Transcription

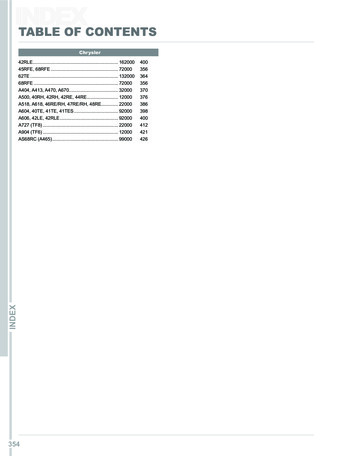

TABLE OF CONTENTSVULCRAFT DESIGN NOTICE . . . . . . . . . . . . .3GENERAL INFORMATION . . . . . . . . . . . . . . .6A. Joist Design Commentary1. Vibration2. Deflection3. How to Specify Concentrated &Other Non-Uniform Loads on Steel JoistsLOAD RESISTANCE FACTOR DESIGN . . . . .8**IMPORTANT NOTICE**BASED UPON FINDINGS OF INDUSTRYSPONSORED RESEARCH, THE STEELJOIST INSTITUTE HAS DEVELOPEDNEW REQUIREMENTS FOR THE USEOF ERECTION STABILITY NALBRIDGING TO BE INSTALLED FORSOMEK-SERIES ANDLH-SERIESJOISTS BEFORE SLACKENING THEHOISTING LINES. THE JOIST SPANSREQUIRING THIS STABILITY BRIDGINGARE SHADED IN THE LOAD TABLES.IT IS VERY IMPORTANT FOR JOISTSPECIFIERSANDERECTORSTOKNOW THAT OSHA IS INTERPRETING29CFR-1926.751 (c)2 TO MEAN ALLJOIST FORTY (40) FEET (12192MM)AND LONGER TO REQUIRE A ROW OFBOLTED BRIDGING TO BE IN PLACEBEFORE SLACKENING OF HOISTINGLINES.K AND KCS SERIES . . . . . . . . . . . . . . . . . . . .9A. General InformationB. K-U.S. Customary Load TablesC. KCS Load Tables (U.S. and Metric)D. K-Metric Load TablesE. K-SpecificationsACCESSORIES AND DETAILS . . . . . . . . . . .31A. VS Series and Loose OutriggersB. K-DetailsC. LH and DLH-DetailsLH AND DLH SERIES . . . . . . . . . . . . . . . . . .43A. General InformationB. LH-U.S. Customary Load TablesC. DLH-U.S. Customary Load TablesD. LH-Metric Load TablesE. DLH-Metric Load TablesF. LH and DLH SpecificationsSLH SERIES . . . . . . . . . . . . . . . . . . . . . . . . .63A. General InformationB. SLH DetailsC. SLH-Load TablesD. SLH-SpecificationsJOIST GIRDERS . . . . . . . . . . . . . . . . . . . . . .74A. General InformationB. Joist Girder DetailsC. Bottom Chord Brace TablesD. Joist Girders in Moment Resistant FramesE. Joist Girder Weight Table-U.S. CustomaryF. Joist Girder Weight Table-MetricG. Joist Glrder SpecificationsFIRE RESISTANCE RATINGS WITHSTEEL JOIST AND JOIST GIRDERS . . . . .103ECONOMICAL JOIST GUIDE . . . . . . . . . . .107RECOMMENDED CODEOF STANDARD PRACTICE . . . . . . . . . . . . .119PUBLICATIONS . . . . . . . . . . . . . . . . . . . . .127FRONT COVER PICTURE:Brown & Root Employee CenterHouston, TexasGeneral Contractor: Brown & RootSteel Fabricator: Palmer Steel Supplies, Inc.1

1995 REVISIONSPAGE1SECTIONCHANGEAdded notice regarding bridging.6VibrationRevised.7Concentrated LoadsRevised.8LRFDAdded.9K-SeriesNew bridging tables.10-13K-SeriesAdded shading and OSHA note for erection stability requirement.14-17KCS-SeriesChange from CS-Series, added metric.18-21K-SeriesAdded metric load tables.22-29K-SeriesRevised specifications to include metric and new bridging criteria.31Accessories & DetailsRevised VS-Series.35-36Accessories & DetailsNew bridging requirements.39Accessories & DetailsNew top chord extension load table-metric.40Accessories & DetailsRevised camber tables to include metric.43LH-DLH SeriesNew bridging tables.44-46LH-SeriesAdded shading and OSHA note for erection stability requirement.47-48DLH-SeriesAdded shading for erection stability requirement.49-52LH-SeriesNew metric tables.53-54DLH-SeriesNew metric tables.55-62LH-DLH SeriesRevised specifications to include metric and new bridging criteria.77Joist GirdersRe-worded.78Joist GirdersAdded detail "F".80-88Joist GirdersEnhanced weight tables and added stepped line to indicate whena 10 inch deep bearing should be used.89-95Joist GirdersNew metric design example and metric weight tables.96-102Joist GirdersRevised specifications to include metric.103-106Fire Resistance RatingsRevised stress limitations and revised some fire resistance ratings.107-118Economical Joist GuideAdded shading for erection stability requirements. Method of listingjoists in order of economies has been revised.119-126Recommended Codeof Standard Practice2Revised to include metric and new bridging criteria.

A WORD ABOUT QUALITYNOTICEIn manufacturing steel joists, there can be no compromise on quality. Your business depends on it. Our reputation and success depends on it. As the largestmanufacturer of steel joists in the United States, a lotof buildings and a lot of people depend on Vulcraft forconsistently high standards of quality that are demonstrated in reliable performance.Vulcraft, a Division of Nucor Corporation, has providedthis catalog for use by engineers and architects indesigning and using Vulcraft open web joists and openweb girders. It includes all products available at thetime of printing. Vulcraft reserves the right to change,revise or withdraw any Products or procedures withoutnotice.In the manufacturing of steel joists and joist girders,Vulcraft uses high quality steel. Welding to exact specifications is the key to making structurally sound joists-and the most critical step in the entire process. Thisbeing the case, all Vulcraft welders are certified toAmerican Welding Society standards. All welds are inaccordance with the Steel Joist Institute’s welding criteria and all Vulcraft joists are manufactured to meetthe required design loads of the specifying professional.The information presented in this catalog has beenprepared in accordance with recognized engineeringprinciples and is for general information only. While itis believed to be accurate, this information should notbe used or relied upon for any specific application without competent professional examination and verification of its accuracy, suitability and applicability by anengineer, architect or other licensed professional.To further insure the precision and quality of everyweld, every Vulcraft quality assurance inspector is alsocertified to these same high standards. FurthermoreVulcraft’s quality assurance supervisors report directlyto the engineering manager. Vulcraft also employs anongoing program of mechanical testing that includesfull scale load tests at every facility.As the leading manufacturer of steel joists and joistgirders in the United States, Vulcraft’s reputationdepends on successfully managed quality control programs. That’s why quality is important at Vulcraft. Youhave our word on it.Vulcraft is a manufacturer of open web steel joists, joistgirders, floor deck and roof deck. Vulcraft employs astaff of engineers for the design, manufacture andmarketing of its products. Vulcraft does not accept theresponsibility as the design professional of record forany structure. Vulcraft accepts the delegation of theengineering responsibility only for the products it manufactures, provided the application and applicableloading for these products are specified by the designprofessional of record. Vulcraft provides engineeringfor the design of its products and does not displace theneed on any project for a design professional ofrecord.3

VULCRAFTSTEEL JOISTS AND JOIST GIRDERS,STEEL ROOF AND FLOOR DECK,COMPOSITE JOISTSVULCRAFT OFFERS A WIDE RANGE OFJOISTS, JOIST GIRDERS AND DECK PRODUCTS.FOR MORE INFORMATION,CONTACT A VULCRAFT SALES OFFICEVULCRAFTMANUFACTURING LOCATIONS:P.O. Box 637Brigham City, UT 84302* (435) 734-9433Fax: (435) 732-5423P.O. Box 100520Florence, SC 29501(843) 662-0381Fax: (843) 662-3132P.O. Box 680169Fort Payne, AL 35968(256) 845-2460Fax: (256) 845-2823P.O. Box 186Grapeland, TX 75844(936) 687-4665Fax: (936) 687-4290P.O. Box 59Norfolk, NE 68702(402) 644-8500Fax: (402) 644-8528P.O. Box 1000St. Joe, IN 46785(219) 337-1800Fax: (219) 337-1801P.O. Box 280Chemung, NY 14825(607) 529-9000Fax: (607) 529-9001*STEEL JOISTS, JOIST GRIDERS AND COMPOSITE JOISTS ONLY.www.vulcraft.com312 Elm Building, Cincinnati, OhioArchitect: Space Design InternationalStructural Engineer: Stanley D. Lindsey and AssociatesDeveloper: Duke Construction ManagementSteel Fabricators: Ferguson SteelSteel Erector: Ben Hur Construction4

INDIANAALABAMAP.O. Box 680169, Fort Payne, Alabama 35968Joists & Deck(256) 845-2460Fax: (256) 845-2823NEBRASKAP.O. Box 59, Norfolk, Nebraska 68702Joists & Deck(219) 337-1800Fax: (219) 337-1801SOUTH CAROLINA(402) 644-8500Fax: (402) 644-8528P.O. Box 100520, Florence, South Carolina 29501(843) 662-0381Joists & DeckFax: (843) 662-3132(936) 687-4665Fax: (936) 687-4290P.O. Box 637, Brigham City, Utah 84302JoistsUTAHTEXASP.O.Box 186, Grapeland, Texas 75844Joists & DeckP.O. Box 1000, St. Joe, Indiana 46785Joists & DeckComing By Fall 2001 Vulcraft of New York(435) 734-9433Fax: (435)723-54235

JOINT DESIGN COMMENTARYFLOOR VIBRATIONFloor vibration occurs, in varying degrees, in all typesof building construction. Unlike steady state vibration,which can be isolated, vibration due to human impactis inconsistent in amplitude and frequency and therefore, more difficult to control.The Steel Joist Institute has studied this phenomenonfor many years. Laboratory research has been performed and numerous buildings, exhibiting both goodand bad characteristics, were tested using seismicrecording instruments. The findings have been published by the SJI in Technical Digest #5.The vast majority of structures, including those utilizingsteel joists, do not exhibit floor vibrations severeenough to be considered objectionable. However,human sensitivity to vibratory motion varies, and a satisfactory framing solution is dependent upon the soundjudgement of qualified structural engineers.The following observations are in keeping with theresearch data for vibrational characteristics not objectionable to normal human response, and are recommended only as a guide.DEFINITIONSFloor vibration is measured in terms of amplitude andfrequency. These two factors are not objectionable toall people at the same level since human sensitivityvaries.Amplitude is defined as the magnitude or total distancetraveled by each oscillation of the vibration.Frequency is the term used to describe the speed ofthe oscillations and is expressed in cycles per secondor Hz.Acceleration results from combining amplitude andfrequency and is the only vibration factor whichhumans can sense.Damping is defined as the rate of decay of amplitude.OPEN FLOOR AREAS are most subject to vibrationalproblems. Objections occur most often when a 2 l/2"thick slab of lightweight concrete is used on spans inthe range of 28 feet. As the spans both increase anddecrease from this length, the likelihood of objectionable vibration tends to taper off. Partitions, file cabinets, book stacks, heavy furnishings and even crowdsof people provide additional damping and minimizecomplaints.THICKER FLOOR SLABS are an economical solutionto floor vibration, when open floor areas are required.Additional thickness increases floor system stiffnesstransverse to the joists, thus reducing the amplitude. Aslight increase in frequency will be offset by the additional mass of the system, producing a reduction ofobjectionable vibration.WIDER JOIST SPACINGS improve vibrational characteristics only when combined with thicker floor slabs.The resulting increase in joist size does not contribute6significantly to the composite section. When used witha thicker slab, greater resistance to vibration can beachieved, and, since fewer pieces must be installed,may be more economical.PARTITIONS introduce damping and usually eliminatevibration problems. They will be effective either aboveor below a floor. Partitions below provide dampingeven though only attached to suspended ceilings andnot in direct contact with joists.SUPPORT FRAMING BEAMS sometimes greatlymagnify floor vibration. If a floor vibration problem isjudged to be imminent, one needs to calculate the natural frequency and amplitude for both the joist andsupporting joist girders or beams. In this manner theresulting system amplitude and frequency can bedetermined from which the required system dampingcan be calculated. The damping provided in the system should be greater than the calculated requireddamping.INCREASING JOIST STIFFNESS above that which isrequired by live load deflection is not a good solution.Increasing the stiffness of the steel joists themselvesresults in increasing the frequency and slightlydecreasing the amplitude of the floor vibration.BRIDGING of all standard types provide equal floorvibrational characteristics.LONGER FLOOR SPANS have many advantagesover shorter spans, both in construction cost and invibrational response. Floor spans over 40 feet with a2-1/2" thick concrete slab give a vibrational frequencyin the 3-5 cycles per second range. A human can tolerate a larger amplitude at this reduced frequencywithout sensing it. Thus, there is minimal sensation ofmotion and the floor feels extremely stable.ASSISTANCE can be given to architects and engineers on the subject of vibration and steel joist construction. Call the engineering manager at the nearestVulcraft manufacturing facility.PC based software to evaluate vibration of joist supported floor systems is available from the STEELJOIST INSTITUTE, 3127 10th Ave. North Ext., MyrtleBeach, SC 29577, phone (843) 626-1995 andSTRUCTURAL ENGINEERS, INC., 537 WisteriaDrive, Radford, VA 24141, Fax no. (703) 731-3330.CONCLUSIONS:Partitions eliminate vibration problems. When a floorarea cannot have partitions, increasing the slab thickness is the most economical and effective way to prevent vibration objections. Steel joist and concrete slabopen floor areas have generally not given objectionable vibration at spans less than 20 feet or greaterthan 40 feet even with only 2 l/2" slab. Due consideration should also be given to support framing beams asoutlined above.For more information refer to Steel Joist Institute Technical DigestNo. 5 "Vibration of Steel Joist-Concrete Slab Floors."

JOINT DESIGN COMMENTARYDEFLECTION OF STEEL JOISTSThe deflection of a steel joist when loaded with auniformly-distributed load depends upon the followingfactors:w uniformly-distributed load carried by the joist (plf)L (span of the joist -.33)(ft.)E modulus of elasticity of steel (29,000,000 psi)I 26.767 WLL (L3) (10-6) where WLL red figure inload tableTests have shown that deflection at mid-span maybe determined with reasonable accuracy using thefollowing formula:Deflection (inches) 1.15x5wL4 (123) 384El25.8

STEEL ROOF AND FLOOR DECK, COMPOSITE JOISTS VULCRAFT OFFERS A WIDE RANGE OF JOISTS, JOIST GIRDERS AND DECK PRODUCTS. FOR MORE INFORMATION, CONTACT A VULCRAFT SALES OFFICE VULCRAFT MANUFACTURING LOCATIONS: P .O. Box 637 Brigham City, UT 84302* (435) 734-9433 Fax: (435) 732-5423 P .O. Box 100520 Florence, SC 29501 (843) 662