Transcription

Residential GeothermalSaving Energy

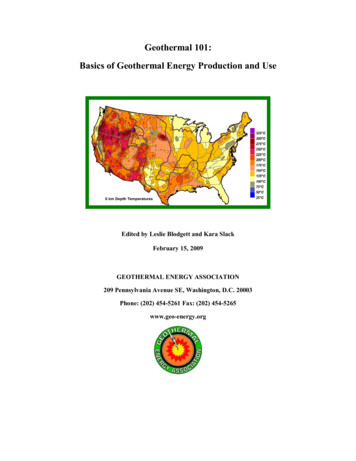

Introduction To Geothermal Subjects to be covered– Energy issues , sources and use– Geothermal opportunities and advantages– Basics of heat pump operation– Types of ground loops– Basic ground loop installation issues

Advantages of Geothermal1. It reduces members energy costs2. It creates a more comfortable environment

ElectricityWhere does it all go?

“Built Environment”HVAC Residential Commercial Institutional 70% of all electric energy consumedOak Ridge National Labs

Residential Energy Usage Heating and air conditioning Lighting Domestic hot water

Residential Energy ConsumptionConventional TechnologiesOver 70% of theenergy consumedby a typical homeis used to meetthermal loads

Ordinary Furnace Efficiency30% of Energy Lost (unusable energy)To Outdoors Through the Chimney1 UnitOf FuelUsed ToGenerateHeat(Purchased)Only 70 - 95% ofEnergy PurchasedGets Into the Home(usable energy)

Air Source Heat Pumpsa mixed blessing

Identified Issue – Winter PeakingSaturday July 24, 2004Monday January 24, 080060060040040020001:0007:0013:00Local Time19:0020000:0006:0012:00Local Time18:0000:00

Geothermal Heat PumpThe Superior Solution Renewable resourceHighly energy efficientAvailable virtually everywhereProvides local employment

Geothermal Heat Pump Efficiency1 unit of energyfrom the gridYields:4-6 units of energyfor the buildingPlus:3-5 units of “free” energyfrom the earth400-600% Efficient

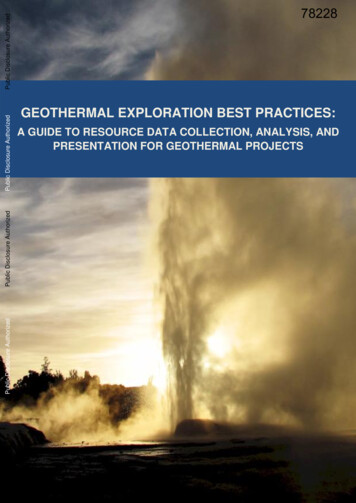

Ground Source HPA Renewable Resource

47% of the solar energy falling on our planetis absorbed by the Earth’s surface

Earth is a better Energy Source

Our Most Abundant Resource Greater than––––––WindPhotovoltaicSolar ThermalCoalNuclearAll fossil fuels combined

Geothermal Heat Pumpsare one of the Most Effectiveand Deployable producing the lowest carbon dioxideemissions, including all source effects, of allavailable space-conditioning technologies(EPA, 1993)

Geothermal Heat Pump Efficiency1 unit of energyfrom the gridYields:4-6 units of energyfor the buildingPlus:3-5 units of “free” energyfrom the earth400-600% Efficient

HVAC Energy Use ComparisonsReduces energy consumption by 50%Geothermal HVAC - HomeConventional HVAC - Home

Basic Geothermal Operation

using Heat Pump TechnologyA geothermal heat pumpcirculates water through asealed underground piping loopwhere it is naturally warmed (orcooled) by the earth

The Earth is the Source of Heat inWinter 72 FOutdoor airdesign temperature:-5 F50 FA geothermal heat pump transfers undergroundheat into the building to provide heating

and an Efficient Place to Reject orStore Heat in Summer 74 FOutdoor airdesign temperature:95 F50 FA geothermal heat pump transfers heat fromthe building into the ground to provide cooling

The Unlimited Energy SourceLots ofEnergy Available150 ft.or more40 BTUs Per Cubic FootSmall Yard Space Large Heat Source40 ft.100 ft.

Geothermal System Components Heat pump Ground loop

Heat Pumps Are All Around Us Air conditioners and airsource heat pumps transferheat from inside houses tothe air outsideHEATHEATRefrigerators transferheat from food intothe kitchen

Ground Source Heat PumpAdvantages No defrost cycle – improved efficiency No outdoor enclosure required – lessexpensive (non-split) Ground moderates EWT – improvedefficiency Quiet operation – no outdoor compressor

Heat Pump Components CompressorRefrigerant reversing valveMetering device – TXVAir heat exchanger – air coilElectrical ControlsFluid heat exchanger – ground loop (Coax)

Heating CycleRefrigeration CoaxCompressorCOAXHWGDischargeOptionTo LoopSource10/10/28/05vcbrev3ToDHW Tank

Ground Loop DesignThe critical component1. Requires specialized training2. Installer needs to be certified3. Installations should be inspected

Geothermal Loop Options Closed loops – Fluid is circulated within aburied, continuous loop– Two types Vertical Horizontal Open Loops – Water is pumped and dumpedor re-injected– Two Types Pond/Lake Well systems

Various Applications

Geothermal Design Basics The ground loop

Equipment Sizing Once Building Loads are determined use ourGeoDesigner Software to assist in the finaldesign.Since the equipment capacity is directlyrelated to the EWT (Entering WaterTemperature), the type of heat source/heatsink must be considered when sizing theequipment.

Ground Source (GSHP) / Closed Loop Benefits––Lower system maintenanceNo additional water requirements Hurdles––Requires more land spaceFirst cost

Closed LoopBasic Design Rules Always prepare a site plan Special consideration should be given tominimum distances from items such as LotLines, Septic/Sewer, Water or other utilities Always check Local, County or StateRegulations for Permits, Documentation,and Inspection Requirements

Closed LoopBasic Design Rules – cont. Fluids will take the path of least resistance, Equal fluid flow between the loops must bemaintained!– Keep all loop lengths within 5% of each other– Use “reverse return” on the loop layout– Use “reverse return” at the manifold

Closed LoopBasic Design Rules – cont. Remove all rocks away from the pipe loop Use wide turns Avoid kinking the pipes during back fill –(reverse return) Always perform a Hydrostatic Pressure TestBEFORE burying the piping system

Horizontal LoopsBasic Design Rules Backhoe or trench excavation.(In areas with any rock - typically backhoe only) Loop Piping installed below frost line– North - 4 - 6 ft max. depth 1 circuit and 3 gpm flow per ton Pipe per ton––North - 600 to 1000 ftSouth - 700 to 1800 ft

Horizontal Loop Types2 feet2 feet2 feet2 feet2 Pipe 1circuit4 Pipe 2circuits2 feet6 Pipe 3circuitsHorizontalSlinky2 feet2 feetFlow Controller IOM Page Figure 144ft pipe/1 ftof trench1 circuitper trench

Backhoe Horizontal Trenching Example

!Think Safety First!Not a good trench to work in, keep the dirt awayfrom trench to reduce danger of cave in

Horizontal Chain Trench - Example

Loop Circuit Header ManifoldReverse Return piping methodDesign Reverse Return Reducing Header Manifoldlengths short to provide ( min.) 2 Feet Per Second (fps)flow rates in all portions of the Header for good airremovalFlow Controller 2 IOMFigure 12 page 13

Vertical Loop installation

Vertical LoopsBasic Rules One bore per ton Bore hole spacing 10 ft minimum One circuit at 3 GPM flow per ton for ¾”and 1” circuits U-Bend pipe sizes ¾” & 1” ID– ASTM PE3408 HD Geothermal PE pipe Many states require bentonite grouting Some locales restrict drilling Bore Hole Depth (typical)– North 150 -200ft/ton– South 250-300 ft/ton

Avg DepthVertical LoopsAvg DepthBoth layouts providethe same Totalamount of pipesurface area Drilling conditions,cost and equipmentmay dictate what youcan do.One PairWhen Loops areshallower thanone ton per loopSeries/Parallel One Pair

Vertical U-Bend with Grout

Multiple Hole Vertical Loop Supply & ReturnPiping exit straight outfrom buildingfoundations-10 feetmin. Header Pit should be10 feet min. frombuilding foundation Simple drawing showstypical bore hole/circuitlayout. Actual Header Manifoldless than 24” long. Parallel circuit piping3/4” & 1.0” dia. Pipesizes

Pond LoopsBasic Design Rules Least expensive ground loopMinimum 1/2 acre and 8 feet deepPond should be within 300’ of structureIn North - need ice cover for good operation– Utilizes 39 deg F water temp (no aeration).– Stagnate water body works best for heating Pipe Circuit length per ton– North and South 300-500 ft/ton

Pond/Lake Loop

Pond Loop LayoutSupply/Return Pipes Exit Perpendicularto Foundation WallTypical Trench/Circuit layout Extended Reverse ReturnHeader/Manifold Parallel Circuit Design 3/4” or 1” HD PE3408 pipe

Antifreeze Materials Methanol– least expensive and best performer, but toxic andflammable Propylene glycol– non-toxic and expensive, but lowest heat transferand unusable in cold loop.Note: Your local Law and Codes may dictateapproved fluid type

Methanol Safety Always mix outdoors Keep away from any open flames Avoid ingestion – highly toxic

Antifreeze containers –(Blue containers best way to identify Methanolverse other fluids.)

ze Percentages by VolumeTypeTemperatureMinimum Freeze Protection Temperatures10 F15 F20 F25 FMethanol25%21%16%10%Propylene Glycol38%25%22%15%12/23/05Rev3vcbFlow Controller IOM Table 4 Page 8

Recommended Freeze ProtectionIOM: D Page 14

Ground Water Open LoopOpen Loop/Well Water Benefits– Lowest first cost– No land requirement– Fast installation for retrofits Hurdles– Requires clean water and maintenance– Larger well pump/pressure tank– Getting rid of water can be difficult– Water Hammer

Loop Flushing Critical step– Cleans any debris from the loop– Flushes air from the system– Mixes antifreeze solution in loop– Pressurizes loop

Flush Cart

Flush Cart Example(Jaquzzi pump – (GeoThermal Supply Co.)

Equipment Sizing Building Heat Gain/Heat Loss is essential forany residential HVAC design, especiallyGeothermal Applications. Whole House methods are fine for theequipment sizing. Room by Room methods should always beused for Duct Sizing.

Comfort1. Homes should be well sealed2. More uniformly heat and cool thanconventional HVAC systems3. Systems are quieter

Equipment Applications Ducted Forced Air Systems– The most common type of heating and cooling distributionsystem is the ducted forced air system, which deliverswarm or cool air to the living space. Water-to-air packagedunits or split system heat pumps are typically connected toa central duct layout, which distributes the conditioned airto the various zones.– As in all forced air systems, properly designed and sealedductwork is crucial to occupant comfort

Questions?

-The most common type of heating and cooling distribution system is the ducted forced air system, which delivers warm or cool air to the living space. Water-to-air packaged units or split system heat pumps are typically connected to a central duct layout, which distributes the conditioned air to the various zones.