Transcription

SuburbanR V F URNA C EService & TRAININGManual

TABLE OF CONTENTSPAGEFurnace Introduction / Model & Serial Number Information. 3General Service Information / Cautions & Safety Information. 4Furnace Specification Sheet. 5Furnace Removal. 6Installation Information. 8Vent Assembly Installation. 9Return Air & Ducting Information. 19Return Air & Ducting Requirements. 20Electrical Supply Information. 23Furnaces Specifications. 24Sequence of Operation (12 VDC 520820 Fan Control Module Board). 26Sequence of Operation (24 VAC 520947 Fan Control Module Board). 27Sequence of Operation (SHD-2542 Furnace). 28Sequence of Operation (Time Delay Relay Equipped Furnaces). 29Troubleshooting Flow Chart (Furnaces Equipped with Time Delay Relay). 30Troubleshooting Flow Chart (Furnaces Equipped with Fan Control Module Board). 31Service Hints, Diagnosis sheet for (24 VAC Time Delay Relay Equipped Furnaces). 32Furnace Wiring Diagrams. 34SF, SH and SHD-2542 Electrode Gap Specifications & Positioning. 37NT and Park Model Electrode Gap Specifications. 38Maintenance. 39

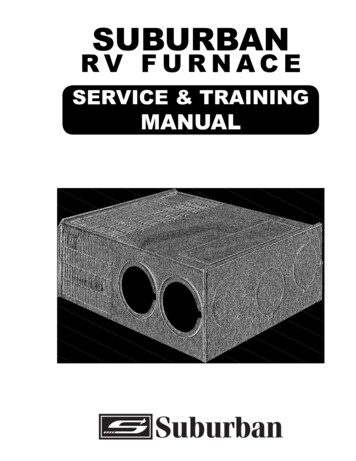

FURNACE INTRODUCTIONSuburban furnaces installed in recreational vehicles are classified as Direct Vent Sealed Combustion Furnaces. A forceddraft furnace utilizes a sealed combustion chamber which is vented to the outside atmosphere. The intake air for combustionis also taken from outdoors and is completely isolated from the room air. A motor is used to drive an impeller wheel to drawintake air into the chamber to support combustion and force the exhaust gases through the furnace chamber to the outsideatmosphere. A second impeller wheel (driven by the same motor yet totally isolated from the combustion air) is used tocirculate room air across the furnace chamber where it is heated. The blower then forces the hot air into the living areaeither through a duct system or through a front grille on the furnace cabinet on direct discharge models.Suburban furnaces operate on 12-volt DC power which is supplied either by a 12-volt battery or a converter system. Arecreational vehicle furnace that is specifically designed for “park model” trailers operates on 120 volts AC. These aredesigned and tested under the same standards as the 12-volt models.Suburban forced draft combustion furnaces used in recreational vehicles are designed for use with Propane gas. Althougha few recreational vehicle furnaces are approved for use with natural gas, one should never attempt to convert such a unitto natural gas unless the conversion is approved by the manufacturer of the furnace.NOTE: Our Service technicians are available to assist you in making repairs or parts replacements from 8:00 AM to5:00 PM Eastern Standard Time, Monday through Friday (except holidays), by calling 423-775-2131 EXT 7102. Emailaddress: SMCSales@suburbanmfg.comMODEL & SERIAL NUMBER INFORMATIONModel and Serial Numbers for Suburban Furnaces are located on a Data Plate attached to the furnace assembly. Belowis an example:MODEL NO. / NUMÉRO DE MODÉLESF-35FSERIAL NO./ NUMÉRO DE SÉRIEMODEL BREAKDOWNSF-35F093102771STOCK NO.INPUT BTU/HR.DEBITCALORIFIQUEOUTPUT BTU/HR.CLARIFIQUEMANIFOLD PRESSUREPRESSION TUBULUREORIFICE SIZEDIMENSION DE L’INJECTEURTYPE OF GASESPECE DE GAZ2332Suburban Furnace35,000 @35,000 BTU10.0” W.C.Front GasSERIAL # BREAKDOWN09310277127,300Year of MFG (2009)10.0” W.C.Week of YR (31)#51LP3Sequential SR#(02771)

GENERAL SERVICE INFORMATIONGas Supply Pressure RequirementsLine Pressure: Minimum 11” WC*, Maximum 14” WC*WC - water columnVoltage RequirementsVoltage DC: 12 volt D.C.Minimum 10.5 volts D.C., Maximum 13.5 volts D.C.Service Tools RequiredManometer gauge/ U-TubeVolt ohm meter capable of testing above 15 ampsModule board tester #641511Gas leak detector OR approved leak check liquidAssorted wrenchesAssorted hand toolsSafety glassesCAUTIONS & SAFETY INFORMATION1.Never use a battery charger to power or test an electronic ignition furnace as they sometimesprovide more than 14.5 DC Volts that could damage the module board.2. Never operate the furnace with the electrode wire disconnected nor with the electrodeassembly removed from the furnace.3. Never use a screwdriver on any part of the electrode assembly while the furnace is inoperation.4. Be certain that the spark from the electrode never reaches the flame sensor portion of theelectrode assembly on remote sense units.5. Install the furnace so electrical components and connections are protected from water.6. Wire the furnace direct to the battery when possible.7. Use two wrenches on gas fittings when tightening gas connections.8. Verify voltage of furnace, do not use 120 volt AC with 12 volt DC.9. Do not modify the furnace in any way.10. Do not vent the furnace to an outside enclosed porch area or where the vent is covered orobstructed.11. Always meet or exceed minimum duct requirements. Also meet the minimum return airrequirements.12. Furnace must be installed and vented correctly. Refer to the Installation Manual for the specificmodel furnace.13. Do not install aftermarket components.4

SUBURBAN RV FURNACESBTU/hINPUTSpec SheetHeightWidthDepthIgnitionShippingWeight12 VDC Direct DischargeNT-16SE16,0009 3/8”9 3/8”21-27 3/4”Electronic27nt-20se19,0009 3/8”9 3/8”21-27 3/4”Electronic279 3/8”9 3/8”22 3/4-29 1/2”Electronic2712 VDC Ducted FurnacesNT-16S16,000NT-20S19,0009 3/8”9 3/8”23 3/8-30 1/8”Electronic27NT-30SP30,00012 1/2”12”23”Electronic40NT-34SP34,00012 1/2”12”23”Electronic40NT-4040,00012 1/2”12”23”Electronic42SF-20/20F20,0007 1/2”17”20”Electronic35SF-25/25F25,0007 1/2”17”20”Electronic35SF-30/30F30,0007 1/2”17”20”Electronic35SF-35/35F35,0007 1/2”17”20”Electronic35SF-42/42F40,0007 1/2”17”20”Electronic35SH-35/35F35,0009 1/4”17”20”Electronic40SH-42/42F40,0009 1/4”17”20”Electronic42SF-20Q/20FQ20,0007 1/2”17”20”Electronic35SF-25Q/25FQ25,0007 1/2”17”20”Electronic35SF-30Q/30FQ30,0007 1/2”17”20”Electronic35SF-35Q/35FQ35,0007 1/2”17”20”Electronic35SF-42Q/42FQ40,0007 1/2”17”20”Electronic35SH-35Q/35FQ35,0009 1/4”17”20”Electronic40SH-42Q/42FQ40,0009 6258ACWDOOR, Optional Access, Colonial White, Standard SF & SFQ Models6258APWDOOR, Optional Access, Polar White, Standard SF & SFQ Models6267ACWDOOR, Optional Access, Colonial White, Standard SH & SHQ ModelsSFV-2020,0007 1/2”17”20”Electronic35SFV-2525,0007 1/2”17”20”Electronic35SFV-3030,0007 1/2”17”20”Electronic35SFV-3535,0007 1/2”17”20”Electronic35SFV-4240,0007 1/2”17”20”Electronic3525/40,0009 1/4”17”20”Electronic4412 1/2”12”23”Electronic46SHD-2542120 VAC Park Model FurnacesP-4040,000AccessoriesDescription050733Duct Cover050715Duct Collar 4”051240Duct Collar 2”280552Rain Shield062164Bottom Duct Gasket, NT-24/30/34SP, NT-40, P40070853Bottom Duct Gasket, SF Models EXCEPT SF-42/42F520009Bottom Duct Kit W/Gasket, NT-24/30/34SP, NT-40, P40520576Bottom Duct Kit W/Gasket, SF Models EXCEPT SF-42/42F, SH-35/35F520753Bottom Duct Kit W/Gasket and Door, SF-42/42F520864Bottom Duct Kit W/Gasket, SH-42/42F, SHD-25425

FURNACE REMOVALTo replace parts or service the SUBURBAN family of RV furnaces, it is necessary to follow thesesteps:DD-17DSI1.2.3.4.5.6.7.8.9.Turn off gas and power, then disconnect gas and power supply at the furnace. Label wires as necessary.Remove the vent cap assembly by removing applicable screws.Remove the cabinet front two (2) screws.Remove the applicable screws securing the furnace to the coach floor.Remove duct from side of furnace, if equipped.Remove the furnace from the cabinet area to gain access to combustion chamber and applicable parts.Some parts can be accessed without removal of the complete furnace.To re-install, reverse this procedure.Rewire applicable wires and perform a leak test on all fittings. Perform a drop pressure test.NT-12/16/20S1.2.3.4.5.Turn off gas and power, then disconnect gas and power supply at the furnace. Label wires as necessary.Remove the vent cap assembly by removing applicable screws.Remove the cabinet front two (2) screws.Remove the (1) one tie down screw securing the chamber to the cabinet.Remove the furnace from the cabinet by pulling chamber outward completely to gain access to all controls andapplicable parts.6. To re-install, reverse this procedure.7. Rewire applicable wires and perform a leak test on all fittings. Perform a drop pressure test.NT-12/16/20SE1.2.3.4.5.Turn off gas and power, then disconnect gas and power supply at the furnace. Label wires as necessary.Remove the vent cap assembly by removing applicable screws.Remove the cabinet front two (2) screws.Remove the (2) two tie down screws securing the chamber to the cabinet.Remove the furnace from the cabinet by pulling chamber outward completely to gain access to all controls andapplicable parts.6. To re-install, reverse this procedure.7. Rewire applicable wires and perform a leak test on all fittings. Perform a drop pressure test.NT-24/30/34SP and NT-401. Turn off gas and power, then disconnect gas and power supply at the furnace. Label wires as necessary.2. Remove the vent cap assembly by removing applicable screws and one (1) flue retaining screw. Not applicable toNT-40.3. Remove the cabinet front two (2) screws.4. Remove the (2) two tie down screws securing the chamber to the cabinet.5. Remove the furnace from the cabinet by pulling chamber outward completely to gain access to all controls andapplicable parts.6. To re-install, reverse this procedure.7. Rewire applicable wires and perform a leak test on all fittings. Perform a drop pressure test.6

FURNACE REMOVALSF-20/25/30/35/42, SF-20Q/25Q/30Q/35Q/42Q, SFV-20/25/30/35/42,SH-35/42 and SHD-25421. Remove the vent cap assembly from the outside access door by removing applicable screws, also the four (4)screws retaining the door to the frame. Remove the door to gain access to the furnace.2. Turn off gas and power, then disconnect gas and power supply at the furnace. Label wires as necessary.3. Remove the (1) one tie down screw securing the chamber to the cabinet.4. Remove the furnace from the cabinet by pulling chamber outward completely to gain access to all controls andapplicable parts.5. To re-install, reverse this procedure.6. Rewire applicable wires and perform a leak test on all fittings. Perform a drop pressure test.SF-20/25/30/35/42F, SF-20FQ/25FQ/30FQ/35FQ/42FQ,SFV-20/25/30/35/42F and SH-35/42F1.2.3.4.5.Turn off gas and power, then disconnect gas and power supply at the furnace. Label wires as necessary.Remove the vent cap assembly by removing applicable screws.Remove the cabinet front two (2) screws.Remove the (1) one tie down screw securing the chamber to the cabinet.Remove the furnace from the cabinet by pulling chamber outward completely to gain access to all controls andapplicable parts.6. To re-install, reverse this procedure.7. Rewire applicable wires and perform a leak test on all fittings. Perform a drop pressure test.NOTE: ON SFV MODELS, REMOVE EXTRA SCREWS FOR CHAMBER REMOVAL.P-30S and P-401. Turn off gas and power, then disconnect gas and power supply at the furnace. Label wires as necessary.2. Remove the vent cap assembly by removing applicable screws and one (1) flue retaining screw. (Not applicableto P40.)3. Remove the cabinet front two (2) screws.4. Remove the (2) two tie down screw securing the chamber to the cabinet.5. Remove the furnace from the cabinet by pulling chamber outward completely to gain access to all controls andapplicable parts.6. To re-install, reverse this procedure.7. Rewire applicable wires and perform a leak test on all fittings. Perform a drop pressure test.7

INSTALLATION INFORMATIONThere are several important aspects of the installation which will pertain to all Suburban forced draftfurnaces, regardless of the model or the method in which they are installed. They are:1.2.3.4.5.Selecting a LocationVentingReturn AirDuctingElectrical SupplyRefer to the furnace installation manual for all installation requirements.Location and Installation- Locate the furnace near lengthwise center of the coach. Choosea location for installation out of the way of wires, pipes, etc. which might interfere with theinstallation. Adhere to the minimum clearances from cabinet to combustible construction aslisted in the installation manual for your specific furnace model. Secure furnace cabinet tothe floor of the coach using the holes provided in the furnace cabinet.Figure 18

VENT ASSEMBLY INSTALLATIONVenting- By definition of a Direct Vent Sealed Combustion Furnace, it must be vented to the outsideatmosphere and also draw combustion air from outdoors. Therefore, it is imperative that the vent beunobstructed and there must be a seal between the exhaust and intake (caulking) . Refer to the ventassembly installation in the manual. The vent must be straight. There can be no offsets or turns inthe vent. All vent tubes which connect to the furnace exhaust and intake must overlap a minimumof 1/2” on intake, and 1 1/4” on exhaust. Check your furnace model number for vent installationprocedures. Vents cannot be altered as supplied from the factory.OUTSIDE SKIN (PANEL)VENT CAP ANDEXHAUST TUBETUBE, INTAKE AIRWITH GASKETVENT CAP ANDEXHAUSTTUBE, AIR INTAKEWITH GASKETCAULK BEHIND VENT CAP AS SHOWN TO SEALBETWEEN EXHAUST AND INTAKE AND TOPREVENT MOISTURE INSIDE FURNACECOMPARTMENT. APPLY CAULKING GENEROUSLYAROUND PERIMETER OF VENT CAP AND ACROSSCENTER AS SHOWN. CENTER PUTTY STRIP ISESSENTIAL.SEE DETAIL "A"(2) 2 1/4"DIA. HOLESDETAIL "A"REMOVABLE PANEL OFCOACH WALL MUSTSEAL WATER TIGHTOUTSIDE SKIN (PANEL)ELECTRICALCONNECTIONFRONTGAS CONNECTIONINSIDE WALLFURNACE CABINET2" MAXIMUM WALL THICKNESSFigure 2 SF & SFQ MODELSVENT CAP ANDEXHAUST TUBEOUTSIDE SKIN (PANEL)TUBE, INTAKE AIRWITH GASKETTUBE, AIR INTAKEWITH GASKETVENT CAP ANDEXHAUST3 3"83 13"16CAULK BEHIND VENT CAP AS SHOWN TO SEALBETWEEN EXHAUST AND INTAKE AND TOPREVENT MOISTURE INSIDE FURNACECOMPARTMENT. APPLY CAULKING GENEROUSLYAROUND PERIMETER OF VENT CAP AND ACROSSCENTER AS SHOWN. CENTER PUTTY STRIP ISESSENTIAL.SEE DETAIL "A"(2) 2 1/4"DIA. HOLESCL"13 6617"88DETAIL "A"3"4179 3"4REMOVABLE PANEL OFCOACH WALL MUSTSEAL WATER TIGHTOUTSIDE SKIN (PANEL)ELECTRICALCONNECTIONFRONTGAS CONNECTIONINSIDE WALLFURNACE CABINETFigure 2A SH MODELS92" MAXIMUM WALL THICKNESS

VENT ASSEMBLY INSTALLATIONFURNACETIE-DOWN SCREW(FURNACE TO CABINET)OUTSIDE SKINCAULK ALONG THE EDGE OF THE CUTOUT(ALL THE WAY AROUND)ANCHOR FURNACE CABINET TO COACHFLOOR (2) PLACES AS ILLUSTRATEDBACK OF CABINET MUST BUTTAGAINST THIS EDGE OF THE FRAME98 32DOOR FRAMECAULK BEHIND VENT CAP AS SHOWN TO SEALBETWEEN EXHAUST AND INTAKE AND TO PREVENTMOISTURE INSIDE FURNACE COMPARTMENT. APPLYCAULKING GENEROUSLY AROUND PERIMETER OFVENT CAP AND ACROSS CENTER AS SHOWN. CENTERPUTTY STRIP IS ESSENTIAL.ELECTRICALCONNECTIONAIR INTAKE TUBEWITH GASKET718 32GASCONNECTIONCL2"MAX.79 646 SCREWS(SUPPLIED)4 SCREWSDOOR MOUNTINGSECURE FRAME TOOUTER PANEL WITH SCREWS(16 PLACES)FURNACE ACCESS DOORVENT CAP & EXHAUST TUBEFigure 3 SF & SFQ MODELSFURNACETIE-DOWN SCREW(FURNACE TO CABINET)OUTSIDE SKINCAULK ALONG THE EDGE OF THE CUTOUT(ALL THE WAY AROUND)ANCHOR FURNACE CABINET TO COACHFLOOR (2) PLACES AS ILLUSTRATEDBACK OF CABINET MUST BUTTAGAINST THIS EDGE OF THE FRAME11032DOOR FRAMECAULK BEHIND VENT CAP AS SHOWN TO SEALBETWEEN EXHAUST AND INTAKE AND TO PREVENTMOISTURE INSIDE FURNACE COMPARTMENT. APPLYCAULKING GENEROUSLY AROUND PERIMETER OFVENT CAP AND ACROSS CENTER AS SHOWN. CENTERPUTTY STRIP IS ESSENTIAL.ELECTRICALCONNECTIONAIR INTAKE TUBEWITH GASKET718 32GASCONNECTIONCL2"MAX.79 646 SCREWS(SUPPLIED)4 SCREWSDOOR MOUNTINGSECURE FRAME TOOUTER PANEL WITH SCREWS(16 PLACES)FURNACE ACCESS DOORFigure 3A SH & SHD-2542 MODELS10VENT CAP & EXHAUST TUBE

VENT ASSEMBLY INSTALLATIONSF-20F, SF-25F, SF-30F, SF-35F, SF-42F, STANDARD VENT INSTALLATIONX"234DIA.FRONT GASHOOKUPCL INTAKE234DIA.TRAILER SKINCL EXHAUSTINTAKE: 1/2" MINIMUM OVERLAPEXHAUST: 1 1/4" MINIMUM OVERLAP1"MOUNTINGSURFACEVENT CAPX" DIMENSION EXTENSION TUBES KIT NO.0" TO 1 1/2"520767USE VENT SUPPLIED WITH FURNACE1 1/2" TO 3"5207683" TO 4 1/2"4 1/2" TO 7 1/2" 5209685205517 1/2" TO 9"NEVER INSTALL THE EXHAUST TUBE WITH LESS THAN1 1/4" OVERLAP, OR THE INTAKE TUBE WITH LESS THAN1/2" OVERLAP.STANDARD VENT ASSEMBLY FURNISHED WITH FURNACE.SPECIAL EXTENSION TUBES, IF NEEDED, MUST BEORDERED SEPARATELY. EXTENSION KITS COME WITHCOMPLETE INSTALLATION INSTRUCTIONS.Figure 4 SF & SFQ MODELSSH-35F, SH-42F STANDARD VENT INSTALLATION234DIA.FRONT GASHOOKUPCL INTAKETRAILER SKIN234DIA.X"CL EXHAUSTINTAKE: 1/2" MINIMUM OVERLAPEXHAUST: 1 1/4" MINIMUM OVERLAP1"MOUNTINGSURFACEVENT CAPX" DIMENSIONEXTENSION TUBES KIT NO.0" TO 1 1/2"1 1/2" TO 3"3" TO 4 1/2"4 1/2" TO 7 1/2"7 1/2" TO 9"520767USE VENT SUPPLIED WITH FURNACE520768520769520551NEVER INSTALL THE EXHAUST TUBE WITH LESS THAN 1 1/4" OVERLAP,OR THE INTAKE TUBE WITH LESS THAN 1/2" OVERLAP.STANDARD VENT ASSEMBLY FURNISHED WITH FURNACE. SPECIALEXTENSION TUBES, IF NEEDED, MUST BE ORDERED SEPARATELY.EXTENSION KITS COME WITH COMPLETE INSTALLATION INSTRUCTIONS.Figure 4A SH Models11

VENT ASSEMBLY INSTALLATION (SFV MODELS)* CUTOUT FOR FURNACE ACCESS DOOR FRAMEGAS CONNECTION(REAR)ELECTRICAL CONNECTIONGAS CONNECTION(FRONT)CUTOUT AS VIEWED FROM OUTSIDER.V.SPACERS ON LEFT SIDEOF FURNACE ARE FLUSHWITH LEFT SIDE OFCUTOUT8.281*CABINET MOUNTINGBRACKETCL2.000" MAX.TIE-DOWN SCREW(FURNACE TO CABINET)OUTSIDE SKIN**.220MIN.DOOR FRAME3.3752.062SECURE FRAME TO OUTER PANELWITH SCREWS (16 PLACES)CABINET MOUNTINGBRACKET(ONE PER SIDE)*18.218BRACKET2.060BACK OF CABINET MUST BUTTAGAINST THIS EDGE OF FRAMEFLOORFURNACECL*8.281"FURNACE.375** SEE NOTCH DETAIL AFLOORFURNACE ACCESS DOOR4 SCREWSDOOR MOUNTINGANCHOR FURNACETO FLOOR USING(2) #10 X 3/4SCREWS PROVIDED**NOTCH DETAIL**FLOOR AND OUTER SKINMUST BE NOTCHED ASSHOWN BELOW.CAULK ALONG THE EDGE OF THECUTOUT (ALL THE WAY AROUND))0M.226 SCREWS SUPPLIEDHTEIG(HIN.CAULK BEHIND VENT CAP AS SHOWN TO SEAL BETWEEN EXHAUSTAND INTAKE AND TO PREVENT MOISTURE INSIDE FURNACECOMPARTMENT. APPLY CAULKING GENEROUSLY AROUND PERIMETEROF VENT CAP AND ACROSS CENTER AS SHOWN. CENTER PUTTY STRIPIS ESSENTIAL.*18.218".625MIN.AIR INTAKE TUBE WITH GASKETVENT CAP & EXHAUST TUBE(TH138.3 IN. DTH)M WI(ICKNESSANCHOR BRACKETTO FLOOR USING(2) #10 X 3/4SCREWS PROVIDED)CABINET SUPPORT BRACKETWELDED TO CABINETDETAIL AFigure 5SFV-20F, 25F, 30F, 35F, 42F VENT INSTALLATION FOR VERTICAL MOUNTBRACKET REAR VERTICALMOUNTING-USE IF POSSIBLE"X"NEVER INSTALL THE EXHAUST TUBE WITH LESSTHAN 1 1/4" OVERLAP, OR THE INTAKE TUBEWITH LESS THAN 1/2" OVERLAP.CLSUBURBANDO NOT BLOCK OPENINGSHOTEXHAUST & INTAKETRAILER SKIN23 4"DIA. TYP.1.000VENT CAPGASKET, BOTTOM DUCTX" DIMENSIONEXTENSION TUBES KIT NO.0" TO 1 1/2"1 1/2" TO 3"3" TO 4 1/2"4 1/2" TO 7 1/2"7 1/2" TO 9"520767MOUNTINGSURFACEBRACKET, CABINET MOUNTING(ONE PER SIDE)USE VENT SUPPLIED WITH FURNACE520768520769520551STANDARD VENT ASSEMBLY FURNISHED WITH FURNACE. SPECIAL EXTENSION TUBES, IF NEEDED, MUST BEORDERED SEPARATELY. EXTENSION KITS COME WITH COMPLETE INSTALLATION INSTRUCTIONS.Figure 5A12

VENT ASSEMBLY INSTALLATION (SFV MODELS)RAIN SHIELD INSTALLATION:APPLY CAULKING BETWEEN RV SKIN AND BACK OF RAIN SHIELD.POSITION RAIN SHIELD AS ILLUSTRATED. APPLY A SECOND LAYEROF CAULKING OVER RAIN SHIELD AND BEHIND VENT CAP ASILLUSTRATED. FOLLOW INSTRUCTIONS FOR CAULKING VENT.CAULK BEHIND VENT CAP AS SHOWN TO SEAL BETWEENEXHAUST AND INTAKE AND TO PREVENT MOISTURE INSIDEFURNACE COMPARTMENT. APPLY CAULKING GENEROUSLYAROUND PERIMETER OF VENT CAP AND ACROSS CENTERAS SHOWN. CENTER PUTTY STRIP IS ESSENTIAL.REMOVABLE PANEL OF COACH WALLMUST SEAL WATER TIGHTVENT CAP & EXHAUST TUBEOUTSIDE SKIN (PANEL)TUBE, INTAKE AIRWITH GASKETDETAIL "A"8.000"SEE DETAIL "A"VENT CAP & EXHAUST TUBE(SECURE WITH 6 SCREWS)2.062"OUTSIDE SKIN (PANEL)18.750"GAS CONNECTION (REAR) (SFV-35)ELECTRICAL CONNECTIONFURNACE CABINETTUBE, AIR INTAKEWITH GASKETGAS CONNECTION (FRONT) (SFV-35F)3.375"2.060"FRONTCLCUTOUTCLFURNACEINSIDE WALLREMOVABLE PANELRIGHT SIDEOF CUTOUT(2) 2.250 DIA. HOLES2.000" MAX. WALLTHICKNESS2.060ANCHOR FURNACE TO FLOOR USING THE(4) #10 X 3/4 SCREWS PROVIDED3.750CUT OUT AS VIEWEDFROM INSIDE R.V.FLOORSECURE CABINET MOUNTING BRKTS TO CABINETWITH (2) #8 X 1/2 SCREWSFigure 6SFV-20, 25, 30, 35, 42 VENT INSTALLATION FOR VERTICAL MOUNTBRACKET REAR VERTICALMOUNTING-USE IF POSSIBLE"X"NEVER INSTALL THE EXHAUST TUBEWITH LESS THAN 1 1/4" OVERLAP, ORTHE INTAKE TUBE WITH LESS THAN1/2" OVERLAP.CLSUBURBANDO NOT BLOCK OPENINGSHOTEXHAUST & INTAKETRAILER SKIN23 4 "DIA.TYP.1.000VENT CAPGASKET, BOTTOM DUCTX" DIMENSION0" TO 1 1/2"1 1/2" TO 3"3" TO 4 1/2"4 1/2" TO 7 1/2"7 1/2" TO 9"EXTENSION TUBES KIT NO.USE VENT SUPPLIED WITH KET, CABINET MOUNTING(ONE PER SIDE)STANDARD VENT ASSEMBLY FURNISHED WITH FURNACE. SPECIAL EXTENSION TUBES, IFNEEDED, MUST BE ORDERED SEPARATELY. EXTENSION KITS COME WITH COMPLETEINSTALLATION INSTRUCTIONS.Figure 6A13

VENT ASSEMBLY INSTALLATION (NT SERIES)VENT TUBE INSTALLATION"X"Y"1 3/8"VENT TUBE (EXHAUST) 8" X 2" O.D.TRAILOR SKINVENT CAP2 1/4"DIA.VENT TUBE (INTAKE) SEE CHART2 1/4"DIA.7 1/2"1 1/4" MIN. OVERLAPON EXHAUSTMOUNTING SURFACE1/2" MIN. OVERLAPOF INTAKE TUBE21"PART NO. INTAKE TUBE LENGTH ONLY "X" DIMENSIONX0507112" O.D. X 2 3/4" SPECIAL21" TO 23 1/4"X0507122" O.D. X 5" *STANDARD23 1/4" TO 25 1/2"X0507082' O.D. X 7 1/4" SPECIAL25 1/2" TO 27 3/4"STANDARD TUBE FURNISHED WITH FURNACE.THE SPECIAL TUBES, IF NEEDED, MUSTBE ORDERED.NEVER INSTALL VENT TUBESWITH LESS THAN 1/2" OVERLAPON INTAKE & 1 1/4" ON EXHAUSTFigure 8NT 12/16/20SEINSTALLING VENT CAPIMPORTANT: VENT CAP AND TUBE ASSY. MUST BEINSTALLED FROM OUTSIDE OF COACH.TRAILER SKINOUTLINE OF FURNACEHOLE DIA. IN OUTER SKIN MAY BE 2 1/4"IF OPENING CUT IN COMBUSTIBLE WALLIS CUT AS ILLUSTRATED IN FIGURES 3OR 4. HOLE DIA. MUST BE 2 3/4" IF THE4 X 7 1/2" OPENING AS SHOWN IN FIGURE4 IS NOT CUT THROUGH COMBUSTIBLEWALL.CAULK BEHIND VENT CAP AS SHOWN TO SEALBETWEEN EXHAUST AND INTAKE AND TO PREVENTMOISTURE INSIDE FURNACE COMPARTMENT.APPLY CAULKING GENEROUSLY AROUNDPERIMETER OF VENT CAP AND ACROSS CENTERAS SHOWN. CENTER PUTTY STRIP IS ESSENTIAL.INTAKE TUBEFigure 9NT 12/16/20S and SE14VENT CAP &EXHAUST TUBEASSEMBLY

VENT ASSEMBLY INSTALLATION (NT SERIES)VENT TUBE INSTALLATION NT-16S"X"Y"3/8"TRAILOR SKINVENT CAPVENT TUBE (EXHAUST) 8" X 2" O.D.2 1/4"DIA.VENT TUBE ASSY. (INTAKE) SEE CHART2 1/4"DIA.7 1/2"1 1/4" MIN. OVERLAPMOUNTING SURFACE1/2" MIN. OVERLAPPART NO.INTAKE TUBE LENGTH ONLYX0509062' O.D. X 3" STANDARD22 3/4" TO 25"X0507122' O.D. X 5" SPECIAL25" TO 27 1/4"X0507082' O.D. X 7 1/4" SPECIAL27 1/4" TO 29 1/2"NEVER INSTALL THE EXHAUST TUBE WITH LESSTHAN 1 1/4" OVERLAP, OR THE INTAKE TUBE WITHLESS THAN 1/2" OVERLAP."X" DIMENSIONSTANDARD TUBE FURNISHED WITH FURNACE. THESPECIAL TUBES, IF NEEDED, ARE TO BE ORDERED.Figure 10NT 12/16SVENT TUBE INSTALLATION NT-20S"X"Y"1"VENT TUBE (EXHAUST) 8" X 2" O.D.TRAILOR SKINVENT CAP2 1/4"DIA.VENT TUBE ASSY. (INTAKE) SEE CHART2 1/4"DIA.7 1/2"1 1/4" MIN. OVERLAPMOUNTING SURFACE1/2" MIN. OVERLAPPART NO.INTAKE TUBE LENGTH ONLY "X" DIMENSIONX0509062' O.D. X 3" STANDARD23 3/8" TO 25 5/8"X0507122' O.D. X 5" SPECIAL25 5/8" TO 27 7/8"X0507082' O.D. X 7 1/4" SPECIAL27 7/8" TO 30 1/8"NEVER INSTALL THE EXHAUSTTUBE WITH LESS THAN 1 1/4"OVERLAP, OR THE INTAKETUBE WITH LESS THAN 1/2"OVERLAP.STANDARD TUBE FURNISHED WITH FURNACE.THE SPECIAL TUBES, IF NEEDED, ARE TOBE ORDERED.Figure 11NT 20S15

VENT ASSEMBLY INSTALLATION (NT SERIES)VENT CAP*3 1/2" FROM CENTER LINEOF INTAKE TO CENTER LINEOF EXHAUST** 7 1/2" FROM CENTER LINEOF INTAKE TO FLOORTHE SCREW PROVIDEDMUST BE USED ON ALLINSTALLATIONSTWO 2 1/4" DIA HOLES13INSIDE WALLOUTSIDE SKINEXHAUST23/4AIR INTAKEFURNANCE3112/2 *6327/167/71/2 * *FLOORWASHERGAS FITTINGMAXIMUM WALL THICKNESS 3"NOTE: 0" CLEARANCE PERMISSIBLEAT REAR OF FURNACE FOR A WIDTHOF 3" MAXIMUMGASKET: PEEL OFF PROTECTIVE PAPERTO EXPOSE THE ADHESIVE SURFACE.ATTACH GASKET TO WASHER. PLACEWASHER OVER GAS FITTING. THEGASKET SHOULD SEAL AGAINST CABINETWHEN GAS FITTING IS THREADEDINTO POSITION.ANCHOR TO FLOORFigure 12NT 24/30/34SP P30SMAXIMUM WALL THICKNESSFOR THIS UNIT IS 2 1/4"SEE FIGURE 4 IF MORE THAN2 1/4" WALL THICKNESS.CAULK BEHIND VENT CAP AS SHOWN TOSEAL BETWEEN EXHAUST AND INTAKEAND TO PREVENT MOISTURE INSIDEFURNACE COMPARTMENT. APPLYCAULKING GENEROUSLY AROUNDPERIMETER OF VENT CAP AND ACROSSCENTER AS SHOWN. CENTER PUTTYSTRIP IS ESSENTIAL.EXTENSION TUBE MIN./MAX. LENGTH(Extension Tube Range)KIT NUMBER5204982 1/4” to 3 1/8”5204993 1/8” to 4 7/8”5205004 7/8” to 7”520501INTAKE TUBE2 3/4" DIA. TWO HOLES.ANCHOR VENT ASSEMBLYWITH THE SCREW PROVIDED.BE SURE SCREW ENGAGESFURNACE EXHAUST TUBEAND IS PULLED SECURE.Figure 13NT 24/30/34SP P307” to 9”Figure 14NT 24/30/34SP P30EXTENSION TUBE MIN./MAX. LENGTH(Extension Tube Range)KIT NUMBER5205932 1/4” to 3 1/8”5205943 1/8” to 4 7/8”5205954 7/8” to 7”5205967” to 9”Figure 15NT 40 P4016

VENT ASSEMBLY INSTALLATION (NT40 & P40)HEAT SHIELD COLLAREXHAUST* 3.50" FROM CENTER LINE OF INTAKE TOCENTER LINE OF EXHAUST** 7.50" FROM CENTER LINE OF INTAKE TO FLOORVENT CAP(2) 3.00" DIA. HOLES13INSIDE WALL1/8OUTSIDE SKIN23AIR R SUPPLYWIRESRBANMAXIMUM WALL THICKNESS 2.25"NOTE: 0" CLEARANCE PERMISSIBLEAT REAR OF FURNACE FORA WIDTH OF 2.25" MAXIMUM.GAS FITTINGANCHOR TO FLOORFigure 16NT40HEAT SHIELD COLLAREXHAUST* 3.50" FROM CENTER LINE OF INTAKE TOCENTER LINE OF EXHAUST** 7.50" FROM CENTER LINE OF INTAKE TO FLOORVENT CAP(2) 3.00" DIA. HOLES13INSIDE WALL1/8OUTSIDE SKIN23AIR INTAKE/4FURNACE127/1631/2 *67/3271/2 * *ROOFLSUBUPOWER SUPPLYWIRESTHERMOSTAT WIRESRBANGAS LINESHUT-OFF VALVEGAS LINEELBOWANCHOR TO FLOORFigure 17P4017MAXIMUM WALL THICKNESS 2.25"NOTE: 0" CLEARANCE PERMISSIBLEAT REAR OF FURNACE FORA WIDTH OF 2.25" MAXIMUM.

VENT ASSEMBLY INSTALLATION (NT40 & P40)*3 1/2" X 7" CUTOUTTHRU COMBUSTIBLECONSTRUCTION* 3 1/2"MAXIMUM WALL THICKNESS FOR THISTYPE INSTALLATION IS2 1/4"3 1/2"2 1/4"MAX.CAULK BEHIND VENT CAP ASSHOWN TO SEAL BETWEENEXHAUST AND INTAKE AND TOPREVENT MOISTURE INSIDEFURNACE COMPARTMENT. APPLYCAULKING GENEROUSLY AROUNDPERIMETER OF VENT CAP ANDACROSS CENTER AS SHOWN.CENTER PUTTY STRIP ISESSENTIAL.HEAT SHIELD COLLAR7 1/2"WARNING:COLLAR MUST BE ATTACHEDTO ASSURE SAFEOPERATION. DO NOTREMOVE COLLAR.VENT CAP*7"2 3/4"3" DIA. (2) HOLES(OUTER SKIN)EXHAUST TUBEINTAKE TUBECENTERLINE OF FURNACEINSTALLATIONFigure 18NT40 P40VENT ASSEMBLY INSTALLATION (DD SERIES)Note: Vent cap must be installed on DD Furnace when bench testing.Figure 1918

RETURN AIRThe cabinet that the furnace may be installed in will have louvers or openings for the return air back to the furnace. Whenthe furnace is installed, it is imperative that the return air louvers on the furnace cabinet opening are not obstructed.Usually, these furnaces are installed under a counter, sofa or bed in order to be out of the way. A grille or opening mustbe built into the cabinetry or into the base area of the sofa or bed. Return air from the living area of the trailer is drawn inthrough the grille and into the return air openings in the furnace cabinet. Figure 20 illustrates the return air circulation of thefurnace. Note: Refer to the installation manual for the minimum return air area for your specific furnace model.Insufficient return air will cause the furnace to overheat and cycle on limit. Another symptom of a return air problem is:1. Furnace seems to run continuously in an effort to satisfy the thermostat.OPENING FOR RETURN AIRSPACER BUMPSSPACER BUMPSOPENING FORRETURN AIR0" TO SPACERFURNACE0" TO SPACERMAINTAIN A 1/4" INCH CLEARANCEWHERE DUCTS PASS THROUGHA CABINET WALL. UL LISTED DUCTMATERIALS CAN BE 0" CLEARANCE.THE TOTAL, FREE, UNOBSTRUCTED RETURN AIR OPENINGTO THE FURNACE MUST NOT BE LESS THAN THE MINIMUMSPECIFIED.Figure 20SF 20F/25F/35F/42FDUCTINGSuburban furnaces require that a minimum duct area be maintained throughout entire duct system including throughthe register. It is very important to adhere to the minimum duct area in order to keep the furnace from cycling on highlimit and to assure proper operation of the sail switch (sometimes referred to as a microswitch.) NOTE: (Refer to theinstallation manual for the minimum ducted square inches area foreach model.)NOTE: Ducts terminating in a dead air space (like holding tankcompartments or cargo areas (Toy Boxes) with no means for returnair recirculation should

6. Wire the furnace direct to the battery when possible. 7. use two wrenches on gas fittings when tightening gas connections. 8. Verify voltage of furnace, do not use 120 volt AC with 12 volt DC. 9. Do not modify the furnace in any way. 10. Do not vent the furnace to an outside enclosed porch area or where the vent is covered or obstructed. 11.