Transcription

DOE 76-45/19SSDC-19IJOB SAFETY ANALYSISSYSTEM SAFETYDEVElOPMENT CENTERnDOE EGc.GEG&G Idaho, Inc.P.O . Box 1625Idaho Falls. Ida ho 83401November 1979UN ITED STATESDEPARTMENT OF ENERGYDIVISION OF OPERATIONAL AND EN V IRONMENTAL SAfETY

DISCLAIMERThis report was prepared as an account of work sponsored bythe United States Government. Neither the United States northe United States Department of Energy nor any of theiremployees, nor any of their contractors, subcontractors, ortheir employees, makes any warranty, expressed or implied,or assumes any legal liability or responsibility for theaccuracy, completeness, or usefulness of any information,apparatus, product or process disclosed, or represents thatits use would not infringe privately owned rights.Available from:System Safety Development CenterEG&G Idaho, Inc.P. O. Box 1625Idaho Falls, Idaho 83401

(JOB SAFETY ANALYSISPREPARED BYPAUL VI PAVLOV(NOVEMBER)(1979

(((ACKNOWLEDGMENTInformative and helpful discussions with Dr. R. J. Nertney andM. G. Bullock are acknowledged . Many individuals in the Department ofEnergy and private industry have reviewed this document . Their commentsare acknowledged as significant contributions to the completeness ofthis document.

ABSTRACTThe concepts and techniques for the development and performance ofan effective job safety analysis (JSA) are presented and discussed . Theelements of an analytic tree are identified. These elements includemanagement controls, identification of a method for job selecting,analysis of the job, incorporation of the JSA into operational systemsand monitoring a JSA program. The contribution of employees based ontheir experience and knowledge is illustrated.

GLOSSARY(CS&R - Codes, Standards, and Regulations (Federal, state and localrequirements)dB - Decibel Unit that expresses the relative intensity of sound on ascale from zero for the average least perceptible sound to about 130 forthe average pain levelDOP - Detailed Operating ProcedureJSA - Job Safety AnalysisPPE - Personal Protective EquipmentRSO - Reported Significant ObservationSOP - Standard Operating ProcedureSWP - -Safe Work PermitTWA - Time Weighted Average(

TABLE OF CONTENTSPREFACE. . . . . .1.INTRODUCTION.2II.JSA ANALYTIC TREE31.0Management Controls.52.0Establishing a Method for Selecting Jobs52.12.2563.0Analysis of the Job (Perform JSA). . . . .3.13.23.34.0Selection of Candidate Tasks for Analysis. . . .Prioritization of Tasks. . .Hazards Identification. . . . . . . .Hazards Elimination or Control (JSA).Review the Analysis and Potential SolutionsImplement the JSA Into Operational Systems4. 14.24.34. 47Step-by-Step Procedure. . . . . . .Safety Professional Cognizance . . .Informal Safety Processes . . . . .JSA Used for Training New Employees8.10.11· 12· 12· 12· 12. . . . . . 125. 0 Monitoring a JSA Program· 12CONCLUSION.· 17REFERENCES.· 18

(((FIGURES. . . . . . . .31.Analytic Tree . . . . . . .2.Flow Chart of the Group Discussion andDirect Observation Methods to Analyze a Job .143.Example of JSA Format . . .15APPENDIX A. INDEX OF JOBS TO BE ANALYZED.19APPENDIX B. ENERGY SOURCES.25APPENDIX C. A COMPLETED JSA29

PREFACE(The purpose of this guide is to identify the elements necessary todevelop and evaluate a job safety analysis program . Illustrating howemployees may contribute their personal experience and knowledge in thedesign of a JSA; and gives the concepts and techniques necessary toperform and maintain an effective JSA program.The analytic tree is structured to identify management's responsi bility, how to select a job, how to perform a JSA on that job, how toimplement the analysis and how to monitor the effectiveness of theanalysis. This guide may also be used to evaluate an existing JSAprogram.All necessary management controls are not developed in detail.Some of the identified JSA elements may require further elaboration.Therefore, the ideas presented in this guide will enable the readersto refine additional material .((1

I.INTRODUCTIONJob Safety Analysis (JSA) is a technique for the review of a job.Its purpose is to uncover inherent or potential hazards which may beencountered in the work environment. When properly used, the JSA willbe an effect ive tool for training and orienting the new employee i ntothe work env i ronment . A JSA can also be used to r etrain the olderemployee.During the development of a JSA, supervisors will learn more aboutthe jobs they superv i se . Employees who are encouraged to participatewill develop a better attitude and knowledge of safety. The programwill develop safer job procedures and create a better working environment.An analysis inc ludes five steps:1.Se 1ect a job.2.Break the job down into steps .3.Identify the hazards or determine the necessary contro l s ofthe hazards .4.Apply t he controls to the hazards.5.Evaluate the controls.To increa se the effectiveness of a JSA, a complete program mu st bedeveloped in which management is involved with the employee, supervisor,and safety. Therefore, thi s guide is designed for a complete JSA program.The following fiv e major elements are necessary to establish and maintainthe J SA program:1.Management control s2.Identification of a method for job selecting3.Analysi s of the job (perform JSA)4.Incorporation of the JSA into operational sy st ems5.Monitor; ng a JSA program.2

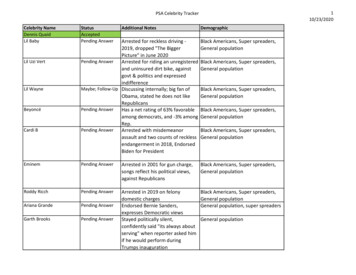

II .(The JSA analytic tree shown in Figure 1 is a representation of thenecessary elements for a JSA program . The following logic symbols areused on the analytic tree:ouo6(ANALYTIC TREEo AND- Gate SymbolCoexistence of all inputs required to produce output .OR- Gate Symbol (Nonexclusive)Output will exist if at least one input is present .RECTANGLEAn event resulting from the combination of morebasic events acting through logic gates .TRIANGLEA connecting or transfer symbol . All tree constructionbelow the "out" triangle is transferred to the treeat "in" triangle location(s) .CONSTRAINT SymbolAppliesgate orgate orsuch asconditions or constraints to basic logicoutput event. When applied to basic ANDOR- gate, it creates special conditional gateExclusive Or, and "Priority AND" .DIAMONDAn event not developed. Sequence is terminated forlack of information or consequences .The purpose of the analytic tree is the design of a new JSA programor the evaluation of an existing one. The following constraints on thetree must be considered :TrainingRoutine or one- time tasksCompliance to codes, standards and regulations.(The participants in the JSA program should receive appropriatetraining on the performance of a JSA .The analysis could be used inall phases of industry from construction , installation, operation, andmaintenance through decommission. Analyses performed on one- time tasksare as important as analyses of routine jobs . All Federal, state andlocal regulations must be complied with in the JSA .3

ObjectiveEstablish/maintainJob safety analYSIsprogram "JSA ".ioiog.Routine or one time tasks.CS&R complianceIIImplement the JSAinto operationalsystemsMonitoring a JSAprogramIEstablishing amethod forselecting jobscontrols1.0Analysis of the job(perform JSA)3.02.0504.0QISelection of tasksfor analysisPrioritization oftasks2.12.2II Eliminateor control Ihazard3.2HazardsidentificationReview the analysisand potentialsolutionst--,,03.100Step by stepprocedures4.1t-- Sa fe ty professionalOptimize decision byconsidering more thanone se lection crileriaL0rline function2.1I HHOrgani zational struc tureand personnel will determinewho analyzes Ihe ta sk,1Employees2.1 1.1Line supervisors2.1.1.2Upper management2.1.1.30JHStaff function,I2.1.2Accident severityH I-Judgment andexpellenceISafety2.2.32121DesignHI l I2.1.2.2Qualityassurance2.1.2.3IOthers2.1 .2.4-JIDirect observationmethod , analysisGroup di sC ussionmethodDirect observationmethodRoutine lobs6t - Break ,ob down stepby stepA.l2.24I-Job changesRecord significantobservationsA.22.2.5Anticipated ease ordifficulty2.2.63.2.1(;HHH1&JSupervisor3. 1.2.1[&,ISystems analyst3.1.2 .2&Record hazardsA3cognizanceAll exce pt personsperforming theanalysis and solutions4.2IIManagemenl3.1.2.3I - Change conditionswhich createhazards32 .1.2r-Change jobprocedure32 .1.3J Safety engineer3. 1.2.4Reduce frequencyof doing job3.2 .1.4&.-32 .26I - Less hazardous wayto dO the job3.2 .1.1Personnel protectiveequipmentH&Supervisol'3.2.2.1H&Systems analyst )3.2.2.2HHHWorker on the Job3.3. 1ISupervisorJSA used fortraining new and oldemployees4.4IIManagement3.3.3HI,ISafety engineer3.3.5H Managem 3.2.2 .3&,Safety engineer3.2.24I51HObserv"tion of task,5.2I,IHFeedback54J'--,I3.3.2Systems analyst3.3.4IIUse of RSOAccident records5.3Informal safet yprocesses4.3J3.1.20Sufficient combi nati onof Individuals tomaximize so luti onst--3.1.1Accident frequency2,2,2HH122.1Group discussionmethod , analysisLHI&INEL-C-14 1113.2.1.5Fi gure 1

(Adequate data for the elements of the analytic tree have beencompiled and are listed below. The subsection numbering system isanalogous to the numbering system of the analytic tree .1.MANAGEMENT CONTROLSManagement controls are needed to establish an effective JSA program .The entire program must be directed and supported t ugh the managementcontrols. Some aspects of management controls are:PoliciesDirectivesResponsioilities (line and staff)Vigor and exampleAccountabilityBudget .[a] For further information on management controls for an effectiveprogram, refer to the MORT Users Manual SSDC- 4.2.(ESTABLISHING A METHOD FOR SELECTING JOBSPotential jobs for analysis should be tasks with sequential steps.The work goal is attained when these steps have been performed.Some jobs can be broadly defined in general terms of the goal.Making paper, building a plant and mining iron ore are examples. Suchbroadly defined jobs are not suitable for a JSA. Similarly, a job canbe narrowly defined in terms of a single action . Pulling a switch,tightening a screw and pushing a button are examples . Such narrowlydefined jobs are sometimes not suitable for a JSA. Sometimes pulling aswitch or tightening a screw is very critical . In those cases, the jobshould be broken into single action steps.To use the program effectively, a method must be established toselect and prioritize the jobs to be analyzed. One method for selectingtasks to be analyzed is for a supervisor to list jobs performed byemployees. The supervisor then selects the jobs which represent thegreatest injury potential for analysis. Different approaches depend onthe organizational structure and objectives.2. 1 Selection of Tasks for Analysis(The structure and objectives of a company will determine theindividual who selects the tasks. If the employee turnover rate ishigh, the management might choose the supervisor or foreman to determinepotential tasks for analysis. An alternative to this approach is forthe safety engineer to develop the list. In some companies, safetyengineers are responsible for more than one facility and may sufficiently5

not be familiar with each area to suggest jobs for analysi s , Therefore,the employee, supervisor, and safety engineer might combine their knowledgeand effectively develop a list, The group discussion method will usuallybenefit the overall safety program (see Section 3), The most knowledgeableindividuals should be used to determine potential tasks for analysisregardless of the method used ,Jobs suitable for JSA are the jobs assigned by a line supervisor .Operating a machine, tapping a furnace, and piling lumber are goodsubjects for job safety analysis. They are neither too broad nor toonarrow . Assignments which require the performance of a number of sequentialsteps to accomplish the task are good candidates for job safety analysis.The following are examples of this kind of job :Material handling (heavy drums)Work on high energy( 480 V) electrical systemsAcid/caustic cleaningCrane repairCrane operationTrenching and excavatingErection and use of scaffoldingBeryllium, zirconium machiningRepairing cau st ic/acid tanksCar/bus service on hoistsOperation of X-ray, low power laser unit.The index of Jobs to be Analyzed is another method for selecti ngpotential jobs for analysis used by United States Steel Corp. In it,all of the occupations or earner groups are listed. Eac h occupation isf urther divided into the jobs performed . (See Appendix A.)2.2Prioritization of TasksThe establishment of priorities for the jobs selected is the nextstep . The tasks must be ranked in the order of greatest acc ide ntpotential (injury and illness or property damage). The tasks with thehighest risks should be analyzed first. To achieve this ranking oftasks, the following criteria should be used. The use of more than oneselection criterion will optimize decisions . Caution must be exercisedwhen selecting jobs for analysis if the employees are inexpe rienced.Analyses should begin with a simple task and proceed to more complexjobs.6

(2.2.1 Accident Frequency . A job that has repeatedly producedaccidents is a candidate for a JSA . The greater the number of accidentsassociated with the job, the greater its priority should be .2.2 .2 Accident Severity . Every job that has produced a disablinginjury should be analyzed. The injuries prove that the preventiveaction taken prior to their occurrence was not successful. Some jobsmay not have a history of accidents but may have the potential for asevere injury.2.2.3 Judgement and Experience. Many jobs qualify for immediatejob safety analysis because of the potential hazard involved . Such typeof hazard might be identified as "it hasn1t happened yet, but when itdoes -- watch out . II A good example is a job involving explosion possibilities or one involving the lifting of exceptionally heavy equipment.Such jobs involve fatality possibilities can cause fatalities eventhough they have not occurred.2.2.4 Routine Jobs. In routine or repetitive tasks with inherenthazards, the employee is exposed repeatedly to these hazards . Forexample , exposures to high lev

an effective job safety analysis (JSA) are presented and discussed. The elements of an analytic tree are identified. These elements include management controls, identification of a method for job selecting, analysis of the job, incorporation of the JSA into operational systems and monitoring a JSA program. The contribution of employees based onFile Size: 481KBPage Count: 47