Transcription

Influence of Striking Edge Radius (2mm versus 8 mm) on InstrumentedCharpy Data and Absorbed EnergiesEnrico LuconSCK CEN, Institute for Nuclear Material ScienceMol (Belgium)* Full paper accepted for publication in International Journal of Fracture (10 Nov 2008)

International Charpy standards ASTM E 23 and ISO 148 are relatively similar One of the most significant differences is theconfiguration of the pendulum striker

Short literature review on strikereffect on absorbed energy (KV) Towers OL (1983), “Effects of Striker Geometry on Charpy Results”, Met Constr15(11):682-686Revise G (1990), “Influence of Dimensional Parameter of an Impact Test Machineon the Results of a Test”, ASTM STP 1072, 35-53Fink DA (1990), “Quantitative Comparison and Evaluation of Various NotchMachining Methods and How They Affect ASTM E23 and ISO R442 TestingEquipment Results”, ASTM STP 1072, 94-119Ruth EA (1995), “Striker Geometry and Its Effect on Absorbed Energy”, ASTM STP1248, 101-110Nanstad RK, Sokolov MA (1995), “Charpy Impact Test Results on Five Materialsand NIST Verification Specimens Using Instrumented 2-mm and 8-mm Strikers”,ASTM STP 1248, 111-139Tanaka M, Ohno Y, Horigome H, Tani H, Shiota K, Misawa A (1995), “Effects of theStriking Edge Radius and Asymmetrical Strikes on Charpy Impact Test Results”,ASTM STP 1248, 153-167Siewert TA, Vigliotti DP (1995), “The Effect of Charpy V-Notch Striker Radii on theAbsorbed Energy”, ASTM STP 1248, 140-152McCowan CN, Pauwels J, Revise G, Nakano H (2000), “International Comparison ofImpact Verification Programs”, ASTM STP 1380, 73-89Heping Li, Report on Relation of KV2 & KV8, presented at ISO TC164 SC4/Pmeeting, Hannover, September 2008.

Summary resultsof the literature review (1) Differences are small below a threshold energy Threshold mostly reported to be around 200 J (Ruth1995; Naniwa et al. 1995; McCowan et al 2000) Other values have also been reported 60 J (Towers 1983; Morita and Kobayashi 2004) 100 J (Siewert and Vigliotti 1995) Threshold energy appears to be material-dependent (Nanstad and Sokolov, 1995) related to the fracture characteristics of the material(Tanaka et al. 1995) Above the threshold, KV2 KV8

Summary resultsof the literature review (2) Main reasons for KV increase above the threshold(all interrelated): non-separation of the specimen halves interaction between specimen and 8mm-striker corners increased friction between specimen and anvils Standard deviation significantly larger for KV2 (Siewertand Vigliotti 1995) Below the threshold, KV2 KV8 or KV2 slightly larger:KV2 mm 1.042 KV8 mm 0.70 (Fink 1990) Other parameters (Naniwa et al. 1990; Nanstad andSokolov 1995; McCowan et al 2000): LE2 generally larger than LE8 SFA2 SFA8

Much more limited information isavailable for instrumented parameters Naniwa T, Shibaike M, Tanaka M, Tani H, Shiota K, Namio H,Shiraishi T (1990), “Effects of the Striking Edge Radius on theCharpy Impact Test”, ASTM STP 1072, 67-80 Nanstad RK, Sokolov MA (1995), “Charpy Impact Test Results onFive Materials and NIST Verification Specimens UsingInstrumented 2-mm and 8-mm Strikers”, ASTM STP 1248, 111139 Tanaka M, Ohno Y, Horigome H, Tani H, Shiota K, Misawa A(1995), “Effects of the Striking Edge Radius and AsymmetricalStrikes on Charpy Impact Test Results”, ASTM STP 1248, 153167 Morita S, Kobayashi T (2004), “Ductile-Brittle TransitionBehaviors with Two Striker Geometries in the InstrumentedCharpy Impact Test”, Mat Sc Forum 449-452:861-864

Example of fully ductile testperformed with 8 mm striker20FmForce (kN)1612"Bump"Fgy8400sm51015Displacement (mm)2025

Analytical approachand data sets considered (1)Round-RobinPeriodASTM E28.07 1997-98NIST2006-07IAEA CRP-82007TOTALRefs*abc,dNo of materialstested4217No of testswith 2mm-striker689910177No of testswith 8mm-striker106608174Also: tests on “half-size” specimens (4.83 4.83mm²) [89 with 2mm;36 with 4mm]Referencesa - Manahan MP, Martin FJ, Stonesifer RB (2000), “Results of the ASTMInstrumented/Miniaturized Round Robin Test Program”, ASTM STP 1380, 223-241b - McCowan CN, Splett JD, Lucon E (2008), “Dynamic Force Measurement: InstrumentedCharpy Impact Testing”, NISTIR 6652, NIST, Boulder COc - Viehrig H-W and Lucon E (2007), “IAEA Coordinated Research Project on Master CurveApproach to Monitor Fracture Toughness of RPV Steels: Effect of Loading Rate”, ASME PVP2007/CREEP 8, San Antonio TX, paper PVP2007-26087.d - Lucon E, Viehrig H-W (2007), “Round-Robin Exercise on Instrumented Impact Testing ofPrecracked Charpy Specimens (IAEA Coordinated Research Program Phase 8)”, ASME PVP2007/CREEP 8, paper PVP2007-26088.

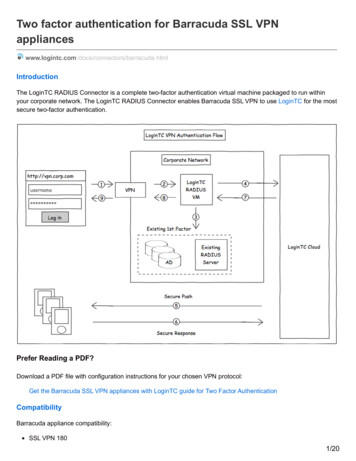

Analytical approachand data sets considered (2)SCK CEN data (mostly unpublished)MaterialERM low energy(batch 1-30-E11)ERM low energy(batch 1-AF-30)ERM medium energyDIN 22NiMoCr37JSPS (A533B)TOTALNo of testswith 2mm-strikerNo of testswith 8mm-striker45542420352131135RemarksTests at room temperatureTests at multiple temperatures Variables considered: Fgy, Fm, sm, Wt, KV Comparison mean values and standard deviations 2mm/8mm Statistical significance of mean value differences analyzed usingthe unpaired t-test (two-tailed probability P with threshold value0.05; P 0.05 not significant; P 0.001 very significant)

Results of the statistical analyses2mm 8mm(t-test)(very significant)2mm 8mm (significant)2mm 8mm(extremely significant)2mm 8mm (not significant)

Analysis of the t-test results Mean values of probability P calculated (P 0 assumed when P 0.0001) “Striker Influence Index” (SII) defined by replacing symbolsfor with numbers ( 1; 2; 3; -1; -2; -3; 0)FgyFmsmWtKV0.066 0.050 0.070 0.305 0.296Full-size specimens PSII 0.66 -1.60 -1.71 0.60 0.700.221 0.000 0.047 0.052 0.310Sub size specimens PSII -0.66 -3.00 -0.25 -0.75 0.00 Highest P least sensitive to striker radius; lowest P most sensitive SII 0 higher values with 2mm-striker; SII 0 higher values with 8mm Low absolute value SII low sensitivity to striker or effects compensate

Assessment of the t-test resultsFgyFmsmWtKV0.066 0.050 0.070 0.305 0.296Full-size specimens PSII 0.66 -1.60 -1.71 0.60 0.70 Absorbed energy values are not very sensitive to striker configuration;slight tendency for 2mm to provide higher values Largest influence on Fm and sm, with higher values yielded by 8mmstrikers Fgy also significantly affected (higher values for 2mm strikers), butsome inconsistencies are observedFgyFmsmWtKV0.221 0.000 0.047 0.052 0.310Sub size specimens PSII -0.66 -3.00 -0.25 -0.75 0.00 Available data is limited, particularly for 4mm strikers Similar effects for KV, Fm and sm; opposite effects for Wt and Fgy

SCK CEN transition curves22NiMoCr37 (high upper shelf)252 mm8 mm141185-1002 mm8 mm22Maximum forces Fm (kN)17191613-50050100150200Temperature ( C)25030010-100350-5005010043.532.521.512 mm8 mm0.50-100150Temperature ( C)4.5Displacement sm (mm)General yield forces Fgy (kN)20-50050100150Temperature ( C)200250300350200250300350

SCK CEN transition curves22NiMoCr37 (high upper shelf)250USE2mm/USE8mm 0.88150100502 mm8 mm2500-100-50050100150200250300USE2mm/USE8mm 0.87350Temperature ( C)200Absorbed energies KV (J)Absorbed energies Wt (J)200150100500-1002 mm8 mm-50050100150Temperature ( C)200250300350

SCK CEN transition curves22NiMoCr37 (high upper shelf)2.51.510.50-1002 mm8 mm-50050100150Temperature ( C)200250300100350Shear Fracture Appearance (%)Lateral expansion (mm)27550252 mm8 mm0-100-50050100Temperature ( C)150200250300

SCK CEN transition curvesJSPS (low upper shelf)222 mm8 mm2 mm8 mm17Maximum forces Fm (kN)1914115-10016138-50050100150200Temperature ( C)25030035010-100-500501002.51.510.52 mm8 mm0-100150Temperature ( C)2Displacement sm (mm)General yield forces Fgy (kN)20-50050100Temperature ( C)150200250300200250300350

SCK CEN transition curvesJSPS (low upper shelf)90Absorbed energies KV (J)756045302 mm158 mm0-100-50050100Temperature ( C)150200250300

SCK CEN transition curvesJSPS (low upper shelf)1.751.2510.750.52 mm8 mm0.250-100-50050100Temperature ( C)150200250100300Shear Fracture Appearance (%)Lateral expansion (mm)1.57550252 mm8 mm0-100-50050100Temperature ( C)150200250300

Analytical correlations between2mm and 8mm strikers40FgyForce using 2mm-striker (kN)35Standard error of estimate Fgy : 1.55 kN Fm : 0.99 kNFm3025Fgy,2mm 0.873 Fgy,8mm 2.712R 0.906720Fm,2mm 1.037 Fm,8mm - 1.83R2 0.97971510500510152025Force using 8mm-strikers (kN)303540

Analytical correlations between2mm and 8mm strikers3.5Standard error of estimate : 0.16 mmsm using 2mm-striker (mm)32.52sm,2mm 0.889 sm,8mm - 0.0451.5R2 0.977810.5000.511.522.5sm using 8mm-strikers (mm)33.5

Analytical correlations between2mm and 8mm strikers225Wt200Energy using 2mm-striker (J)KV175Standard error of estimate Wt : 2.54 kN KV : 3.08 kNKV2mm 1.0255 KV8mm 0.0141150Upper shelf values22NiMoCr372R 0.9966125Upper shelf valuesJSPS100Wt,2mm 1.0281 Wt,8mm - 0.406752R 0.9977502500255075100125150Energy using 8mm-strikers (J)175200225

Overall correlation betweenstrikers in terms of KV500Fink 1990Revise 1990Ruth 1995Siewert-Vigliotti 1995Tanaka et al. 1995McCowan et al. 2000Heping 2008This studyUSE 22NiMoCr37 (SCK-CEN)KV using 2 mm-strikers (J)400300113 datapoints (77%below 200 J)Below 200 JKV2mm 1.01 KV8mm 0.545R2 0.996200Above 200 JKV2mm 0.5747 KV8mm 76.423R2 0.77510000100200300KV using 8mm-strikers (J)400500

Influence of material toughnesson 2mm/8mm .050.80020406080100120140160 1.00Average KV (J)Ratio 2mm/8mmRatio e KV (J)100120140160

Influence of material toughnesson 2mm/8mm relationship1.20WtKV1.15USE2mm/USE8mm(JSPS)Ratio 7)0.850.80050100Average KV (J)150200

Influence of striker configurationon data scatter6KVFgyFmsmWt2mm/8mm SD ratio543KV 200 JAll data210050100150200250Average KV (J)300350400450

Conclusions Fgy values are affected, but not systematically; larger valuesare observed for 2mm strikers, but difference decreases withtoughness Fm and sm show the most significant effect, with 8mm strikersdelivering higher values with increasing toughness Wt and KV behave similarly. The effect is marginal (a few %)below 200 J. Above 200 J, 8mm strikers deliver progressivelyhigher values Data scatter tends to be higher for 2mm strikers Our results are consistent with the existing literature For sub-size specimens: Effect on Fm, sm is consistent with full-size specimens Effect on Fgy is unclear Up to 10-11 J, Wt and KV do not show large sensitivity to striker radius Due to the limited database, analytical correlations were not derived

Machining Methods and How They Affect ASTM E23 and ISO R442 Testing Equipment Results”, ASTM STP 1072, 94-119 Ruth EA (1995), “Striker Geometry and Its Effect on