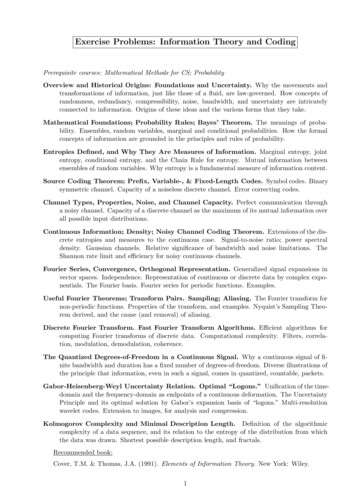

Transcription

Marking, coding and systems solutionsPharmaceutical and Medical Devices

Perhaps to a greater degree than otherindustries, pharmaceutical and medicaldevice packaging demands the highestquality variable coding. Legibility andcontrast are non-negotiable when itcomes to coding healthcare products.And yet, coding solutions must alsofacilitate line productivity and integrateseamlessly into today’s sophisticatedproduction lines.2

Protect your products andyour consumers.Addressing regulatory requirementsacross a diverse array of substratesrequires a partner with the technologyand expertise to help meet your projectrequirements.Our dedicated Pharmaceutical and OEM sales teamsare ready to partner with you on your projects. Withdecades of experience, we’re well-versed with industrystandards and global regulations, making us the rightpartner for your coding technology needs.Uptime advantageBuilt-in productivityWith complex production schedules supportingglobal operations, you cannot afford coder relateddowntime. Our technology is designed to deliveroptimal code quality while keeping your linesrunning.Videojet equipment integrates seamlessly into awide array of pharmaceutical equipment,facilitating work flow to help meet yourproduction goals.Code AssuranceSimple usabilityAs serialization requirements continue to evolve,data management becomes more complex andcritical. Our printers are designed to intelligentlymanage your data to get the right code, on theright product, time after time.Our solutions are easy to operate and requireless maintenance due to industry-leadinghardware and software innovation, designedwith your packaging process in mind.3

Expertise forseamless integrationOptimal coding solutions are part of a holistic approach topharmaceutical manufacturing, with the printer playing a smallbut integral role in addressing industry regulations. While physicalintegration remains a vital consideration, demand is increasingfor equipment that can handle more complex data managementresponsibilities without compromising product safety or legislativecompliance.Videojet solutions are designed with these requirements in mind,helping create serialized, human- and machine-readable codes toaddress pharmaceutical regulations. In addition, Videojet service andtechnical support teams help ensure that the installation is done rightand provides support throughout the life of the printer.Coding technologiesBlister/CartonerCoding may occur in several locations, eitherintegrated into the cartoner itself or on theoutfeed conveyor. Printing may also occurupstream of the cartoner on the primarypack as required.Laser Marking SystemsA beam of infrared light focused and steered with a seriesof carefully controlled small mirrors to create marks wherethe heat of the beam interacts with the packaging surface.Thermal Inkjet (TIJ)Ink-based, non-contact printing using heat and surfacetension to move ink onto a package surface. Generallyused to print 2D DataMatrix and other bar codes.Continuous Inkjet (CIJ)Fluid based, non-contact printing of up to five lines of text,linear and 2D bar codes, or graphics, printed on a varietyof packaging types via traversing systems.4Thermal Transfer Overprinting (TTO)A digitally controlled printhead precisely melts ink from a ribbondirectly onto flexible films to provide high resolution, real-time printsLarge Character Marking (LCM)Ink-based, non-contact printing of tall codes, includingalphanumeric logos, and bar codes in large sizes primarily for casesLabel Printer Applicator (LPA)Prints and places labels of various sizes on multiplepackage types

Coding technologies for your packaging type:Printing applicationTIJParenteralsLaserCIJ Blister packs Cartons Bottles and tubesLabels Flexible materials Cases TTOLPALCM Checkweigher/Serialization moduleLeveraging a checkweigher’s precise materialhandling improves overall print and DataMatrixquality. The printer can generate its own codes orintegrate into a broader serialization solution.Side grip conveyorSimple coder integration with a side gripconveyor allows for marking of either visible orcovert codes on the top or bottom ofpharmaceutical bottles. Downstream codeverification can be easily accommodated whilethe bottle is engaged by the conveyor.5

Bottle labelerPrecise control facilitates high qualityalphanumeric and bar code printing on thelabel. Discrete codes can be applied to thebottles before or after label application.StarwheelConsistent code accuracy is critical for internaltraceability codes commonly placed on vials andampules. The highly precise motion of thestarwheel offers ideal material handling for thisapplication.ThermoformerPrecise mechanical and controls integrationhelps ensure high quality marking on web-basedmaterials, including blister lidding foils and otherbarrier films. Traversing solutions are availablefor thermal and continuous inkjet systems.6

ParenteralsHigh resolution coding evenin tight print windowsWhether being used for customer-facing information or bright stocking, coding injectableproducts is inherently challenging, given the small size and reduced radius of the packaging.Integrating the coding solution into OEM equipment provides improved product control,leading to higher quality human and machine readable codes. Videojet dedicatedpharmaceutical and OEM specialists can help you select the correct solution for yourapplication, whether it is plastic, glass or aluminum.Continuous Inkjet (CIJ)Laser Marking Systems Robust ink portfolio includingautoclave resistant, visible and UV inks Creates high resolution 2D codes onaluminum vial caps for internaltraceability Videojet high resolution printersenable more content in small spacessuch as flip tops, vial skirts, andsyringes Videojet offers multiple scan heads andprecision optics to achieve desired markquality7

Blister packsCoding solutions for thefast lanesBlister coding requires keeping pace with rapid linear speeds whilepotentially coding multiple lanes simultaneously. Codes need to fitinto small print areas and adhere throughout the life of theproduct. Videojet has the broadest portfolio of inkjet and laserprinters to meet your blister coding needs.8Continuous Inkjet (CIJ)Laser Marking SystemsThermal Inkjet (TIJ) Wide range of both dark and lightcolored inks for maximum contrast Creates permanent codes on a varietyof blister materials CleanFlowTM printheads resist inkbuild-up, lessening maintenancerequirements Large marking windows maximizeengagement time for coding multiplelanes simultaneously Four distinct printhead modelsfacilitate integration into blisterpacking equipment Patented Black Solvent ink ispurpose-built for blister foilapplications

CartonsUnlock track and tracecapabilitiesAs the most common saleable unit for pharmaceutical and medical products, carton coding iscritical for track and trace initiatives. Global regulations require up to 4 lines of text and a 2Dbar code, but code quality and line speeds cannot be compromised. Videojet solutions can helpyou meet your regulatory requirements without compromising code quality or throughput.Thermal Inkjet (TIJ)Laser Marking SystemsContinuous Inkjet (CIJ) Prints complex, detailed codes at upto 600 x 600 dpi Permanent coding solution withvirtually no consumables Wolke m600 oem provides secure,ultra-fast processing of up to 20records per second, including 2DDataMatrix Videojet’s 32 standard beam deliveryoptions facilitates integration, helpingcreate the best possible code quality Adheres to virtually all common cartonmaterials, including non-porous andwater-resistant coatings Smart CartridgeTM fluid delivery virtuallyeliminates spills9

Bottles and tubesInnovative solutions designedwith your challenges in mindSuccessful bottle coding is defined by the adherence, contrast, and permanence of the applied code.Achieving these characteristics relies on pairing the right printing technology with sound integration.Videojet has the technology and the expertise to achieve your coding objectives, whether it be on theside, bottom, shoulder or cap of the bottle.10Continuous Inkjet (CIJ)Laser Marking Systems Integrates seamlessly into side gripconveyors for inline code verificationapplications UV wavelength marks permanent, highresolution and high contrast codes ontoHDPE/ LDPE Precise drop placement can createmachine-readable 2D codes 360 Arc Compensation softwareenables high quality marks onrotational devices, virtually eliminatingdistortion

LabelsProven solutions to hit yourmark windowsLabel marking requires thoughtful integration to achieve effective placement and highquality. Videojet offers a wide array of printing technologies capable of label marking, andhas dedicated experts to help you select the right technology for your application.Thermal TransferOverprinting (TTO) Simple, direct contact coding methodfor high resolution text and bar codes Configurable with a wide array ofbracketry alternatives to integrate intothe line prior to label applicationThermal Inkjet (TIJ)Laser Marking SystemsContinuous Inkjet (CIJ) No wear parts and simple cartridgechanges help protect uptime Ablates preprinted mark windows tocreate indelible, high-resolution coding Revolutionary Videojet 8610 printerfeatures MEK-based inks to adhere tocoated and plastic labels Optimized software calculates mostefficient path for marking, improvingthroughput Flexible umbilical and small printheadsimplifies integration into labelingequipment With over 175 different inks, Videojetcan partner with you to identify theideal ink for your application11

Flexible materialsSolutions for a wide varietyof web-fed materialsFrom pouches to stick packs to Tyvek , flexible materials are used to package a variety ofpharmaceutical and medical device products. Integration into OEM equipment is oftenessential for reliable, high quality coding. Videojet works closely with leading equipmentproviders to develop solutions that perform well in web-based applications.Thermal TransferOverprinting (TTO) High resolution, wide format printingof alphanumerics, bar codes and singlecolor icons Clutchless ribbon drive maintainsoptimal ribbon tension, virtuallyeliminating coder-related downtimeThermal Inkjet (TIJ)Continuous Inkjet (CIJ)Laser Marking Systems Performs well on sterile medicalpackaging such as Tyvek Capable of coding on uneven surfaces,making it a strong solution for alreadyformed flexible packages Laser coding flexible materials canproduce both high-contrast and discretecodes, depending on the substrate Ultra High Speed printers can createbold, font-like codes to improvelegibility for consumers With CO2, UV and Fiber laser sources,Videojet is equipped to create theoptimal code contrast for your product Configurable with up to 4 stackedprintheads to code multiple packageson the web in a single pass12

CasesCreate traceabilitythroughout the supply chainEffective traceability only works with highly accurate, clearly readable information on yourshipping cases. Many companies are implementing aggregation to track individualproducts through the distribution chain, requiring a coder than can work with machinevision solutions and packing equipment. The Videojet product range can address both yourinternal and external supply chain requirements.Thermal Inkjet (TIJ) Delivers high resolution DataMatrixand linear bar codes Compact printheads integrate easilyinto automated case packingequipmentLabel PrinterApplicator (LPA)Large CharacterMarking (LCM) Create GS1 bar code labels to meetdistributor standards and facilitateaggregation Print high resolution bar codes, logosand other information directly on cases Laser marking a SunLaseTM coatedcase produces a dark black, highresolution print Eliminates costs of labels or pre-printedcases where not precluded by localstandards Ideal for water-resistant coated boxes,as it enables printing without damageto the protective coating Videojet 9550 direct applies labelsimmediately after printing, limitingerrors in serialized applicationsLaser Marking Systems13

Videojet solutionsProven technologies to convey vital informationAs pharmaceutical and medical device manufacturers, we understand you are faced with a great deal ofcomplexity. Packaging materials span a wide range of substrates and coding requirements are driven bynumerous local and regional regulations. Additionally, codes must contain a significant amount ofcontent, often including a machine-readable DataMatrix code. One area you can simplify is with yourcoding provider. Our portfolio of innovative, tested solutions across a variety printing technologiesuniquely positions Videojet to meet your needs.14ThermalInkjet (TIJ)Laser MarkingSystemsContinuousInkjet (CIJ)Ideal for high quality text and bar codeson boxes, cartons, and cases ensuringthat even complex and detailedcodes are clearly readable for yourdownstream partners and consumers.Improve the contrast and readabilityof your codes by permanently etching thematerial surface without physical contact orany need for solvents or extra supplies.Most versatile of all variable technologies,combined with a portfolio of over 175 inks,CIJ prints on nearly any materialand shape.Thermal TransferOverprinting (TTO)Label PrintApplicator (LPA)Large CharacterMarking (LCM)Perfect for your flexible packagingapplications, TTO gives you high qualitycodes and images, from date and timeto DataMatrix codes and logos in avariety of colors.When your customers require labels or youare using darker corrugated cases, LPAautomatically applies labels to cases tohelp ensure high accuracy across a rangeof substrates.Eliminate pre-printed boxes and labels byprinting your supply chain information directlyto case, saving time and reducing costs.

Global Service offeringBroad service offering built with you in mindStart-upPreventiveProtectiveComprehensiveThe perfect introductionto peace of mind,ensu

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types via traversing systems. Optimal coding solutions are part of a holistic approach to pharmaceutical manufacturing, with the printer playing a small but integral role in addressing industry regulations. While physical