Transcription

Programmable logic relay systemExtremely compact control and switching

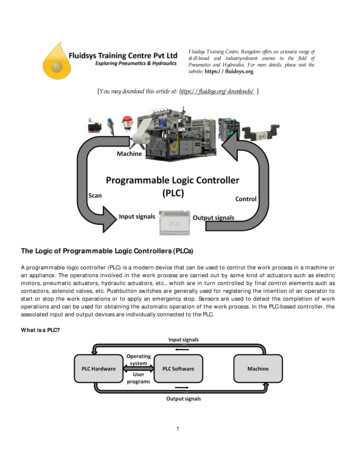

Extremely compact control andswitchingOn the logic module market, the PLC logicrelay system is the first to combine logic,interface, and field connection levels in asingle solution. This means that you canswitch and control I/O signals using asingle compact system. You can combinethe new PLC logic module with thecorresponding relay and analog modules asrequired. The modular structure opens upa wealth of applications.The new standard forthe control cabinet.More information onpages 16 to 19.2PHOENIX CONTACT

Advantages at a glanceCarry out small automation tasks and benefit from the advantages ofpluggable switching elements. You can implement your projects quicklywith the aid of the free LOGIC software.Extremely compact controlIN 1IN 2IN 3& OUT 10OUT 12OUT 14Flexible combinationAssemble each channel individuallyas an input or output with an overallwidth of just 50 mm. Depending onthe application requirements, relay oranalog modules are available for this.Easy projectimplementationLOGIC is the intuitivesoftware which allows youto implement your projectsquickly.Wireless operation andmonitoringHigh system availabilitythanks to pluggable switching elements.For wireless access to processdata between the logic moduleand the mobile end device, theBluetooth adapter, combinedwith the PLC logic app, isavailable to you.PHOENIX CONTACT3

The system at a glanceYou can flexibly extend the system,thanks to the wide choice of differentmodules. In addition to the basic module,expansion modules are also available formore complex tasks. Eight relay and analogmodules can be freely selected for eachbasic module. Up to 48 I/O signals canbe acquired and switched with one basicmodule and two expansion modules.The components in detail12Basic moduleExpansion modulesPLC logic processes16 I/O signals with onebasic module at an overallwidth of just 50 mm.The basic module andexpansion module areconnected via integratedconnectors – no toolsrequired.4PHOENIX CONTACT3Relay and analogmodulesThe modular design withthe widest variety ofrelay and analog modulesenables channel-specificassembly.45PLC logic appMemory blockEasy and quickparameter adjustmentsand monitoring usingan app. Thanks to thecorresponding Bluetoothadapter, you can accessthe process data quicklyand wirelessly.Save programs or easilycopy them to otherdevices.

Integration into common bus systemsPLC logic is integrated into various networks via optionaladaptable fieldbus gateways. This enables bidirectionalcommunication with a higher-level controller for remotecontrol as well as diagnostics and visualization. Gatewaysare available for transmitting data via PROFIBUS DP,RS-232, RS-485, Modbus/TCP, DeviceNet , CANopen,PROFINET, and EtherNet/IP. A connection to Inlinecontrollers is also possible.PHOENIX CONTACT5

Intuitive programmingusing LOGIC LOGIC is the intuitive software whichallows you to implement your projectsquickly.Select the right components for your task.The easy handling helps when it comes toconfiguration and startup of the products.The programs created can be simulatedoffline on the PC and tested online duringoperation.6PHOENIX CONTACT

Easy programming – Step by step1. Configuration in the hardware editorEach channel can be configured as an input or output with relay oranalog modules. Benefit from clear assignment of the inputs andoutputs, thanks to the graphical representation of the hardwareconnections.2. Creating a programInsert the inputs and outputs and the logic modules into the logicdiagram via drag & drop. The software is intuitive and simplifies yourwork. You do not need any in-depth programming knowledge.3. Simulating the new configurationUse the simulation function to easily check and simulate theprogrammed contents. The screen display shows all the statescurrently possessed by your application. Possible conflicts areindicated.Download nowDownload the free LOGIC software and a number ofcomplete programs for applications from our website.Did you know? LOGIC is ideal for testing PLC logicin advance without hardware.For additional information onthe LOGIC software, simplyenter the web code in thesearch field on our website.Web code: #0139PHOENIX CONTACT7

Wireless operation and monitoring withthe PLC logic appFor wireless access to process databetween the logic module and the mobileend device, the PLC logic app combinedwith the Bluetooth adapter is available toyou.Once the app is installed on yoursmartphone or tablet, you can use it toadjust parameters of the logic modules.The app can be used for operation andmonitoring, as it can access all programvariables.The Bluetooth connection enables efficientmonitoring of multiple logic modules, withjust one visualization device.8PHOENIX CONTACT

Display examplesThe visualization view is created via the editor of theweb server integrated in the logic modules. It is possibleto access all program variables: Inputs and outputs (digital, analog) Flags Numerical values Time valuesCommunication with the PLC logic app is accomplishedusing a Bluetooth adapter. The app is available for free inthe Apple App Store.Visualization using a touch panelFor jobs requiring control, operation, and monitoring,the BTP 2000 series HMIs go perfectly with PLC logic.Basic touch panels can be used to visualize all the logicmodule process data.Three different display sizes enable clear representation,from simple alphanumeric images to graphics-intensiveimages with object animation.PHOENIX CONTACT9

Easy wiringwith PLC logicPLC logic combines the strengths ofestablished relay technology with logicfunctions. In contrast to conventional logicmodules, the modular design with a varietyof relay modules enables channel-specificassembly. On the field side, sensors andactuators can be connected directly to therelay.Your advantages: Fast, clear wiring Easy to install Cost and space saving Electrically isolated inputs and outputsReduce your wiring costs with PLC logic24 V DCWith conventional logicmodules, wiring is complex andtime consuming. To avoid thedisadvantages of permanentlysoldered relays, additionalrelay modules are often usedin front of the inputs andoutputs.PLC logic replaces conventionalswitching and control devicesand reduces the wiringrequired.Logic level24 V DCInterface levelField levelConventional wiring10PHOENIX CONTACTWiring with PLC logic

Rapid connection forsensors and actuatorsBenefit from sensor and actuatorversions for direct connection of thesupply and return conductor. You canalso take advantage of the pluggablepotential bridges to minimize your wiringrequirements.Save time and costs by using theseversions as no additional potentialterminal blocks are required.PHOENIX CONTACT11

Logic modulesThe logic modules have eight integrated digital inputs, two of which can be configured as analog inputs (0–10 V). A further eightchannels can be configured with corresponding relay or analog modules as digital inputs or outputs. The modules can be programmedwith the intuitive LOGIC software.Connection/designationStand-alone moduleOrder No.Push-in connectionPLC-V8C/PT-24DC/SAM22907443Push-in connectionPLC-V8C/PT-24DC/BM22907446Push-in connectionPLC-V8C/PT-24DC/EM2905137With 16 I/Os, cannot be extended,connection to PC via microUSB socket. Integrated real-timeclock, accommodates externalIFS-CONFSTICK memory module.Basic moduleWith 16 I/Os, can be extendedup to a maximum of 48 I/Os.Connection to PC via microUSB socket. Integrated real-timeclock. Accommodates externalIFS-CONFSTICK memory block.Optional connection to fieldbusgatewaysExpansion moduleWith 16 I/Os, for extending thebasic module. A maximum oftwo expansion modules can beconnected to each basic module.Relay modulesRelay outputs12PHOENIX CONTACTConnection/designationOrder No.1 changeover contact,6 A, 250 V AC/DCPush-in connectionPLC-RPT-24DC/2129002991 changeover contact,50 mA, 36 V DC, gold contactPush-in connectionPLC-RPT-24DC/21AU29003061 N/O contact,6 A, 250 V AC/DC, actuator typePush-in connectionPLC-RPT-24DC/1/ACT29003121 N/O contact with switch,6 A, 250 V AC/DCPush-in connectionPLC-RPT-24UC/1/S/H2900328

Solid-state relay outputsConnection/designationOrder No.PLC-OPT-24DC/48DC/1002900352Screw connectionPLC-OSC-24DC/48DC/1002966728Push-in connectionPLC-OPT-24DC/24DC/22900364Screw connectionPLC-OSC-24DC/24DC/22966634Push-in connectionPLC-OPT-24DC/230AC/12900369Screw connectionPLC-OSC-24DC/230AC/129678403 A, 3 V DC . 33 V DC,actuator typePush-in connectionPLC-OPT-24DC/24DC/2/ACT2900376Screw connectionPLC-OSC-24DC/24DC/2/ACT2966676750 mA, 24 V AC . 253 V AC,actuator typePush-in connectionScrew connectionPLC-OSC-24DC/230AC/1/ACT2967947Push-in connectionPLC-OPT-24DC/300DC/12900383Screw connectionPLC-OSC-24DC/300DC/12980678Push-in connectionPLC-OPT-24DC/24 DC/10/R2900398Screw connectionPLC-OSC-24DC/24DC/10/R2982702Push-in connectionPLC-OPT-24DC/48DC/500/W2900378Screw connectionPLC-OSC-24DC/48DC/500/W2980636Push-in connectionPLC-OPT-24DC/TTL2900363Screw connectionPLC-OSC-24DC/TTL2982728100 mA, 3 V DC . 48 V DC3 A, 3 V DC . 33 V DC750 mA, 24 V AC . 253 V AC1 A, 12 V DC . 300 V DC10 A, 3 V DC . 33 V DC500 mA, 3 V DC . 48 V DC,electronic changeover contactTTL, 50 mA, 5 V DCRelay inputsPush-in connectionConnection/designationInput voltage 24 V DCInput voltage 120 V AC/DCInput voltage 230 V AC/DCInput voltage 5 V DC(basic terminal block without relay)Relay for 5 V DC basic terminal blockSolid-state relay inputsInput voltage 24 V DCInput voltage 120 V AC/DCInput voltage 230 V AC/DCDummies or reservesOrder No.Push-in connectionPLC-RPT-24DC/1AU/SEN2900313Screw connectionPLC-RSC-24DC/1AU/SEN2966317Push-in connectionPLC-RPT-120UC/1AU/SEN2900314Screw connectionPLC-RSC-120UC/1AU/SEN2966320Push-in connectionPLC-RPT-230UC/1AU/SEN2900315Screw 1/SEN2980267REL-MR-4,5DC/21AU2961370Push-in connectionScrew connectionPush-in connectionScrew connectionConnection/designationPush-in connectionPLC-OPT-24DC/V8C/SENOrder No.2908172Screw connectionPLC-OSC-24DC/V8C/SEN2908173Push-in connectionPLC-OPT-120UC/V8C/SEN2908174Screw connectionPLC-OSC-120UC/V8C/SEN2908175Push-in connectionPLC-OPT-230UC/V8C/SEN2908176Screw esignationOrder No.Push-in connectionPLC-BPT-24DC/212900445Screw connectionPLC-BSC-24DC/212966016Push-in connectionPLC-BPT-24DC/1/SEN2900262Screw connectionPLC-BSC-24DC/1/SEN2966061Basic terminal block outputBasic terminal block inputThe products shown are simply a selection from our product range. Visit us online at www.phoenixcontact.comPHOENIX CONTACT13

Analog modulesThe analog modules can be connected to stand-alone modules and basic modules. No signals from the analog discs can be processedwith the expansion modules.Analog input discsConnection/designationInput signal:0.10 V, 2.10 V, 0.20 mA,4.20 mAInput signal:Pt 100 or Pt 1000 sensorAnalog output discsScrew connectionPLC-ASC-UI-IN2906916Push-in connectionPLC-APT-UI-IN2906917Screw connectionPLC-ASC-PT100-IN2906918Push-in ationOutput signal:0.10 V, 2.10 V, 0.20 mA,4.20 mAOrder No.Order No.Screw connectionPLC-ASC-UI-OUT2906920Push-in connectionPLC-APT-UI-OUT2906921Starter kitDesignationStarter kitContents: Stand-alone logic module (SAM2) and eight relay outputterminals with Push-in connection technology, programming cable14PHOENIX CONTACTPLC-LOGIC-STARTERKIT3Order No.2909916

AccessoriesDesignationOrder No.Memory blockIFS-CONFSTICK2986122Programming cableCAB-USB A/MICRO USB B/2,0M2701626T-BUS connecting cablePLC-V8C/CAB/TBUS/0,3M2905263Bluetooth adapterfor wireless access to process databetween the logic module and mobileend deviceIFS-BT-PROG-ADAPTER2905872Feed-in terminalfor supplying power to the bridgepotentialsPLC-ESK GY2966508Continuous plug-in bridges500 mm long, can be cut to length,for potential distributionFBST 500-PLC RD2966786FBST 500-PLC BU2966692FBST 500-PLC GY2966838IFS gatewaysOrder No.For PROFIBUS DPEM-PB-GATEWAY-IFS2297620For RS-232EM-RS232-GATEWAY-IF2901526For RS-485EM-RS485-GATEWAY-IFS2901527For Modbus/TCPEM-MODBUS-GATEWAY-IFS2901528For DeviceNet EM-DNET-GATEWAY-IFS2901529For CANopen EM-CAN-GATEWAY-IFS2901504For PROFINETEM-PNET-GATEWAY-IFS2904472For EtherNet/IP EM-ETH-GATEWAY-IFS2901988For Inline ControllerIB IL IFS-MA-PAC2692720The products shown are simply a selection from our product range. Visit us online at www.phoenixcontact.comPHOENIX CONTACT15

COMPLETE line –The comprehensive solution for the controlcabinetCOMPLETE line is a system comprising technologically leading and coordinatedhardware and software products, consulting services, and system solutions that helpyou optimize your processes in control cabinet manufacturing. Engineering, purchasing,installation, and operation become significantly easier for you.Web code: #208916PHOENIX CONTACT

Your advantages in detail:Comprehensive product portfolioIntuitive handlingWith COMPLETE line, we offer a completeproduct portfolio of technologically leadingproducts. This includes: Controllers and I/O modules Power supplies and device circuit breakers Terminal blocks and distribution blocks Relay modules and motor starters Signal conditioners Safety technology Surge protection Heavy-duty connectorsThanks to the simple, intuitive handling ofthe coordinated hardware components, youwill save time during installation, startup,and maintenance. Push-in connectiontechnology enables you to wire applicationsquickly – without using tools. The broad,technologically leading product portfolio willalways provide you with the right product forstandard or special applications.Reduced logistics costsOptimized processes in controlcabinet manufacturingThe new standardfor the control cabinetCOMPLETE line supports you, fromengineering through to manufacturing, indesigning your control cabinet production asefficient as possible. Thus, your customizedconcept for optimizing your processes incontrol cabinet manufacturing is created. Ourterminal strip production helps you to flexiblymanage order peaks or to supply your controlcabinet production with fully assembled DINrails just in time.Discover the extensive COMPLETE lineproduct portfolio and find out more aboutCOMPLETE line and your comprehensivesolutions for the control cabinet.Reduced variety of parts, thanks tostandardized marking, bridging, and testingaccessories. The COMPLETE line systemcoordinates products, design, and accessoriesso that you benefit from maximum reusabilityand thus reduce your logistics costs.Time savings across the entireengineering processThe PROJECT complete planning and markingsoftware supports the entire process ofcontrol cabinet manufacturing. The programfeatures an intuitive user interface thatenables the individual planning, automaticchecking, and direct ordering of terminalstrips.Visit our website:phoenixcontact.com/completelinePHOENIX CONTACT17

Worldwide service and support –We are there for youAt Phoenix Contact, the focus is always on you, the customer. With over50 subsidiaries around the world and more than 30 agencies, we are always close by.As a result, you receive verified, first-hand advice and benefit from fast and timelydelivery of a complete package consisting of high-grade, optimally coordinatedcomponents. Our expertise and the high levels of production depth allow customizedsolutions tailored to you. We will also support you after the purchase withcomprehensive after-sales services.Web code: #224718PHOENIX CONTACT

Your advantages in detail:Fast terminal strip productionIndividual set solutionsCustomer-specific solutionsThe terminal strip production service provideshelp in managing order peaks flexibly, andenables terminal strips to be deliveredjust-in-time for series production. The fullyassembled and marked terminal strips, alreadyequipped with accessories, then simply haveto be installed and connected.To reduce the effort of materials and stockmanagement, you can order pre-pickedmaterial sets under a single order number.Can't find what you're looking for in ourrange? No problem: from minor adaptationsto completely new product developments, wefocus on your specific requirements.Global approvals and certificatesComprehensive after-sales services Comprehensive training programOur numerous certificates are proof thatyou can put your full trust in our products,because quality is essential. We strive tosatisfy this requirement in every respect.For this reason, our systems, processes, andproducts are inspected and certified severaltimes over.We are there for you – not just before yourpurchase, but also afterwards with ourcomprehensive after-sales services. Thisincludes a repair service, a replacementservice, and a spare part service.From the basics to specialist expertise: we willprovide you with the skills you need to theextent and configuration you require.PHOENIX CONTACT19

In dialog with customers and partners worldwidePhoenix Contact is a globally present, Germany-based market leader. Our groupis synonym for future-oriented components, systems, and solutions in the fields ofelectrical engineering, electronics, and automation. A global network across more than100 countries, and 17,400 employees ensure a close proximity to ourcustomers, which we believe is particularly important.The wide variety of our innovative products makesit easy for our customers to find future-orientedsolutions for different applications and industries.We especially focus on the fields of energy,infrastructure, process and factory ortugalTunisiaMexicoDominican RepublicGuatemalaHondurasNicaraguaTrinidad and TobagoCosta RicaPanama ssiaCzech ary MoldovaRomaniaSloveniaCroatiaBosnia andSerbiaHerzegovina nUgandaKenyaSouth KoreaGeorgiaUzbekistanArmeniaChinaTurkey AzerbaijanLebanon an BahrainQatarSri LankaSaudi AlgeriaGhanaBelarusPolandBlomberg, GermanyBelgiumFranceLithuaniaNetherlandsUnited pinesVietnamSingaporeEcuadorPeruJapanTaiwan, ChinaMauritiusBotswanaParaguayChileSouth AfricaUruguayArgentinaAustraliaNew ZealandYou will find our completeproduct range at:PHOENIX CONTACT GmbH & Co. KGFlachsmarktstraße 832825 Blomberg, GermanyPhone: 49 52 35 3-00Fax: 49 52 35 3-4 12 00E-mail: info@phoenixcontact.comphoenixcontact.comIIF 06-19.000.L3MNR 52005426/2019-03-15/03Printed in Germany PHOENIX CONTACT 2019phoenixcontact.com

On the logic module market, the PLC logic relay system is the first to combine logic, interface, and field connection levels in a single solution. This means that you can switch and control I/O signals using a single compact system. You can combine the new PLC logic module with the corresponding relay and analog modules as required.