Transcription

UNIVERSITY OF tered by:Environmental Health and SafetyBuilding 179PO Box 112190Gainesville, Florida 32611

IntroductionThe following document contains the University ofFlorida‟s Asbestos Operations and Maintenance(O&M) plan. The primary objective of this plan is toprotect building occupants and workers byminimizing the potential for exposure to asbestosfibers.The reader is to use this document as a supplement tohis or her current asbestos training. Also refer to thecomplete OSHA asbestos standards, Florida DBPRrequirements, U.S. EPA regulations, the UniversityAsbestos Policy (Appendix G), and other relevantasbestos guidance documents.Address questions aboutthe use of this plan, orits interpretation toEnvironmental Healthand Safety at(352) 392-3393[Suncom 622-3393], ortladun@ehs.ufl.edu.Asbestos is the name of a class of minerals that occurin fibrous form. Due to its heat and chemicalresistance and its strength and flexibility, asbestoshas been used in thousands of different building andnon-building related materials. While most uses ofasbestos have been banned, some asbestos containingproducts remain on the market today. The mostcommonly encountered types of asbestos containingmaterials at UF include floor tile and mastic, pipeinsulation, fireproofing, window glazing, asbestoscement products and roofing. All building materialsin structures built prior to 1981 must be presumed tocontain asbestos unless laboratory analysis orhistorical data indicate otherwise. EPA regulationsrequire that all buildings, regardless of age, besurveyed for asbestos prior to demolition orrenovation.Health effects related to asbestos exposure are due tothe inhalation or ingestion of asbestos fibers.Asbestos is a known carcinogen that can cause cancerin the lungs, larynx, trachea and other locations of thebody. The debilitating respiratory disease, asbestosis,may also result from asbestos exposure.Asbestos in good condition that remains undisturbeddoes not represent an exposure hazard. It is importantto check with the appropriate contact beforedisturbing building materials suspected of containingasbestos.See Appendix A for a list of definitions relevant tothis O&M Plan.2011 RevisionUniversity of Florida – Asbestos Operations and Maintenance2

Surveillance of BuildingsThe University maintains a program of periodicsurveillance of all known or suspected asbestoscontaining materials. All accessible functional spaceswith known or suspected asbestos containingmaterials other than flooring are visually inspectedtwice a year. Spaces with known or suspectedasbestos containing flooring are inspected once peryear. Scheduling leniency is permitted in sensitiveareas (e.g. some research labs, housing units). Thecurrent condition of the asbestos containing materialis evaluated relative to its condition at previoussurveys. Deterioration or a change in the condition ofany asbestos containing material is documented. Ifthis deterioration results in an increased exposure riskto building occupants the deteriorated area isscheduled for hazard abatement.Inspections are performed by individuals who arecurrently certified as EPA Asbestos BuildingInspectors or who have been trained to recognizeasbestos hazards.NotificationBuilding OccupantsBuildings presumed to contain asbestos containingmaterials are posted with a notice sign (Appendix B)alerting occupants to the presence of asbestos andproviding guidance on where to find furtherinformation. These notices are posted inside of thebuildings near the entrances.ContractorsContractors arriving on campus to work are notifiedabout the presence of asbestos containing materialsthrough their contract documents. Specifically, theform titled “Statement for Bids” is included in the biddocuments for all construction projects. It givesnotice of the possibility of encountering asbestoscontaining materials in University buildings.For selected contractors, there is a form titled “Noticeto Contractors of Asbestos Containing Materials inUniversity Buildings”. This form is included withletters sent by Purchasing to successful vendors.Information pertaining to asbestos is also included inthe University Construction Manual.2011 RevisionTraining of EmployeesThere are various levels of training requireddepending on the type of involvement with asbestosmaterials. Each division (i.e., Health Center, IFAS,Physical Plant Department, Reitz Union) isresponsible for ensuring employees are trained fortheir level of asbestos involvement. EnvironmentalHealth and Safety can guide and assist in training.Documentation of training activities must beprovided to the EH&S office.Awareness TrainingThis is the minimum level of training, and is requiredfor all custodial and maintenance employees havingthe potential to come into contact with asbestosduring their normal job duties. The training isrequired within 30 days of initial assignment andannually thereafter.Class I and Class II TrainingEmployees who will be removing or disturbingasbestos or presumed asbestos containing materialsmust receive training meeting the requirements of theEPA Model Accreditation Plan or completespecialized training as described below.Specialized Class II TrainingTraining to allow Class II work on vinyl and resilientflooring, resinous and cementitious (Transite )panels, roofing material, gaskets, and siding materialis available through Environmental Health andSafety, TREEO and other outlets. With the specificexceptions of roofing material and vinyl and resilientflooring, projects performed after this training arelimited to 160 square feet or 260 linear feet perproject for maintenance purposes only.Class III TrainingFollow requirements for Class I or Class II asappropriate.Competent Person for Class I and ClassII WorkThe competent person shall be trained in all aspectsof asbestos removal and handling, including:abatement; the contents of the OSHA standard; theidentification of asbestos; and other practices forreducing the hazard. Such training shall be obtainedin a comprehensive course for supervisors, such asthe State approved course conducted by TREEO, or acourse equivalent in stringency, content and length.Annual refresher training is required.University of Florida – Asbestos Operations and Maintenance3

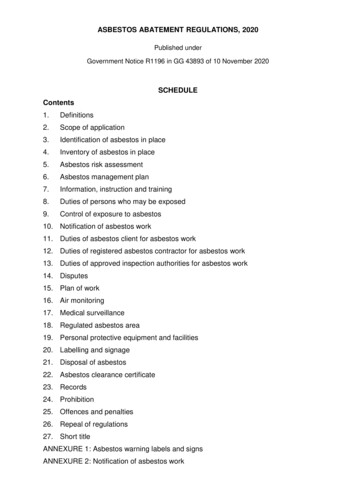

Medical SurveillanceMedical examinations and consultations are requiredfor all employees who are engaged in asbestos workfor a combined total of 30 or more days per year or;are exposed at or above the permissible exposurelimit or excursion limit; and for employees who wearnegative pressure respirators. Days when fewer thansixty minutes of asbestos work are completed are notincluded in the 29-day count.These examinations are repeated at least annuallythereafter. If the examining physician determines thatany of the examinations should be provided morefrequently than specified, affected employees will beexamined at the frequencies specified by thephysician.Medical examinations include a medical and workhistory, with special emphasis directed to thepulmonary, cardiovascular, and gastrointestinalsystems. Along with a pulmonary function test, anyexaminations or tests deemed necessary by theexamining physician will be included.Information Provided to the PhysicianThe following information must be provided to thephysician by the employee‟s supervisor before thephysical. A description of the affected employee‟sduties as they relate to the employee‟sexposure. The employee‟s representative exposurelevel or anticipated exposure level. A description of any personal protectionequipment to be used by the employee. Any information from previous medicalexaminations of the affected employee thatis not otherwise available to the examiningphysician.conditions that may result from asbestos exposure. Astatement will also be included that the employee hasbeen informed by the physician of the increased riskof lung cancer attributable to the combined effect ofsmoking and asbestos exposure.The physician will not reveal in the written opinionspecific findings or diagnoses unrelated tooccupational exposure to asbestos. The supervisorwill provide a copy of the physician‟s written opinionto the affected employee within 30 days from itsreceipt.Scheduling an ExaminationAsbestos examinations for University employees aregenerally provided by the Occupational MedicineClinic located in the Dental Science Building. Otherproviders may be used with the prior approval ofEnvironmental Health and Safety.Call the Occupational Medicine Clinic at (352) 3920627 to schedule an exam. Tell the person whoanswers that you wish to schedule an asbestosexamination. Indicate whether this will be an initialor annual exam. You will be asked for theemployee‟s name, department number and the nameof the employee‟s supervisor.Once the appointment has been scheduled, contactEnvironmental Health and Safety at (352) 392-3393and inform them of the pending appointment. A copyof the physician‟s written opinion shall be providedto Environmental Health and Safety when it has beenreceived.Physician’s Written OpinionThe examining physician provides a writtenstatement consisting of the physician‟s opinionwhether the employee has any detected medicalconditions that would place the employee at anincreased risk of health impairment from exposure toasbestos. Any recommended limitations on theemployee, or on the use of personal protectiveequipment such as respirators, will be noted in theopinion.The opinion will also include statements that theemployee has been informed by the physician of theresults of the medical examination, and any medical2011 RevisionUniversity of Florida – Asbestos Operations and Maintenance4

Updated Asbestos Surveysto be completed by the Competent Person as a reportof the work.An updated asbestos survey, identifying both friableand nonfriable asbestos containing materials, must beconducted of any building or section of a buildingthat is scheduled for renovation or demolition. Adraft copy of the survey must be reviewed by theUniversity Asbestos Coordinator for completenessprior to accepting the final product. A copy of theupdated survey must be kept on site until therenovation or demolition activities are completed.The survey must be conducted under the supervisionof a Florida licensed asbestos consultant. Individualsperforming asbestos surveys must be certified as EPAasbestos inspectors through a Florida approvedtraining provider.The Competent Person must assess the expectedexposures during the planned work. This assessmentprovides information necessary to assure that allcontrol systems planned are appropriate for thatoperation and will work properly. All projects musthave a Negative Exposure Assessment (NEA) inaccordance with the OSHA regulations for asbestosin construction, or special written permission of theAsbestos Coordinator to be carried out.Notification Prior to AsbestosRemoval ActivitiesOccupants of areas adjacent to planned asbestosremoval projects must be notified prior to the start ofremoval activities. This notification may be inwriting or by personal communication and mustinclude information pertaining to what material isbeing removed and what measures are being taken toprevent exposure to asbestos fibers.Administrative Procedures:In-house Work Other than FlooringWhich May Disturb AsbestosContaining MaterialsTo initiate a project, the Competent Person completesthe front page of a Maintenance Activity ProjectSubmittal (MAPS, see Appendix C), and an AsbestosProject Notification Form (APNF, Appendix D).Estimates are acceptable for costs and dates, and maybe corrected at the completion of the project.These forms are then sent (POB 112195 Universityof Florida) or faxed (352 392-3414) to the UniversityAsbestos Coordinator. The University AsbestosCoordinator will provide the necessary notificationsto the Department of Environmental Protection. Withthe exception of emergency projects, this notificationmust be given a minimum of ten days prior to thebeginning of the project.The University Asbestos Coordinator will review thesubmittal, and will indicate approval by verifying theworker qualification, record-keeping and notificationinformation on the MAPS. The work may begin afterthe approved MAPS have been returned to theCompetent Person. The second page of the MAPS is2011 RevisionEnvironmental Health and Safety can assist indeveloping the NEA. Call (352) 392-3393 [Suncom622-3393], or e-mail to tladun@ehs.ufl.edu foradditional information.During the project, the Competent Person maintainsthe daily log and checklist for activities at the projectsite. It is the responsibility of the Competent Personto arrange for necessary project monitoring and finalclearance air testing.Within one week of completing site activities theCompetent Person will need to obtain, if applicable, acopy of the air monitoring report, and attach it to theMAPS. The Competent Person will then make copiesof the MAPS, along with any attachments, for him orherself and the Division Representative, and send theoriginal MAPS with attachments to the UniversityAsbestos Coordinator at Environmental Health andSafety. An amended APNF should be included ifcorrections have been made to the originalinformation.After site activities are completed, bagged waste willnormally be taken to a temporary storage site oncampus until sufficient wastes have beenaccumulated to make it cost effective to visit thelandfill. These sites are selected by, and theresponsibility of the Competent Person.When waste materials are temporarily stored oncampus the Competent Person will identify thestorage site on the MAPS. These sites must besecured and have limited access, and provided withappropriate warning signs as required under State andOSHA regulations.When waste materials are taken to the landfill, theCompetent Person shall send a copy of the landfillwaste receipt to the University Asbestos Coordinator.The University Asbestos Coordinator shall attach thereceipt to the MAPS. When a single landfill receiptcovers wastes generated during multiple O&Mprojects the Competent Person must provide onecopy of the receipt for each project, and indicate tothe University Asbestos Coordinator, which projectsUniversity of Florida – Asbestos Operations and Maintenance5

were associated with the receipt (the waste sitemanifest could serve this purpose)Administrative Procedures:In-house Flooring RemovalTo initiate a project the Competent Person completesSection I of an Asbestos Project Notification Form Flooring (APNF - F, Appendix E). Estimates areacceptable for costs and dates, and may be correctedat the completion of the project.This form is then sent (POB 112195 University ofFlorida) or faxed (352 392-3414) to the UniversityAsbestos Coordinator. With the exception ofemergency projects, this notification must be given aminimum of ten days prior to the beginning of theproject.The University Asbestos Coordinator will review thesubmittal, and will indicate approval after verifyingthe worker qualifications. The work may begin onlyafter the approved APNF-F has been returned to theCompetent Person and after a required “Notice ofRemoval of Resilient Floor Covering” notificationform is submitted to the Department of Business andProfessional Regulation (DBPR). The DBPRnotification must be submitted at least 3 days prior tothe start of the project and will be submitted byEH&S based on the information provided in theAPNF.Administrative Procedures:Contracted WorkTo initiate a project the Project Manager selects anapproved asbestos abatement contractor and alicensed asbestos consultant, if required. An AsbestosProject Notification form (APNF, Appendix D)would then be completed and submitted to EH&S.Estimates are acceptable for costs and dates, and maybe corrected at the completion of the project.The completed APNF is sent (POB 112195University of Florida) or faxed (352 392-3414) to theUniversity Asbestos Coordinator by the ProjectManager. The selected contractor shall provide thenecessary notifications to the Department ofEnvironmental Protection and/or the Department ofBusiness and Professional Regulation (floor coveringremovals only).Within 30 days of completing site asbestos activitiesthe Project Manager will need to obtain projectreports from the asbestos contractor, and if applicablethe licensed asbestos consultant, and provide them tothe Asbestos Coordinator at Environmental Healthand Safety. An amended APNF should be sent ifcorrections have been made to the originalinformation.Section II of the APNF-F is to be completed by theCompetent Person as a report of the work.The Competent Person must assess the expectedexposures during planned work. This assessmentprovides information necessary to assure that allcontrol systems planned are appropriate for thatoperation and will work properly.Each University Division conducting asbestos floortile removal must conduct a negative exposureassessment (NEA) of their work practices on anannual basis (or more frequently if determined to benecessary by EH&S). A NEA is required to verifythat the work practices are in compliance with OSHAand University requirements. Sampling for the NEAmust be performed under the direction of a licensedasbestos consultant and a copy of the NEA reportmust be submitted to EH&S for review and filing.Failure to perform an annual NEA may result in thesuspension of a Divisions approval to removeasbestos floor coverings.See appendix H for specific requirements concerningthe removal of asbestos containing floor coverings.2011 RevisionUniversity of Florida – Asbestos Operations and Maintenance6

Maintenance of AsbestosContaining MaterialsAll asbestos work on campus shall be conducted incompliance with the applicable OSHA standard: 29CFR 1926.1101 or 1910.1001 depending or the typeof work. OSHA enforces these standards forcontractors and consultants, and the US EPAenforces them under the Worker Protection Rule 40CFR 763 for University employees. Additional Stateof Florida requirements are found under FS 255.551– 255.565 and FS Chapter 469.Prohibited PracticesThe following work practices shall not be used forany work that disturbs asbestos containing materials,regardless of measured levels of asbestos exposure orthe results of initial exposure assessments: High-speed abrasive disc saws that are notequipped with point of cut ventilator orenclosures with HEPA filtered exhaust air;Compressed air used to remove asbestos, ormaterials containing asbestos;Dry sweeping, shoveling or other dry cleanup of dust and debris containing ACM andPACM;Employee rotation as a means of reducingemployee exposure to asbestos.as it remains in an intact and undamaged state. ThePhysical Plant Division annually or more often ifneeded applies wax to the floor tile which serves toseal the flooring and to further minimize the risk ofexposure.Sanding of flooring material is prohibited. Strippingof finishes shall be conducted using the least abrasivepads possible at a speed lower than 300 rpm andemploying wet methods.Burnishing or dry buffing may be performed only onflooring that has sufficient finish so that the padcannot contact the flooring material, and the tiles andadhesives remain intact throughout the process.Building occupants must not alter the floor coveringin any way that may result in an asbestos fiberrelease. Care must also be used when movingequipment across any asbestos tile. Any observeddamage to the tile must be promptly reported to theappropriate maintenance division, and to EH&S at392-1591 immediately.See appendix H for specific requirements concerningthe removal of asbestos containing floor coverings.Projects without a negative exposure assessment maynot be carried out without the written permission ofthe University Asbestos Coordinator.Specific work practices are in place for tasksimpacting wallboard systems containing less than onepercent ( 1%) asbestos (see Appendix I).Routine Maintenance and CleaningIt is important to minimize the disturbance ofasbestos-containing materials and the subsequentrelease of asbestos fibers. This can be accomplishedby staying out of physical contact with materials thatcontain, or are presumed to contain, asbestos.Dust and debris in an area containing visiblydeteriorated ACM shall not be dusted or swept dry,or vacuumed without using a HEPA vacuum filter.This cleaning shall only be carried out by certifiedasbestos workers.Asbestos-Containing Flooring MaterialAll floor tile installed prior to 1990 must be treated asasbestos containing unless sampling has indicatedthat the material is asbestos free. The asbestos floorcovering poses no significant health concerns as long2011 RevisionUniversity of Florida – Asbestos Operations and Maintenance7

Removing or Disturbing AsbestosContaining MaterialsFinal Clearance Air MonitoringWhen friable asbestos containing material is removedor non-friable asbestos containing material becomesfriable during removal, and the amount of material is3 square or linear feet or greater, final air clearancesampling must be conducted. For projects 3 linear orsquare feet to 260 linear or 160 square feet, PCMclearance testing is required. For projects over 260linear or 160 square feet, TEM clearance testing willbe required. All final clearance testing must followthe published AHERA protocol methods.Class I WorkThis is work involving the removal of thermal systeminsulation, or surfacing material, and typically willnot be performed by University employees.Class II WorkWhere a negative exposure assessment cannot bedocumented, or where the job conditions indicatethere may be exposure above the PEL, or where theasbestos containing material cannot be removed in asubstantially intact state, a negative pressureenclosure must be used. These barriers are necessaryto prevent the migration of airborne asbestos from theregulated area. The effectiveness of the barriersshould be verified by perimeter area monitoring orvisual surveillance.Class II work also may be performed using a methodallowed for Class I work, and glove bags and gloveboxes are allowed if they fully enclose the Class IImaterial to be removed. Impermeable drop clothsmust be placed on surfaces beneath all removalactivity.Flooring or its backing is not to be sanded, ground,abraded or intentionally broken or chipped. Vacuumsequipped with HEPA filter, disposable dust bag, andmetal floor tool (no brush) shall be used to cleanfloors.Resilient sheeting shall be removed by cutting withwetting of the snip point and wetting during removal.Rip-up of resilient sheet floor material is prohibited.All scraping of residual adhesive and/or backing shallbe performed using wet methods.Dry sweeping is prohibited. Mechanical chipping isprohibited unless performed in a negative pressureenclosure. Tiles must be removed substantially intact.Roofing MaterialRoofing materials are exempted from the 160 squarefoot limit. This work requires specialized trainingprovided, or approved, by the University of FloridaAsbestos Coordinator.When removing roofing material that containsasbestos, remove the roofing material in an intactstate to the extent feasible.Cutting machines shall be continuously misted duringuse, unless the competent person determines thatmisting substantially decreases worker safety. Allloose dust left by the sawing operation must beHEPA vacuumed immediately. Cutting of cementasbestos (Transite ) is prohibited without the writtenpermission of the University Asbestos Coordinator.Unwrapped or unbagged roofing material must beimmediately lowered to the ground by way ofcovered, dust-tight chute, crane or hoist, or placed inan impermeable waste bag or wrapped in plasticsheeting and lowered to ground by the end of thework shift.Upon being lowered, unwrapped material shall betransferred to a closed receptacle in such manner topreclude the dispersion of dust. Roof level heatingand ventilation air intake sources shall be isolated orthe ventilation system shall be shut down.For Class II work the competent person must bespecially trained in a course that meets the criteria ofEPA‟s Model Accreditation Plan (40 CFR 763) forproject supervisor, or its equivalent.Specialized Class II WorkRemoving Vinyl and Resilient Flooring MaterialsVinyl and resilient flooring materials are exemptedfrom the 160 square foot limit. This work requiresspecialized training provided, or approved, by theUniversity of Florida Asbestos Coordinator.2011 RevisionUniversity of Florida – Asbestos Operations and Maintenance8

Cementitious Asbestos Siding & Transite PanelsThese materials are limited to 160 square feet perproject, for maintenance purposes only. This workrequires specialized training provided, or approved,by the University of Florida Asbestos Coordinator.Cutting, abrading or breaking siding, shingles, orTransite panels, is prohibited unless the competentperson can demonstrate that methods less likely toresult in asbestos fiber release cannot be used. Allnon-roofing cement asbestos materials with exposedasbestos surfaces shall be sprayed with amendedwater, or encapsealant before removal.GasketsIf a gasket is visibly deteriorated and unlikely to beremoved intact, removal shall be done within aglovebag. The gasket shall be thoroughly wetted withamended water before its removal. The wet gasketshall be immediately placed in a disposal container.Any scraping to remove residue must be performedwet. This work requires specialized trainingprovided, or approved, by the University of FloridaAsbestos Coordinator.2011 RevisionUniversity of Florida – Asbestos Operations and Maintenance9

Requirements forAsbestos ContractorsRequirements forLicensed Asbestos ConsultantsWork is to be performed in accordance with the 29CFR 1926.1101 (OSHA Asbestos ConstructionStandard), in addition to accepted industry workprocedures, and other applicable Federal, State, andCounty regulations.Work is to be performed in accordance with theASTM E 1368-00, Standard Practice for VisualInspection of Asbestos Projects, in addition toaccepted industry work procedures, and applicableFederal, State, and County regulations.On site superintendent must be a “competent person”as defined in 29 CFR 1926.1101 (b). Superintendentmust be on the job site full time during the entirecontract period of work execution. Superintendentmust have a minimum (3) three years experience intype(s) of work and products specified for the project.On site representatives must be a “competent person”as defined in 29 CFR 1926.1101 (b). At a minimum,the on site representative must have NIOSH 582 orequivalent asbestos air sampling and analysiscertification and have an up to date asbestosabatement project management and supervisioncertification from a Florida approved trainingprovider.All work, for all routine projects is to be conductedwith asbestos exposures at or below the OSHApermitted exposure level (PEL). Written approval bythe University Asbestos Coordinator is required forprojects that are intended to exceed the PEL.InsuranceContractor must comply with the liability insuranceand other pre-job submittal requirements listed inAppendix F.If the on site representative is not able to perform hisor her duties due to any contractor created safety orhealth hazard at the site, the representative mustdirect the contractor to correct the hazard. If thecontractor cannot, or will not correct the hazard, theon site representative shall notify the UniversityProject Manager, and shut the project down until thehazard can be corrected.Air monitoring by the licensed asbestos consultantshall include adequate personnel samples to confirmcontractor‟s compliance with the NEA.The on site representative shall have the necessarytraining, equipment and experience to verify that thecontractor is maintaining adequate diminishedpressure and air changes per hour in the NPE.2011 RevisionUniversity of Florida – Asbestos Operations and Maintenance10

Appendix ADefinitionsAsbestos: includes chrysotile, amosite, crocidolite, tremolite asbestos, anthophylliteasbestos, actinolite asbestos, and any of these minerals that has been chemicallytreated or altered.Asbestos-Containing Material (ACM): any material containing more than onepercent asbestos.Class I Asbestos Work: the removal of thermal system insulation and/or surfacingmaterial (ACM or PACM).Class II Asbestos Work: removal of any ACM which is not Class I, such aswallboard, floor tile, ceiling tile, linoleum, transite board, roofing materials andmastics.Class III Asbestos Work: repair and maintenance operations where ACM is likely tobe disturbed.Class IV Asbestos Work: maintenance and custodial activities during whichemployees contact but do not disturb ACM, and activities to clean up dust anddebris which may be generated by Class I, II, or III work.Clearance Air Monitoring: Air monitoring conducted by an Asbestos Project Monitor at the conclusion of anasbestos project. Clearance air monitoring includes the successful completion of a final visual inspection forwork area debris and the collection and analysis of air samples in accordance with AHERA protocols.Competent person means, in addition to the definition in 29 CFR 1926.32 (f), one who is capable of identifyingexisting asbestos hazards in the workplace and selecting the appropriate control strategy for asbestos exposure,who has the authority to take prompt corrective measures to eliminate them, as specified in 29 CFR 1926.32(f):in addition, for Class I and Class II work who is specially trained in a training course which meets the criteria ofEPA's Model Accreditation Plan (40 CFR 763) for supervisor, or its equivalent and, for Class III and Class IVwork, who is trained in a manner consistent with EPA requirements for training of local education agencymaintenance and custodial staff as set forth at 40 CFR 763.92 (a)(2).Friable Asbestos Containing Material: any material containing more than onepercent asbestos, which when dr

2011 Revision University of Florida - Asbestos Operations and Maintenance 2 Introduction The following document contains the University of Florida‟s Asbestos Operations and Maintenance (O&M) plan. The primary objective of this plan is to protect building occupants and workers by minimizing the potential for exposure to asbestos fibers.