Transcription

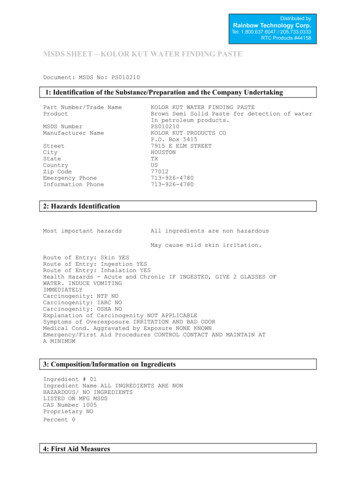

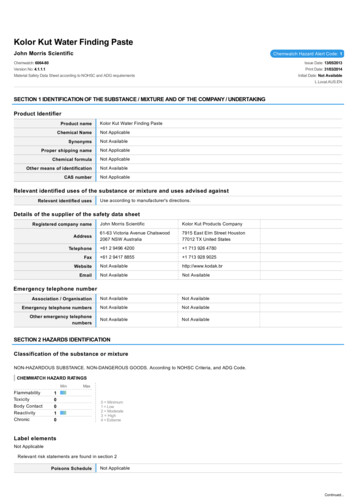

Kolor Kut Water Finding PasteJohn Morris ScientificChemwatch Hazard Alert Code: 1Chemwatch: 6064-80Issue Date: 13/05/2013Version No: 4.1.1.1Print Date: 31/03/2014Material Safety Data Sheet according to NOHSC and ADG requirementsInitial Date: Not AvailableL.Local.AUS.ENSECTION 1 IDENTIFICATION OF THE SUBSTANCE / MIXTURE AND OF THE COMPANY / UNDERTAKINGProduct IdentifierProduct nameChemical NameSynonymsKolor Kut Water Finding PasteNot ApplicableNot AvailableProper shipping nameNot ApplicableChemical formulaNot ApplicableOther means of identificationCAS numberNot AvailableNot ApplicableRelevant identified uses of the substance or mixture and uses advised againstRelevant identified usesUse according to manufacturer's directions.Details of the supplier of the safety data sheetJohn Morris ScientificKolor Kut Products Company61-63 Victoria Avenue Chatswood2067 NSW Australia7915 East Elm Street Houston77012 TX United StatesTelephone 61 2 9496 4200 1 713 926 4780FaxRegistered company nameAddress 61 2 9417 8855 1 713 928 9025WebsiteNot Availablehttp://www.kodak.brEmailNot AvailableNot AvailableAssociation / OrganisationNot AvailableNot AvailableEmergency telephone numbersNot AvailableNot AvailableOther emergency telephonenumbersNot AvailableNot AvailableEmergency telephone numberSECTION 2 HAZARDS IDENTIFICATIONClassification of the substance or mixtureNON-HAZARDOUS SUBSTANCE. NON-DANGEROUS GOODS. According to NOHSC Criteria, and ADG Code.CHEMWATCH HAZARD RATINGSMinFlammabilityToxicityBody ContactReactivityChronicMax100100 Minimum1 Low2 Moderate3 High4 ExtremeLabel elementsNot ApplicableRelevant risk statements are found in section 2Poisons ScheduleNot ApplicableContinued.

Chemwatch: 6064-80Version No: 4.1.1.1Risk PhrasesLegend:Indication(s) of dangerPage 2 of 7Issue Date: 13/05/2013Kolor Kut Water Finding PastePrint Date: 31/03/2014Not Applicable1. Classified by Chemwatch; 2. Classification drawn from HSIS ; 3. Classification drawn from EC Directive1272/2008 - Annex VINot ApplicableSAFETY ADVICENot ApplicableOther hazardsNot ApplicableSECTION 3 COMPOSITION / INFORMATION ON INGREDIENTSSubstancesSee section below for composition of MixturesMixturesCAS No%[weight]NameNot Available100ingredients determined not to be hazardousSECTION 4 FIRST AID MEASURESDescription of first aid measuresEye ContactSkin ContactInhalationIngestionIf this product comes in contact with eyes:Wash out immediately with water.If irritation continues, seek medical attention.Removal of contact lenses after an eye injury should only be undertaken by skilled personnel.If skin or hair contact occurs:Flush skin and hair with running water (and soap if available).Seek medical attention in event of irritation.If fumes, aerosols or combustion products are inhaled remove from contaminated area.Other measures are usually unnecessary.Immediately give a glass of water.First aid is not generally required. If in doubt, contact a Poisons Information Centre or a doctor.Indication of any immediate medical attention and special treatment neededTreat symptomatically.SECTION 5 FIREFIGHTING MEASURESExtinguishing mediaWater spray or fog.Foam.Dry chemical powder.BCF (where regulations permit).Carbon dioxide.Special hazards arising from the substrate or mixtureFire IncompatibilityAvoid contamination with oxidising agents i.e. nitrates, oxidising acids, chlorine bleaches, pool chlorine etc.as ignition may resultAdvice for firefightersFire FightingAlert Fire Brigade and tell them location and nature of hazard.Wear breathing apparatus plus protective gloves.Prevent, by any means available, spillage from entering drains or water courses.Use water delivered as a fine spray to control fire and cool adjacent area.DO NOT approach containers suspected to be hot.Cool fire exposed containers with water spray from a protected location.If safe to do so, remove containers from path of fire.Equipment should be thoroughly decontaminated after use.Continued.

Chemwatch: 6064-80Version No: 4.1.1.1Fire/Explosion HazardPage 3 of 7Issue Date: 13/05/2013Kolor Kut Water Finding PastePrint Date: 31/03/2014Combustible.Slight fire hazard when exposed to heat or flame.Heating may cause expansion or decomposition leading to violent rupture of containers.On combustion, may emit toxic fumes of carbon monoxide (CO).May emit acrid smoke.Mists containing combustible materials may be explosive.Combustion products include:,carbon dioxide (CO2),other pyrolysis products typical of burning organic materialSECTION 6 ACCIDENTAL RELEASE MEASURESPersonal precautions, protective equipment and emergency proceduresMinor SpillsClean up all spills immediately.Avoid contact with skin and eyes.Wear impervious gloves and safety goggles.Trowel up/scrape up.Place spilled material in clean, dry, sealed container.Flush spill area with water.Major SpillsClear area of personnel and move upwind.Alert Fire Brigade and tell them location and nature of hazard.Control personal contact with the substance, by using protective equipment.Prevent spillage from entering drains, sewers or water courses.Recover product wherever possible.Put residues in labelled containers for disposal.If contamination of drains or waterways occurs, advise emergency services.Personal Protective Equipment advice is contained in Section 8 of the MSDS.SECTION 7 HANDLING AND STORAGEPrecautions for safe handlingLimit all unnecessary personal contact.Wear protective clothing when risk of exposure occurs.Use in a well-ventilated area.Avoid contact with incompatible materials.When handling, DO NOT eat, drink or smoke.Keep containers securely sealed when not in use.Avoid physical damage to containers.Always wash hands with soap and water after handling.Work clothes should be laundered separately.Use good occupational work practice.Observe manufacturer's storage and handling recommendations contained within this MSDS.Atmosphere should be regularly checked against established exposure standards to ensure safe workingconditions are maintained.Safe handlingStore in original containers.Keep containers securely sealed.Store in a cool, dry, well-ventilated area.Store away from incompatible materials and foodstuff containers.Protect containers against physical damage and check regularly for leaks.Observe manufacturer's storage and handling recommendations contained within this MSDS.Other informationConditions for safe storage, including any incompatibilitiesMetal can or drumPackaging as recommended by manufacturer.Check all containers are clearly labelled and free from leaks.Suitable containerStorage incompatibilityAvoid contamination of water, foodstuffs, feed or seed.Avoid reaction with oxidising agentsAvoid strong acids, acid chlorides, acid anhydrides and chloroformates.PACKAGE MATERIAL INCOMPATIBILITIESNot AvailableContinued.

Chemwatch: 6064-80Version No: 4.1.1.1Page 4 of 7Issue Date: 13/05/2013Kolor Kut Water Finding PastePrint Date: 31/03/2014SECTION 8 EXPOSURE CONTROLS / PERSONAL PROTECTIONControl parametersOCCUPATIONAL EXPOSURE LIMITS (OEL)INGREDIENT DATANot AvailableEMERGENCY LIMITSIngredientTEEL-0TEEL-1TEEL-2TEEL-3Kolor Kut Water Finding PasteNot AvailableNot AvailableNot AvailableNot AvailableIngredientOriginal IDLHRevised IDLHKolor Kut Water Finding PasteNot AvailableNot AvailableMATERIAL DATAExposure controlsEngineering controls are used to remove a hazard or place a barrier between the worker and the hazard.Well-designed engineering controls can be highly effective in protecting workers and will typically be independentof worker interactions to provide this high level of protection.The basic types of engineering controls are:Process controls which involve changing the way a job activity or process is done to reduce the risk.Enclosure and/or isolation of emission source which keeps a selected hazard "physically" away from the workerand ventilation that strategically "adds" and "removes" air in the work environment. Ventilation can remove ordilute an air contaminant if designed properly. The design of a ventilation system must match the particularprocess and chemical or contaminant in use.Employers may need to use multiple types of controls to prevent employee overexposure.General exhaust is adequate under normal operating conditions. If risk of overexposure exists, wear SAAapproved respirator. Correct fit is essential to obtain adequate protection. Provide adequate ventilation inwarehouse or closed storage areas. Air contaminants generated in the workplace possess varying "escape"velocities which, in turn, determine the "capture velocities" of fresh circulating air required to effectively removethe contaminant.Appropriate engineeringcontrolsType of Contaminant:Air Speed:solvent, vapours, degreasing etc., evaporating from tank (in still air)0.25-0.5 m/s(50-100 f/min)aerosols, fumes from pouring operations, intermittent container filling, low speed conveyer0.5-1 m/stransfers, welding, spray drift, plating acid fumes, pickling (released at low velocity into zone(100-200 f/min.)of active generation)direct spray, spray painting in shallow booths, drum filling, conveyer loading, crusher dusts,gas discharge (active generation into zone of rapid air motion)1-2.5 m/s(200-500 f/min)grinding, abrasive blasting, tumbling, high speed wheel generated dusts (released at highinitial velocity into zone of very high rapid air motion).2.5-10 m/s(500-2000 f/min.)Within each range the appropriate value depends on:Lower end of the rangeUpper end of the range1: Room air currents minimal or favourable to capture1: Disturbing room air currents2: Contaminants of low toxicity or of nuisance value only2: Contaminants of high toxicity3: Intermittent, low production.3: High production, heavy use4: Large hood or large air mass in motion4: Small hood - local control onlySimple theory shows that air velocity falls rapidly with distance away from the opening of a simple extractionpipe. Velocity generally decreases with the square of distance from the extraction point (in simple cases).Therefore the air speed at the extraction point should be adjusted, accordingly, after reference to distance fromthe contaminating source. The air velocity at the extraction fan, for example, should be a minimum of 1-2 m/s(200-400 f/min.) for extraction of solvents generated in a tank 2 meters distant from the extraction point. Othermechanical considerations, producing performance deficits within the extraction apparatus, make it essential thattheoretical air velocities are multiplied by factors of 10 or more when extraction systems are installed or used.Continued.

Chemwatch: 6064-80Version No: 4.1.1.1Page 5 of 7Issue Date: 13/05/2013Kolor Kut Water Finding PastePrint Date: 31/03/2014Personal protection···Eye and face protectionSkin protectionSafety glasses with side shieldsChemical goggles.Contact lenses may pose a special hazard; soft contact lenses may absorb and concentrate irritants. A writtenpolicy document, describing the wearing of lenses or restrictions on use, should be created for each workplace ortask. This should include a review of lens absorption and adsorption for the class of chemicals in use and anaccount of injury experience. Medical and first-aid personnel should be trained in their removal and suitableequipment should be readily available. In the event of chemical exposure, begin eye irrigation immediately andremove contact lens as soon as practicable. Lens should be removed at the first signs of eye redness or irritation- lens should be removed in a clean environment only after workers have washed hands thoroughly. [CDC NIOSHCurrent Intelligence Bulletin 59], [AS/NZS 1336 or national equivalent]See Hand protection belowHand protectionWear general protective gloves, eg. light weight rubber gloves.Body protectionSee Other protection belowOther protectionNo special equipment needed when handling small quantities.OTHERWISE:Overalls.Barrier cream.Eyewash unit.Thermal hazardsNot AvailableRecommended material(s)Respiratory protectionGLOVE SELECTION INDEXGlove selection is based on a modified presentation of the:"Forsberg Clothing Performance Index".The effect(s) of the following substance(s) are taken into account in thecomputer-generated selection:Kolor Kut Water Finding Paste Not AvailableMaterialCPI* CPI - Chemwatch Performance IndexA: Best SelectionB: Satisfactory; may degrade after 4 hours continuous immersionC: Poor to Dangerous Choice for other than short term immersionNOTE: As a series of factors will influence the actual performance of theglove, a final selection must be based on detailed observation. * Where the glove is to be used on a short term, casual or infrequentbasis, factors such as "feel" or convenience (e.g. disposability), maydictate a choice of gloves which might otherwise be unsuitable followinglong-term or frequent use. A qualified practitioner should be consulted.SECTION 9 PHYSICAL AND CHEMICAL PROPERTIESInformation on basic physical and chemical propertiesAppearancePhysical stateBrown semi-solid with slight ammonia odour; mixes with water.Non Slump PasteRelative density (Water 1)1.1OdourNot AvailablePartition coefficient n-octanol /waterNot AvailableOdour thresholdNot AvailableAuto-ignition temperature ( C)Not AvailablepH (as supplied)Not AvailableDecomposition temperatureNot AvailableMelting point / freezing point( C)Not AvailableViscosity (cSt)Not AvailableMolecular weight (g/mol)Not AvailableTasteNot AvailableExplosive propertiesNot AvailableInitial boiling point and boilingrange ( C)343Flash point ( C)185Evaporation rateNot AvailableContinued.

Chemwatch: 6064-80Version No: 4.1.1.1FlammabilityUpper Explosive Limit (%)Lower Explosive Limit (%)Vapour pressure (kPa)Page 6 of 7Issue Date: 13/05/2013Kolor Kut Water Finding PastePrint Date: 31/03/2014Not AvailableOxidising propertiesNot AvailableNot AvailableSurface Tension (dyn/cm ormN/m)Not AvailableNot AvailableVolatile Component (%vol)0.1Solubility in water (g/L)MiscibleVapour density (Air 1)Not Av

)luh ([sorvlrq d]dug &rpexvwleoh 6oljkwiluhkd]dugzkhqh[srvhgwrkhdwruiodph ohqwuxswxuhrifrqwdlqhuv