Transcription

Air IPARTNETECHNOLOGYYOU CANTRUSTSIMP LI CIT Y

Air IPARTNETECHNOLOGYYOU CANTRUSTSIMFunctionalitiesSuitable for any application using compressed air: Storage function in order to handle high air consumption Stabilize pressure peaks and provide a stable air flow Perform a preliminary separation and removal of condensateP LI CIT YTypesUser benefitsPainted vesselsPressure stabilizationPainted vessels are used in the majority of the cases, where the air receiver is notsubmitted to extreme weather conditions and perfectly clean air is not an absoluteprerequisite. The paint job ensures protection against corrosion.Benificial for the pneumatic toolsusing the compressed airStorage functionFor handling high air consumptionImprovement of the lifetime,reliability and functionalityof your compressor- Pulsation reduction- Velocity reduction- Temperature reduction- Condensate seperationRisks to avoidInstalling an air receiver allows youto avoid the following risks:- Unstable pressure peaks- Multiple start/stop ofthe compressor- More condensate riskGalvanized vesselsGalvanization is used to protect steel against corrosion. The process itself is simple:the vessel is completely submerged in a zinc liquid bath.As a result, the zinc coating perfectly adheres to the entire surface of the tank,ensuring full protection of the steel.Vitrified vessels (vitroflex)These vessels are treated with vitreous enamel, making them water and steamresistant. The complete reliability of this type of treatment is the result of the inorganiccomposition and the link created between the enamel and metal surface.After having been baked at 850 C, the enamel no longer absorbs water and fullyprotects the vessel against corrosion.

AVAILABILThere is no one rule that fits all as some applications require larger air tanks because of the process.However, two rules of thumb that can help to finetune:Your air receiver capacity should be at least 1/4 of your free air delivery expressed in m³/min.Base yourself on the compressor’s motor power and calculate the capacity: Motorpower in HP x 30 Example: If you install a 10HP screw compressor, your receiver capacity should be minimally 300 literCorrectly sizing your air receiver brings following benefits for your compressors’ operations: Less waste during unloading period Overall smoother operation Avoid mechanical stress on several componentsConnection kitERSHITYTNYOGOLNHANTEC OU C TYSUTRIPSI M PLICABRELI ILITYPARHow to select the size of my receiver?SERVICEABILITYAIR RECEIVER CAPACITYYIT

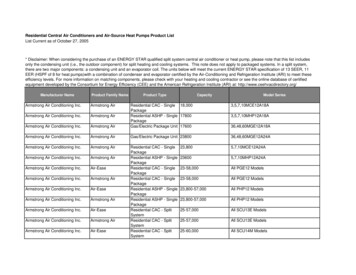

TECHNICAL DATAPainted standard vesselsCapacity ure (bar)1111111110,8111211,511,511,511,511,5Diameter Ø37044650060075080080010001000120014501450H tot 70h ”1/41”1/41”1/41”1/41”1/4l (mm)298397599775895860745590595700780780m 0Kit type included1234467BBBBBWeight (kg)375162127180200204278352537802923Norm & standards87/404/CE97/23/CE (PED)Zinc standard vesselsCapacity ure r Ø37043050060079079079010001000120014501450H tot 70h 1”1/41”1/41”1/41”1/41”1/41”1/4l (mm)447397442689690800725590595700780780m 30Kit type included1AAAAABBBBBBWeight (kg)4055661431842092243063875918821025Norm & standards87/404/CE97/23/CE (PED)Vitroflex standard vesselsCapacity ure ter ØN.A.43050060079079079010001000120014501450H tot 70h 1”1/41”1/41”1/41”1/41”1/4l (mm)N.A.397442689690800725590595700780780m 30Kit type includedN.A.AAAAABBBBBBWeight (kg)N.A.5060130167190204278352537802932Norm & standardsN.A.87/404/CE97/23/CE (PED)

AVAILABIL2000300040005000Pressure (bar)161616161616Diameter Ø6008001000120014301430H tot (mm)205523152810293031103610h �2”2”2”2”2”f2”2”2”2”2”2”l (mm)775745565645765765m (mm)156016852340237024502945Kit type included58CCWeight (kg)159246490620ERSHITY1000ABRELI ILITY500Norm & standards 87/404/CEGYLONO ANHTEC OU C TYUSTRTNCapacity (L)SERVICEABILITYPARPainted high pressure vesselsYITIPSI M PLICnot included905105597/23/CE (PED)Zinc high pressure vesselsCapacity (L)50010002000300040005000Pressure (bar)161616161616Diameter Ø6007901000120014301430H tot (mm)212023652810293031103610h ��l (mm)50053056564576576524502945m (mm)1760197523402370Kit type includedCCCCWeight (kg)176308539682Norm & standardsDøeaanot included995116097/23/CE (PED)cVitroflex high pressure vesselsCapacity (L)50010002000300040005000Pressure (bar)161616161616Diameter Ø6007901000120014301430H tot (mm)212023652810293031103610h ��l (mm)500530565645765765m (mm)176019752340237024502945Kit type includedCCCCWeight (kg)160280490620Norm & standards97/23/CE (PED)dH totmblhnot included905b1055f

HTYRSIPRELIABILIPARTNETECHNOLOGYYOU CANTRUSTSIMP LI CIT YAir Receivers A high quality product and technology you can trust Choosing our air receiver ensures your compressed air availability Our products are simple, easy to use and give strong reliability Serviceability and aftermarket are guaranteed Original Parts and Services Dealers are always nearby and complete the strong partnership you can expectContact your local sales representative now!6999100350Increase your profit and improve the image of your company 2014, All rights reserved. All mentioned brands, product names, company names, trademarks and service marksare the properties of their respective owners. Our products are constantly being developed and improved. We thus reserve theright to modify product specifications without prior notice. Pictures are not contractually binding.AVAISERVICETYILIABYILITBLA

Example: If you install a 10HP screw compressor, your receiver capacity should be minimally 300 liter Correctly sizing your air receiver brings following benefits for your compressors’ operations: Less waste during unloading period Overall smoother operation Avoid mechanical stress on several components Connection kit