Transcription

ABB High Voltage Induction MotorsTechnical catalogue

High Voltage Induction MotorsFrom 100 to 2800 kWContentsPage11Standard motors522Engineered motors4933Motors with VSD129ABB reserves the right to change thedesign, technical specification anddimensions without prior notice.ABB/ BU Machines / HV Induction motors IEC catalogue EN 12-20073

General InformationThis catalogue includes three sections: standard,engineered and motors with VSD. The availability ofstandard motors is shown in the Section 1. Standardmotors of up to 750 kW are available with the electricaland mechanical design characteristics as shown in thiscatalogue.Section 2 presents ABB's high voltage engineeredinduction motor range of up to 2800 kW. Engineeredmotors are made according to customers'specifications. This section includes preliminarystandard technical data and drawings of engineered4motors. All the engineered motors are configured andoptimized for each order and application.Section 3 describes ABB's engineered motors for lowvoltage variable speed drives range of up to 2240 kW.This section includes preliminary standard technicaldata and drawings with low voltage main terminal box.The basic mechanical construction is the same asdescribed in Section 2. As with the engineered motorsall the motors with VSD are configured and optimizedfor each order and application.ABB/ BU Machines / HV Induction motors IEC catalogue EN 12-2007

High Voltage Process PerformanceCast Iron MotorsTotally enclosed squirrel cage three phase highvoltage motors,Sizes 315 - 450, 110 to 750 kW1www.abb.com/motors&generators Motors High Voltage Motors Process PerformanceCast Iron Motors, 315-450Mechanical design .6Ordering information .21Technical data.22Variant codes. .40Dimension drawings .41Accessories .44Construction .46Cast iron motors in brief .47ABB/ BU Machines / HV InductionmotorsIEC catalogue/ StandardmotorsmotorsIECENcatalogue12-2007 / Standard motors EN 12-2007ABB/BU Machines/ HV Induction55

Mechanical designThis is a standard motor catalogue with limitedoptional features and accessories. In case you need anengineered cast iron motor, please contact your localABB Sales office for further information.Stator frameThe motor frames including feet and bearing housingare made of cast iron. Terminal box is made ofstructural steel. Integrally cast feet allow a very rigidmounting and minimal vibration.Motors can be supplied for foot mounting (horizontal),foot and flange mounting (horizontal) or flangemounting (vertical).Drain holesFor applications with a vertical mounting, the upperplug must be hammered home completely. In verydusty environments, both plugs should be hammeredhome.ClosedOpenMotor sizes 315-450As standard with drain holes and closable plugs.6ABB/ BU Machines / HV Induction motors IEC catalogue / Standard motors EN 12-2007M0002411All the high voltage motors are fitted with drain holesand closable plugs. The drain hole plugs are open ondelivery and users must ensure that the drain holesface downward when mounting the motors.

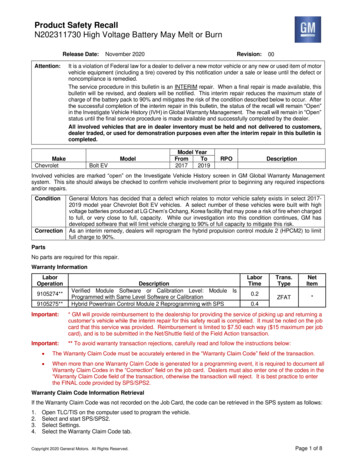

Terminal boxesThe high voltage terminal box up to 6.6 kV is shownbelow. The main technical data are listed below.Technical data:Voltage (max.)Current (max.)No of cables (max.)Cross section of cables (max.)Cable glandClearance (min.)Creepage (min.)Gross volumeUsable volumeConnection screwsConnection nuts tightening torqueGround connectionsWeightProtectionStandardCable gland plateConnection screwsIsolatorsGrounding padwelded structural steel(thickness min. 3 mm)steelBronze Bzepoxy casting resin orpolyurethane resinstainless steelOther features:- rigid welded construction- ample size for making connections of supply cables- box turnable to allow cable entry from left or right side- box turnable in steps of 90 - either 3-phase or 1-phase cables can be connected- pressure relief plate in the bottom of the box in caseof an arching short circuitM000242Dynamic short circuit current6.6 kV400 A1 per phase300 mm2/cableblind gland (1 pcs)60 mm90 mm47.3 dm342.1 dm3M16 (3 pcs)40 NmM12 (both in- andoutside)33 kgIP 66DIN 42962 TEIL 1,A230 kA rms x 0.25 s/75 kA peakMaterials:BoxHigh voltage terminal box up to 6.6 kV.ABB/ BU Machines / HV Induction motors IEC catalogue / Standard motors EN 12-200771

The high voltage terminal box up to 11 kV is shownbelow. The main technical data are listed below.Technical data:Voltage (max.)Current (max.)No of cables (max.)Cross section of cables (max.)Cable glandClearance (min.)Creepage (min.)Gross volumeUsable volumeConnection screwsConnection nuts tightening torqueGround connectionsWeightProtectionStandard1Cable gland plateConnection screwsIsolatorsGrounding padwelded structural steel(thickness min. 3 mm)steelBronze Bzepoxy casting resin orpolyurethane resinstainless steelOther features:- rigid welded construction- ample size for making connections of supply cables- box turnable to allow cable entry from left or right side- box turnable in steps of 90 - either 3-phase or 1-phase cables can be connected- pressure relief plate in the bottom of the box in caseof an arching short circuitM000333Dynamic short circuit current11 kV400 A1 per phase300 mm2/cableblind gland (1 pcs)110 mm150mm122 dm3116 dm3M16 (3 pcs)40 NmM12 (both inand outside)62 kgIP 66DIN 42962 TEIL 2,C230 kA rms x 0.25 s/75 kA peakMaterials:BoxHigh voltage terminal box up to 11 kV.8ABB/ BU Machines / HV Induction motors IEC catalogue / Standard motors EN 12-2007

The high voltage star point terminal box up to 6.6 kVis shown below (option, variant code 750). The maintechnical data are listed below.Technical data:Voltage (max.)Current (max.)Cable glandCreepage (min.)Gross volumeUsable volumeConnection screwsConnection nuts tightening torqueGround connectionsMaterials:BoxCable gland plateConnection screwsConnection barIsolatorsGrounding padwelded structural steel(thickness min. 3 mm)steelBronze BzCopper Cuepoxy casting resin orpolyurethane resinstainless steelOther features:- rigid welded construction- box turnable to left or right side- box turnable in steps of 90 - pressure relief plate in the bottom of the box in caseof an arching short circuitM000324WeightProtection6.6 kV400 Ablind gland (1 pcs)90 mm47.3 dm342.1 dm3M16 (3 pcs)40 NmM12 (both in- andoutside)33 kgIP 66High voltage star point terminal box up to 6.6 kV.ABB/ BU Machines / HV Induction motors IEC catalogue / Standard motors EN 12-200791

The high voltage star point terminal box up to 11 kVis shown below (option, variant code 750). The maintechnical data are listed below.Technical data:Voltage (max.)Current (max.)Cable glandCreepage (min.)Gross volumeUsable volumeConnection screwsConnection nuts tightening torqueGround connectionsWeightProtectionCable gland plateConnection screwsConnection barIsolatorsGrounding padwelded structural steel(thickness min. 3 mm)steelBronze BzCopper Cuepoxy casting resin orpolyurethane resinstainless steelOther features:- rigid welded construction- box turnable to left or right side- box turnable in steps of 90 - pressure relief plate in the bottom of the box in caseof an arching short circuitM000334111 kV400 Ablind gland (1 pcs)110 mm122 dm3116 dm3M16 (3 pcs)40 NmM12 (both inand outside)62 kgIP 66Materials:BoxHigh voltage star point terminal box up to 11 kV.10ABB/ BU Machines / HV Induction motors IEC catalogue / Standard motors EN 12-2007

M000245Star point terminal box (optional)1M000359M000360Delivery without main terminal box (optional)ABB/ BU Machines / HV Induction motors IEC catalogue / Standard motors EN 12-200711

M000246Dimensions for terminal box inlet, blind flange1M000335Blind flange up to 6.6 kV.Blind flange up to 11 kV.12ABB/ BU Machines / HV Induction motors IEC catalogue / Standard motors EN 12-2007

Auxiliary boxesM000248M000325Auxiliary box is used for control equipment and heatingelements.1- one box as default- stator Pt-100- bearing Pt-100 (optional, variant code 107)- heating element (optional, variant code 450/451)- separate auxiliary box for heating element (optional,variant code 447)Specification:Material designationMaterial standardSurface treatmentAl-Si10Mg (pressure die cast)EN 573-3RAL 7001 (grey)Other features:- equipped with assembly rail ARH 22(DIN-35, 35x203 mm)- main dimensions 125x222x81- degree of protection IP 66 (IEC 529)- gasket material polyurethane- temperature resistance -50 - 140 C (material), 80 C (continuous use)- max. terminal blocks:34 pcs 2.5 mm228 pcs 4.0 mm2- weight 1.6 kgABB/ BU Machines / HV Induction motors IEC catalogue / Standard motors EN 12-200713

Other features:- equipped with assembly rail ARH 22 (DIN-35)- main dimensions 125x222x81, 222x330x180- degree of protection IP66 (IEC 529)- gasket material polyurethane- temperature resistance -50 - 140 C (material), 80 C (continuous use)- weight 1.6 – 5.6 kgOption with bearing dial type thermometers- Measuring range 0 120 C- Degree of protection : IP65 (IEC529)- Temperature durability of display -40 60 C14Al-Si10Mg (pressure die cast)EN 573-3RAL 7001 (grey)M000358Specification:Material designationMaterial standardSurface treatmentM0003571one box as default- stator Pt-100 (6 pcs)- bearing Pt-100 (optional, variant code 107)- heating element (optional, variant code450/451)- dial type thermometers for bearings(optional, variant code 651/652)*- Pt-100 (12 pcs) inside stator slots(optional, variant code 653)*- Provision for vibration sensors (optional,variant code 654)** The bigger auxiliary box is needed if any ofthese variant codes is selected.M000356M000355--Temperature durability of capillary tube-40 100 CWith or without contacts (optional, variantcodes 652/651)ABB/ BU Machines / HV Induction motors IEC catalogue / Standard motors EN 12-2007

BearingsThe motors are normally fitted with single-row deepgroove ball bearings as listed in the table below.If the bearing at the D-end is replaced with a rollerbearing (NU-), higher radial forces can be handled.Roller bearings are suitable for belt drive applications.Basic version with deep groove ball bearingsVersion with roller bearings, variant code 037MotorNumberDeep groove ball bearingsMotorNumberRoller bearings, variant code 037sizeof polesD-endN-endsizeof polesD-end31526316M/C36316M/C33154-6NU 319/C34-66319/C36316/C33554-6NU 322/C326316M/C36316M/C34004-8NU 324/C34-66322/C36316/C34504-8NU 317M/C34-86326M/C36322/C33554004501Axially-locked bearingsAll motors are equipped as standard with an axiallylocked bearing at the D-end.The bearing's outer ring is tightly locked betweenbearing's covers and the housing fit.The N-end bearing is axially free and can take thethermal expansion. Note! NU-bearing is axially lockedat N-end.Transport lockingMotors with roller bearings are fitted with a transportlock to prevent damage to the bearings duringtransport. All high voltage motors are fitted with awarning sign when the transport lock is fitted toprevent operational damage and alert operators.Locking may be fitted in any other situations wherethe transport conditions are considered as potentiallydamaging.ABB/ BU Machines / HV Induction motors IEC catalogue / Standard motors EN 12-200715

Bearing sealsAll high voltage motors are equipped with labyrinthsealed bearings.M000251M000250Axially free (N-end)116M000253M000252Axially locked (D-end)ABB/ BU Machines / HV Induction motors IEC catalogue / Standard motors EN 12-2007

LubricationOn delivery, the motors are pre-lubricated with highquality grease. The grease grade is stamped on thelubrication plate fastened to the motor frame. Seepage 20 for an example of a lubrication plate.More information about lubrication and greases canbe found in ABB's High Voltage Process PerformanceManual delivered with the motor.Motors with relubrication nipplesMotors are lubricated while running and the bearingsystem on all high voltage motors has been built so thata valve disc can be used for lubrication.The grease outlet opening has closing valves at bothends that should be opened before greasing and closed1-2 hours after regreasing. Closing the valves ensuresthat the construction is tight and dust or dirt cannot getinside the bearing.Lubrication intervalsThe lubrication interval is defined by following theL1-principle. This means that 99% of ABB's motorswill achieve the normal service intervals. Values for thelubrication intervals can also be calculated accordingto the L10-principle, which are normally doubledcompared to L1-values. Values are available from ABBon request.Framesize3000Ambient Cr/min1500r/minThe table below gives lubrication intervals for differentspeeds (according to the L1-principle). The values arevalid for motors using the synthetic base oil mentionedin ABB’s High Voltage Process Performance MotorsManual.For more information, see ABB's High Voltage ProcessPerformance Motors Manual. 1000Framer/minsizeAmbient C30001500 1000r/minr/minr/minBall bearings, horizontal motor: lubrication intervals in duty hoursBall bearings, vertical motor: lubrication intervals in duty hours3152559008800880031525-6600880031540 1)30006600880031540 1)-360044003552544008800880035525-4400880035540 1)22005100880035540 40040300066008800450251500360080001)For generation code B motors, same lubrication intervals arevalid for 50 C ambient.FramesizeAmbient C30001500 1000r/minr/minr/min450401)1)1)For generation code B motors, same lubrication intervals arevalid for 50 C ambient.Roller bearings: lubrication intervals in duty hours31525-4400880031540 1)-2200510035525-4400440035540 1)-2200220040025-3000440040040 1)-1500220045025-30004400-15002200450401)1)For generation code B motors, same lubrication

induction motor range of up to 2800 kW. Engineered motors are made according to customers' specifi cations. This section includes preliminary standard technical data and drawings of engineered motors. All the engineered motors are confi gured and optimized for each order and application. Section 3 describes ABB's engineered motors for low voltage variable speed drives range of up to 2240 kW .