Transcription

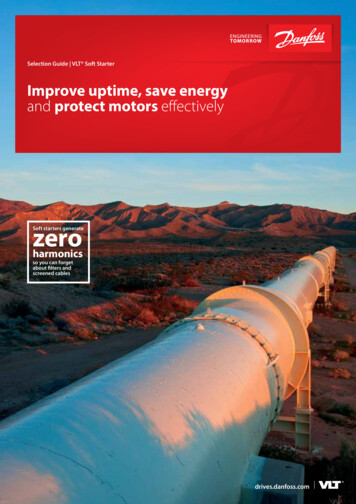

Selection Guide VLT Soft StarterImprove uptime, save energyand protect motors effectivelyzeroharmonicsSoft starters generateso you can forgetabout filters andscreened cablesdrives.danfoss.com

When to use a soft starterNeed more uptime and less maintenance? Then install a soft starter onyour direct-on-line (DOL) or start-deltainstallation.Payback is fast and you get these additional benefits:n Lower inrush current reducesmechanical stress – and minimizespenalty from the utility companyn Extended system lifetime due toreduced wear on– Motor– Power cables– Electrical distribution systemn Reduced water hammer in pumpapplications. For more applicationbenefits, see pages 4 and 5.n After start-up, you can bypass thesoft starter, switching over to rundirect-on-line.After initial start-up, running DOLsaves energy, by reducing losses andthus reducing cooling requirements.Danfoss provides an easy solutionfor switching back and forth to DOL– the VLT Soft Starter MCD 500 withintegrated bypass.More protection, less spaceSelect a Danfoss soft starter to winunique benefits:n Care for your motor and soft starter– get good motor and soft starterprotection value, with more protection features in the soft starter.2Danfoss Drives · DKDD.PB.550.A3.02nnnnSave panel space with a very compact footprintIntegrate the soft starter withVLT drivesProgramme the soft starter via yourPC using the VLT Motion ControlTool MCT 10 set-up software*Enjoy the integrated bypassas standard for VLT Soft StarterMCD 500 ratings up to 961 A*Requires optional USB moduleWhy use a soft starterfor speed control?Forget harmonicsAC drives, also known as variable speeddrives (VSD) work by changing thefrequency input to the motor – andthis causes harmonics on the supplynetwork. Harmonics do not affect theAC drive itself. However, if not keptunder control, harmonics can reduceperformance and reliability of otherequipment connected to the grid, suchas generators and circuit breakers. Thesolution is to install filters and screenedcables but even then the harmonic effect is not completely removed.Therefore it’s reassuring to know thata soft starter already fulfils all emissionand immunity requirements laid outby the EMC directive. The soft starterdoes not change the frequency andtherefore does not generate harmfulharmonics. So when using a soft starterthere is no need to consider harmonicsat all.Reduce torque and currentUsing a soft starter you can adjusttorque to the exact level required,whether or not the application isloaded. By reducing the startingtorque, mechanical stress onequipment is alleviated, saving onservice and maintenance costs.The soft starter also reduces startingcurrent which means you can avoidvoltage drops in the network.Save costSoft starters cost up to one-tenth theprice of high-power drives. So if yourcontrol requirements are covered bylimiting current only at start and stop,with no need for constant acceleration and torque control, then there aresignificant savings to be won.Save spaceSoft starters are smaller than AC drivesand the difference becomes moresignificant the higher the amp ratinggets. You can save on panel space.

Integrated bypass – for all-round savingsThe VLT Soft Starter MCD 500 providesan integrated bypass to allow directon-line operation as an alternative. Theintegrated bypass offers multiple costsaving benefits.Reduce heat lossIntegrated bypass provides the opportunity to switch over to direct-online operation, after initial start-up viathe soft starter. By running partiallydirect-on-line, you win the advantagesof reduced losses and need for heatdissipation, thus saving energy due todecreased cooling requirements.ExampleIn the example, a soft starter regulates a water pump,with motor specifications as follows:MotorSupply.400 V ACRating.132 kWFLC.245 AStart duty.300% for 30 secondsElectricity prices.(industry – EU)Estimated savings, non-bypassed versus bypassedSave more with bypass, compared to no bypass.The energy saved depends on the relationship between ramping and running.The more the application is running the more the bypass will save – see illustration.Save spaceThe MCD 500 with integrated bypasstakes up less panel space than a softstarter with an external contactor.70% running30% ramping80% running20% rampingSave timeWith only six terminals instead oftwelve, it is much faster to wire anMCD 500 with integrated bypass, thanan alternative soft starter with externalcontactor. Less cable is required, whichadditionally reduces cost. Save evenmore time, by using the handy set-upsoftware tool VLT Motion Control ToolMCT 10 to configure the MCD 500 viaPC. You can use the same set-up toolwith VLT drives.Save energy – fast paybackThe soft starter with integrated bypasscontactor saves space by comparisonto an external contactor connected toa non-bypassed unit.Select a soft starter with integratedbypass when you want to save costs.The payback time is just months, usingthe MCD 500 with integrated bypass.See how in this example:NobypassExternalbypassIntegratedbypass,MCD 50095% running5% ramping0200,00400,00600,00800,001000,00Savingsin 1200,00Cost saving using a bypass, showing the beneficial savings effectof increased running time and reduced ramping time.Integrated bypass versus external bypassWin back your investment faster with integrated bypass, compared to externalbypass. The payback period is only a few months.InvestmentNo bypass,(indexed values)Soft starterDirect-on-lineSoft starter withexternal bypassSoft starter with integratedbypass VLT Soft StarterMCD 500100100137Bypass contactor wiring mounting0580Extra panel space, parts,and labour030100161137Extra cost comparedto no bypass-6137Simple payback period[months]–3.32TotalDanfoss Drives · DKDD.PB.550.A3.023

ApplicationsCentrifugal pump– WaterCentrifugal fan– HVACCompressor– Protect your motorNeed to reduce water pressuresurges and mains supply disturbanceat start-up? Then a gentle startusing a soft starter is a good idea.It also provides a soft stop to controlthe effects of fluid hammer oftenassociated with uncontrolled pumpstop – ultimately extending pumplife and reducing running costs. Fornew projects, build these savings inat design phase – there is no need tospecify pressure surge tanks and motorized valves to cater for repetitivehigh-pressure surges. The minimumstart current function reduces electrical disturbance on mains supply andlimits demand on supply as well –reducing reticulation costs for example in farmland irrigation projects.Extend the life of centrifugal fansby adding a soft starter – to ensuregentle acceleration and deceleration,minimizing wear on coupling, belts,and bearings.Has the compressor ever locked up,for instance due to entry of liquidammonia? Using a soft starter, ongoing monitoring prevents damage tomotor, compressor, and couplingsin a lock up situation. Soft startersprovide instant protection againstmotor overload, by tripping the motor immediately.The soft startern Prevents motor overheating viaintegrated protectionn Ensures that pump does not runin reverse, via start-up protectionn Detects blocked pipes or lack offluid via undercurrent protection,thus preventing unnecessarypump damage4Danfoss Drives · DKDD.PB.550.A3.02The soft startern Reduces electrical disturbanceon the supply via a minimal startcurrentn Prevents overheating of motorwindings and bodyn Prevents starting when fan direction is reversed, avoiding damagen Trips in the event of excess starttime, indicating a jammed orstalled fan, also providing earlyindication of bearing failuren Detects broken couplings andbelts or clogged fan filter, via andoptional trip or flag for motorundercurrentTo integrate the soft starter directlywith a BMS, the VLT Soft StarterMCD 500 supports monitoring fanloading, without the need for extraequipment an analog output.The soft startern Enables load shedding before thesoft starter trips, for compressoroverload or motor overtemperaturen Trips to prevent motor damagewhen start-up time exceeds a preprogrammed limit, for exampledue to a jammed or stalled compressorn Monitors the compressor loadusing a 0-20 mA/4-20 mA analogoutputn Enables optimized compressorperformance with dual speeddahlander motor controln Avoids short cycling via restartdelay, promoting longer life ofmotor, compressor, and couplingn Is an easy retrofit for start/deltastarters

Conveyor belt – Foodand beverage industriesCrusher and mill– MiningExtend the life of your conveyorbelt, and gain the benefit of consistent start-up regardless of whetherthe belt is loaded or not. The softstarter ensures gentle accelerationand deceleration, reducing risk ofproduct damage due to jerky startsand sudden stops. It also protectsthe couplings, belts, and bearingsagainst mechanical wear.Maximise your crusher or millthroughput by installing a soft starterat the motor input. The soft starterallows the motor to operate at itsupper thermal limit, while carefully monitoring thermal capacity toensure motor protection. The crushercan then safely ride through temporary product overload situationsThe soft startern Prevents conveyor belt slap during startn Reduces stress on counter- balances and weightsn Reduces electrical disturbance onthe supply, via a minimum startcurrent functionn Provides protection against accidental running in reversen Detects broken couplings orbroken belts, and trips the motorimmediatelyn Detects overload, or a jammedor stalled conveyor, and protectsequipment by tripping the motorimmediatelyThe soft startern Eliminates the need for specialcontrol equipment, by connecting motor thermistors directlyinto the VLT Soft Starter MCD 500thermistor inputn Extends the life of couplings, belts,and bearings by gentle start-up,minimizing torque transientsn Reduces electrical disturbance onthe supplyn Limits the demand on the supply,especially critical on remote sitessupplied by generator setsn Prevents damage due to unintentional running in reverse, bypreventing start when rotationof the 3-phase incoming supplychangesn Detects broken couplings andbroken crusher belts via undercurrent protection, and trips toprevent further damageDanfoss Drives · DKDD.PB.550.A3.025

Soft starter guide:Find the right product for your mpressor (Reciprocating, unloaded)HighConveyorHighnnHighnMixerHighnPositive displacement pumpHighBelt conveyornnnnnnnnnnHighHammer millHighRock crusherHighnnnnnnnnnnRoller millHighnTumblerHighnWire draw machineHighBottle hnShredderHighnBall millHighnCentrifugeHighnExtruderHighnScrew conveyorHighnBall millHighGrindernnnnnMaterial conveyorHighnPalletizerHighnPressnnnnRoller millHighnRotary tableHighnBandsawHighnChipperHighnCircular sawnnnnDebarkernnnnEdgernnnnHydraulic power packnnnnnnnPlanerSander6nnFan (undamped)SlicerLumber & woodproductsnnRoller conveyorTransport &machine toolnnGrinderPetro-chemicalMCD 500nDust collectorPulp & paperMCD 202Compressor (Screw, unloaded)Submersible pumpFood processingMCD 201Centrifugal pumpFan (damped)Metals & miningMCD 100HighDanfoss Drives · DKDD.PB.550.A3.02Highnn

Step 1. Determine what kind of speed control you needConsider first, whether start/stop control or continuous speed control is required.Then consider the scale of both initial investment and running costs.Speed controlInitial costVSDStart/stopContinuousspeed controlDOLSSTSSTDOLAC drive(VSD)Soft starter(SST)Direct-on-line(DOL)If you selected an AC drive (VSD), read more about DanfossVLT and VACON d rives on drives.danfoss.com.If you selected a soft starter, then read on.CAPEXVSDOPEXDirect-on-line (DOL) drawbacksWear on motor bearingsn Wear and tear on gearboxn Water hammernStep 2. Match your applicationDetermine the size of the soft starter based on inertia level.Refer to the Soft Starter guide on page 6.Step 3. Match your needsFind the right match between your application and the soft starter features you need.The guide recommends which model of Danfoss VLT soft starter is best for the job:n VLT Soft Start Controller MCD 100n VLT Compact Starter MCD 201 or 202n VLT Soft Starter MCD 500MCD 100MCD 201MCD 202MCD 500Power size0.1-11 kW7.5-110 kW7.5-110 kW7.5-850 kWStart/stopTimed voltage rampTimed voltage rampCurrent limited startedAdaptive Acc. Cont. (AAC)ProtectionNoneNone7 features19 featuresOutputsNone1 output relay2 output relay3 programmable outputsControl2 wire control /3 rotary switches2-3 wire control /3 rotary switches2-3 wire control /8 rotary switches8 language graphical displayOptionsNoneInitial cost,indexed1Fieldbus / remote display and PC software1.82.23.1Danfoss Drives · DKDD.PB.550.A3.027

VLT Soft Starter MCD 500VLT Soft Starter MCD 500 is a total motor starting solution.Current transformers measure motor current and providefeedback for controlled motor ramp profiles.AAC, the Adaptive AccelerationControl, automatically employs thebest starting and stopping profile forthe application. Adaptive AccelerationControl means that for each start andstop, the soft starter compares andadapts the process to the chosenprofile best suited to the application.The VLT Soft Starter MCD 500 has afour-line graphical display and a logickeypad making programming easy.Use the advanced setup to viewoperational status.Three menu systems: Quick Menu,Application Setup and Main Menuprovide the optimum programmingapproach.Power range21-1600 A, 7.5-850 kW(1.2 MW inside Delta Connection)Versions for 200-690 V ACFeatureBenefitUser friendlyAAC Adaptive Acceleration ControlAdjustable bus bars allow for both top andbottom entry (360 – 1600 A, 160 – 850 kW)DC injection braking distributed evenlyover three phasesInside Delta (6-wire connection)Log menus, 99 events and trip log provideinformation on events, trips and performanceAuto ResetJog (slow-speed operation)Second-order thermal modelInternal bypass contactors(21 – 215 A, 961 A)Auto-start/stop clockCompact size– amongst the smallest in their class4-line graphical displayMultiple programming setup(Standard Menu, Extended Menu, Quick Set)Multiple languages8Danfoss Drives · DKDD.PB.550.A3.02– Automatically adapts to the chosen startingand stopping profile– Space saving, less cable costand easy retrofitting– Less installation cost andless stress on the motor– Smaller soft starter can be selectedfor the application– Eases analysis of the application– Less down-time– Application flexibility– Allows motors to be used to their full potentialwithout damage from overloading– Save space and wiring compared to externalbypass– Very little heat dissipates when running.Eliminates costly external fans, wiringor bypass contactors– Application flexibility– Saves space in cabinets and otherapplication set-ups– Optimum programming approach and setupfor viewing operational status– Simplifies the programming, but still holdingto maximum flexibility– Serving the whole world

MCD 500 operation optionsStartingn AAC Adaptive Accelerationn Controln Current Rampn Constant Currentn KickstartStoppingCoast to stopTVR Soft StopAAC Adaptive DecelerationControln BrakennnVLT Control Panel LCP 501100%90%80%Select a screen view set-up from oneuser-programmable and 7 standardviews.Language selectionEnglish, Chinese, German, Spanish,Portuguese, French, Italian, Russian.The LCP 501 is connected to theMCD 500 by using a 3 m cable using a9-pin (D-sub) plug and 3 m cableprovided with the IP65 (NEMA 12)door-mount kit.Speed70%60%50%40%30%20%10%0TimeThree Adaptive Acceleration Control (AAC) startprofiles; early, constant and late accelerationCurrent (% motor full load current)100% easy connectionn The Modbus, PROFIBUS, EtherNet/IPand D eviceNet modules use anotherport on the MCD 500, located at theside of the soft startern Separate LCP 501 output at thebottom for 9 pin plug and 3 m cablen One ordering number (LCP withdoor-mount kit and cable)n Plug & play connection, even whenthe soft starter is powered upn One cable for power and communicationn Powered up by soft startern Copy of parameter set-upEverything you can do with theVLT Soft Starter MCD 500 controlsis also possible via theVLT Control Panel LCP 501.700%600%500%400%300%200%100%10% 20% 30% 40% 50% 60% 70% 80% 90% 100%Rotor speed (% full speed)Once connected, the soft starter askswhether you want to copy parametersfrom LCP to starter or starter to LCP(if different).Constant current/ current ramp – here shownwith kickstartDimensionsCurrent rating[A]21, 37, 43 and 536884, 89 and 105131, 141, 195 and 215245331 and 396469, 525, 632,744, 826 and 9611200, 1410 and 295G4120856585364G5213EnclosuresizeG19

VLT Compact Starter MCD 200VLT Compact Starter MCD 200 series fromDanfoss includes two soft starters in thepower range 7.5-110 kW.The series offers easy DIN rail mounting for sizes up to 30 kW, 2-wire or3-wire start/stop control and excellentstarting duty (4 x Ie for 6 seconds).MCD 201URampdownRamp upHeavy starting ratings at 4x Iefor 20 seconds.Initial torqueM3 Compatible with grounded deltapower systems.Power rangeMCD 202MCD 202 provides enhanced soft start functionalityand various motor protection features7.5 – 110 kWIRemote operationRampdownRamp upThe dedicated remote operatorkit facilitates remote operation ofVLT Compact Starter MCD 201 andVLT Compact Starter MCD 202 .The operator (IP54/NEMA 12) ismounted on the cabinet front andallows remote control, status indicationand motor monitoring of an individualVLT Compact Starter using RS485serial communication.UCurrentlimitM3 Initial currentFeatureBenefitSmall footprint and compact size– Saves panel space– Minimizes installation cost andeliminates power loss– Reduces heat build up. Savings incomponents, cooling, wiring and labor– Allows enhanced functionality– Allows more starts per hour,at higher loadMaximum up-time– Reduces overall project investmentBuilt-in bypassAdvanced accessoriesAdvanced SCR control algorithmsbalance output waveformReliableEssential motor protection (MCD 202)Max. ambient temperature 60 Cwithout deratingUser friendlyEasy to install and useEasy DIN rail mounting for sizes up to 30 kW– No external cooling or oversizing necessarySave commissioning– Saves time and spaceDimensionsPower range (400 V)Height [mm]10Danfoss Drives · DKDD.PB.550.A3.027-30 kW37-55 kW75-110 kW203215240Width [mm]98145202Depth [mm]165193214

VLT Soft Start Controller MCD 100VLT Soft Start Controller MCD 100 is a cost-effectiveand extremely compact soft starter for AC motors up to11 kW, due to a unique semiconductor design.VLT Soft Start Controller MCD 100 is atrue “fit and forget” product. Selectioncan be made on the basis of the motorpower – exactly as with traditionalcontactors.VLT Soft Start Controller MCD 100products provide timed voltage rampup and down. Ramp time can beindividually adjusted with rotaryswitches from 0.4 to 10 seconds.Ramp-up time0.5–10 sec.Motor torque(Voltage)Ramp-down time0–10 sec.100%“Kick start”200 msec.of max. torque0%TimeInitial Torque up to85% of nominal torqueThe start torque can be adjusted from0 to 85% of the direct on-line torque.All sizes are rated for line voltage up to600 V AC.FeatureBenefitSmall footprint and compact sizeSelection can be based on motor power– Saves panel space– Easy selection– Simplifies selection– Keeps stock at a minimum– Simplifies installation– Reduces required panel spaceMaximum up-time– Reliable operationUniversal control voltage“Fit and forget” contactor designReliableRobust semiconductor designAlmost unlimited number of startsper hour without deratingMax. ambient temperature 50 Cwithout deratingUser friendlyEasy to install and use– Prevents unauthorized changes– No external cooling or oversizing necessaryDigitally controlled rotary switchesEasy DIN rail mounting for sizes up to 30 kWSave commissioning and operating cost– Saves times– Secures precise settings andsimplifies installation– Saves time and spaceDimensionsPower range1.5 kW7.5 kW11 kWHeight [mm]102110110Width [mm]22.54590Depth [mm]123.5128.1128Danfoss Drives · DKDD.PB.550.A3.0211

Serial communicationVLT Compact Starter MCD 201 and202, and VLT Soft Starter MCD 500come with optional plug-in modulesfor serial communication.nnnnnStart/stop, resetLED for start, run, tripTrip codesCurrent displayMotor temperature displayDeviceNetEtherNet/IPPROFIBUSModbus RTUUSBMCD 100MCD 201MCD 202MCD 500nnnnnnnnnnnnnnnnnn4 – 20 mA outputProgramming keypad, graphical displaynOrdering typecodeVLT Soft Starter MCD 500[1][2]MCD 5 ––[3]– T[4]– G[5]X –[1] FLC, [A]002100370043005300680084008901050131 FLC, [A]01410195021502450331039603600380[6]– C V0428046905250595061906320744FLC, [A]0790082609270961120014101600[2] Bypass indicationBWith internal bypass contactorWithout internal bypass contactorC(continuous)VLT Compact Starter MCD 200[1]MCD 2 0[2]–[3]– T[4]– C V[1] Series1Soft start/stop2Soft start/stop protection[2] Nominal motor kW, 400 V055 E.g. 55 kW110 110 kW12Danfoss Drives · DKDD.PB.550.A3.02[3] Line supply voltage4200-440 V6200-575 V[4] Control supply voltage124 V AC/DC3110-240 V AC and 380-440 V AC[3] Supply voltage5200-525 V AC7380-690 V AC[4] Enclosure1Enclosure size 12Enclosure size 23Enclosure size 34Enclosure size 45Enclosure size 5[5] IP rating00IP0020IP20[6] Control voltage124 V AC or 24 V DC2110 or 220 V AC

Size indicationsVLT Compact Starter MCD 201/MCD 202Power size(kW)7.5151822303745557590110Rated currentAC-53b* (A)18 A: 4-6: 35434 A: 4-6: 35442 A: 4-6: 35448 A: 4-6: 35460 A: 4-6: 35475 A: 4-6: 59485 A: 4-6: 594100 A: 4-6: 594140 A: 4-6: 594170 A: 4-6: 594200 A: 4-6: 594VLT Soft Start Controller MCD 100Power size(kW)ApprovalsRated current(A)3 A: 5-5:10(AC 53b)15 A: 8-3:100-3000(AC 53a)25 A: 6-5:100-480(AC 53a)1.57.5ULC – ULCECCCC-tickLloyds11ApprovalsUL, CE* Example: AC 53b: 42 A: 4-6: 354 starting current max. 4 times FLC (42 A)in 6 seconds. 354 seconds minimum between starts.Size indication for VLT Soft Starter MCD 500Motor size(kW)@ 400 50500Motor size(kW)@ 400 ed FLC (40 C, 1000 m),outside delta motor connectionMedium 400%, 20s,Internal 12606684796Starts perhourMax. arts perhourMax. 0231227176263299309434455579661107111141353G1(no fan)G1G2G2xG4xG4xG5xLight 300%, 30s,Internal 632744826961Heavy 450%, 30s,Internal 516571664Note: Optimize your selection with WinStart Soft Starter PC tool.Danfoss Drives · DKDD.PB.550.A3.0213

SpecificationsVLT Soft Starter MCD 500VLT Soft Start Controller MCD 100TypennThe total motor starter solution.Provid es advanced control methods for starting and stoppingand protection of motor and applicationnA true “fit and forget” soft starter for DIN rail mount,MCD 100 provides basic soft start and stop functionnnnnnnSoft startSoft stop0.1-11 kW @ 400 V208-600 V mains voltage24-480 V AC/DC control voltage2-phase SCR controlConceptnnnnnnEnhanced soft start and soft stopMotor and system protection7.5-850 kW @ 400 V (21-1600A)200-690 V mains voltage110-220 V AC or 24V AC/DC control supply3-phase SCR controlStart/stopnnnnnnAdaptive Acceleration Control (AAC)Current limit startCurrent ramp startDual parameter functionKick-startJognnnTimed voltage ramp-upAdjustable start torqueSelectable kick-start functionnnnnnAdaptive Deceleration Control (AAC)TVR soft stop (Timed Voltage Ramp)Coast to stopDC brake function – three phaseSoft brake functionnTimed voltage ramp-downnnUniversal two-wire controlProgrammable via 3 rotary switchesnExtremely robust SCR design for unlimited n umberof starts per hour, LED indication, IP20ProtectionSame as MCD 202 and:n Under currentn Current imbalancen Starter overtemperaturen Restart delayn Warning before tripsn Adjustable phase imbalance sensitivity– Programmable input trip– Individual phase loss trips– Individual shorted SCR trips– Int. bypass relay overload– Int. bypass relay failn Fully adjustable protectionsn Network communication timeoutn Heatsink overtemperaturen Battery/clock failuren Supply frequencyn External tripOutputnnThree programmable output relays:Programmable analogue outputMotor thermistorControlnnnn8 language graphical display and keypadQuick menu and appplication menuButtons for start, stop, reset and remote controlInputs for two- or three-wire controlOptionaln Modules for serial communicationn VLT Control Panel LCP 501n PC softwareOther featuresnnnnnnnnnn14Bypass up to 961A (500 kW)Configurable bus bars from 360 A and upOperation timersJog – slow speed operationAuto reset of fault situationsEmergency run99 event logTrip logUser programmable metering and monitoringSimulation before connecting line voltageDanfoss Drives · DKDD.PB.550.A3.02

VLT Compact Starter MCD 201VLT Compact Starter MCD 202TypenA physically compact starter providing basic soft startand stop functionalitynPhysically similar to MCD 201 but providing enhanced soft start func tionality and various motor protection functionsnnnnnnnCurrent limit startSoft stopMotor protection7.5-110 kW @ 400 V200-575 V mains voltage110-440 V AC or 24 V AC/DC control s upply2-phase SCR controlConceptnnnnnnSoft startSoft stop7.5-110 kW @ 400 V200-575 V mains voltage110-440 V AC or 24 V AC/DC control s upply2-phase SCR controlStart/stopnnTimed voltage ramp-upAdjustable initial torquennCurrent limit startInitial current ramp-upnTimed voltage ramp-downnTimed voltage ramp-downnnnnnnnMotor overload (adjustable trip class)Excess start timeReverse phase rotationMotor thermistor inputShorted SCR – no startSupply fault – no startInstantaneous overloadnTwo output relays:– Line contactor control– Run contactor or trip f unctionnTwo- or three-wire controlProgrammable via 3 rotary switchesReset push buttonnnnTwo- or three-wire controlProgrammable via 8 rotary switchesReset push buttonOptionalModules for serial communicationRemote operator kitPC softwareOptionaln Modules for serial communicationn Remote operator kitn PC softwareProtectionOutputnOne output relay:Line contactor controlControlnnnOther featuresnnnnnIntegral SCR bypass for minimum physical size andheat dissipation during nominal operationLED status indicationIP20 (7.5 – 55 kW @ 400 V)IP00 (75 – 110 kW @ 400 V)Protection kit availablennnnnIntegral SCR bypass for minimum physical size andheat dissipation during nominal operationLED status indicationIP20 (7.5 – 55 kW @ 400 V)IP00 (75 – 110 kW @ 400 V)Protection kit availableDanfoss Drives · DKDD.PB.550.A3.0215

Danfoss DrivesDanfoss Drives is a world leader in variable speed control of electric motors.We aim to prove to you that a better tomorrow is driven by drives. It is as simpleand as ambitious as that.You can rely on us to share yourgoals. Striving for the best possibleperformance in your applications is ourfocus. We achieve this by providing theinnovative products and applicationknow-how required to optimizeefficiency, enhance usability, andreduce complexity.From supplying individual drivecomponents to planning anddelivering complete drive systems;our experts are ready to supportyou all the way.DKDD.PB.550.A3.02We draw on decades of experiencewithin industries that include: Chemical Cranes and Hoists Food and Beverage HVAC Lifts and Escalators Marine and Offshore Material Handling Mining and Minerals Oil and Gas Packaging Pulp and Paper Refrigeration Water and Wastewater WindYou will find it easy to do business withus. Online, and locally in more than50 countries, our experts are never faraway, reacting fast when you needthem.Since 1968, we have been pioneersin the drives business. In 2014, Vaconand Danfoss merged, forming one ofthe largest companies in the industry.Our AC drives can adapt to any motortechnology and we supply products ina power range from 0.18 kW to 5.3 MW.EtherNet/IP and DeviceNet are trademarks of ODVA, Inc.We offer you unparalleled competitiveedge through quality, applicationoptimized products targeting yourneeds – and a comprehensive rangeof product lifecycle services. Copyright Danfoss Drives 2016.06

more time, by using the handy set-up software tool VLT Motion Control Tool MCT 10 to configure the MCD 500 via PC. You can use the same set-up tool with VLT drives. Save energy - fast payback The soft starter with integrated bypass contactor saves space by comparison to an external contactor connected to a non-bypassed unit.