Transcription

APPENDIX BOPERATIONS & MAINTENANCE PLAN(O & M Plan)Guidance ManualforPreparingPublic Water Supply SystemO & M PlansMAY, 2000Drinking Water Permitting & Engineering ProgramGeorgia Environmental Protection Division205 Butler Street, S.E.Floyd Towers East, Suite # 1362Atlanta, Georgia 30334Revision.05172000.OES.2.0B-1

FOREWORDThe guidance and procedures outlined in this document are intended to supplement existingrequirements. They do not replace the rules and regulations administered by the Georgia EPD. Nothingin this document intended to be more stringent than the regulatory requirements. The guidance andprocedures herein are not an adjudication or a regulation. The guidance and procedures merely explainhow and on what basis Drinking Water Permitting and Engineering Program of the EPD will administerand implement its responsibilities with respect to Operations and Maintenance Plans.EPD reserves the discretion to deviate from the guidance and procedures in this document ifcircumstances warrant.In the preparation of this part of the publication, EPD primarily used the technical guidance documentspublished by the Bureau of Water Supply Management of the State of Pennsylvania's Department ofEnvironmental Protection. The following two technical guidance documents are used:1.Pennsylvania Department of Environmental Protection, Bureau of Water Supply Management,"Public Water Supply Manual, Part V-Section I and II - Operations and Maintenance (ID No. 3833110-111)", November 1, 1997.2.Pennsylvania Department of Environmental Protection, Bureau of Water Supply Management,"Public Water Supply Manual, Part V (Appendix A) Operations and Maintenance for SmallGroundwater Systems (ID No. 383-3110-211)", May 1, 1999.B-2

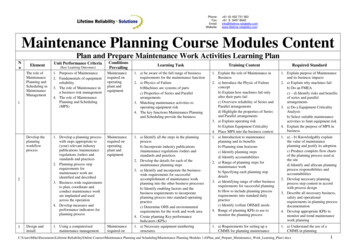

OPERATION & MAINTENANCE PLAN OUTLINEFOREWORD B-2INTRODUCTION B-5SECTION I - PREPARATION OF OPERATION & MAINTENANCE PLAN . B-6CHAPTER 1 - DESCRIPTION OF FACILITIES . B-13CHAPTER 2 - START-UP AND NORMAL OPERATING PROCEDURES .B-18CHAPTER 3 - PLANNED MAINTENANCE PROGRAM B-24CHAPTER 4 - RECORDS AND REPORTING SYSTEM .B-28CHAPTER 5 - SAMPLING AND ANALYSIS PROGRAM ANDCOMPLIANCE MONITORING B-34CHAPTER 6 - PUBLIC NOTIFICATION .B-49CHAPTER 7 - STAFFING AND TRAINING .B-53.CHAPTER 8 - SANITARY SURVEY PROGRAM B-57CHAPTER 9 - SAFETY PROGRAM B-60CHAPTER 10 - EMERGENCY PLAN AND OPERATING PROCEDURES .B-70SECTION II - OPERATION AND MAINTENANCE PROCEDURES .B-73CHAPTER 1 - SOURCES OF SUPPLY B73CHAPTER 2 - TREATMENT . .B-79CHAPTER 3 - DISTRIBUTION .B130CHAPTER 4 - LABORATORY EQUIPMENT MAINTENANCE .B-145B-3

SECTION III - OPERATION AND MAINTENANCE FORSMALL GROUNDWATER SYSTEMS B-155INTRODUCTION .B-155PART A - GUIDANCE B-156A.1 - DESCRIPTION OF FACILITIES .B-156A. 2 - START-UP AND NORMAL OPERATING PROCEDURES B-157A.3 - MAINTENANCE .B-160A. 4 - RECORDS . .B-161A. 5 - SAMPLING AND AND COMPLIANCE MONITORING . B-163A. 6 - PUBLIC NOTIFICATION . .B-169A. 7 - STAFFING AND TRAINING . B-171A. 8 - SANITARY SURVEY PROGRAM B-171A. 9 - SAFETY PROGRAM .B-172A. 10 - EMERGENCY RESPONSE PLAN .B-174TECHNICAL INFORMATION .B-175A.11 - SOURCES OF SUPPLY .B175A.12 - TREATMENT .B-176A.13 – DISTRIBUTION .B180A.14 - LABORATORY EQUIPMENT MAINTENANCE .B-192B-4

INTRODUCTIONThe purpose of this part is to provide assistance to the water supplier in the preparation anddevelopment of an Operation and Maintenance (O & M) Plan and the operation and maintenanceprocedures for each system. It is presented in three sections:Section I contains the detailed guidance on how to prepare an O & M Plan for the system. Once anacceptable plan is in place, it becomes a reference book for the entire water system.Section II contains detailed operation and maintenance procedures that can be used to assist the watersupplier in preparing the O & M Plan. These detailed O & M procedures are provided as examples fordescribing typical facilities, and operations and maintenance procedures. This information can be usedor adapted for use on any water system. However, the water supplier may want to develop customizedprocedures applicable to a particular process or system.Section III is to assist the small ground-water systems in the preparation and development of anOperation and Maintenance (O & M) Plan.B-5

SECTION I - PREPARATION OF AN O & M PLANWhy is an O & M Plan necessary?This plan should be developed by every public water supplier to provide a written source of materialthat can be easily referred to for guidance in operating a water system.This plan will be a valuable reference tool for the operating personnel because standard operatingprocedures for the system and guidelines for start-up and emergency situations will beat their fingertips.The O &M Plan will also provide a ready reference for all equipment data which is necessary forperforming normal maintenance and for ordering replacement parts and supplies. It will be an organizedsystem for keeping records of the operation of the system. These records are useful for monthly andannual reports, as supporting documentation of proper operation, and to support the need forreplacement or upgrading of treatment facilities. It will have detailed instructions for water sampling andtesting which are required for compliance with the Safe Drinking Water Act (SDWA) and for routinemonitoring of the treatment process for compliance with generally accepted good waterworksprocedures.The plan will contain information regarding start-up and normal operating procedures and emergencyoperating procedures; descriptions of equipment and facilities; organization responsibilities; names,addresses, and phone numbers of all key personnel; all contractors and suppliers; and state and localofficials.The O & M Plan will become a training manual to provide personnel with a handy source referencewhile they learn to operate the facilities. The O & M Plan will be used by experienced operatingpersonnel to monitor normal procedures for changes or emergency conditions; as a source for namesand phone numbers when emergency notification is required; and as a check of proper maintenanceprocedures.How to Develop an Effective O& M PlanO & M Plans are often prepared by engineers and managers; however, they must be certain that theyobtain information from persons actually experienced in plant operation and maintenance.The procedures must be described in terms and language which are readily accepted and understood bythe operators. Because of the technical nature of the water treatment process, a basic level of knowledgeand understanding by the operators must be assumed. The experienced operator will usually refer to theO & M Plan for confirmation of normal operation and maintenance procedures and as a reference guidefor unusual operating conditions. The entry level operator should frequently refer to the O & M Plan forguidance and instruction,Some water suppliers may have O & M Plans or certain parts of O & M Plans established for theirsystem. These may include Emergency Response Plans, Safety Programs, Water ConservationPrograms, Cross-Connection Control Programs, or other formalized procedures. This guidance manualB-6

is not intended as a required format which must be followed, but as a presentation of procedures whichcan be considered for your use in the preparation of your O& M Plan.Plans and programs which have been accepted as good, operating procedures can be directly included inyour O & M Plan without rewriting; however, it would be a good idea to review and update yourprocedures.Your O & M Plan will be a collection of plans and programs which will probably be stored in loose-leafnotebooks. The appearance of your plan is not as important as the availability of the information to theoperating personnel and the ability to revise and update it.How to Use Section I:Preparation of an 0peration and Maintenance PlanThe chapters in Section I are organized in a simple and logical manner that can be followed in thepreparation of an O & M Plan for a water supply system. Each chapter in Section I provides details ofinformation which should be considered in the preparation of an O & M Plan.The following is a brief look at what is in each chapter of Section I to help locate specific subjects andareas:Chapter 1 - Description of Facilities The Owner(s) - Who is responsible and where can they be contacted? The Service Area - How far does the system extend? Permits - What kind of permits and what are the conditions? System/Facilities Description - Describes sources, treatment, pumping, transmission and distributionsystem, storage facilities, and other features of the system. Distribution Map - What should a distribution map show? Flow Charts for Treatment Plants - How to show the treatment process in simple terms. Pressure Gradients - Pressure surveys and hydraulic gradients. Other Maintenance Requirements - What is needed? What areas need help or equipment? Thissection suggests guidelines for major maintenance consideration.Chapter 2 - Start-Up and Normal Operating Procedures Process Description - This helps to understand the operating procedures. Relationship to Adjacent Processes - How does each process work with the next process? Controls - What controls each unit and what can be controlled?B-7

Start-up Procedures - How to start up? What kinds of check procedures are needed? What is thesequence of start-up? Normal Operating Procedures - What are normal operating procedures? What are the check pointsfor normal operation? What are the minimum and maximum values of the checkpoints? What is thenormal range of chemical dosages?Alternate Operating Procedures - How does the plant operate when the normal conditions change,the raw water quality changes, or a process or piece of equipment is out of service? An alternateoperation procedure is usually a planned change to accommodate major maintenance, increaseddemand, or use of an alternate source. Emergency Operating Procedures - An emergency is thought to be sudden, unforeseen, orunexpected, requiring immediate action. A water supplier should anticipate that these conditionscould happen and by having procedures established for those conditions, many emergencies becomejust alternate operating procedures. The water supplier is then able to continue safe, adequateservice until the return to normal conditions. Common Operating Problems - What kinds of problems regularly occur? What causes them? Howcan they be controlled or prevented?Chapter 3 - Planned Maintenance Program Equipment Data Base Equipment Record Cards - Used to record and document the maintenancehistory for each piece of equipment. Maintenance Procedures, Routine and Periodic. Work Order System - The work order format and file system. Prioritizing Work Requests - Planning and scheduling maintenance. Spare Parts Inventory Control. In-house vs. Contracted Labor. Manufacturer's Recommendations.Chapter 4 - Records and Reporting System Types of Records.Physical PlantOperationRegulatory AgenciesPreventative MaintenanceOperating CostsPersonnelB-8

Emergency Conditions Preservation of Records.Chapter 5 - Sampling and Analysis Program and Compliance Monitoring Sampling and Analysis - How to schedule the sampling. What are the criteria for samplinglocations? Who collects samples and how do they handle them? Quality Assurance of Samples - How to take the samples. What precautions are taken to preventcontamination of the sample? What are the time requirements for each type of sample? Compliance Monitoring - Who checks if it is on schedule? Who interprets results? How are recordskept?Chapter 6 - Public Notification Regulatory Requirements for Public Notification - Safe Drinking Water Act Content of Notification - Information to be included and description of notice. Advance Preparations - Media notification and direct notice. Sample Notices.Chapter 7 - Staffing and Training Staffing - Influences and task classifications. Job Descriptions - How are job descriptions prepared? Organizational Staff - Defines the responsibilities of each position. Certification - Under Georgia law. Training Requirements - Needs and availability.Chapter 8 - Sanitary Survey Program Watershed Surveillance - Geology, sources of pollution, flooding.B-9

Evaluation of Source Protection, Intake Structures, and Transmission Facilities - Facilities toevaluate, evaluation of hazards, evaluation of operating ability, condition of facilities, vulnerabilityof transmission mains. Treatment Facilities Inspection - Raw and finished water quality review, condition and operatingcapabilities of components and evaluation of power systems. Finished Water Storage Facilities - Capacities, sanitary protection, condition, and water quality.Distribution System and Pressure Surveys - Water quality, unaccounted-for water, valve and firehydrant program, and tabulation of pressure survey results.Chapter 9 - Safety Program How to start and maintain a program - Designate responsible person, form committees, and issuepolicy. O & M Safety Plan - Identify hazards, develop safety manual.Chapter 10 - Emergency Plan and Operating Procedures Emergency Plan and Operating Procedures Preparation - Components, emergencies to be addressed,and emergency equipment hookup procedures. Evaluation Program - Reviews and inspections, rehearsals/drills. Emergency Operating Procedures. Emergency Plan and Operating Procedures Outline - (sample).How to Use Section II: Operations and Maintenance ProceduresThe chapters in Section II are presented to provide easy to follow examples of typical operations andmaintenance procedures for a water system. This information should be readily adaptable for use in theO & M Plans of a large number of water suppliers. Some systems will not have all of the processesdescribed and some will have other, more sophisticated processes. The water supplier may adapt thoseparts of this information they want and can use other sources for similar material. The following is abrief overview of what is in each chapter.Chapter 1 - Sources of Supply Surface Water - Quality, quantity, permits, treatment, watershed. Intakes - Intake appurtenances, intakes on rivers and streams, silt removal operations and typicalmaintenance.B-10

Dams - Types and sizes, regulation, emergency preparedness, O & M procedures. Wells - Records, pumps, well bore maintenance, water quality.Chapter 2 - Treatment Chemical Addition and Handling - Coagulation and pH adjustment, taste and odor, corrosion,disinfection, fluoridation, and softening chemicals. Conventional Filtration Treatment Plant - Rapid mix, coagulation/flocculation, sedimentation, solidscontact units, filtration. Disinfection - Chlorination, chlorine dioxide, other disinfection systems. Fluoridation - Sodium fluoride, hydrofluosilicic acid, sodium silicofluoride, start-up, normaloperations, chemical feed equipment, fluoride feed rates and records. Softening - Lime-soda ash, ion exchange. Aeration - Start-up, shut-down, normal operations, monitoring, records, maintenance, operationproblems. Adsorption - Powdered activated carbon, granular activated carbon.Chapter 3 - Distribution Plans and Records - Distribution system maps, pressure zones, updating and correcting plans,production and pumping records. Distribution System - Transmission and distribution mains, valves, fire hydrants, blow-offs, records. Pumps - Types of pumps, capacities and purposes, reports of operations and maintenance,monitoring operations. Distribution Storage Facilities - Types of reservoirs and tanks, maintenance, safety protection,records. Unaccounted-for Water - Basic calculation, normal operating ranges, control. Maintenance of Water Mains and Services - Customer complaints, water main repairs, thawing offrozen mains and services.B-11

Chapter 4 - Laboratory Equipment Maintenance Glassware, laboratory support equipment, analytical balance. Jar Test Apparatus - Stirring machine, floc illuminator, beakers pH Meter - Maintenance, calibration. Specific Ion Meter - Maintenance, calibration. Turbidimeter - Maintenance, calibration. Spectrophotometer - Maintenance, calibration. Safety Equipment.Section III - Operation and Maintenance for Small Groundwater SystemsThis section is a summary of the chapters in Sections I and II which provides assistance for the watersystems with a well, disinfection, distribution, and distribution storage. This will be useful to the smallgroundwater system which does not have engineering or management services available.B-12

SECTION I - PREPARATION OF AN OPERATION &MAINTENANCE PLANCHAPTER 1 - DESCRIPTION OF FACILITIESChapter I presents key information needed to prepare a physical, operational, and legal description ofa public water supply system.1.01.1OwnerA.A description of the owner should provide the following information: operator (if not theowner), contact person(s), addresses, phone numbers, type of ownership, (e.g., private,municipality, authority).B.An organization chart indicating the chain of command should be included in this chapter.Service AreaThe service area needs to be definedinvestor-owned system; by municipalarticles of incorporation for a regionalpage view or as a fold-out, as well asdescription of a small system. Seedistribution system map.1.2both legally and physically. It may be defined legally for anboundary for a municipal water system; or by an authority'swater authority. A map of the service area, scaled for a singlea view of the distribution network will be an adequate physicalSection 1.4 of this chapter for additional information for aPermitsWater suppliers must be aware of the permits (including any standard and/or special conditions), laws,and regulations under which their system was built and operates. The O & M Plan for the facility allowsthe water supplier to integrate these documents into the recordkeeping system for easy retrieval. Copiesof various documents may be included in a dedicated appendix or bound under separate cover andappropriately referenced. The section of the manual referencing the permits should have a listing of allpermits issued, the facilities approved, dates the permits were issued, and the approved hydrauliccapacities. It is important to note that any addition or modification to an existing public water supplywill require the approval of EPD.Primary permits include:A.Permit to Operate a Public Water Supply SystemB-13

B.Permit to Withdraw Surface WaterC.Permit to Withdraw GroundwaterD.National Pollution Discharge Elimination System Permit (for establishment of effluent limitationsregarding discharges of wastewater from drinking water treatment plants)1.3System/Facilities Description Provide general descriptions of:A.Sources of Supply1. Surface sourcea.2.3.4.b.A map of the watershed area indicating the drainage area in square miles, thelocation of the water system facilities, and the names of major water sources.Indicate the portions of the drainage area owned or controlled by the water system.c.Indicate the allocated maximum / average daily withdrawal.Wellsa.Describe its location, diameter, depth, length of casing, depth of grout, static waterlevel, pumping water level, pumping rate, date of installation, and any expansionsor modifications.b.Describe drainage area around well site, nearest source of pollution, well seal, andwell enclosure.c.Include well log, if available, and well driller's name.d.Describe land ownership access and control.Springsa.Describe location, capacity, enclosure, land ownership, access, and control.b.Include date acquired and dates of any modifications.Purchased Watera.List name of system, address, phone number, and contact person.b.Date system connection was installed.c.Describe mode of operation, such as emergency, intermittent, or continuous.d.Describe pressure and volume (flow) normally received.e.Describe any additional treatment or pumping required.f.Describe meter (who owns and is responsible for maintenance) and valving.B-14

B.Treatment Process1.GeneralDescribe in general terms the treatment processes used at each facility. Include a flowdiagram of the treatment facilities as part of this description.2.Discuss each part of the treatment process separately with details of the component andits operation.a.b.c.d.Intake or Raw Water Source1)Describe the control gates or valves including size and type of operation.2)Describe any bar screens or trash removal facilities.3)Describe any raw water pumps.4)Include dates facilities were installed and/or modified.Chemical Additions1)It is probably best to describe each chemical addition as a separateprocess. Provide the name of the chemical applied, chemical formulaand strength, name of chemical supplier, and type and size of containers.Indicate the type of chemical feeder, manufacturer's name, modelnumber, maximum capacity, and normal range of feed rates. Describewhere the chemical is applied to the water, what controls the dosage ofchemical, and what tests are made to determine dosage.2)What are the safety precautions applicable to this chemical? What safetyequipment is available?3)When were chemical feeders installed?Rapid Mix1)What is the size, capacity, number of units, and construction of rapidmix chambers? What is the detention time at design flow rate?2)Describe the mechanical mixers, manufacturer, size, model, and speed.3)When were the mixers installed?Flocculation1)What is the size, capacity, number of units, and construction of theflocculator chambers? What is the detention time at design flow rate?B-15

2)e.f.g.h.Describe the mechanical flocculators, including manufacturer, size,model, and speed.3)When were the flocculators installed?Sedimentation1)What is the size, capacity, number of units, detention time at design rate,and construction of the sedimentation basins? Are the basins baffled?2)Describe the mechanical sludge handling equipment. Are the basinsdrained and cleaned periodically?3)When were the basins installed?Filters1)Describe their size, capacity, number of units, type and size of filtervalves.2)Filter media.3)Filter appurtenances, date installed or rebuilt.Clearwell1)Size, detention time at rated plant capacity.2)Is the clearwell baffled?Disinfection1)Describe the chlorine chemical, chlorine feed equipment, point ofapplication, and maximum capacity of chlorinators.C.Major Pumping Systems - Describe the purpose of each pump, size, capacity, rpm, manufacturer,model number, motor manufacturer, horsepower, motor frame size, location, suction and dischargepiping size, and pressure controls. A copy of the pump performance curve showing the impellerdiameter, the designed capacity, and head should be included with each pump description.D.Transmission and Distribution Systems - Total system size (miles of pipe), number of serviceconnections (or customers), and highlights of transmission line characteristics (main size, dates oforiginal installation and expansions).E.Storage - Effective capacity, maximum withdrawal rate, materials of construction, coatings, andaltitude valves (i.e., how does the tank operate), and geographic location of reservoirs and elevatedstorage tanks.Other - Alternative or emergency sources of water, shared utilities (e.g., power generatingcapabilities employed by others), and other unusual aspects of the system.F.B-16

1.4Distribution MapIf not already detailed in the definition of Service Areas, the supplier should have a detailed map of thesystem's transmission and distribution facilities. On a typical water distribution system map, each type ofpipe can be identified with a number. This number may reference the plan number (since most systemsrequire multiple plans). Additionally, valves and hydrants are identified and assigned identificationnumbers. Pipe sizes, year installed, and materials are identified alongside the pipe. Other pertinentinformation may be included to aid in the maintenance of the system.While it is not necessary to show all of this information, it is a valuable planning tool for development orrehabilitation.1.5Flow Charts for Treatment PlantsEach treatment plant should be represented by a line diagram depicting flow of water through thefacility. Major equipment and systems should be labeled on the chart. Although proper scale is notrequired, some attempt should be made to depict the plant in its actual layout1.6Pressure GradientsA tabulation of the annual pressure surveys and hydraulic gradients for major transmission mains shouldbe included.1.7Other Maintenance RequirementsSuppliers need to be aware of and document long-term maintenance needs such as five-year equipmentinspections, tank painting, facility (such as roof) requirements, and routine items such as sludgedisposal.B-17

CHAPTER 2 - START-UP AND NORMAL OPERATING PROCEDURESThis portion of the O & M Plan discusses the normal operation of each treatment unit/process andprovides guidance for alternate and emergency operations. The information provided in this sectionshould address valve positions, capacities of each process, pump adjustments, and process controlvariables. Schematics and drawings should be used as part of these discussions.2.0Process DescriptionA well-written and prepared O & M Plan provides a means to understand the overall objectives ofthe treatment plant in addition to the immediate objectives of each process. In order to do this, theO & M Plan must provide detailed descriptions of the various treatment processes in the plant.A.The descriptions of the individual processes should follow the same order as the flowthrough the plant. It should contain information regarding the expected results orefficiency of each process and the anticipated operating parameters for each process.For example:1.Aeration - used as a method for oxidation of iron and manganese and for theremoval of hydrogen sulfide, carbon dioxide and volatile organic compoundsthrough oxidation and stripping;2.Rapid Mix - provides quick and thorough contact with chemical treatment aidsprior to n - causes suspended and dissolved particles to "clump"together under the influence of chemical aids for easy removal;4.Sedimentation - removes suspended or dissolved matter (turbidity) from water;5.Filtration - removes suspended or colloidal particles from water as it is passedthrough the filter media;6.Disinfection - destroys or inactivates harmful, disease-causing microorganisms;7.Chemical Addition/Handling - utilizes various chemicals/equipment to enhancethe treatment or quality of water;8.Fluoridation - provides for the reduction of tooth decay in the generalpopulation. The addition of fluoride compounds to water is based upon localand state requirements;9.Softening - removes dissolved magnesium and calcium compounds present ascarbonate or noncarbonate forms.B. Provide a brief description of each unit within each process.B-18

1.Identify the number of units available and state their operating or standby2.Provide a physical description of each unit including:status.3.a.Dimensions - length, width, depth, diameter;b.Design loadings/capacities - gpm, lbs/ft2, gaIs/ft2, etc.A description should be provided for each major component of a unit.a.The description should reference the component's relationship to othercomponents within the unit and should include:1)2)3)4)2.1Functions;Limitations;Operating features;Component interlocks.Relationship to Adjacent ProcessesThe operation of a process is made clearer by understanding the processes that both precede andfollow it.2.2A.Provide a general description giving type and function of preceding units and processesas they relate to the unit and process under consideration. This description shouldinclude the effects of inefficient operation of the preceding processes upon the processunder consideration.B.Provide a general description, giving type and function of supporting processes as theyrelate to the process under consideration.C.Provide a general description, giving type and function of following processes as theyrelate to the process under consideration. This description should include the effects ofinefficient operation of the process.ControlsThe key to the proper operation of a process is understanding how to control the equipment variables aswell as the process variables.A.Describe methods of controlling each component of the process including any limitations toprocess operation.Example:1.Flow rates;2.Chemical Dosages (List each chemical and normal dosage in lbs/day or mg/L);B-19

3.2.3Other.Start-UpSuccessful start-up of new or out-of-service facilities is dependent upon having a well-definedprocedure to follow which details all steps involved. For example:A.Equipment Inspection1.2.Physical: The O & M Plan should include a procedure for performance of a physicalinspection of all units.a.All tanks should be checked for construction debris such as boards, concrete chunks,loose nuts and bolts, tools, etc.b.All weirs, baffles, sumps, etc. should be checked for missing bolts, caulking, proper fit,defective protective coatings or other discrepancies which may affect the immediate orfuture operation of the unit or process.Mechanical: The mechanical inspection prior to start-up is extremel

EPD reserves the discretion to deviate from the guidance and procedures in this document if circumstances warrant. In the preparation of this part of the publication, EPD primarily used the technical guidance documents published by the Bureau of Water Supply Management of the State of Pennsylvania's Department of Environmental Protection.