Transcription

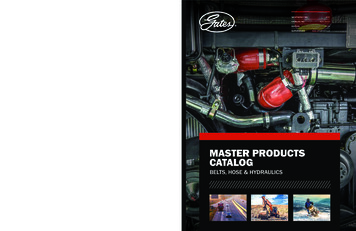

Weatherly No.400Catalog No.431-2061Edition2016SupersedesGROUNDS MAINTENANCEEQUIPMENTCommercial & Residential Lawnand Garden EquipmentFarm & Agricultural Equipment431-2061 (2013)

OWN YOUR LAWN & GARDEN BELT MARKETWITH GREAT SUPPORT FROM GATES.Boost Your V-Belt Sales.There are all kinds of equipment besides cars and trucks thatuse belts. We can help you grow your lawn and garden belt businesswith great support programs for BladeRunner , PoweRated and TruFlex belts.POWERATED BELT MERCHANDISERGates. Powering Progress

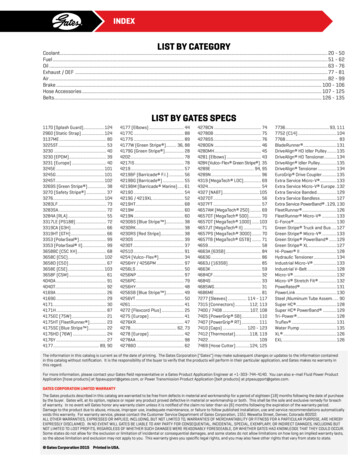

Table of ContentsTable of Contents & Warranty. A1Product Pages. A2- A59Abbreviations. A60Belts for Riding Mowers. 1-257Belts for Walk Behind Mowers. 258-315Belts for Compact Tractors. 316-319Belts for Snow Blowers/Throwers. 320-343Belts for Tillers. 344-384Belts for Lawn Equipment. 385-403Belts for Lawn Attachments. 404-439Belts and Coolant Hose for Combines. 440-501Belts and Coolant Hose for Cotton Equipment. 502-505Belts and Coolant Hose for Harvesters. 506-508Belts and Coolant Hose for Hay Equipment. 509-510Belts and Coolant Hose for Sprayers. 511-512Belts and Coolant Hose for Tractors. 513-659Belts and Coolant Hose for Windrowers. 660-665Straight Hose Size Lists. 666-667Truflex and PoweRated V-Belt Size Lists. 668-669FleetRunner Micro-V Belt Size Lists. 670-675Century Series Micro-V Belt Size Lists. 676-685Industrial Micro-V Belt Size Lists. 686FleetRunner Heavy-Duty V-Belt Size Lists. 687-688XL V-Belt Size Lists. 689-692Green Stripe Truck and Bus V-Belt Size Lists. 693-696Green Stripe Truck and Bus PowerBand Belt Size Lists . 697-698Hi-Power II V-Belt Size Lists. 699-700Hi-Power II PowerBand Belt Size Lists. 701Super HC V-Belt Size Lists. 702Super HC PowerBand Belt Size Lists. 703Tri-Power V-Belt Size Lists. 704Special Belt Size Lists. 705-706Green Stripe Vulco-Flex Coolant Hose (Heavy-Duty) Size Lists. 707-708Vulco-Flex II Coolant Hose (Standard) Size Lists. 709-710Changeover Listing – FleetRunner to Standard Belts. 711-712WarningBe safe! Do not use Gates belts, pulleys or sprockets on any aircraftpropeller or rotor drive systems or in-flight accessory drives. ThoseGates products are not designed or intended for aircraft use.CautionUse Gates products only on applications specified in Gates literature.Install and maintain products according to the vehicle manufacturers’recommended procedures and with recommended tools. Failure tofollow these instructions could result in injury or property damage.Gates disclaims all liability due to failure to follow these instructions.Limited Warranty for the Life of the MerchandiseGoods are warranted to be free from defects in material or workmanshipfor the life of the Goods (or the published recommended replacementinterval specified by Gates). Gates will replace or repair, at its option,any Goods proved defective in material or workmanship during thewarranty period. This is the sole remedy for breach of warranty. Colorfade and color difference is not warranted. This warranty is void if thedefect is caused by improper installation, use or maintenance of theGoods, or used for racing or competition. Goods are not warrantedto comply with laws that may apply to uses of the Goods not statedin related materials, e.g., use in manned or unmanned aviation or lifesupport applications.ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUTNOT LIMITED TO WARRANTIES OF MERCHANTABILITY AND FITNESSFOR A PARTICULAR PURPOSE, ARE EXPRESSLY DISCLAIMED. FAILURETO REPLACE TIMING BELTS OR OTHER GATES PRODUCTS AS SPECIFIEDMAY RESULT IN CATASTROPHIC ENGINE OR EQUIPMENT DAMAGE FORWHICH GATES DISCLAIMS ALL RESPONSIBILITY, TO THE EXTENTPERMITTED BY APPLICABLE LAW.This publication contains the latest information available to ourengineers. If you require additional application or part numberinformation, contact the Automotive Product Application Tech Lineat 303-744-5651.www.Gates.comA1

Lawn GardenBladeRunner BeltsThe BladeRunner belt is an aftermarket belt designed to fit specific applications. The BladeRunner belt providesexact OE fit, construction and performance when installed on leading lawn, garden and outdoor power equipment. Meets or exceeds the performance of the OE belt on the equipment that it is applied to, whichreduces costly downtime and labor associated with belt replacement. Utilizes Aramid Cord construction which has a higher tensile strength than steel. Exact fit to ensure smooth engagement of clutch and reduced harshness of operation. Various constructions (V, Cogged, Synchronous) available in order to meet the needs of thecustomer. Superior performance over standard fractional horsepower belts on recommended applications.PoweRated V-BeltsGates PoweRated V-belts are design-engineered to handle virtually any utility application because they transmitmore horsepower than conventional utility belts - up to 17 horsepower. Gives outstanding performance on driveswith backside idlers. R einforced with aramid tensile cord, pound for pound stronger than steel. G reen Flex-Weave cover resists heat, oil and cracking. uperior performance on clutching and backside idler drives. S U niversal construction features cord placement and cover that provide smooth, quiet operationwith reduced vibration. C oncave sides fill out to make even contact with the sides of the sheave grooves to distributewear uniformly. ates PoweRated V-belts can be substituted for equivalent sizes of FHP low horsepowerNote: GGates Truflex V-belts.Truflex V-BeltsRecommended for lower horse-power lawn and garden equipment, heating and home air conditioning drives, lightduty appliances, shop and miscellaneous fractional horsepower applications. O il and heat resistant. R esists ozone, weather and many chemicals and detergents. U niversal construction features cord placement and cover that provide smooth, quiet operationwith reduced vibration. C oncave sides fill out to make even contact with the sides of the sheave grooves to distributewear uniformly.Note: Do not use on applications where FHP medium horsepower V-belts are recommendedA2www.Gates.com

IndustrialSuper HC V-BeltsPioneered by Gates, these “narrow” cross-sections can transmit up to three times the horsepower of the classicalcross-sections (A, B, C and D) in the same amount of drive space. Suitable for all industrial applications, particularlywhere space, weight and horsepower capacity are critical. Gates curves provide proper cord support and full contact with the sheave-groove for uniformloading, uniform wear and increased belt life. Flex-bonded cords are strongly bonded to the body of the belt resulting in equal loaddistribution and the absorption of bending stress without cord deterioration. T he Flex-Weave cover is constructed for longer cover life, providing extended protection to thecore of the belt from oil, dirt, and heat. Meets ARPM/RMA IP-3-2 oil and heat resistance standards. Meets ARPM/RMA IP-3-3 static conductivity requirements. Gates also offers Super HC PowerBand belts allowing multiple belts to function as a single unitwith even load distribution and each strand fitting securely in the sheave groove.Super HC Molded Notch V-BeltsConstructed with Gates proprietary construction, this belt has a superior combination of flex and load carryingcapacity, as well as transmitting more horsepower than the classical cross sections in the same amount of drivespace. Suitable for all industrial applications, particularly where space, weight and horsepower capacity are critical. Notches molded into the belt during manufacturing increase flexibility, making this belt wellsuited for drives with smaller diameter sheaves. Belt edge is machined for even sheave groove contact resulting in smoother running, less slipand wear.· F lex-bonded cords are strongly bonded to the body of the belt resulting in equal loaddistribution and the absorption of bending stress without cord deterioration. Patented ethylene material construction provides -70 F to 250 F (-57 C to 121 C)temperature range to resist belt cracking. Meets ARPM/RMA IP-3-2 oil and heat resistance standards. Meets ARPM/RMA IP-3-3 static conductivity requirements. Gates also offers Super HC Molded Notch PowerBand V-belts allowing multiple belts to functionas a single unit with even load distribution and each strand fitting securely in the sheave groove.Industrial Micro-V Belts (J, L and M Series)Exclusive truncated (shortened) profile gives Gates Micro-V belts increased flexibility, reduced heat build-up andallows performance at higher speeds on smaller diameter sheaves. Well suited for applications such as appliances,outdoor power equipment, roller conveyors, machine tools, medical equipment and exercise equipment. Fiber reinforced ribs for excellent wear resistance. High modulus, low stretch tensile member for added strength and dependability. Smooth running for minimal vibration at high speeds. Meets ARPM/RMA IP-3-2 oil and heat resistance standards. Meets ARPM/RMA IP-3-3 static conductivity requirements.www.Gates.comA3

Heavy-Duty FleetFleetRunner Micro-V BeltsDesigned for the toughest applications, FleetRunner construction provides superior flexibility, stability, loadcapacity and unsurpassed belt life. Patented materials deliver peak performance at extreme prolonged operatingtemperatures making this belt the ultimate problem solver. An advanced blend of EPDM rubber technologywithstands the modern threats of deterioration from increased exposure to ozone and water-based coolants.FleetRunner does this all while providing the lowest cost per mile for fleets, including ¾ and 1 ton pickups. Belt of choice by fleets, including ¾ and 1 ton pickups. Lowest cost per mile. Consistently outperforms all competitors. Outstanding crack resistance at extreme temperatures. Problem-solver designed for the toughest applications.FleetRunner Heavy-Duty V-BeltsPatented EPDM construction with distinct green overcord built specifically for more durability and longer lifeon heavy-duty drives. Outperforms the competition on the most troublesome drives. Special compound provides un-matched flexibility, stability, load carrying capacity and belt life. Patented material provides peak performance at extreme prolonged operating temperatures. Heavy-duty construction resists cracking and wear. Oil and heat-resistant. Unique undercord notch pattern offers increased flexibility for smaller diameter pulleys. Available in over 70 sizes.Green Stripe PowerBand BeltsDesigned for problem, heavy-duty, heavily vibrating applications requiring belt sets. Tie-band feature joining beltstogether ensures stability lacking in ordinary belt sets.A4 Even load distribution between strands provides better shock load absorption. Belt cannot turn over or slip off drive. Unique tensile cord design gives belt extra strength, added flexibility and shock-loadresistance. Molded notches reduce bending stress, especially on small diameter pulleys,while dissipating heat. Meets or exceeds SAE J1459 specifications.www.Gates.com

Heavy-Duty FleetGreen Stripe Truck and Bus Series V-BeltsSpecifically designed for heavy-duty truck, bus and off-road equipment applications. Absorbs normal shock loadswithout damage to belt. Special tensile cords give high stretch resistance. Special notch design resists cracking while providing tensile member support during operation. Oil and heat-resistant construction throughout. Meets SAE J636b and SAE J637 specifications. Gates also offers Green Stripe Truck and Bus Series PowerBand V-belts for problem, heavyduty, heavily vibrating applications requiring belt sets.Hi-Power II V-BeltsFeaturing a composite, multi-purpose construction, these belts resist oil and heat, ozone, sunlight, weather andaging. Suitable for all industrial applications, including v-flat drives. Gates curves provide proper cord support and full contact with the sheave-groove for uniformloading, uniform wear and increased belt life. Flex-bonded cords are strongly bonded to the body of the belt resulting in equal loaddistribution and the absorption of bending stress without cord deterioration. T he Flex-Weave Cover is constructed for longer cover life, providing extended protection to thecore of the belt from oil, dirt and heat. Meets ARPM/RMA IP-3-2 oil and heat resistance standards. Meets ARPM/RMA IP-3-3 static conductivity requirements. Gates also offers Hi-Power II PowerBand V-belts allowing multiple belts to function as a singleunit with even load distribution and each strand fitting securely in the sheave groove.Tri-Power V-BeltsConstructed with Gates proprietary construction, this belt has a superior combination of flex and load carryingcapacity, as well as less stretch resulting in less maintenance. Suitable for all industrial applications, particularlywhere small or sub-minimal sheave diameters are required. N otches molded into the belt during manufacturing increase flexibility, making this belt wellsuited for drives with smaller diameter sheaves. Belt edge is machined for even sheave groove contact resulting in less slip and wear. Flex-bonded cords are strongly bonded to the body of the belt resulting in equal loaddistribution and the absorption of bending stress without cord deterioration. Meets ARPM/RMA IP-3-2 oil and heat resistance standards. Meets ARPM/RMA IP-3-3 static conductivity requirements. Gates also offers Tri-Power II PowerBand V-belts allowing multiple belts to function as a singleunit with even load distribution and each strand fitting securely in the sheave groove.www.Gates.comA5

Accessory Belt Drive SystemXL V-BeltsReplacement belt for the most demanding engine drives. Due to thermal forces, this variable notched belt tightenson the drive as it gets hot. This results in improved belt performance by reducing tension decay and noise. Fiber-loaded rubber stock puts more flexibility along the length of the belt, yet givesthe belt greater lateral stability in the pulley. Thermally active tensile cords for maintenance-free performance when properlyinstalled and tensioned. Form ground to ensure precise top width and sidewall dimensional control for properfit in pulley as well as a smoother, quieter running belt. Meets or exceeds SAE J636C specifications. Gates also offers Green Stripe XL V-belts as a premium-quality replacement forheavy-duty engines.Century Series Micro-V BeltsImport or domestic, car or truck, every vehicle can depend on the superior quality of Gates precision fit CenturySeries Micro-V belts. With advanced technology that matches the OE size, construction and materials Century SeriesMicro-V ensures optimal vehicle performance. Micro-V belts provide peak operating performance while delivering thehighest value available. M eets or exceeds all specifications from the Original Equipment Manufacturer. esigned for small diameter pulleys, backside idlers, and for use with (or without) automatic Dtensioners. S pecial belt constructions eliminate belt noise, reduce tension loss, and solve problem driveapplications. U tilizes advanced materials like Aramid Fiber found in bullet-proof vests and crack and heatresistant EPDM materials. nique form grinding of each individual belt assures precise dimensional control. U M eets or exceeds SAE J1459, SAE J2432, and SAE J1596 specifications. Gates also offers Century Series Micro-V Green Stripe belts with greater load-carryingcapacity designed for demanding, heavy-service drives.Century Series Aramid BeltsGates, the leader in automotive Serpentine belt drive systems, collaborates with OE manufacturers globally tocontinually evolve the performance and durability of belt drives. Certain vehicle engines require specific beltconstructions, such as aramid tensile cord, to provide long belt life, and eliminate noise and vibration that areinherent on these drives. Utilizing this same technology for the Aftermarket, Gates offers Century Series Aramidcord belt for specified vehicles. This construction matches the OEM to assure a quiet and smooth functioning belt,with the same performance and durability as the OEM part. For guaranteed OE performance, use Gates CenturySeries Aramid Serpentine Belts.A6 E xact OEM aramid cord construction replacement – superior to polyester tensile cords as mostserpentine belts come with. E ssential for specific demanding accessory belt drives (Turbo, Diesel, high RPM). R educes noise and vibration. E xtends life of the belt and other accessory drive components.www.Gates.com

Accessory Belt Drive SystemCentury Series Micro-V Dual-Sided BeltsFor replacing original equipment belts on serpentine drives that require a higher degree of efficiency when transmittingpower. Designed for small diameter pulleys and for use with or without automatic tensioners. V -ribbed on both sides of the belt. S pecially designed to resist wear and cracking due to overall reduced thickness in construction. B road coverage on unique applications. C ustom setup for Gates specialized solution kits for Serpentine drives that cause problemsfrom the OEM.DriveAlign Automatic Belt TensionersGates is a global leader in Original Equipment (OE) System Design. With a full line of tensioners and internationalmanufacturing locations, you can count on Gates to supply premium quality DriveAlign Automatic Belt Tensioners.Gates ensures that every tensioner they manufacture is built to rigid tolerances and specifications that guaranteeOE fit, form and function. Full line coverage for Import, Domestic and Heavy-Duty applications. Manufactured using the same technology as Original Equipment Manufacturer (OEM)part, assuring a factory match. Patented vibration damping system improves tensioners, belts and accessory life. Torsional round spring design provides consistent tension and does not allow contamination. Comprehensive line includes parts to fit cars, vans, SUV’s and light trucks.DriveAlign Idler PulleysBuilt to last by resisting dirt, salt, and other under-hood contaminants and are designed for use on passenger carsand light trucks as a locked center tensioning pulley, an automatic belt tensioner pulley or an idler pulley. Steel or thermoplastic construction provides high durability for long life. Bearing meets or exceeds OE and is designed for application specific speedand load requirements. Reliable operation under severe conditions. Applicated for Import and Domestic vehicles. Mounting hardware included on some popular applications.www.Gates.comA7

Coolant Systems - HoseHose Shelf LifeStorage environment, along with rubber materials, can vary the shelf life limit. Shelf life is difficult to quantify asmany variables affect the hose. Proper storage precautions can result in three to five years of shelf life. Beyondthis time, there can be a significant service life decrease, depending on storage environment variables.Some variables include:Hose should be stored in a cool, dry area never exceeding 100 F ( 38 C). If stored below freezing, pre-warmingmay be required prior to handling, testing and placing into service. Store hose in original container. Never stackhose too high, as its weight can crush hose at the bottom of the stack. Gates recommends hose in extendedstorage be visually inspected and tested prior to use. Hose judged marginal should be replaced to avoid potentialfailure, property damage or bodily injury. Store hose on a first-in/first-out basis. Unusually long storage, or poorstorage environment can deteriorate hose, reduce performance and may lead to premature failure.Molded Coolant HoseGates molded coolant hose is manufactured to fit specific applications. Equivalent in design to OEM specifications.Approved for marine applications. Recommend for upper, lower, by-pass, heater and other coolant hose applications. Heat and ozone resistant cover. Engineered to resist electrochemical degradation - the leading cause of hose failure.ELECTROCHEMICAL Re-engineered materials resist vacuum collapse, this reduces the need for internal springsRESISTANTin many applications. Meets SAE 20R4 and 20R3 Type EC Class D-1 and D-2 specifications. Temperature rating: -40 F to 275 F (-40 C to 135 C) in coolant hose applications.Note: Gates recommends replacing standard worm drive and spring loaded clamps withGates PowerGrip SB clamps each time a new coolant hose is installed.Caution: Do not use for fuel or oil transfer applications.Vulco-Flex II Coolant HoseGates Vulco-Flex II hose will bend in almost any direction. It easily replicates the angles and planesof a wide variety of expensive original equipment coolant hose, for quick, easy replacement. Improved sealing surface for greater leak resistance and increased flexibilityfor easier installation. Heat and ozone resistant cover.ELECTROCHEMICALRESISTANT Rated for SAE 20R5 Class D-2 performance. High temperature rating up to 257 F ( 125 C).Note: Gates recommends replacing clamps each time a new coolant hose is installed.Caution: Do not use for fuel or oil transfer applications.A8www.Gates.com

Coolant Systems - HoseGreen Stripe Vulco-Flex Coolant HoseHeavy-duty flexible hose designed to replace straight or curved coolant hoses. The benefit is maximum coveragewith minimum inventory. Hose inside diameter remains constant from end to end. No convolutions inside hose sotube is smooth, allowing free coolant flow. Approved for marine applications. Excellent flexibility, yet collapse and kink resistant. Extra strength fabric reinforcement with helical steel wire spiral molded between tubeand cover. Heat-resistant construction throughout. EPDM tube and neoprene cover for extended service life. Performs to SAE 20R5 Type EC Class D-2 specifications. Engineered to resist electrochemical degradation – the leading cause of hose failure.ELECTROCHEMICAL Temperature rating: –40 F to 257 F (–40 C to 125 C).RESISTANT Working pressure 40 psi maximum.Caution: Do not use for fuel or oil transfer applications.Vulco Straight Coolant HoseSpecially engineered stick hose is ideal for straight coolant/air connections in automotive, stationary engine,industrial and home applications. Heat-resistant cover. Meets SAE 20R1 Standard Wall Class D-2 requirements. Cover marked in one-inch increments for easy measuring and cutting allows“custom fit” light-duty coolant installations. Temperature rating: -40 F to 257 F (-40 C to 125 C).Caution: Do not use for fuel or oil transfer applications.PartNo.I.D.(In.)240081 224012 3 47/8240142401612401811/82402011 42402213/82402411 Work.Press.(psi)2402615/813 417/8221/821 423/821 4225/823 427/8331 431 2430302525201812240442404624048240522405624064A9

Coolant Systems - HoseWire-Inserted Green Stripe Coolant HoseProvides the ability to replace many sizes of tailor-made curved hoses. Results in maximum coverage withminimum inventory. Approved for marine applications. Heavy-duty fabric reinforcement with helical carbon steel wire. Bends easily to make curved connections. Cuts easily with knife and wire cutters to reduce installation time. Exceeds SAE 20R2 Type EC (Class D2 Tube and cover) except in vacuum applications. Engineered to resist electrochemical degradation – the leading cause of hose failure. Temperature rating: –40 F to 257 F (–40 C to 125 C).Note: Long spans must be supported every 3 feet.Caution:Do not use for fuel or oil transfer applications.ELECTROCHEMICALRESISTANTPart No. Part No.I.D.5 Ft.10 8332—28336Work.Press. Vacuum(psi)(In. Hg.)100110011/811 410013/88511 28515/87513 4 7517/86026021/85521 455Min. BendRadiusPart No. Part No.I.D.(In.)5 Ft.10 98024996221 221 2331 231 2441 241 251 251 56———Work.Press. Vacuum(psi)(In. Hg.)23/85021 25025/84023 4 4027/84034031 235430515615202015151515151055Min. BendRadius(In.)61 261 271 271 29912202430Green Stripe Vibraflex Coolant HoseFor heavy-duty applications requiring short length hose that must absorb vibration and/or fitting misalignment.High flexibility reduces installation time and provides lower cost-per-mile operation. Oil and heat-resistant nitrile tube. Oil, abrasion and heat-resistant neoprene cover. Exceeds SAE J20 (Class B Tube and Class C Cover). Two-ply fabric reinforced. Temperature rating: -40 F to 212 F (-40 C to 100 C).Caution: Do not use for gasoline or diesel transfer )23505235112351523520235312353311 4 x 413/8 x 511 2 x 513 4 x 52 x 31 22x570606055505023547235572355923562235502356621 4 x 41 223/8 x 523/8 x 61 421 2 x 41 221 2 x 623 4 x 31 5672356823572235752358523 4 x 41 223 4 x 53/83x43x731 2 x 51 23030252525www.Gates.com

Coolant Systems - HoseGreen Stripe 2-Ply Straight Coolant HoseStick hose designed for demanding heavy-duty coolant/air applications. Approved for marine applications. Two-ply bias fabric construction to maximize flexibility and strength. Resists “cold water leaks” due to advanced EPDM tube and cover that stay soft andpliable, even under adverse operating conditions. Exceeds SAE 20R1 Type EC (Class D-1 Tube, and cover, Standard Wall). Cover marked in one-inch increments to facilitate approximate cut lengths, allows“custom-fit" installations. Engineered to resist electrochemical degradation – the leading cause of hose failure. Temperature rating: –40 F to 257 F (–40 C to 125 C).Note: For a maintenance free connection, use PowerGrip SB clamps.Caution: Do not use for fuel or oil transfer n.)Work.Press.(psi)24212 3 4 1007/8242141002421611002421811/81002422011 41002422213/81002422411

Catalog No. 431-2061 Edition 2016 Supersedes 431-2061 (2013) POWERATED BELT MERCHANDISER Gates. Powering Progress OWN YOUR LAWN & GARDEN BELT MARKET .