Transcription

Modula WMSThink Vertical, Think Modulam o d u la .u s

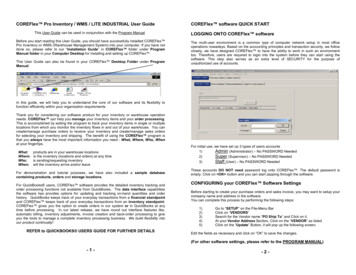

Modula WMSWMSWarehouse management systemModula WMS software is a complete inventory management software ideal for all Modula automatedstorage equipment, such as VLM’s, vertical carousels and horizontal carousels as well as with traditionalstorage methods, such as shelving or racking.Modula WMS software is able to be used as the perfect compliment to all Modula units for additionalspace and utilization management or even as a stand alone software tool for your warehouse.It allows for a real-time management of items via a PC interface. All that is needed to be supplied is a PC toact as the software’s server and customers may choose to add additional “client” PC’s for their use, depending on the number of storage area locations or specific needs.Modula WMS installs the Express version of Microsoft SQL Server, which is free and does not require anyadditional licenses. The SQL Server database used must be exclusively for Modula WMS to use.HOSTCORPORATESERVERDATA BASECORPORATE NETWORKEth 1SERVERMODULAWMSEthMODULA WMSDATABASECLIENTMODULAWMSEth 2MODULA NETWORK2

Benefits of Modula WMSCONTROL AND EFFICIENCYUsing your data to its fullest potential to improveand maximize the overall performance of youroperation. Repetitive tasks and procedures are automated. Material movements are well planned tooptimize tasks. Processes and paperwork are substantiallyreduced.INVENTORY OPTIMIZATIONWMSINTEGRATION TO YOURHOST SYSTEMModula WMS provides an easy ability to integratewith your ERP or Host systems (SAP, Oracle,Microsoft, etc.), MRP or other applications,providing an exchange of accurate andcontinuous information between systems andModula WMS.PRODUCTIVITYIMPROVEMENTSModula WMS software continuously searches foroptimal locations to further maximize space andoptimize inventory in the best possible manner.By optimizing order management, Modula WMSprovides users with the ability to increase speedof order execution for both picking andreplenishment operations, all done with completeitem traceability.EASE OF USECONFIGURABILITYOperating procedures are efficiently designedfor an intuitive and easy to use experience, byeven lower skilled users.Modula WMS is easily adapted to existing corporatesoftware systems and organizational needs. Theresult is minimal impact to current procedures andpreferences.3

Software PACKAGESSoftware packagesBASEMODULAWMS BASEThe BASE software module is theincluded package provided with allModula units sold. It provides thebasic tools necessary to manage the space and utilizationof units, such as order register management, graphicaltray location management, the ability to requestindividual items by way of orders or individual itemrequests, execution of physical inventories and theability for integration with a client’s managementsystem by means of a manual text file exchange with apredefined path.STANDARDMODULA WMSSTANDARDThe STANDARD software moduleincludes functionality designedto make Modula units as efficientas possible, added functionalities include: Dynamic item to compartment allocationmanagement. Dynamic batching and item serial & lotnumber,management. FIFO and expiration date management.It also provides warehouse statistical analysis toolsas well as print report customization.LINKWMSBASEPLUSMODULA WMSBASE PLUSThe BASE PLUS software moduleadds two important functionalities in addition to the BASE software module. Advanced security management tolimit access to specific trays or items, based on theuser’s login profile. And an automatic and configurable import/export data exchange with a client’smanagement system, using text files or shared tables accessible via ODBC, .XML, ASCII or Excel files.DRIVERMODULAWMS DRIVERThe DRIVER software moduleallows clients who already have a“Host Management” type ofsoftware in place to have the ability to manageseveral Modula units for their picking, replenishmentand cycle-counting needs using the in place Hostsystem. Communication is made possible using textfiles or shared tables. It is possible to use visual pickingaid accessories such as the X-Axis LED Bar,Alphanumeric LED Bar and Laser Pointers. The CoPilotconsole is used to allow operators to interact withunits, although all item and order requests are doneusing the existing WMS.MODULA LINKModula LINK allows clients who already have a “Host Management” type of software in placeto have the ability to control the automation commands of several Modula units.Communications with the supervisory Host PC is accomplished via sockets. In this case there isno order information exchanged, rather specific machine movement commands to movestorage locations are sent based on the items needed. It is possible to use visual picking aidaccessories such as the Alphanumeric LED Bar and Laser Pointers. The Copilot console in thiscase is not used by operators to interact with the unit. In this case it is necessary to use RFterminals or another PC to execute orders and interact with the external host system.4

Software MODULESSupplementary software modulesWMSAvailable to be added to Modula WMS StandardADVANCED ITEMMANAGEMENTMANUAL WAREHOUSEMANAGEMENTThe advanced item management module providesadditional functionality to the STANDARD software: Extended fields for advanced item management Ability to associate images to items for pickingoperations Ability to group items into families for improvedsearch and filtering capabilities Advanced security management options able tolimit access to specific trays for users Multiple, pre-defined types of order managementpossibleThe manual warehouse management module allows forthe creation and management of manual storage areas.Users can also manage material transfers between areas aswell as incoming materials received.REMOTE ASSISTANCEADVANCED ITEM PICKINGThe remote assistance module provides the abilityto connect remotely to Modula SMS through a webbrowser. It allows for easy error diagnostics andassistance in troubleshooting issues quickly and easilywithout having to wait for a software technician toarrive.The advanced item picking module providesadditional functionalities to improve pickingactivities such as batch picking “put-to-light”system management, packing list management, andassembly kitting management. RADIO FREQUENCYThe RF software module is only available in additionto the manual warehouse module and it furtherextends its functionalities. The RF module allows theuse of Windows CE or Mobile based RF terminals tomanage manual storage areas.SAP IDOCThe SAP IDOC module allows for interfacing withSAP WM module by means of standard SAP IDOC’s.5

WMS ServicesWMSServices providedIn addition to Modula WMS software, the following services are available to users.SOFTWARE INSTALLATIONWARRANTY AND SUPPORTModula WMS software is installed by computerspecialists using a fast guided procedure. Oncethe program has been installed on the serverand on any clients and the Modula VLM unitshave been configured in Modula WMS, the system is immediately ready for use.Modula WMS is covered by a limited warrantyand support until the end of the software’s lifecycle. The licensor reserves all rights not expresslystated herein.STAFF TRAININGTECHNICAL SERVICEAfter installation and the initial configuration ofthe Modula VLM units, the staff that will be usingthe software will receive basic training in the useand operation of the software and its functionalities. On request, additional in-depth trainingsessions are available to be organized if needed.Telephone support and/or remote service supportis provided using the Remote Assistance module.INTEGRATION WITH AHOST MANAGEMENTSoftware integration consultation and support isavailable when required and its goal is to provide the support required for a fast and effectiveintegration to the host or ERP system.6

Our REFERENCESAccessoriesConstruction IndustryBlack&DeckerUSAAluplastColgate Palmolive CompanyUSAI.K.O.ItalySaint GobainCostanCristian LaySpainDeny FontaineFranceDewaltUSAGGBUSAIncoldItalyMaria GallandGermanyOsramMexico/ItalySeco ToolsFranceAdministrative/Public/ArmyA.O.U. Ospedali Riuniti Di TriesteItalyUS Army / Airforce / NavyUSAGOZ Obukhov State PlantRussiaGuardia di FinanzaItalyNational Institutes of STDSUSANHS National Services ScotlandGreat BritainAeronauticUSABombardierGermanyDassault AviationFranceEmbraerBrazilEurocopterFranceIsrael Aerospace IndustriesIsraelJPRFranceKrasny TItaly/SerbiaFordSpainGoodyearGermanyIveco (FIAT)SpainJohn DeereUSARenaultFranceNew Holland Tractor (FIAT)Pagani AutomobiliPorscheVolkswagenSpainIndiaPamesa CeramicaSpainPorcelanosa GroupUSASacmiItaly/MexicoSerenissima ainDupontUSAFirmenichSwitzerlandGermanyWacker ChemieGermanyElectrical/Electronic IndustryGermany/ChinaFatro SPAItalyEstoniaEmerson Industrial AutomationItalyOtisVesuviusPaper Industry/PublishingGermany/RussiaFranceMexicoFood IndustryAcetaia di ModenaItalyBeam GlobalSpainContri SpumantiItalyDammSpainRocktenn ayerMexicoUSABelgiumJohnson & JohnsonUSARocheItalyPlastic IndustryLavel GommaItalySchwartz GmbhTrelleborgGermanyGreat Britain/ChinaVision ExtrusionCanadaEnergy IndustryBabcock & WilcoxBP British PetroleumUSAGreat BritainUSAUSADow-KokamUSAGreat BritainDuke EnergyPepsi CorporationUSASwedenVonpar RefrescosBrazilYoplait (General Mills)FranceNordex Energy GmbhPetrobrasSchlumbergerCSX c/Oledynamic/Pneumatic IndustrySpainFesto PneumaticsMexicoUSAHawe HydraulicsUSA/ChinaItalyItaly/Great BritainGreat ort IndustryAVTO LOGISTIKAFrankeSag/Sagom TubiBrazilSofidelConoco PhilipsMarsUSACanadaSICPAItalyMarchesi ono PumpsUSAMPOItalyItalyUSAUSAIrving TissueFresenius KabiMexicoSymriseGermanyCooper VisionMoogIMM HydraulicsBrazil/ChinaItalyKemetHP HydraulicsItalyThyssenkruppJanssen ris esini GroupGermanyEdilkaminItaly/RomaniaGermanyJohnson ControlsSpendrupsGermanyKBA nuc RoboticsAmgenDisano IlluminazioneAlexandria MouldingsGermanySpainInfracor GmbhTyco ElectronicsItaly/RomaniaCrane&CoAkzo NobelItalyItalyNeodentItalyKajaria CeramicsSiemensItalyComauIMA IndustriesEuroceramiqueABBBonfiglioli RiduttoriHoneywell GarrettCooperativa Ceramica di ImolaFurnishingBiotecMerit Medical SystemsGermanyCeramic IndustryHollandBiomechanical/Biomedical IndustryMedison co.USAWilo SERexroth Bosch GroupAutomobili LamborghiniCNH Industrial (FIAT)CanadaGrupo AC MarcaBarry Controls AerospaceBremboMechanical/ManufacturingItalyDB Service GmbhInfrabel RailwayKuhne NagelMTA Metro North ile Industry/Clothing IndustryCotton RepublicMexicoGiorgio Armani OperationsItalyJeans Knit PVT LtdIndiaMax Mara GroupItalyValentinoItaly

Modula is present in 5 Continents with dealers and branches located in over 30 countries.Your local contact:MODULA US HEADQUARTERS90 Alfred A. Plourde ParkwayLewiston, ME 04240Tel. 1.888.233.6796Fax 1.207.786.0271info@modula.uswww.modula.usMODULA ITALY HEADQUARTERSVia San Lorenzo, 41 - 42013Salvaterra di Casalgrande (Re) ITALYTel. 39 0522 774111Fax 39 0522 774175info@modula.euwww.modula.euModula is part ofAll information provided on this catalogue is for informative purposes only and is not binding. Modula reserves the right to change informationon this catalogue at any time. Modula will not accept liability for or guarantee the accuracy of the information contained herein.

WMS Modula WMS Warehouse management system Modula WMS software is a complete inventory management software ideal for all Modula automated storage equipment, such as VLM’s, vertical carousels and horizontal carousels as well as with traditional . (SAP, Oracle, Microsoft, etc.), MRP or othe