Transcription

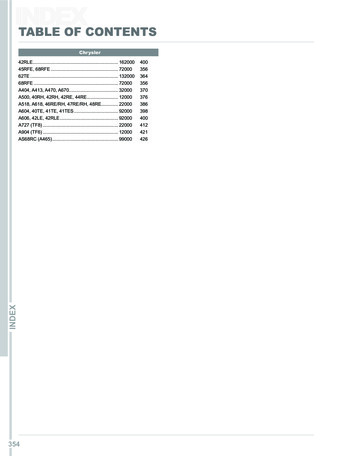

table of contentsserpentine belts. 3belt tensioners & pulleys . 7harmonic balancers . 15timing components . 21v-belts & industrial belts . 25snowmobile / atv belts . 33hose . 39coolant hose . 40hose clamps . 48service hose . 50garage exhaust hose. 58splash protectors . 61stands, cabinets & kits . 63belt & hose installation tools . 69instructions for accessing hydraulic crimp specs . 74notes . 75hydraulic hose . 77couplings and adapters. 83hydraulic crimping equipment . 87hydraulic stands, cabinets and kits . 90notes . 92The following are Registered Trademarks of Dayco Products, LLCDAYCO POLY COG POLY RIB GOLD LABEL NO SLACK TOP COG GPL VX-Wedge V-Wedge Quick-Fit Insulone Factfinder aWEARness The following are Registered Trademarks of Parker-Hannifin CorporationThoro-Flo The following are Registered Trademarks of SubaruSubaru Impreza Forester Outback daycoproducts.com1

about DaycoDayco is a global leader in the research, design, manufacturing and distributionof essential engine products, drive systems and services for automobiles, trucks,construction, agriculture and industry.Dayco’s contributions are integral to how people get from place to place, goods aretransported, food is harvested, and infrastructure is built. The company operatesaccording to long-held values — keeping promises, delivering on time all the time,and an intense commitment to service no matter what the obstacles. For more thana century, Dayco has overcome challenges, emerging stronger and smarter at everyturn.Dayco improves how the world moves by creating products, systems and relationshipsthat endure. Move Forward. Always. Dayco has more than 50 locations in 18 countries and over 4,500 associates.For more information about Dayco, visit the Company’s website at www.dayco.com.On Twitter @Dayco ProductsOn Facebook at facebook.com/DaycoProducts2daycoproducts.com

serpentine belts

serpentine beltsW ProfilePOLY RIB Serpentine BeltDayco approaches the market differently from most of its competition, believing that one serpentine belt constructionwill not perform best with all applications.Built for cars and light-duty trucks, Dayco’s extensive line of Poly Rib serpentine belts are engineered for highmileage, demanding drives found in today’s vehicles. As the manufacturer of the first original equipment multi-ribbedserpentine belt, Dayco’s commitment to automotive product excellence and innovation is unwavering.The Dayco Poly Rib W Profile Serpentine Belt is the most innovative advancement in serpentine belt design in over30 years. Developed through extensive laboratory and actual road mileage testing, this unique rib profile EPDM belthas been engineered to conform to high mileage, worn or misaligned drives and help eliminate noisy belt conditions.Constructed with aramid reinforced EPDM compounds, the Dayco W Poly Rib Serpentine Belt delivers more than justoriginal equipment (OE) required quality, it delivers the solution to troublesome drive problems.GOLD LABEL POLY RIB Serpentine BeltThe Dayco Gold Label Serpentine Belt is a diesel grade belt that features higher performance construction overconventional light duty belts in order to meet the high torque and power pulses exerted by today’s demanding dieselengines. The specially treated cords within the belt resist stretching and ensure the length stability that is essentialfor drive systems on high output diesel and gas engines.The belt’s heavy duty construction provides additional integrity without sacrificing flexibility or belt-to-pulleycompatibility. The Dayco Gold Label Serpentine Belt is also engineered with high-grade EPDM compounds and isbuilt to resist the heat and harsh under hood environments experienced in over-the-road and off-road conditions.4daycoproducts.com

serpentine beltsPOLY RIBAramid Serpentine BeltAs the demand for higher output engines and tighter engine packaging increases, Original Equipment Manufacturers(OEM) have elected to use serpentine belts with aramid tensile cord on specific applications that may have noise,vibration or harshness issues, or in-drive systems in which tensioner take-up is minimal.The Dayco Poly Rib Aramid Serpentine Belt has been engineered to maintain a quiet, vibration-free belt drive system.Unlike polyester-corded belts, the Dayco Poly Rib Aramid Serpentine Belt will resist the expected elongations,especially during high accessory loading. This unique feature of length stability and minimal stretch can aid in thosedifficult drives where span vibrations and tensioner movements are excessive, resulting in reduced belt noise. TheDayco Poly Rib Aramid Serpentine Belt also features Dayco’s W Profile, the solution to troublesome drive problems,and is built with Dayco’s specially designed EPDM rubber compounds that resist cracking and perform better underextreme temperature ranges.Double SidedPOLY RIB Serpentine BeltDesigned for multiple accessory drives that require the transmission of power from both sides of the belt. TheDouble Sided belt, which Dayco introduced to the automotive aftermarket, features a construction that uses a highlyfiber-loaded compound on both sides of the belt to maximize load carrying requirements while minimizing pulleymisalignment noise.5

serpentine beltsela Serpentine BeltDayco ela Belts, also known as “stretch” belts, are specifically designed for two to four point drives that do notrequire automatic or manual tensioning. Although these belts may look like standard poly rib belts, they are verydifferent. These specially designed belts have self-tensioning capabilities required by specific OE drives designed fora “stretch” belt. Vehicles that are manufactured with “stretch” belts must replace those belts with “stretch” belts.These belts are not interchangeable with standard constructed belts of the same size.Dayco ela Belts utilize a proprietary EPDM construction that is designed to elongate over the fixed pulley system, andthen maintain the required belt tension over the life of the belt. The backbone behind the Dayco ela Belt is its speciallydeveloped polyamide tensile member, which allows for high elongation required for installation, yet provides theproper tension maintenance properties to transmit the accessory loads demanded for the drive. This belt constructionincorporates a wear resistant EPDM rib material, along with a highly elastic EPDM cushion rubber that surrounds thepolyamide tensile cord, thus providing the required adhesion and flexibility to maintain lasting performance.“Stretch” belts have unique installation instructions depending on the OE application. Installation may require aspecialized tool for the application or a simple zip tie. Do not attempt to install by prying the belt on the pulleys. Daycoprovides detailed instructions on the reverse side of the sleeve.Dismounting and reusing stretch belts is not recommended. A new belt should be installed anytime one is removed.6daycoproducts.com

belt tensionersand pulleys

NO SLACKSerpentine belt drives consist ofa single belt that powers most, ifnot all, of the engine’s accessories.Designed to maintain constanttension on serpentine belt drives,the Dayco Automatic Belt Tensionerfeatures the original flat springdesign engineered to provide lessoperating range variations in tension.This innovative design reduces therisk of premature accessory bearing8 failure due to high tension when anew belt is installed and lessensthe risk of belt noise and slippage,or poor accessory performancecaused by low tension after thebelt begins to stretch and wear. APTFE strip wound within the springresists abrasion and the flat springis coated to resist rust.

belt tensioners and pulleysAutomatic Belt TensionerOther superior design features include: Steel locator pin (where the application demands) Heavy duty cast aluminum spring case that resists cracking and fatigue Heavy duty cast aluminum arm which offers additional strength and less distortion Steel pivot tube (where the application demands) which provides additional strength for critical torquerequirements Thermoplastic rubber spring slot plug (where applicable) that helps keep out harmful contaminants Lubricated nylon pivot tube bushing and spring bushing for quieter performance Rubber “O” ring which seals against dust and grime (where applicable) Zinc-coated mounting bolt that resists rust (where applicable)Dayco also manufactures a variety ofround spring and hydraulic-controlledtensioners depending on the originalequipment design and applicationrequirements.9

GOLD LABEL As the major supplier to heavy dutyoriginal equipment manufacturers,Dayco Gold Label Heavy DutyTensioners are guaranteed to beengineered and manufactured tothe strictest design specifications.Designed for heavy duty dieselengine accessory drive applications,the heavy duty cast aluminum bodyand pulley arms translate into extrastrength and durability.The Dayco Gold Label Heavy DutyTensioner features multiple patented10components that are engineered tohandle the higher torque and powerpulses exerted by today’s dieselengines. Rugged pulleys with dualpermanently lubricated bearingsdeliver long lasting, dependableservice. In addition, many of theDayco Gold Label Heavy DutyTensioners feature highly dampeddesigns using a wave spring and ametal ring with a bonded polymericsurface to act as a radial shockabsorber for the tensioner arm whilereducing contamination.daycoproducts.com

belt tensioners and pulleysHeavy Duty AutomaticBelt TensionerDayco Gold Label belt tensioners feature: Built with Dayco’s original flat spring design Designed for heavy duty diesel engine accessory drive applications Heavy duty cast aluminum body and pulley arms translate into extra strength and durability Features multiple patented components that are engineered to handle the higher torque andpower pulses exerted by diesel engines Rugged pulleys with dual permanently lubricated bearings deliver long lasting, dependableservice Many of Dayco Gold Label Heavy Duty Tensioners feature highly damped designs using a wavespring and a metal ring with a bonded polymeric surface to act as a radial shock absorber forthe tensioner arm while reducing contamination Supplies over 90% of the heavy dutyoriginal equipment market’s belts andtensioners Made in USA11

belt tensioners and pulleysNO SLACK Idler / TensionerPulleyDayco’s reputation for top performance idler and tensioner pulleys is a result of advanced automotivetechnologies employed in materials research, design engineering, and manufacturing of our pulleys. Inaddition to our spun steel pulleys, Dayco also provides specially formulated glass-filled polymers to ensurea high strength, wear-resistant plastic pulley designed to replace serpentine and V-belt idler and tensionerpulleys.The use of state-of-the-art 3-D computer aided design and finite element analysis guarantees the optimaldesign and maximum structural integrity for both plastic and steel pulleys. The manufacture of pulleyswith smoother surfaces and tighter dimensional tolerances translates into less vibration and thereforelonger belt life. Lifetime lubricated ball bearings and double high temperature seals assure peak bearingperformance, the most critical element of a pulley’s service life.12daycoproducts.com

belt tensioners and pulleysGOLD LABEL Heavy DutyIdler / TensionerPulleyThe performance demands of OEM of over-the-road trucking and off-road equipment requires a built-forpunishment heavy duty constructed pulley.Designed to replace idler and tensioner pulleys for serpentine drives in heavy duty diesel engineapplications, Dayco Gold Label Heavy Duty Pulley

a century, Dayco has overcome challenges, emerging stronger and smarter at every turn. Dayco improves how the world moves by creating products, systems and