation SequenceTechnique (MOST)1

Overview-PMTS Defined An alternative to direct time study that does not requireperformance rating. PMTS is a database of basic motion elements and theirassociated normal time values, together with procedures forapplying the data to analyze manual tasks and establishstandard times for the tasks Basic motions include:o Reacho Graspo Moveo Release The time required to perform these basic motions usuallydepends on certain work variables (reach and distance; moveand weight of object; etc.).2

PMTS Procedure To apply PMTS to a task the analyst must accomplish thefollowing steps:1.Analyze method that would be used to perform the task The method is described in terms of basic motionelements2.Retrieve normal time values for each motion element Sum the element times to determine the task normaltime3.Evaluate method to make improvements by eliminating motions reducing distances using both hands simultaneously etc.4.Apply allowances to determine standard time3

PMTS Levels and Generations There are various types of PMT systems, and these typesare variety in the basic motion elements. First-level PMT Systems use the basic motion elements Reach, grasp, and move used separately to definethe task Higher-level systems combine several motion elementsinto motion aggregates Reach and grasp combined into one element called“get”, “Put” which combines move and position4

PMTS Levels and Generations(CONT.) First-level systems were chronologically the first to bedeveloped and are called first generation PMTS (MTM-1) MTM-2 is the second generation of PMT systems wasdeveloped. MTM-3 is the third generations. Some of Predetermined Motion Time systems: Method Time Measurements (MTM) Maynard Operation Sequence Technique (MOST)5

ComparisonsFirst-level PMTSHigher-level PMTS Most accurate Less accurate High application speed ratio Less time to set standards Most suited to highly repetitiveshort cycles Longer cycle times feasible Basic motion elements Very detailed Highest flexibility Motion aggregate Less detailed; easier to apply Less flexible6

Methods-Time Measurement (MTM) MTM is a procedure which analyzes any manualoperation or method into the basic motions required toperform it and assigns to each motion a predeterminedtime standard which is determined by the nature of themotion and the conditions under which it is made Time units are TMUs (Time Measurements Units)1 TMU 0.00001 hr 0.0006 min 0.036 sec1 sec 27.8 TMU MTM is a family of products available through the MTMAssociation (www.mtm.org) and the original MTM is nowcalled MTM-1.7

Methods-Time Measurement8

MTM-1 Operates at the basic motion element level in ourpyramidal structure of work (same in therbligs) Most MTM-1 basic motions involve hand and armmovements Also includes elements for eye, leg, foot, and bodyactions More appropriate for tasks that are highly repetitive andcycle times are less than 1 min Time unit in MTM are called TMUs (time measurementunits).1 TMU 0.00001 hr 0.0006 min 0.036 sec9

MTM-1: Motion Elements1- Reach (R): Basic motion elementsinvolves moving the hands and fingers to thenew destination.Normal Time inTMUExample: R1C takes 3.6 TMUsMotion elementSymbol Case anddescriptionDistance(inches)Normal Time (Tn) 3.6 * 0.036 0.130 sec10

MTM-1: Motion Elements(Cont.)2- Grasp (G): Use fingers and hands togain control on one object or more.Example: G1C3 takes 10.8 TMUsMotion elementSymbolCase anddescription Normal Time 0.389 sec11

MTM-1: Motion Elements(Cont.)3- Move (M): Using the hand and fingers torelocate an objectExample: M6B12.5 takesMotion elementSymbolType ofcaseWeightup toDistance ininchesTMU Constant Factor * (TMU value fromtable) 3.9 1.11(8.9) 13.8 TMUs Normal Time 13.8 * 0.036 0.497 sec12

MTM-1: Motion Elements(Cont.)4- Position (P): A relatively short hand motion employed to align, orient or engagethe object to another.Example: P3NSD takes 53.4 TMUsMotion elementSymbol classSymmetryEasy handle ORDifficult Normal Time 53.4* 0.036 1.92 sec Round peg in a round hole: S(ymmetrical)Key inserted in a lock: N(on)S(ymmetrical)13

MTM-1: Motion Elements5- Release (RL): A hand and fingermotion element in order to release(free) an objectExample:(Cont.)6- Disengage (D): A hand and finger motionelement in order to separate one object fromanother one (disassemble)Example: RL1 takes 2.0 TMUs D3E takes 22.9 TMUs Normal Time 0.072 sec Normal Time 0.824 sec14

Example (MTM-1)Q1. A worker seated at a table performs a REACH. The sought-afterobject is jumbled with other objects in a tote pan, and the distance ofthe reach is 18 in. Determine the MTM-1 symbol and normal time inTMUs for this motion element.Solution:MTM-1 symbol R18C (From Reach table)So, the normal time (from Reach table) 18.4 TMUThe normal time in sec 18.4 TMU * 0.036 0.662 sec15

Example (MTM-1)(Cont.)Q2. A work element in a manual assembly task consists of thefollowing MTM-1 elements: (1) R16C, (2) G4A, (3) M10B5, (4) RL1,(5) R14B, (6) G1B, (7) M8C3, (8) P1NSE, and (9) RL1. (a) Determinethe normal times in TMUs for these motion elements. (b) What is thetotal time for this work element in sec?Solution:(a) The individual motion element times are given as follows:(1) R16C, Tn 17.0 TMU(2) G4A, Tn 7.3 TMU(3) M10B5, Tn 2.2 1.06(12.2) 15.1 TMU (4) Rl1, Tn 2.0 TMU(5) R14B, Tn 14.4 TMU(6) G1B, Tn 3.5 TMU(7) M8C3, Tn 2.2 1.06(11.8) 14.7 TMU(8) P1NSE, Tn 10.4 TMUand (9) RL1, Tn 2.0 TMU.Total 86.4 TMU.16

Example (MTM-1)(Cont.)(b) The normal time of the manual assembly task in second:Total normal time of the task in second 86.4 TMU (0.036) 3.1 sec17

Maynard Operation Sequence Technique(MOST) MOST is a high-level PMTS based on MTM Same time units as MTM: TMU MOST is a product of H.B. Maynard andCompany (an educational and consultingfirm), Pittsburgh, Pennsylvania(www.hbmaynard.com)18

MOST in the Work Pyramid19

Basic MOST Focused on work involving the movement of objects (e.g.,parts, tools) from one location to another in the workplace Uses motion aggregates Called activity sequence models Three activity sequence models: General move – object moved freely in space Controlled move – object remains in contact with asurface Tool use – use of hand tools (e.g., hammer,screwdriver)20

Activity Sequence Model Consists of sequence model parameters, which correspondroughly to basic motion elements Sequence model parameters for General Move: A – Action distance (move hands or feet) – horizontalbody motions B – Body motion (sit, stand up) – vertical body motions G - Gain control (closely related to grasp) P – Placement (e.g., position, lay aside, orient) Standard sequence in General Move:ABGABPAABG: to get an object;ABP: to move the object to a new location;A: return to original position21

Normal Time in TMU 10 * (sum of index values)22

Example: General Move Develop the activity sequence model and determine the normaltime for the following work activity: A worker walks 5 steps,picks up a small part from the floor, returns to his originalposition, and places the part on his worktable. SolutionA10B6G1A10B0P1A0where A10 walk 5 steps;B6 bend and arise;G1 gain control of small part;A10 return back;B0 no body motion;P1:lay aside part on table;A0 no motionThe sum of index values: 28.Normal time: 10*28 280 TMUs 280*0.036 10.1 sec23

Controlled move Used when an object is moved through a path that issomehow constrained. In this case we need additionalthree new parameters beside previous parameters of thegeneral move (A, B and G): M-Move, used to describe any manual body motionrequire to move an object with controlled condition. X-Process time: since it may include the operation ofmachinery. I-Align: this parameters is used when the manual motionsare performed at the end of the control move to align object Standard sequence in controlled move:ABGMXIAABG: to get an object;MXI: to move the object followed by a process time andalignment,24A: to return

Controlled move(Cont.)25

Controlled moveType of Milling Machine(Cont.)26

Controlled move(Cont.)27

Example: Controlled moveQ1. Develop the activity sequence model and determine thenormal time for the following work activity: A worker takes 2steps, grasp the waist-level feed lever on the lathe in standposition, pulls up the lever approximately 15 cm to engagethe feed. Process time to turn the part is 25 sec and alignsthe lever with one specific speed and then he needs to returnthe original workstation with 5 steps. Solution:28

Example: Controlled moveQ2. Develop the activity sequence model and determine thenormal time for the following work activity in second: Amachinist standing in front of his milling machine, grasps thewaist level feed lever on the machine, and rotates the leverone crank to engage the feed. The process time to mill thepart is 50 sec. There is no alignment and no action by theworker at the end of the process time. Solution:29

Methods-Time Measurement (MTM) MTM is a procedure which analyzes any manual operation or method into the basic motions required to perform it and assigns to each motion a predetermined time standard which is determined by the nature of the motion and the conditions under which it is made Time units are TMUs (Time Measurements Units)