Transcription

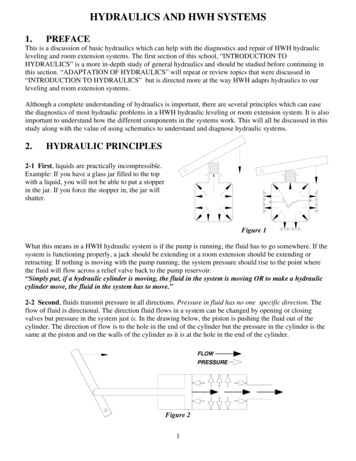

INDUSTRIALGLOBAL SOLUTIONS

32 branex - Fotolia.comEXPERTS YOU CAN COUNT ONFOR OPTIMAL SOLUTIONS SPECIFIC TO YOUR INDUSTRYREDEFINING WHAT’S POSSIBLECIRCOR is redefining what's possible in fluid handling for industrial applications, by partnering with engineers and facilityowners like you.You have a challenging job. Engineers and operators ofindustrial plants face greater challenges than ever before interms of environmental protection, operations, safety, andavailability. While the systems are becoming more complex,your customers are demanding more throughput, higherquality, and lower costs. CIRCOR can help you overcomethese challenges by working with you from the beginning ofthe design process, all the way through to startup andoperation.The CIRCOR team of specialists will:As your partner in design, development, and maintenance, CIRCOR offers you more than just off-the-shelf products for yourbiggest challenges. We offer you the best fluid handling system for each application.n EngageBy choosing CIRCOR, you get 150 years of application experience and access to technologies whose reliability is proven ona daily basis in numerous industrial systems around the world. And you are backed by a team of product and serviceexperts who are committed to maximizing the efficiency and reliability of your system every step of the way, from projectplanning and installation to final commissioning and ongoing production.n UseThis is made possible by a wide range of pumps and systems from brands that you know and trust: Allweiler , HouttuinTM,Imo , and Warren . This gives you the peace of mind that comes with extraordinary reliability and a high level of technicalservice that is essential during configuration, commissioning, and ongoing operations. As your single-source globalsupplier, we call this "Total Savings of Ownership," reducing the overall costs of your operation and increasing yourprofitability.CIRCOR offers a variety of products and technical solutionsthat reliably ensure the performance and effectiveness ofyour systems. We do this by offering pumps and solutionsspecifically tailored to your industry.cross-functional team members to support allaspects of design, optimization, and maintenance.tools that simplify the design and selection process.n Focuson keeping your plant competitive in a toughglobal economy.Industry Products & ServicesALLWEILER HOUTTUIN IMO WARREN

54YOUR SINGLE SOURCEREDEFINING WHAT MATTERS MOST TO YOUPumps and fluid handling systems from CIRCOR are offeredunder the trusted brands Allweiler , HouttuinTM, Imo , andWarren . These solutions support a wide range of missioncritical applications and are essential for the reliable andsafe operation of all types of industrial systems, includingsewage plants; process technology and chemistry; mining;pulp and paper; building and construc-tion; production offood, beverages, and cosmetics; polymers/textilesprocessing; heat transfer; and machine tool.Through our standard and custom engineered solutions, weoffer a wide range of designs for fluid handling systems inindustrial systems.PPPULP & PAPERBCMTBUILDING & CONSTRUCTIONMACHINE TOOLHTHEAT TRANSFERMIMININGPTIndustrial plant operators and engineers turn to CIRCOR tohelp redefine the metrics that matter most to them:POLYMERS & TEXTILESWATER & WASTEWATERWWn Technology:providing the right pumping and systemsolution for every applicationn Reliability:maintaining performance of the systemregardless of operating conditionsn Availability:n Uptime:FCFOOD & COSMETICSmaximizing the time for productionensuring run-time consistency without failn Compliance:sustaining the commitment to environmentalresponsibilityn Cost-effectiveness:global economykeeping the plant competitive in a toughCPCHEMISTRY & PROCESS TECHNOLOGYAPPLICATIONSCP CHEMISTRY & PROCESS TECHNOLOGY BC BUILDING & CONSTRUCTIONn Pumping of acids and lyes,washing and absorptionliquids,salt solutions,solvents,hot liquidsMT MACHINE TOOLn Pumping of fuel oiln Supply of warm and cold water,heating systemsn Elevator technology, liftingplatforms, theatrical stagesn Pumping ofcooling-lubricant solutionsand emulsions,cutting and grinding oilsn High-pressure coolant feedfor internally cooled toolsn Pumps for cooling-lubricantHT HEAT TRANSFERn Pumping of thermal oiln Pumping of hot waterMI MININGn Pumping and dosing of chemicalsand explosive liquidsn Pumps used in:MiningDrillingn Lubrication and control of ore-mining machinessupply systems (individualand centrally managed)PP PULP & PAPERn Pumping ofcoating inks (pigments,binders, additives),kaolin,calcium carbonate,latex,starch,caustic soda,paper stockn Dosing of additives andchemicalsn Supply pumps forlamination, coatings, andcookingWW WATER & WASTEWATERn Pumping of various sludges:raw, pre-clarification, waste,activated, digested, postclarification, recirculated, andthickenedn Dosing of neutralizingagents and flocculantsFC FOOD & COSMETICSn Pumping of fibrous liquids,liquids with solids, highvalue and sensitive liquidsn Dosing in batch operation,in filling systems, foradditives, or during productblendsn Complete solutions forpre- and post-clarification,recirculation,denitrification andnitrificationn Industrial wastewatertreatment in clarificationplantsPT POLYMERS & TEXTILESn Pumping of startingproducts for fiberproductionn Process pumps inpolyester manufacturingIndustry Products & ServicesALLWEILER HOUTTUIN IMO WARREN

67INNOVATIVE, RELIABLE PUMPS AND SYSTEMSOPTIMAL SOLUTIONS FOR ALLINDUSTRIAL APPLICATIONSFROM THE NAMES YOU KNOW AND TRUSTWITH PERFORMANCE AND EFFICIENCY BUILT INBREAKDOWN OF TOTAL COSTS OF OWNERSHIP FOR A PUMP10%investmentcostsWhen you consider the pump's entire service life, thepurchase price accounts for only about ten percent of thetotal costs, while energy and availability costs account fornearly 90 percent.25%maintenancePumps from CIRCOR reduce energy costs, downtime, andcosts associated with unscheduled maintenance, labor, andreplacement parts.CIRCOR delivers innovative and reliable pump units as well as engineered systems from names you know and trust: Allweiler , HouttuinTM, Imo and Warren . Our engineering and technical specialists conduct extensive researchand testing before developing and manufacturing this broad portfolioof products in accordance with international standards. The focus is singular andclear: to meet the highest levels of manufacturing and product quality.TWO-SCREW PUMPSWe call this value to you and your customers, "TotalSavings of Ownership." HOUTTUIN WARRENDouble-entry, self-priming, low NPSH values, dry-runningcapable.65%energyApplication: Ideal for applications in the plant periphery,for pumping large volumes of lubricating or nonlubricating liquids, and especially low-viscosity liquids.Performance dataPumps and solutions from CIRCORChemistry & Process Technology Machine ToolMiningPulp & PaperWater & WastewaterFood & CosmeticsPolymers & Textiles up to 100 bar / 1,450 psiViscosity:0.5 to 100,000 cSt emsSystTHREE-SCREW PUMPSALLWEILER IMO Self-priming, very high efficiency, and low-noise. Enablesfully continuous, pulsation-free pumping. Pressure:ubpsOilmist/PurLumrpelleProp up to 5,300 m³/h / 23,340 gpmepsel pann Capacity:Liquid temperature: up to 400 OC / 752 OFumps -chifuntrCeGearpuatocerMa Sidempsrspulticsta Heat TransferBuilding & ConstructiongalpmpumsitycavProg stry/application Application: For pumping oils and other lubricating andnon-corrosive liquids, like those used in fuel technology,hydraulics, mechanical engineering, general industrialtechnology, and the chemical and petrochemical industries.Performance dataCapacity:up to 750 m³/h / 3,300 gpmPressure:up to 280 bar / 4,060 psiViscosity:1 to 5,000 cStLiquid temperature: up to 260 OC / 500 OFIndustry Products & ServicesALLWEILER HOUTTUIN IMO WARREN

89PROGRESSING CAVITY PUMPSSingle- or multi-stage pumps, self-priming, for use as animmersion pump in horizontal or vertical design. Pumpingis continuous with virtually no pulsation and withoutformation of emulsions. Ideal for dosing.ALLWEILER Application: For pumping or dosing liquids with a varietyof viscosity levels and corrosion properties. Also suitablefor multi-phase liquids and contaminated liquids likesludges and waste/leak oils.Performance dataCapacity:up to 450 m³/h / 1,980 gpmPressure:up to 64 bar / 928 psiViscosity:1 to 300,000 cStSIDE CHANNEL PUMPSSelf-priming, segmental type. Insensitive to cavitation atvariable vapor pressure.ALLWEILER liquids with gas- or vapor-forming components (up to 50%),i.e. for low-boiling liquids like liquefied gas. Universal usein a variety of industries.Application: For pumping pure, turbid, gaseous, neutralor aggressive, non-abrasive, cold or hot liquids. Also forPerformance dataLiquid temperature: up to 150 OC / 302 OFCapacity:up to 36 (50*) m³/h / 158 (220*) gpmPressure:up to 40 (25*) bar / 568 (355*) psiDelivery head:up to 350 (250*) m / 1,148 (820*) ftLiquid temperature: -40 to 220 OC / -40 up to 428 OFPERISTALTIC PUMPSDry self-priming, rotating displacement pumps withoutseals or valves.ALLWEILER as applications where the pump must be capable of dryrunning for extended periods.Application: For pumping neutral or aggressive, pure orcontaminated, cold or hot liquids or liquids interspersedPerformance dataup to 60 m³/h / 265 gpmPressure:up to 16 bar / 232 psiViscosity:1 to 100,000 cStDisplacement pumps, multi-stage configuration for veryhigh or medium pressures with very low-viscosity fuels.Virtually pulsation-free, low-noise pumping with highefficiency.Performance dataZENITH IMO Application: From lifting oils to fuel injection, the CIG gearpump from CIRCOR is the perfect pump solution forturbines that were derived from aerospace.Capacity:up to 50,000 m³/h / 220,167 gpmPressure:up to 6 bar / 85 psiDelivery head:up to 12 m / 39 ftwith solids in chemical engineering and process technology.Used in wastewater and clarification as recirculation pumpsas well as for pumping return sludge or rainwater duringpotable water reclamation, e. g. in seawater desalinationplants.Liquid temperature: up to 200 OC / 392 OFCENTRIFUGAL PUMPSDesignation, rated power, and dimensions according to EN733 or EN 2858. The EN performance ranges have beenexpanded with additional sizes.Capacity:up to 28 m³/h / 123 gpmPerformance dataPressure:up to 345 bar / 5,003 psiCapacity:up to 1,500 m³/h / 6,600 gpmViscosity:0.5 to 50,000 cStPressure:up to 16 bar / 227 psiDelivery head:up to 150 m / 492 ftLiquid temperature: up to 510 OC / 950 OFALLWEILER Performance dataLiquid temperature: up to 80 OC / 176 OFGEAR PUMPSPROPELLER PUMPSHorizontally or vertically installed pumps for largecapacities and high heads up to 12 m. Materials andinstallation/drive adaptable to requirements.Application: For pumping or dosing liquids with a varietyof viscosity levels and corrosion properties. Also suitablefor multi-phase liquids and contaminated liquids as wellCapacity:* Performance data for high-pressure centrifugal pumps in a modular system, up to 15 stages depending on pump sizeLiquid temperature: up to 400 OC / 752 OF ALLWEILERApplication: For pumping neutral or aggressive, pure orcontaminated, cold or hot, and toxic liquids.

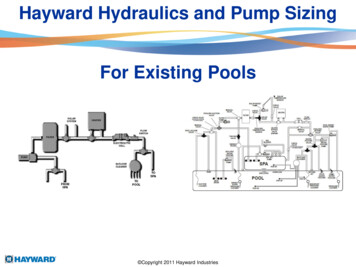

1011MACERATORSSize-reduction elements are the rotating impeller (withexchangeable highly wear-resistant milling cutters) and astationary cutting ring. ALLWEILERprocess-engineering applications; in communal andindustrial wastewater-treatment plants; and in thetreatment of waste products in every industrial segment.Application: Chopping and homogenization of fibers andsolids contained in liquids. Smaller solids sizes permitpumping of the liquids; used for chopping, mixing, andup to 160 m³/h / 705 gpmLiquid temperature: up to 80 OC / 176 OFOIL SERVICES ThermoJet Oil Purifier is a state-of-the-art, on-line industrialoil-purification system that removes free, emulsified anddissolved water and light hydrocarbons from industriallubricants and hydraulic oils.Application: The unique air/gas stripping technology makes itpractical and efficient — allowing the ThermoJet Oil Purifierto outperform centrifuges, coalescers and the more complexvacuum dehydration systems.Performance dataParticulate filtration: ISO 4406 15/13/10Process flow rate:680 l/h / 180 gal/hPUMP MONITORINGSmart Technology IN-1000 Series – Condition and OperationMonitoring for greater stability and lower operating costs.IN-1000 is a modular and fully-automated electronic monitoringsystem with the ability to monitor several pumps simultaneously. It may be retrofitted at any time. An integrated Webserver permits transfer of data to a control station and remoteservices. When unusual operating conditions appear, they areannounced immediately and displayed on the color screen.As a result, it becomes possible to plan ahead for maintenanceand repairs. Unplanned production downtime is prevented,maintenance intervals are extended, and expenses for maintenance and spare parts are reduced.DECADES OF EXPERIENCE COMBINED WITH MODERN DESIGN AND PRODUCTIONPumps and systems from CIRCOR employ a variety of technologies that make them ideal for virtually any liquid in a widerange of industrial applications. When you partner with CIRCOR, you get the best solution, no matter what your industry orapplication.WATER & WASTEWATERPerformance dataCapacity:TAILOR-MADE SOLUTIONS FOR EACH INDUSTRYLSC CIRCOR supplies OEMs, operators, and engineering firmswith solutions that are optimized for all areas ofwastewater treatment, including water treatment,wastewater purification, drainage, water supply, andwastewater disposal. Pumps in the sewage plant's inletmust lift arriving raw wastewater up to the operationallevel. Since this liquid still contains a high proportion ofsolids, it is essential for the pump units to resist cloggingand abrasion. Progressing cavity pumps are particularlywell-suited for this purpose. With a variety of designs andoptions, such as rotor coatings, various geometries, one ortwo feed screws as needed, and approximately 20 differentelastomers for the stator, these pumps adapt fully to theliquid. If the sludge contains clogs and cakes, maceratorsare needed to reduce solid sizes. In the purification stages,insensitive, self-aerating centrifugal pumps and progressingcavity pumps move the thin sludges to prevent gas formation. darknightsky - Fotolia.comIn the chemical cleaning process, special proportioning pumps are used to move additives like acids, lyes, lime, or polymersthat are needed as precipitation and flocculant aids for eliminating phosphate and facilitating drainage.CHEMISTRY & PROCESS TECHNOLOGYPumps used in the chemical processing industry (CPI) mustpump a wide variety of liquids used in organic and inorganicchemistry. Examples include lyes and acids, solvents,pigments, coatings, explosives, rubber, resin, and fertilizers.The international and regional standards that are demandedof chemical companies make this industry one of the mostdynamic in the world. For operators, this makes it evenmore important to have trustworthy suppliers for devicesand solutions that enable continuous and safe productionprocesses with the highest possible efficiency.CIRCOR develops, designs, and manufactures reliablesolutions for even the most complex chemical processes.Chemical pumps from CIRCOR meet these requirementsthrough a wide offering of materials, the capability to handlea wide range of viscosities, pressures, and temperatures, andcompliance with ISO 2858/EN 2858.Industry Products & ServicesALLWEILER HOUTTUIN IMO WARREN

1213MININGFOOD & COSMETICSIn an increasingly global economywith high demand for raw materials,productivity of mining and extractionoperations is critically important.CIRCOR pumps and solutions are used in applications thatmust fulfill the most stringent regulations for hygiene whenpumping high-value and sensitive liquids. Examples includethe production of food and beverages, dairy processing, andpharmaceuticals and cosmetics. Special stainless steel pumpsin CIP configuration are capable of residual- and bacteria-freecleaning. They have a gentle, low-pulsation pumping actionthat is economical and uniform. Even fibers and solid particles will not interrupt their operation. All pumps fulfill FDA and 3AUS Sanitary Standards.CIRCOR supports productivity andreliability of mining operations withpumps to supply lubricating andcontrol oil to equipment, hermeticallysealed pumps to safely handleenvironmentally hazardous andexplosive liquids, and dosing pumpsfor the preparation of minedmaterials.POLYMERS & TEXTILESCIRCOR delivers pumps that are specifically adapted topumping polymers, synthetic fibers, and non-woven fabrics.Examples of applications are textile manufacturing, themanufacturing of PET objects, and thicker industrial yarns.The pumps move high-viscosity liquids at high pressure andextreme temperatures. The solutions are ideal in situationsthat require repetitive, precise dosing of liquids ormovement of hot liquids, such as during the production ofnylon and polymers. tomas - Fotolia.comPULP & PAPERIn the cellulose and paper industry,production typically runs 24/7/365,making service and support critical toa profitable operation. With pumpsto cover all applications – fromsupply pumps for lamination andcooking, dosing of additives andchemicals to pumps for coating inks– and a global service and supportnetwork, CIRCOR supports ownersand operators of pulp & paper plantswith the most reliable fluid handlingsolutions.MACHINE TOOLCooling lubricant pumps from CIRCOR are used in everyaspect of mechanical engineering, plant construction,machine tools, and the automotive industry. Theycontribute to excellent surface quality of machined partsand are valued particularly in the automotive industry fortheir long service life. In addition to cooling lubricants andemulsions, pumps from CIRCOR are also well suited forcutting and grinding oils.When used in conjunction with the redesigned ALLSPEED control system, operating costs for machine tools are reduced by as much as 75% with the same investment volume. zpk - zpk.chBUILDING & CONSTRUCTIONIndustrial plants, administrativebuildings, large structures, andcommunity heating plants move fueloils with high-efficiency pumps fromCIRCOR. High-efficiency pumps alsosupply hot and warm water and moveliquid through heating and coolingsystems. In addition, pumps fromCIRCOR are commonly used with lownoise, maintenance-free, andcompact elevator systems. onizu3d - Fotolia.comHEAT TRANSFER Andrei Merkulov - Fotolia.comKadmy - Fotolia.com Kadmy - Fotolia.comWithin the realm of heat-transfer technology, centrifugalpumps from CIRCOR are used in supply loops, solar powerstations, recirculation systems, and heating systems. Theymove hot water and heat-transfer oil. Pumps from theALLHEAT series reflect one of the few pump designs onthe market that (with absolutely no changes) can pumpthermal oil up to 350 C/662 F or hot water up to about 207 C/405 F.ALLHEAT pumps are also suited for use with modern, verylow-viscosity synthetic thermal oils.

1514CIRCOR snapfoto105 - Fotolia.comALLWEILER GmbHAllweilerstr. 178315 RadolfzellGermany1710 Airport RoadMonroe, NC 28110USAUnit 1803, 18/FClifford Centre778 Cheung Sha Wan RoadLai Chi Kok, KowloonHong KongTel. 49 7732 86 0Tel. 1 704 289 65 11Tel. 852 3473 2700Unit 804,Venture International ParkBuilding BNo. 2679 Hechuan RoadShanghai 201103ChinaTel. 86 21 6248 1395THE BEST FLUID HANDLING SYSTEM AT THE CORE OF EVERY INDUSTRIAL PLANTPumps and engineered systems from CIRCOR are the most trusted names in fluid handling applications all over theworld.Your CIRCOR team focuses on developing and delivering the best solution for individual requirements, whatever yourchallenges, wherever they are in the world. We call this "Total Savings of Ownership." Savings from CIRCOR begins with afair price, but "Total Savings of Ownership" involves an understanding of what it takes to optimize profitabilitythroughout the life of your plant.www.circorpt.comPartner with CIRCOR for our deep base of industry knowledge, engineering experience, and application expertise thatallows us to optimize system performance while ensuring your team has the knowledge and training it needs. With thetools to simplify your design and engineering processes and the global presence to ensure you have what you needwhen you need it, we are committed to being a partner in your success by redefining what's possible for you and yourcustomers.REDEFINING GLOBAL SOLUTIONSCIRCOR maintains regionalengineering and manufacturingfacilities to support you around theworld and around the clock.Global HeadquartersRegional Manufacturing andEngineering Support FacilitiesGlobal Distributor NetworkPower & Industry Products & ServicesALLWEILER HOUTTUINTM IMO WARREN CIRCOR, ALLWEILER, IMO, TUSHACO and WARREN are registered trademarks and HOUTTUIN is a trademark of CIRCOR or itssubsidiaries in the U.S. and/or other countries. (c) 2018, CIRCOR. All rights reserved. 488170 - 2018.04

H-J Paulsen - Fotolia.comwww.circorpt.comCOMMERCIAL MARINEDEFENSEOIL & GASPOWER & INDUSTRYRELIABILITY SERVICES

Performance data Capacity: up to 28 m³/h / 123 gpm Pressure: up to 345 bar / 5,003 psi Viscosity: 0.5 to 50,000 cSt Liquid temperature: up to 510 OC / 950 OF Performance data Capacity: up to 60 m³/h / 265 gpm Pressure: up to 16 bar / 232 psi Viscosity: 1 to 100,000 cSt Liquid temperature: up to 80 OC / 176 OF Performance data