Transcription

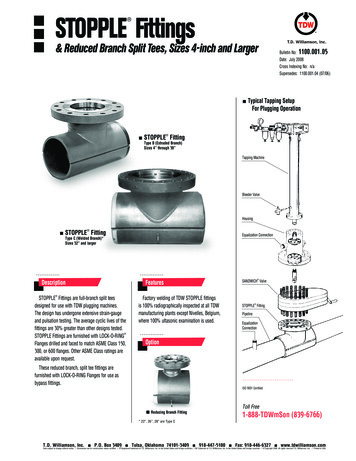

STOPPLE Fittings & Reduced Branch Split Tees, Sizes 4-inch and LargerBulletin No: 1100.001.05Date: July 2008Cross Indexing No: n/aSupersedes: 1100.001.04 (07/06)Typical Tapping SetupFor Plugging OperationSTOPPLE Fitting Type B (Extruded Branch)Sizes 4” through 30”Tapping MachineBleeder ValveHousingSTOPPLE Fitting Equalization ConnectionType C (Welded Branch)*Sizes 32” and largerDescription SANDWICH ValveFeaturesSTOPPLE Fittings are full-branch split teesdesigned for use with TDW plugging machines.The design has undergone extensive strain-gaugeand pulsation testing. The average cyclic lives of thefittings are 30% greater than other designs tested. STOPPLE Fittings are furnished with LOCK-O-RINGFlanges drilled and faced to match ASME Class 150,300, or 600 flanges. Other ASME Class ratings areavailable upon request. Factory welding of TDW STOPPLE fittingsis 100% radiographically inspected at all TDWmanufacturing plants except Nivelles, Belgium,where 100% ultasonic examination is used. STOPPLE FittingPipelineEqualizationConnectionOptionThese reduced branch, split tee fittings arefurnished with LOCK-O-RING Flanges for use asbypass fittings.ISO 9001 CertifiedToll FreeReducing Branch Fitting1-888-TDWmSon (839-6766)* 22”, 26”, 28” are Type CT.D. Williamson, Inc.P.O. Box 3409Tulsa, Oklahoma 74101-3409918-447-5100Fax: 918-446-6327www.tdwilliamson.comData subject to change without notice. / Dimensions not for construction unless certified. / Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / Copyright 2008. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part NumbersSTOPPLE Fittings Class 1100.001.05 Pg. 2Maximum allowable operating pressure (in psi) per ASME B31.8 at -20 to 100º FDesign factorLbs.Kg.0.720.60.50.4Part 20006-8807-28152895 130328528528524806-8807-30152320 104428528525820606-8807-34152780 ----4Maximum Allowable Operatiing Pressure perASME B31.4 at -20 to 180º F 285 psi1. For sizes 4- through 12-inch and 16-inch sizes, see bulletins 1100.005.01 and 1100.006.01.2. For B31.4 applications. 0.72 and 0.6 Design Factor only.3. For B31.8 applications4. Consult the factory.Class um allowable operating pressure (in psi) per ASME B31.8 at -20 to 100º FDesign FactorLbs.Kg.0.720.60.50.4Part 2630195088574062552041506-8807-28302985 134374074074067206-8807-30303065 137974068557045506-8807-34303780 ----4Maximum Allowable Operatiing Pressure perASME B31.4 at -20 to 180º F 740 psi1. For sizes 4- through 12-inch and 16-inch sizes, see bulletins 1100.005.01 and 1100.006.01.2. For B31.4 applications. 0.72 and 0.6 Design Factor only.3. For B31.8 applications4. Consult the factory.T.D. Williamson, Inc.P.O. Box 3409Tulsa, Oklahoma 74101-3409918-447-5100Fax: 918-446-6327www.tdwilliamson.comData subject to change without notice. / Dimensions not for construction unless certified. / Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / Copyright 2008. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part NumbersSTOPPLE Fittings & Reduced Branch Split Tees Maximum allowable operating pressure (in psi) per ASME B31.8 at -20 to 100º FDesign FactorLbs.Kg.0.720.60.50.4Part 7093214801245103583006-8807-26602730 123814801270106084506-8807-28603180 143114801255104583506-8808-30604640 208814801372114391406-8807-34605990 269614801335111089006-8807-36606705 304114801315109587506-8807-40607650 347014801265105084006-8807-4260--------4Class 600Inches114141818202022242628303436404248Maximum Allowable Operatiing Pressure perASME B31.4 at -20 to 180º F 1480 psi1100.001.05 Pg. 12001. For sizes 4- through 12-inch and 16-inch sizes, see bulletins 1100.005.01 and 1100.006.01.2. For B31.4 applications. 0.72 and 0.6 Design Factor only.3. For B31.8 applications4. Consult the factory.Reducing Branch FittingHLReducing Branch Split Tees (Hot Drawn) with LOCK-O-RING Flanges Class 600SizeInchesDN6x4150 x 1008x4200 x 10010 x 6 250 x 15012 x 6 300 x 15014 x 8 350 x 20016 x 12 400 x 30020 x 12 500 x 300T.D. Williamson, Inc.Dimension 041924.00061024.000610P.O. Box 3409Dimension 4815.93840518.312465Maximum allowable operating pressure (in psi) per ASME B31.8 at -20 to 100º FWeightDesign FactorLbs.Kg.Part lsa, Oklahoma 74101-3409918-447-5100Fax: 918-446-6327www.tdwilliamson.comData subject to change without notice. / Dimensions not for construction unless certified. / Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / Copyright 2008. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers1100.001.05 - p4STOPPLE Fittings Description of FittingsType BType B: Hot-drawn, full-branch opening, snug-fitting sleeve and a LOCK-O-RINGFlange of the desired series.Type CHType C: Fabricated full-size nipple, branchoutlet welded to snug-fitting sleeve and aLOCK-O-RING Flange of the desired series.HReducing-Branch Split Tee: Hot-drawn,reduced-branch opening, snug-fitting sleeveand a LOCK-O-RING Flange or standard weldneck flange of the desired series.LLStandard cataloged Class 600 STOPPLE fittings and Class 600 reduced-branch fittings are designed for working pressure of 1480 psi (102 bar) with a design factor F of .72 per ASME B31.8-1995 and B31.4-1992.Consult the factory for fittings for other applications or design peBBBCBCCBCCCCCL (All 54165.0001651-------H (Class 10-------NOTE: Flanges in sizes 10” (250 mm) and below are drilled and faced according to ANSI B16.5.Flanges above 10” (250 mm) are drilled and faced according to MSS-SP44. When ordering replacementfittings, please specify fitting equipped with flanges which will fit existinghot tap or STOPPLE equipment.T.D. Williamson, Inc.P.O. Box 3409H (Class 25-------H (Class 77-------1 Class 600 50.00 (1270)Tulsa, Oklahoma 74101-3409918-447-5100Fax: 918-446-6327www.tdwilliamson.comData subject to change without notice. / Dimensions not for construction unless certified. / Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / Copyright 2008. All rights reserved T.D. Williamson, Inc. / Printed in USA

STOPPLE Fittings ASME B31.3 - Sizes 4- through 12- & 16-inchBulletin No: 1100.004.01Date: November 2008Cross Indexing No: n/aSupersedes: January 2008Typical Tapping SetupFor Plugging OperationOffset incloseupTapping MachineNew fittings incorporate a designedand manufactured offset allowing theplacement of back-up stripsBleeder ValveSTOPPLE Fitting LOCK-O-RING Plug, Blind flange,studs, nuts and gasket sold separatelyAll pressure-containing welds on the fittingshave undergone X-ray inspection per ASMErequirements.DescriptionSTOPPLE Fittings are 4- through 12- & 16-inchfull-branch split tees designed for use with theTDW STOPPLE plugging system. They meet B31.3specifications for use in refinery and chemical plantpiping systems. STOPPLE Fittings are furnished with LOCK-O-RING Flanges to accept a LOCK-ORING Completion Plug, permitting removal of thetapping valve after work is completed. Flange-to-sleeve weld joints and sleeves aredesigned to meet pressure and reinforcementrequirements of ASME codes, and are available inClass 150, 300 and 600. Other ASME Class ratingsavailable upon request.Fittings are manufactured with a controlledcarbon equivalent to make welding easier in harshenvironments. Back-up strips are provided for allfittings.P.O. Box 3409Equalization ConnectionFitting sleeves are an extruded type design.They are manufactured from a pressure-vesselquality, normalized, killed carbon steel platewith hardness below Rc22.SANDWICH ValveThe Charpy impact value of the sleevesat -50 F is 15 ft-lbs average with 12 ft-lbsminimum.STOPPLE Fitting PipelineEqualizationConnectionOptionsFeaturesT.D. Williamson, Inc.HousingRapid delivery: If the desired fittingmeets standard specifications, it can beshipped from stock or within two weeksin most cases.Choice of flanges.Available also to ASME B31.4 and B31.8specificationsUse the grid inside to develop the part numberfor the STOPPLE fitting of your choice*Contact the factory for information concerning ordering ofsplit sleeves (tees).*Please confirm your choice with a Factory RepresentativeTulsa, Oklahoma 74101-3409918-447-5100ISO 9001 CertifiedToll Free1-888-TDWmSon (839-6766)Fax: 918-446-6327www.tdwilliamson.comData subject to change without notice. / Dimensions not for construction unless certified. / Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / Copyright 2008. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part NumbersSTOPPLE Fittings - ASME B31.3 1100.004.01 Pg. 236-1041-XXXX-XXExample36-1041-0630-11 is a STOPPLE Fitting with 6” (run) x 6” (branch), with an RF standard weight flange,A105 TDW std. flange material, BUNA-N o-rings, class 300, and A 537 CL. 1 TDW Std. sleeve material withback-up strips. HDLSTOPPLE Fitting Size Inches(Nom.)040608101216Class 1507.0158.82810.15611.21812.40616.172STOPPLE Fitting ASME Class Dim. H (Inches)Class 3007.0158.82810.15611.21812.90616.172Dim. LInches10.7514.0016.5020.0022.0030.00Class 6007.2669.07810.40612.84413.92216.546Dim DInches4.6566.7818.81210.93812.96816.218Part Number153060Option150 LB300 LB600 LBFlange and O-Ring MaterialOption1X2X3X4X5X6X7X8XFlange/O-Ring MaterialO-Ring Temp RatingsA105 w/ Buna-N O-Rings212º FA694 F46 w/ Buna-N O-Rings (See Note)A105 w/ NEOPRENE O-Rings225º FA694 F46 w/ NEOPRENE O-Rings (See Note)A105 w/ VITON O-Rings400º FA694 F46 w/ VITON O-Rings (See Note)A105 w/ EPDM O-Rings250º F / 500º F SteamA694 F46 w/ EPDM O-Rings (See Note)Sleeve MaterialOptionX1X2Sleeve MaterialA537 CL1A516 GR 70Note: Standard flange material for 4- through 12-inch is A105, 16-inch is A694 F46.Viton is a registered trademarks of DuPont Performance Elastomers LLC Ltd Fitting Weights and Pressure RatingsSizeInches (Nom.)040608101216Weight (lbs.)Class 1505590135190300580Weight (lbs.)Class 30060100140190300600Weight (lbs.)Class 60065105160280380700Class 150285285285285285285MAOP (in psi) @ -20 to 100 FClass 300Class 60074014807401145740915740965740930740965Tulsa, Oklahoma 74101-3409918-447-5100Consult factory for other pressure and temperature requirementsT.D. Williamson, Inc.P.O. Box 3409Fax: 918-446-6327www.tdwilliamson.comData subject to change without notice. / Dimensions not for construction unless certified. / Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / Copyright 2008. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part NumbersSTOPPLE Fittings - ASME B31.3 1100.004.01 Pg. 3Pressure and Temperature Ratings4-, 6- and 8-inch 300 LB A105 Flangeand A537 CL1 or A516 GR 70 Sleeve285260230200170140740Pressure - PSIPressure - PSI4-, 6- and 8-inch 150 LB A105 Flangeand A537 CL1 or A516 GR 70 ture - ºF500600700-20/1004-inch 600 LB A105 Flangeand A537 CL1 or A516 GR 70 Sleeve300400Temperature - ºF5006007005006007006-inch 600 LB A105 Flangeand A516 GR 70 Sleeve1155114511151480Pressure - PSI1360131012651205Pressure - PSI20011351060-20/100200300400Temperature - ure - ºFPressure - PSI6-inch 600 LB A105 Flangeand A537 CL1 Sleeve115511351120NOTE: The pressure/

hot tap or STOPPLE equipment. 1 Class 600 50.00 (1270) Type B: Hot-drawn, full-branch opening, snug-fitting sleeve and a LOCK-O-RING Flange of the desired series. Type C: Fabricated full-size nipple, branch outlet welded to snug-fitting sleeve and a LOCK-O-RING Flange of the desired series. Reducing-Branch Split Tee: Hot-drawn,