Transcription

Cam System Design

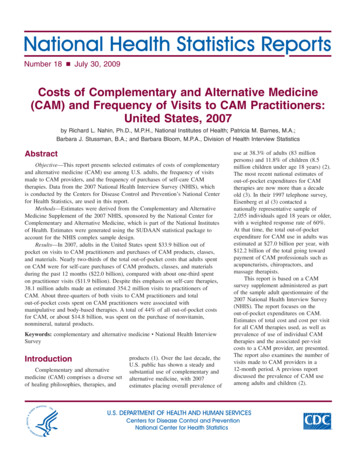

MAE 342 – Kinematics & Dynamics of Machinery2Typical Problem Design a cam system to:1.2.3.4.5.Open a valve 0.05 inches in 0.0025 secondsStay open for 0.0050 secondsClose in 0.0025 seconds, andStay closed for 0.02 seconds.Repeat continuously.y (in)0.00250.00750.03250.05000.0010.002 Use a roller follower. Make accelerations as small as possible.0.003t (s)

MAE 342 – Kinematics & Dynamics of MachineryClassification of Cams3

MAE 342 – Kinematics & Dynamics of MachineryClassification of Followers4

MAE 342 – Kinematics & Dynamics of MachineryReciprocating vs. Oscillating5

MAE 342 – Kinematics & Dynamics of MachineryOffset vs. Radial Follower6

MAE 342 – Kinematics & Dynamics of Machinery7Mechanical Constraint Cam SystemsDucati desmodromic camImage from MECH 324 Colorado State University

MAE 342 – Kinematics & Dynamics of MachineryDesigning Cam Systems1. Create a displacement diagram2. Select geometric parameter values8

MAE 342 – Kinematics & Dynamics of MachineryCreating Displacement Diagram Lift and dwell are usually applicationdependent (given by application requirements) Therefore mainly need to design transitions: Full-riseHalf-rise Full-returnHalf-return9

MAE 342 – Kinematics & Dynamics of MachineryDesigning Transitions Select an equation to meet maximumvelocity, acceleration and jerk raterequirements: Parabolic motion Simple harmonic motion Cycloidal motion Polynomial10

MAE 342 – Kinematics & Dynamics of MachinerySelecting Geometric Parameters Geometric parameter values need tobe chosen to avoid problems such as: Interference/undercuts High pressure angles Large enough face on follower11

MAE 342 – Kinematics & Dynamics of Machinery12Parameter selection: Roller Follower Select values of R0, e, etc. to avoid high pressureanglespressureangleΦ To obtain pressure angles, draw cam with follower in each position andmeasure or use nomograph (Fig. 6.28) to find maximum φ if possible.

MAE 342 – Kinematics & Dynamics of Machinery13Parameter selection: Roller Follower Select values of R0, e, etc. to avoid undercuts Minimum curvature (ρmin) must be greater than 0.To obtain ρmin draw cam and measure it or use Fig.s 6.30– 6.34 if possible.

MAE 342 – Kinematics & Dynamics of MachineryParameter selection: flat face follower Select R0, e, etc. to avoid undercutting14

MAE 342 – Kinematics & Dynamics of MachineryParameter selection: flat face follower Select face size & position so that facestays on cam15

Design a cam system to: 1. Open a valve 0.05 inches in 0.0025 seconds 2. Stay open for 0.0050 seconds 3. Close in 0.0025 seconds, and 4. Stay closed for 0.02 seconds. 5. Repeat continuously. 2 0.05 y(in) t (s) 0 0 0.001 0.0025 0.0075 0.002 0.003 Use a roller follower. Make accelerations as small as possible. 0.0325