Transcription

CEDAR CREEKWastewater Treatment Facility

Where does the waste originatefrom? Private homesBusinessesCondominium complexesNursing homesApartmentsANY DWELING THAT USES WATER AND ISCONNECTED TO THE SEWER SYSTEM WITHINDISTRICT #3

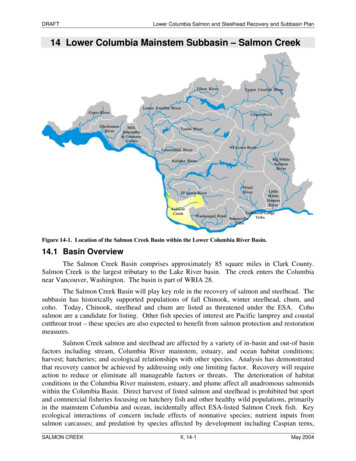

SANITARY SEWER DISTRICT #3 Collection area Freeport to Suffolk BorderLIE to Great South BayThe district has approximately 40,583 lines Equating to 1,528 miles of sewer pipe

How does it get here? The sewage flows from homes andbusinesses into laterals within the streetadjacent to the propertyThe laterals feed into mains which flowsprimarily by gravity to the waste waterplant, maintaining a minimum velocity of2-feet per second.

What happens in low lying areas? When the sewage can no longer flow bygravity due to the low lying topography, it israised up utilizing lift / pump stations.Once lifted gravity continues to move thesewage to the treatment facility.Depending on the location of original sewageit may need to be lifted / pumped severaltimes before it arrives at the treatment plant.

Pump Station (Submersible Pumps )

Pump Station (Dry Well Pumps)

Waste Water Treatment SystemsFixed growth systems RBC’sTrickling Filters Less technologically advancedEffluent quality (moderate to good)Less capital costTypically less operating cost than suspendedgrowth

Waste Water Treatment SystemsSuspended growth systems (CEDAR CREEK WPCP)Activated Sludge More technologically advancedBetter effluent quality (good to excellent)More capital costsTypically more operating costs than fixed growth

Suspended Growth(activated sludge) There are different modes of operations foractivated sludge processes. Conventional-plug flow (CEDAR CREEK WPCP)Step-feedContact StabilizationExtended aerationCannibal processes (specialized process)Ponds & Lagoons (most basic process)

Cedar Creek Plant Overview Preliminary TreatmentPrimary TreatmentSecondary TreatmentDisinfection / DischargeSolids HandlingPower GenerationAncillary Equipment

CEDAR CREEK WPCP

Preliminary Treatment Protects downstream equipment fromdamage (Pumps & Piping) Bar Screens – remove solid material (paper,plastics, ect )Grit Removal – removes inorganic abrasivematerial (sand, fine rocks, pebbles) by slowingthe velocity of the sewage down toapproximately 1-Ft/sec

CEDAR CREEK WPCP

Primary Treatment Primary Clarifiers (10-units in total) Removes up to: 99% of settleable solids40 -60% suspended solids10 -15% total solids20 – 40% BODAccomplished by slowing the velocity of thesewage down to achieve gravitational settling 1-Ft/sec – detention times 2-3 hours

CEDAR CREEK WPCP

Secondary Treatment Secondary treatment is composed of aeration basins (6units / 4-passes) & final clarification (12-units)In the secondary treatment process bacteria is culturedwithin a controlled environment (AERATION TANKS)The bacteria reduces the pollutants (BOD, TSS ect )to acceptable levels prior to discharge, detention times6-8 hoursFinal clarifiers rely upon gravity settling to separate thesolids from the treated water, detention times 1-3hours

CEDAR CREEK WPCP

Secondary OverviewPrimary EffluentAeration Tanks(mixed liquor suspended solids)Final ClarifiersWasteReturn Activated Sludge (RAS)SludgeEffluent(WAS)Gravity BeltThickeners

How do I check my bacteria? Bacteria are extremely small, andmeasured in units called (microns), onemicron 1/1000 of a millimeterSince bacteria is so small and can not beseen under a regular microscope, we relyupon indicator organisms to determine theamount of bacteria we are culturing

Indicator organisms FlagellatesAmoeboidsFree swimming ciliatesStalked ciliatesRotifersNematodes

Stalked Ciliates

Rotifer

Disinfection / Discharge By the time the sewage exits the final clarifier'sit has undergone secondary treatment,however it still contains pathogenic bacteriaThe pathogens have to be reduced through theprocess know as disinfectionDisinfection is accomplished with sodiumhypochlorite prior to discharge to AtlanticOcean (approximately 6-miles from CC-plant)

CEDAR CREEK WPCP

Solids Handling Thickening The sludge that is not returned to the aerationsystem is treated through a process know asthickening.WAS waste activated sludge is mixed with cationic emulsion polymerThe polymer reacts with the sludge causing thesludge particles to coagulate allowing thetrapped water to drop out

CEDAR CREEK WPCP

Why do we thicken sludge? To reduce the volume Save money WAS (waste activated sludge) is 1% solidAfter thickening it is between 4% to 8% solidThe energy expenditure to heat the water istremendousAid the Process Un-thickened sludge would greatly reduce thedetention time in the digesters

Solids Handling Digestion Digestion is the process of volatile solidsreduction of the primary and secondarysludge, accomplished by bacteria Acid formers & methane fermentersThe organisms operate in the mesophilic range (98̊F)Detention time, approximately 21-days

Solids Handling Digestion (continued) By products of digestion Methane gas * utilized in power generation & mixingCarbon dioxideWater vaporDigesting the sludge allows for more disposaloptions

CEDAR CREEK WPCP

Solids Handling Dewatering Dewatering is the process of removing excesswater from the digested sludge prior todisposalPrimary and secondary sludge that hasundergone digestion are treated with cationicemulsion polymer, which reacts with the sludgecausing the sludge particles to coagulate

Solids Handling Dewatering (continued) After conditioning the sludge is applied to the BFP(Belt Filter Press) Gravity zone – gravitational liquid separationLow pressure zone – low pressure exerted to removewater from the sludgeHigh pressure zone – high pressure exerted to removeexcess water from the sludgeSludge enters BFP at 1% to 3% solidSludge exits BFP at 17% to 20% solid

CEDAR CREEK WPCP

Power Generation The Cedar Creek Facility does not importpower from the grid, all plant power isproduced in-house(5) Tri-fuel engine generators Natural Gas#2 Fuel OilBio-Gas (methane from the digestion process)PSEG feeder influent / effluent pumping

Ancillary Equipment Odor Control The plant mitigates odors through the use ofwet chemical scrubbers NaOHNaOCLThe plant also utilizes a bio-filter to mitigateodors emanating from the biological process Wood ChipsWater mist

Ancillary Equipment NOSE System Real time odor control monitoring andmodeling system10-data points around the perimeter of thefacility with constant odor control monitoringand recording

Who monitors the plant? NYSDEC SPDES Permit Title-V Air Permit Monthly DMRBi-annual emission reportsAnnual reportDMR-QA Annual laboratory monitoring / reporting

Main Wastewater TreatmentRequirements TSS 30 mg/l (30-day average) BOD 25 mg/l % (30-day average) Removal 85% (30-day average)

Questions

Secondary Treatment Secondary treatment is composed of aeration basins (6- units / 4-passes) & final clarification (12-units) In the secondary treatment process bacteria is cultured within a controlled environment (AERATION TANKS) The bacteria reduces the pollutants (BOD, TSS ect ) to acceptable levels prior to discharge, detention times