Transcription

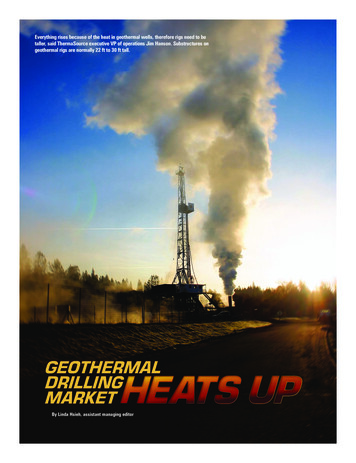

GEOTHERMAL DRILLINGEverything rises because of the heat in geothermal wells, therefore rigs need to betaller, said ThermaSource executive VP of operations Jim Hanson. Substructures ongeothermal rigs are normally 22 ft to 30 ft tall.GEOTHERMALDRILLINGMARKETBy Linda Hsieh, assistant managing editor16September/October 2008D R I L L I N G CONTRACTOR

GEOTHERMAL DRILLINGAS OIL PRICESreach unheardof highs in the 140/bbl range, energysources that have historically beenconsidered too expensive to produceeconomically are getting new leaseson life. Many such energy sources,like wind and solar, tend to reside faroutside the realm of the oil and gasdrilling industry. Geothermal energy,however, stands as one resource thatholds potential opportunities for drilling contractors, especially as thatindustry continues to undergo a significant expansion.far have been concentrated in the West,mostly in California and Nevada. Now,ThermaSource is getting ready to moverigs into Utah and Idaho and plans todo drilling in Oregon and Washingtonin 2009. Outside the US, the companyis drilling on the Caribbean island ofNevis and looking at potential projects in Australia, New Zealand, thePhilippines, Panama, Chile and Peru.These are mostly new drilling projects,Mr Hanson said, and each would entailnew drilling crews and another rigmobilization.Geothermal produces energy off ofheated fluids that reside deep insidethe Earth. Just as wells must be drilledto reach oil or natural gas, geothermalwells must be drilled to reach heatedfluids. As it turns out, the rigs andequipment required to drill geothermalwells are nearly identical to what theoil and gas drilling industry uses.A survey released in August 2008 bythe Geothermal Energy Association(GEA) confirms that geothermal isindeed becoming a high-growth, highdemand market. The GEA surveyshowed continued growth in the number of new geothermal power projectsunder development, with a total of 103developing projects identified.California-based ThermaSource is onethe largest geothermal-focused drillingcontracting companies in the UnitedStates. It was founded in 1980, but fornearly three decades remained strictlyan engineering and consulting firm. In2006, as geothermal drilling amped upand drilling rigs became increasinglyhard to find, ThermaSource decided togo into the rig-owning business, starting with one refurbished rig it boughtfrom the oil/gas drilling market.GEOTHERMAL RIGSSince then, growth for the company hasbeen tremendous, said Jim Hanson,ThermaSource executive vice presidentof operations. The company went fromjust three employees in 2006 to morethan 235 employees in 2008. It alsowent from one rig to eight – plus twomore on order as of August 2008. Italso operates two other rigs not ownedby ThermaSource.This year, the company is evenstarting three service companies –ThermaSource Cementing, mudcompany ChemTech and a yet-to-befinalized mud logging company, MrHanson said. All will focus on geothermal operations.Geothermal drilling also is expandingrapidly geographically, he said. Withinthe United States, most operations soAt the rate that geothermal operatorsare signing up drilling rigs, it appearsunlikely that ThermaSource’s unitswill run out of work anytime soon. Still,if that were to happen, the companycan certainly shift markets relativelyeasily. For the most part, Mr Hansonexplained, geothermal drilling rigs arejust like oil/gas drilling rigs. In fact, allof his rigs could go to work on oil/gasdrilling projects without any modifications, he said.Probably the biggest differencebetween geothermal rig and oil/gasrigs is the height of the substructurerequired. Everything rises because ofthe heat in geothermal wells, therefore rigs need to be taller, even fordrilling 7,000-ft to 11,000-ft wells.Substructures on geothermal rigs arenormally 22 ft to 30 ft tall, he said.The extra height required from rigfloor to the ground often means alarger footprint for geothermal rigs, butMr Hanson noted that ThermaSourcehas been working to make its rigs andoperations as compact as possible.Its newest rig, a Thermal Single rig,was just delivered by MD Cowan inJuly 2008 and can move in 16 loadscompared with 28 loads on older rigs.ThermaSource has been working to make itsrigs and operations as compact as possibleand says it would like to be able to get in a200-ft-by-300-ft location and still do multiplewells.D R I L L I N G CONTRACTORSeptember/October 200817

GEOTHERMAL DRILLINGThermaSource’s 12,000-ft NCPA Rig 1(left) is working in California, and its9,000-ft Rig 101 (above) is working inNevada. Though those two states traditionally encompass the bulk of geothermaldrilling in the United States, new projectsin other states have been identified thatmay soon start up. These include workin Utah, Idaho, Oregon, Washington andothers. A recent survey by the GeothermalEnergy Association cited 103 developingprojects under way in the US.In contrast, air is lighter and won’t plugthe fractures. As it flows up the well, itcan even clean the upper fractures andincrease production, Mr Hanson said.NEW RIGS“We’d like to be able to get in a 200-ftby-300-ft location and still do multiplewells,” he said.Skidding is also a critical capabilitybecause most pads in geothermal drilling are multi-well, usually from three tosix wells per pad. A skiddable rig canmove from one well to the next in aboutthree days, he said. Rigs that can’t skidwould require 7-10 days between wells at 200,000 to 300,000 per rig move.“Our rigs also have an additional 175-200ft of extra electric cabling and lines forpumps, bits and fluid lines that help usto skid,” Mr Hanson added.Additionally, due to environmentalregulations in place in many of the loca-18September/October 2008tions where geothermal drilling is done,attention must be paid to the type ofengines used on the rig. An air qualityact in California, for example, dictatesthat all engines are late-Tier II’s or TierIII’s, “so a lot of the rigs that can operatein Oklahoma or Texas can’t operate inCalifornia,” he said.Pumps and mud capacity is another consideration for geothermal because drilling is usually switched from mud to air(or aerated fluids) in production zones.The geothermal resource is located infractures in the reservoir, he explained,so drilling with mud can plug off thewellbore. If that happens, none of thesought-after geothermal fluid or steammay ever come up the wellbore.Except for the very first rigThermaSource bought in 2006, allother rigs in its fleet were built brandnew. The newest addition, Rig 105, isa Thermal Single rig built by Odessa,Texas-based MD Cowan. It is a variationof the manufacturer’s Super Single rigand designed specifically for geothermaldrilling. It is hydraulic-powered and features a telescoping, 22-ft substructure,two-piece mast and skid-mounted drawworks. The original Super Single’s pipehandling systems, mobility and safetyfeatures and minimal footprint remain,according to MD Cowan.Rigs in the ThermaSource fleet rangefrom 6,000-ft to 20,000-ft capability with450-hp to 2,000-hp drawworks. TheThermal Single will sit in the middle ofthe range, capable of drilling to 12,000 ftwith 1,000-hp drawworks.D R I L L I N G CONTRACTOR

GEOTHERMAL DRILLINGture but not necessarily fluids or permeability, and would use reservoir creationtechniques to create a geothermal reservoir.“(EGS) is manipulating reservoirs tomake it do what you need it to do, notunlike what the oil and gas industrydoes,” said Doug Blankenship, managerof the geothermal research departmentat Sandia National Laboratories. Sandiahas been a long-time partner with theDOE on geothermal research.While there’s no real power beingproduced as of yet with EGS, MrBlankenship said, the base equipmentneeded to make EGS happen is alreadythere. What is still lacking is havingequipment that are more suitable foroperating in extremely high temperatures. Bottomhole temperatures can varywidely in geothermal wells, but 300 C(572 F) is not unheard of.While geothermal drillers used to facethe temperature challenge alone, theadvent of deep and ultra-deep drilling inthe oil and gas wells in recent years hascreated somewhat of a synergy betweenthe two drilling segments. “Temperatureis becoming an issue for everyone,including the oil and gas people,” hesaid. This could become a significantdriver to bring about research and fieldwork needed to develop high-temperature equipment and tools.When drilling rigs became increasingly hard to find in 2006, ThermaSource decided togo into the rig-owning business itself. It now owns eight rigs and is building two more.Two more Thermal Singles are beingbuilt for ThermaSource, with deliveries expected later this year. Mr Hansonadded that, due to strong marketdemand, the company is consideringordering two or three additional ThermalSingles in Q2 2009. Cost for the new rigsare averaging 10.5 million to 11 million.EGSAside from conventional geothermaldrilling exemplified by contractors likeThermaSource, the next generation ofgeothermal is also coming into sight withwhat’s been called enhanced geothermalsystems (EGS), sometimes also called20September/October 2008engineered geothermal systems. The USDepartment of Energy (DOE) believesthat EGS holds significant potential forexpanding the use of geothermal energy.When the DOE announced in June 2008a funding opportunity of 90 millionover four years for advanced geothermalenergy technology and research, EGSwas pointed out as one specific technology that the DOE would like to push tocommercial market.Current geothermal reservoirs beingexploited have a naturally occurringcombination of high temperatures, permeability and fluids. EGS would targetlocations where there is high tempera-High-temperature electronics is clearlyone aspect, with MWD/LWD systems thatcan withstand even higher temperaturesin order to detect fractures downholeand log or monitor temperature, pressure, flow rates and seismic events inwellbores. Current batteries and packers are also problematic at high temperatures and need further work, MrBlankenship said.HT logging tools and sensors was oneof seven critical component R&D needsfor EGS identified by the DOE. Othersinclude: Downhole pumps to augment flowrates by using downhole pumps to addhydraulic head at depth. Fracture characterization to detectand characterize rock mass fracturesystems. Image fluid flow to image fluid in created and/or pre-existing fractures so asto map flow through the reservoir. Stimulation prediction models to simulate a reservoir’s response to stimulation.D R I L L I N G CONTRACTOR

GEOTHERMAL DRILLINGoil and gas wells, too, geothermal costshave gone down, he said.Still, cost per well is undoubtedly stillhigher for geothermal than for oil/gas.ThermaSource’s Mr Hanson pointed outthat in geothermal, larger wells must bedrilled for production – often 8 ½ in. or10 ¾ in. The bigger wellbores are neededin order to achieve high flow rates,which, in turn, are needed to make geothermal wells economical.The high mass flow needed for geothermal wells also means that they areoften produced through casing ratherthan tubing, Mr Blankenship added. Andbecause downhole environments aresometimes highly corrosive because ofhigh H2S levels, expensive titanium casing materials may be needed, again driving up the cost per well.Another potential financial disadvantageof geothermal hits operators specifically– they must wait longer for a return oninvestment. There are no profits from ageothermal well until it is hooked up to apower plant and actually making power,and that could be one to two years fromthe drilling of the well.But once the well is tied to a power plant,Mr Hanson said, it runs 24/7 and, barringa collapse of casing, will run for the lifeof the power plant. Moreover, the geothermal energy itself can power the plant,eliminating any need for outside fuel.To add to the economic viability of geothermal, the US government implemented a permanent investment tax creditin the early ’90s and a production taxcredit around 2005. A significant numberof venture capitalists have found theirway to the “green” industry in the lastfew years, Mr Hanson said, which shouldhelp to boost the geothermal drillingindustry even further.Geothermal drilling rigs are largely similar to oil/gas drilling rigs. They need few, if any,modifications to go from drilling geothermal to drilling for oil or gas. Tracers and tracer interpretation toadapt or develop reservoir tracers and/or tracer interpretation techniques thatprovide information such as fracturesurface area or fracture spacing. Zonal isolation to isolate wellborezones in HPHT environments.THE ECONOMICS OF ITTheoretically, successful EGS wouldmean that geothermal energy can betapped anywhere in the world. Theemphasis is on “theoretically.”22September/October 2008“But then you enter into issues of practicality,” Mr Blankenship said. “Clearly, ifyou drill deep enough, you can tap geothermal energy – remember that the center of the Earth is about the same temperature as the surface of the sun. Butit has to be economically feasible, andthat’s where a lot of the work is going.”Speaking of being economically feasible,Mr Blankenship believes that averagegeothermal well costs have decreasedas drilling efficiency improved with acombination of more experience andtechnology advances. In comparison withThe US is already a leader in geothermal, with about 30% of the world totalonline geothermal capacity. Accordingto the GEA, the US has a total installedcapacity of 2,957.94 MW as of August2008, with power generation occurringin seven states – Alaska, California,Hawaii, Nevada, New Mexico, Utah andIdaho. Oregon and Wyoming may soonbe added to that list.“There’s nothing preventing us fromdrilling geothermal wells today otherthan cost, but we must drive down costand improve the tools available forpeople developing geothermal,” saidSandia’s Mr Blankenship. “There aregoing to be a lot of opportunities in thefuture for drilling contractors.”D R I L L I N G CONTRACTOR

drilling projects without any modifica-tions, he said. Probably the biggest difference between geothermal rig and oil/gas rigs is the height of the substructure required . Everything rises because of the heat in geothermal wells, there-fore rigs need to be taller, even for drilling 7,000-ft to 11,000-ft wells. Substructures on geothermal rigs are