Transcription

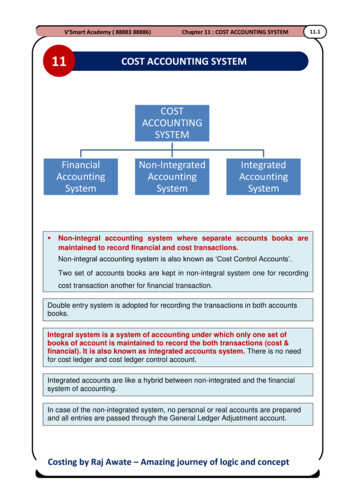

Material Testing

Material TestingReproducible evaluation of material propertiesStatic TestingMaterial response to constant loadingDynamic TestingMaterial response to varying loadingconditions, including magnitude, cycling,and mode

Static Material TestingEvaluation of MaterialStrengthDeformationFractureDesign requirement complianceStandardized TestsTensile testCompression testHardness test

Tensile TestUniaxialA straight line axial force isapplied to a test sample(typically in the y axis)Hounsfield TensometerImage courtesy of NSW Department of Education and TrainingDestructiveForce is applied until sample fails.

Tensile TestStandard Test Sample (dog bone)Ensures meaningful and reproducible results.Uses a uniform cross section.

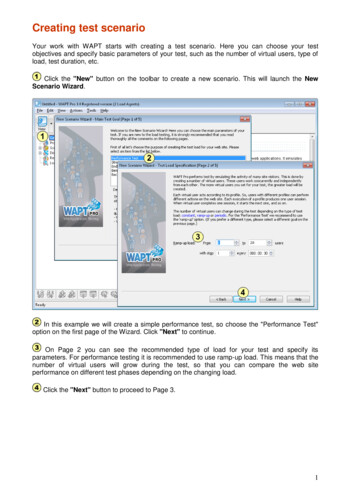

Tensile Test ProcedureDog bone is created to test specificationsDog bone is secured in tester

Tensile Test ProcedureA tension force (F) is applied to the dog boneuntil failure occurs.Simultaneously the applied tension force (F)and dog bone elongation (d) are recorded.FdA plot is created from the stored loadelongation data.

Tensile Test DataAFBdTest sample A and B are 230 red brass. Testsample A has a diameter of 0.125 in. Testsample B has a diameter of 0.375 in.If both samples are tested to failure, will theapplied tension force and elongation be thesame for both tests? NO – Why?

Tensile Test DataLoad-elongation results are dependent uponsample size.Larger sample indicates larger load-elongation.How can test data be manipulated torepresent a material and not an individualtest sample?

Tensile Test DataTo eliminate test results based on samplesize, calculate sample stress.Stress is load per unit area.Divide load (F) by the original test samplecross-sectional area (A0)loadstress areaFσ A

Tensile Test DataCalculate the stress in the dog bone with a430 lb applied force.Fσ Aarea r2area (0.0625 in.) 2area 0.0123in.2430 lb 20.0123 in. 35,000 psi

Tensile Test DataManipulating Elongation ResultsTo eliminate test results based on samplesize, calculate sample strain.Strain (e) – is the amount of stretch per unitlength. Elongation (d) under load, divided by theoriginal length (L0)amount of stretchstrain original length

Tensile Test DataCalculate the strain in the dog bone with anelongation of 0.0625in.amount of stretchstrain original length0.0625in.ε 1.000in. 0.0625

Tensile Test – Stress-Strain Curve

Tensile Test – Stress-Strain CurveProportionalLimitElastic RangeInitial response is linear.Stress and strain are proportionalto one another.

Tensile Test – Stress-Strain CurveProportionalLimitProportional LimitStress at which material starts elongatingmore than the proportion in force.

Tensile Test – Stress-Strain CurveModulus of Elasticity (E)The proportional constant (ratio ofstress and strain).σstressE ε strainA measure of stiffness – The ability of amaterial to resist stretching when loaded.An inherent property of a given material.

Tensile Test – Stress-Strain CurveIf the load is removed, thetest sample will return toits original length.The response is elastic orrecoverable.Exaggerated stretch toillustrate principle

Tensile Test – Stress-Strain CurveElastic Limit Yield PointUppermost stress of elastic behavior .Elastic limit and yield strength mean thesame thing.Elastic limit and proportional limit arealmost identical, with the elastic limit beingslightly higher.

Tensile Test – Stress-Strain CurveResilienceThe amount of energy per unit volumethat a material can absorb while in theelastic range.Area under the stress-strain curve.1 bh2Why would this be important to designers? Hint:car bumper

Tensile Test – Stress-Strain CurveYield PointWhen the elastic limit is exceeded.A very small increase in stressproduces a much greater strain.Most materials do not have a welldefined yield point

Tensile Test – Stress-Strain CurveOffset Yield StrengthDefines the stress required toproduce a tolerable amount ofpermanent strain.Common value is 0.2%

Tensile Test – Stress-Strain CurveYieldPointPlastic DeformationUnrecoverable elongation beyondthe elastic limit.When the load is removed, only theelastic deformation will be recovered.

Tensile Test – Strength PropertiesStress Strain CurvePlastic deformation represents failure.Part dimensions will now be outside ofallowable tolerances

Tensile Test – Stress-Strain CurvePlastic Deformation without neckingElongation continues, some is permanentCross-section decreases along entiresample.Load can continue increasing.

Tensile Test – Stress-Strain CurveTensile StrengthLoad bearing ability peaks.Less force is now required tocontinue elongating.Weakest location begins todecrease in area more than otherlocations – Necking

Tensile Test – Stress-Strain CurvePlastic Deformation with NeckingSample can now be stretched with lessforce.

Tensile Test – Stress-Strain CurveFailureIf continued force is applied,necking will continue until fractureoccurs.DuctilityAmount of plasticity before fracture;The greater the ductility, the more amaterial can be deformed.

Tensile Test – SamplesCompare the material properties of thesethree metal samples.

Tensile Test – Stress-Strain CurveBrittlenessMaterial failure with little or no ductility.Lack of ductility, not lack of strength.

Tensile Test – Stress-Strain CurveToughnessWork per unit volume required to fracture a material.Total area under the stress-strain curve from testinitiation to fracture (both strength and ductility).

Tensile Testing Examplessteel rebar tensile teststeel cylinder tensile testwelded steelconcrete cylindermetal cable

Compression TestStress and strain relationships are similar to tensiontests – elastic and plastic behaviorTest samples must have large cross-sectional areato resist bending and bucklingMaterial strengthens by stretching laterally andincreasing its cross-sectional areaVideo examplesconcrete testcomposite testsoda canconcrete 2

Hardness TestingResistance to permanent deformation.Resistance to scratching, wear, cutting ordrilling, and elastic rebound.Brinell Hardness TestA tungsten carbide ball is held with a 500 lbforce for 15 sec into the material.The resulting crater is measured andcompared.Brinell testing video

Hardness TestingRockwell TestA small diamond-tipped cone is forced intothe test sample by a predetermined loadDepth of penetration is measured andcompared.Rockwell testing video

ResourcesNSW Department of Education and Training (2011). Retrieved Sites/Web/tensile testing/index.htm?Signature %287e02281c-318a-461b-a8ed3394db0c4fe6%29Askeland, Donald R. (1994). The Science and Engineering ofMaterials, 3rd ed. PWS Publishing: Boston.

Dog bone is secured in tester. Tensile Test Procedure A tension force (F) is applied to the dog bone until failure occurs. Simultaneously the applied tension force (F) and dog bone elongation (d) are recorded. A plot is created from the stored load elongation data. F d . Tensile Test Data F d Test sample A and B are 230 red brass. Test sample A has a diameter of 0.125 in. Test sample B has a .