Transcription

HIGH-PRECISION BALL BEARINGSHigh-Precision Ball BearingsProduct Catalogk ü§S RÜΔD0 PrCr( )3–2L1ai–Δda1Δd isa §L nm10L oRT ΔSFr X PrFa YwΔ

HIGH-PRECISION BALL BEARINGSHIGH-PRECISION BALL BEARINGSDesignation system of radial ball bearings – metric / inchRetaining ringDesignation system of radial ball bearings – metric / inchRetaining ringShieldB2ShieldBallsBallsOuter ringShoulder flattenedOuter ringShoulder not flattenedrsInner ringRetainerFD1RetainerrsRing materialVersionCoverBasic markInner ceFBFB1B1Radial clearancegradeFunctional testDiametergradingPairing typePreloadvalueRetainer designLubricant qty.LubricantsG --LE625-P C GPRX-1/ E–HYSSF3/16-ZABEC K GPAXB-2L.%L ZOSVE625/603938-2ZD R(.)XD-3MJTXHB. MGL299-4STXAS-RZX4SA-RSX4BN-VZX4DNZ-VSB -TS-HYSteelballs-100Cr6SS X65Cr13CeramicSV X30CrMoN15-1ballsmade fromS440CSi3N4SA AntimagneticZO Ceramicmaterialballsmade fromCombination ballsZrO2N Full ceramicbearings(balls, IR, AR )of silicon nitrideLE Bearing unit625Metric-Open ball bearingsF Flange3/16Inch-ZSingle shieldE Extendedinner ring625/XXXXXX Acc. todrawing-2ZDouble shield-RZSingle Perbunanrubber shield,non-contact-RS-VZ-VSNZ Full ceramicbearings(balls, IR, AR)made fromzirconium oxide-TSSingle Perbunanrubber contact sealSingle Viton shield,non-contactSingle Vitoncontact sealSingle Teflon contact sealStandardtolerance gradeP0or ABEC1not markedP tolerance gradefor metricbearings in P6,P5, P4 and P2ABECtolerance gradefor inch bearingsin ABEC3,ABEC5 etc.Special tolerancegrades:ABEC9P,P4A, P4S, Metric deep groove radialbearingsC2C3C4C5Standard clearanceNarrower than standardSlightly increased radialclearanceIncreased radial clearanceStrongly increased radialclearanceThe exact values depend on thebearing dimensions, see capter”The classification of radialclearance”.Defined radial clearance: f.e.C1/51 to 5 μmC4/84 to 8 μmC10/15 10 to 15 μmC14/20 14 to 20 μmGPRNoise test(standard100%)XGPAAxial vibrationtestR(.)XDFollowed bya numberindicates startingtorque withX4standard load,max. 16 μNmXBBore and outsidediameter graded in2 classesBack to back/ (O-arrangement)-2Face to face(X-arrangement)Bore graded in2 classesOutside diametergraded in 2 classesBore and outsidediameter graded in4 classesX4BBore graded in4 classesX4DOutside diametergraded in 4 classesDeep groove radial bearings –Preload2-pc. steel retainervalue in [N] EJ2-pc. stainl. steelretainer.%Preload forspindle ballbearings TXHB Machined one-pieceLlightsnap retainer, X standsMmediumfor a number and.MGSstrongdefines the materialPreload otherExample:than L, M, ST19HB Machined syntheticpossiblesnap retainer madefrom XTRAIon-1-3Tandem-4UniversallypairedExample:Deep groove radial bearings:-1/5 ( O-arrangement with5 N preload)Inch deep groove radial bearingsDefined radial clearance: f.e.K020 to .0002“K13.0001“ to .0003“K46.0004“ to .0006“K58.0005“ to .0008“DFurther materialsavailable on requestFull complement ball bearingVAC1 Full complementVAC2 variationsVFSpindle ball bearingsAC1 Outer ring shouldergroundAC2 Inner ring shouldergroundFollowed a by numberindicates contract angleSpindle ball bearingsCContact angle 15 EContact angle 25 For information about TXAand other retainer variantssee chapter ”Retainers forminiature ball bearings”Example:Spindle ball bearings:UM ( universally matched pairs,medium preload)Example:AC1TA Outer ring shouldergrounded & machined solidretainer made from fabricreinforced phenolic resinG No dataStandard quantityL Lubricant quantityL299in % of the freespace onlyfor lubricatedB bearings)Lubricantquantities specified in mg orindication ofquantity rangee.g. 10 –15 % or6 –10 MGGreaseOildrybearingSpecialtreatment

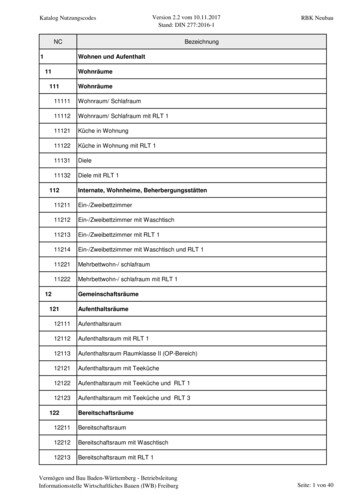

HIGH-PRECISION BALL BEARINGSHIGH-PRECISION BALL BEARINGSContentsProfiled rollers72Bearing units73Thin-section bearings74Hybrid and full ceramic ball bearings754Special ball bearings76Closures5Coated bearings78Retainers for miniature ball bearings6Lubricants8Our Company2Preface3GRW Modular SystemMaterials for rings and ballsFundamentals of Ball Bearing DesignShaft and housing shouldersGRW XTRATRAA - Enhancing PerformanceXTRAXTRA80XTRAt - The new GRW coating system 81XTRAcoat10XTR lube - The lubrication for longer lifeXTRAXTRAlube81XTRAlXTRAlon- The premium retainer material82ur success with GRW XTRAXTRA bearingsYour83Special installation configurations11Fitting tolerances12Load ratings and L-10 life14Limiting speeds16Elastic behavior of deep groove radialbearings17Spring washers84Relationship between radial play, axialplay, contact angle and tilting angle18Retaining rings, shaft circlips,bore retaining rings86Calibration of bore and outside diameters19Reduction in radial play20Radial play classification23Functional tests24Ball Bearing PortfolioTolerance and runout tables – inner ring26Tolerance and runout tables – outer ring28Designation system for radialball bearings – metric / inchAccessoriesShimsServiceTest equipment – Orakel III30Deep groove radial ball bearings – inch52Spindle / angular contact bearings58Duplex bearings59Installation and configuration of duplexball bearings60Designation system for spindle ball bearings62Spindle ball bearings6488GRW laboratory services89Correct handling of GRW high-precisionminiature bearings90PackagingGRW quality: International Certifi cationDIN EN 91009293CoverDeep groove radial ball bearings – metric84Manufacturing in a Nut Shell94Index96 1

HIGH-PRECISION BALL BEARINGSHIGH-PRECISION BALL BEARINGSOur CompanyPrefaceAs a global corporation with more than 500 employees,GRW is headquartered in Rimpar, near Würzburg, withassembly facilities in Prachatice (Czech Republic) and adirect sales office in the USA.Our radial ball bearings range in bores from 1 mmto 35 mm with outer diameters from 3 mm to 47 mmmeeting any condition from mini series to high volumestandard applications.GRW is the premier developer and manufacturer ofminiature precision ball bearings, assemblies andaccessory parts utilizing state-of-the-art equipmentand manufacturing processes. We specialize inproduction of high precision, small, miniature andinstrument bearings as well as spindle bearings andbearing units. GRW also welcomes the opportunity todesign, develop and produce customized applicationsusing customer specifications.GRW bearings are produced in both metric andinch dimensions making them truly applicable to anycustomer in the world. Whether your application requires mini series, standard high volume or customizedspecifications, you can always rely upon GRW to meetany requirement or challenge.GRW complies with the highly recognized standard ofquality in process and performance as evident by ourISO certifi cation, DIN EN 9100:2018.„Miniature precision meets extreme demands“In order to successfully meet the challenges of themarket, our products are being continuously developedand their performance improved, based on the latestinnovations from GRW.Developments that we have achieved in the areasof product design, ball bearing steels, retainer designand materials, lubricants and surface coatings, are thebasis for the technological leadership the companyhas today.We can do even better – just challenge us.Our sales engineers are available to consult with you.We are looking forward to your call:USA:Singapore:Customized solutionsOur latest advance: XTRA – Enhancing Performance!With GRW XTRA, we are not so much reinventingthe ball bearing but using our expertise to improve, forexample, performance levels in terms of running noise,service lifetime and speed! The ball bearing designedby GRW to your individual requirements acquiressuperior performance due to XTRA. 1 (860) 769 3252 65 6725 9861since 1942.2013Construction of the new production site in the Czech RepublicOpening of new sales office on the East Coast of the USASee page 79 of this product catalog for more details.2011Formation of GRW AcademyHeadquarter and production site at Rimpar2003Formation of GRW USA2001Reorganization of the corporate strategy in terms ofin-house production and cooperative productionGRW. . . the premier providerfor customized high-precision ball bearing solutions.1942Company founded in Würzburg19422 1945195019551998Restructuring in the Czech Republic1987Extension of Rimpar sitebuildings III and IV1962First cleanroom assembly in Rimpar1958Factory construction in Rimpar(Buildings I and II)1960ww.grwbearing.com196519702009Relocation of theadministration to thenew administrativebuilding in Rimpar1975198019851996Purchase and constructionof production site inthe Czech Republic200520102013 3

HIGH-PRECISION BALL BEARINGSHIGH-PRECISION BALL BEARINGSMaterials for rings and ballsClosuresGRW ball bearings are manufactured by usingtechnological advancements in steel production and heattreatment. Our ball bearings are made of chrome steel(100Cr6), stainless steel (X65Cr13), or high corrosionresistant steel (X30CrMoN 15-1). It is now possible toachieve comparable load ratings for all these steel types.Ceramic balls, e.g. hybrid ball bearings, can be used inall versions as required by your application.Hybrid ball bearingsGRW hybrid, or ceramic ball bearings are made of oneof the steels previously mentioned as well as silicon nitride(Si3N4) or zirconium oxide (ZrO2), both which offerspecific benefits.These types of bearings are used most commonly indental handpieces, spindle bearings and vacuum pumpsto extend speed limits or increase bearing stiffness.Using GRW Si3N4 ceramic balls reduces load rating by30 %, while the dynamic load rating remains unaffected.The low affinity to other materials allows a particularly lowadhesive wear. As a result, hybrid or ceramic bearingsprovide extended lifetime run times when used in mixedtorque applications.Materials for rings and ballsPrefixUnit–SSSVHYZODIN100Cr6X65Cr13X30CrMoN esDensity[g/cm³]7.817.77.73.26.0Hardness[HRE] 60 58 58 75 [x 10–6 edgoodvery goodvery icmagneticmagneticnon magnetic(1)non magneticIntegrated ball bearing shields and seals provide two vitalpurposes: to prevent dirt and foreign particles frominfiltration and to prevent lubricants from leaking out.Non-contact shieldsTogether with the shoulder of the inner ring, the closurecreates a narrow gap. Similar to open ball bearings,this closure neither increases running friction nor limitsthe maximum permissible speed because the shieldsdo not touch the inner ring. This is sufficient for mostapplications. Shields prevent contamination with dirt particles but cannot achieve a hermetic seal.Metal shields ZFor the majority of our bearings, shields are stamped fromcorrosion-resistant steel. They are fastened and securedto the outer ring by means of a circlip and can thus beremoved. Bearings can also be fitted with pressed-inshields made from a deep drawn steel sheet; theseshields cannot be removed.RZ/VZ rubber sealThe RZ closure is made of synthetic buna N rubberwith a steel support shield and can be used attemperatures from -30 C to 120 C.The VZ closure is made of synthetic Viton fluoroelastomerwith steel support shield and can be used attemperatures from -20 C to 230 C.Both shield types are secured by snap fit.Teflon seal TSThe TS seal is made of a glass-fiber reinforced Teflon sheet that is fastened in the outer ring by means ofa circlip.TS seals are universally resistant to chemicals. Bearingsusing TS seals are normally made of corrosion-resistantsteel. In appropriately large quantities, TS seals can alsobe made available for chrome steel bearings.RS/VS sealsThe RS seal is made of synthetic buna N rubberwith a steel support shield and can be used attemperatures from -30 C to 120 C.The VS seal is made of synthetic Viton fluoroelastomerwith a steel support shield and can be used attemperatures from -20 C to 230 C.Both shield types are secured by snap fit.Custom shields and sealsGRW can also manufacture custom accessories andcombinations of different shields and seals to meetyour specifications.For improved sealing effect between steel shields andouter ring GRW offers a special laminated shield.In this context, we would like to point outthat certain lubricants cannot be used with allclosures. Please consult our sales engineersabout difficult applications.Contact sealsThis type of seal touches the shoulder of the inner ring,causing an increase in start up and running torque.Teflon seals can be used at working temperatures of-240 C to 300 C. The friction is lower than for rubberseals due to the low friction combination (PTFE /steel) andthe low contact force of the sealing lip.(1)May contain magnetic parts for production technology reasonsOur sales engineers will gladly inform you about the chemical resistance properties of the materials.Subject to change.4 www.grwbearing.com 5

HIGH-PRECISION BALL BEARINGSHIGH-PRECISION BALL BEARINGSRetainers for miniature ball bearingsRetainers are vital for efficient operation of ballbearings. First, they keep the balls separated andevenly spaced, ensuring a uniform distribution ofload and thereby reducing heat while enhancing thebearing life expectancy.Secondly, the retainer guides the balls in the loadfree zone and prevents the balls from dropping out ofseparable bearings. Using our customized designs andmaterials, retainers can be manufactured to meet anyapplication. We recommend usage of a two-part ribbonretainer for the majority of applications.In this context, we would like to point outthat certain lubricants cannot be used withall retainers.See the following list for our range of different retainer variants:GRW retainerdesignationEJIllustrationDescription/ materialTwo-piece retainer made from– steel sheet ( E )– stainless steel sheet ( J )Retainer clamping types:– without additional sign standard– F retainer tightly clamped– L retainer loosely clampedGRW retainerdesignationJH: For deep groove radial bearings.Used primarily for small ball bearings and low tomedium speeds.Description/ materialScope of application / purposeL2TL2T inner ring separable,outer ring guidedFor separable angular contact ball bearings/spindle bearings with highest speeds. High rigidity.Working temperature from -50 C to 130 C.Can be impregnated with oil.L2TXXTRAIonL2TX inner ring separable,outer ring guidedX stands for a number and defi nesthe material.For separable angular contact ball bearings/spindle bearings with highest speeds. Highrigidity and emergency running properties.Working temperature, depending on the material,up to 250 C or even 300 C.Scope of application / purposeE/J: Standard retainer for deep groove radialbearings. For stainless bearings:retainer always made from stainless steel sheet.To avoid torque peaks as far as possible, thisretainer can also be mounted in a looselyclamped condition.IllustrationThese retainer can also be ordered with our new retainer material XTRAIon, for even longerservice life! Please find more information about XTRAIon on page 82.TA/TBMachined one-piece solid retainer madefrom fiber-reinforced phenolic resin.A outer ring guidedB inner ring guidedOnly used with AC types. Non-separable.For angular contact bearings/spindle ballbearings with highest speeds. High rigidityand emergency running properties. Workingtemperature from -50 C to 130 C. Can beimpregnated with oil.TXA/TXBXTRAIonMachined one-piece solid retainer madefrom a special material.X stands for a number and defines thematerial.A outer ring guidedB inner ring guidedOnly used with AC types. Non-separable.For angular contact bearings/spindle ballbearings with highest speeds. High rigidityand emergency running properties. Workingtemperature, depending on the material, up to 250 C or even 300 C.JHOne-piece snap-type retainer made ofstainless steel ( JH )TNHOne-piece molded synthetic snap retainer.For deep groove radial bearings in mediumspeed range with good running and torquecharacteristics. Working temperature from–30 C to 80 C, short term up to 100 C.TNXHOne-piece molded synthetic snap retainermade from glass fiber reinforced plastic.X stands for a number and defines thematerial.For deep groove radial bearings in a speedrange above that of the TNH retainer. Workingtemperature from –30 C to 120 C, short termup to 180 C.VAC1VAC2Used for medium speeds, high radial loads andhigh axial loads in one direction.Machined one-piece snap retainer madefrom fiber-reinforced phenolic resin.A outer ring guidedB inner ring guidedFor deep groove radial bearings with very highspeeds. High rigidity and emergency runningproperties.Working temperature from -50 C to 130 C.Can be impregnated with oil.Full complement bearing, without retainer,cannot be disassembled.VAC1 shoulder relieved on outer ringVAC2 shoulder relieved on inner ringOuter ring or inner ring shoulder ground onone side.VFUsed for medium speeds and high radial loads.Machined one-piece snap retainer madefrom a special material.X stands for a number and defines thematerial.A outer ring guidedB inner ring guidedFor deep groove radial bearing with very highspeeds. High rigidity and emergency runningproperties. Working temperature, depending onthe material, up to 250 C or even 300 C.Full complement ball bearing, withoutretainer, non-separable, with filling slot forinserting the balls.THATHBTXHATXHBXTRAIonThese retainer can also be ordered with our new retainer material XTRAIon, for even longerservice life! Please find more information about XTRAIon on page 82.These retainer can also be ordered with our new retainer material XTRAIon, for even longerservice life! Please find more information about XTRAIon on page 82.As not every retainer is available for all sizes, please contact us for additional information. We will gladly recommend other bearing and retainerdesigns as well as retainer materials for special requirements.GRW offers some of the highest performance syntheticmaterials including Vespel , Torlon , PEEK, PTFE andMeldin as well as various metallic materials andphenolic resins.In addition to using proven materials, GRW, in close cooperation with its customers and suppliers, is constantly6 www.grwbearing.comdeveloping new options or enhancing existing variations.As a result, GRW is the sole owner of some exclusivelicenses and patents for using specifically developedretainer materials such as the new developed premiummaterial XTRAIon. Detailed information concerningXTRAIon you can find on page 82. 7

HIGH-PRECISION BALL BEARINGSHIGH-PRECISION BALL BEARINGSLubricantsWhy do bearings need lubricants?Miniature ball bearings are perfect for high stressenvironments, but require special lubricants to minimizewear, in order to increase operational life, performance,and safety of the product.GRW lubricants provide permanent lubrication to minimizesliding friction between balls, rings and retainer. Thisprevents excessive wear and thermal overheating,protecting balls and raceway from micro-welding andthereby extending operational life while reducing runningnoise. The bearing application specification determinesthe best type of lubrication to use.Grease lubricationThanks to their ability to dispense a lubricating film overtime, grease lubricants offer an additional advantagewhen being used in maintenance-free applications.Most of GRW bearings are grease-lubricated, withapproximately 300 different greases to select from. Thestandard recommended amount of grease (lubricantquantity) is one-third (33 %) of the remaining free spacein the bearing. Grease quantities deviating from thisstandard are indicated in the bearing part number justbefore the type of lubricant, preferably in percent oralternatively in milligrams.Furthermore, our customers can choose other specialtreatments for grease applications, for example adispersion or a thin defined layer of grease. Here thedesignation system differentiates between TF (thin film),MF (medium film) and SF (strong film).Oil lubricationMiniature bearings lubricated with oil may offer advantagesover those lubricated with grease.Oil is primarily used in applications where a minimal torqueis required. In particular, high speed spindle bearings aretypically lubricated with high performance oils.When compared to grease lubrication, oil lubricationsometimes uses a dispersion of oil and a solvent toachieve a better distribution of oil throughout thebearing.With more than 100 special oils to choose from, GRWcan help you to select the oil that perfectly matches yourapplication. If no special lubrication is needed, all of ourbearings whether open or shielded, are preserved withlight instrument oil when they leave our factory.Proper lubrication practicesAt GRW, all bearings are lubricated during finalassembly under clean-room conditions. Since dustparticles can cling to the oiled or greased bearings,it is important that the customer maintains a highstandard of cleanliness in their application. In additionwe recommend using a clean-room for removal of thebearings from their package and during assembly.With greased bearings, the specified quantity of lubricant,accurate to milligrams, is injected directly into specifiedlocations of the miniature ball bearing. Usually thelubricant is injected from only one side, however it is alsopossible to lubricate each bearing from both sides forbetter distribution.Solid lubricantsLubricants in medical applicationsNon-lubricated bearings may be used in certainapplications and are also available from GRW. Thesenon-lubricated bearings are typically required for ultra-highvacuum (UHV) temperature extremes and for applicationsin aviation and aerospace. Here the operating conditionsgo beyond the functional limits of oil and greaselubricants. The use of a bearing without a protectivelubricant will negatively impact its tribological system;however lubrication with solids is a viable alternative.Sterilization (autoclaving) is mandatory for the properuse and maintenance of medical instruments accordingto the guidelines of the Robert-Koch Institute. This appliesto the hygienic treatment of surgical devices and dentalturbines that depend on miniature ball bearings.GRW offers its customers a variety of different dry filmcoatings. Applying thin layers of precious, Wolfratherm or MoS2 provides protection and lubrication for thebearing.For oil or grease lubricated bearings, this processensures reliable performance in case of lubricantdeprivation (emergency running conditions). In GRW’spart numbering system, the surface treatment of„bearing components is indicated by a B“, followedby a four-digit number code indicating the type ofsurface treatment.Custom treatmentsIn addition to varying lubricants and surface treatments,GRW can custom treat bearing components to improvetribological behavior. For example, the phenolic retainercan be vacuum-impregnated with oil (up to 5% by weight).GRW‘s stainless steel and retainer materials can easilywithstand sterilization in an autoclave subjected tosuperheated steam, where most lubricants do notsurvive. Combined with the extreme high speedstresses of dental turbines, these lubricants arerequired to provide exceptional surface adhesion andsterilization resistance.As manufactured, GRW bearings utilize a range oflubricants that are resistant to the sterilization processand well suited for dental and surgical devices. Thisoptimization results in a longer life under extremeenvironmental conditions.XTRAlubeFor enhanced performance and longer life time werecommend the new by GRW developed lubricationXTRAlube.More information about XTRAlube you can find onpage 81.The benefit of a vacuum-impregnated retainer is its abilityto release small amounts of lubricant continually duringoperation. This process improves the general lubricationperformance and ensures emergency running propertiesin lube deprived situations.For lubrication with standard oils, the oil is poured over thebearing which is then spun. Alternatively, a specified oilquantity can be directly injected into the bearing.8 www.grwbearing.com 9

HIGH-PRECISION BALL BEARINGSHIGH-PRECISION BALL BEARINGSShaft and housing shouldersCertain design and assembly factors are critical foroptimum performance of bearings. For instance, shaftand housing shoulders should accurately allow axial loadto be transferred to the inner and outer ring withoutpermitting the rings to tilt in opposite directions.The associated dimension tables provide limits for thelargest (da max) and the smallest (da min) permissibleshoulder diameter for the inner ring and the largestpermissible shoulder diameter for the outer ring(Da max).See Dimension Tables on pages 30 to 57.Special installation configurationsPlease note the following considerations:Flanged bearings The housing shoulder diameter for the outer ring mustalways be smaller than (Da max) and the shaft shoulderdiameter at the inner ring must not be smaller than (da min).Using miniature and instrument bearings with a flange on theouter ring offers several advantages. The corner radius between fit and shoulder must not belarger than the corner clearance (rs min) of the bearing.Here an undercut is preferable to a corner radius.The edge radii of the bearing are not designed as alocating surface for the bearing in any way. The axial runout of the mating surfaces should not begreater than the maximum axial runout of the bearingused. Otherwise the function of the bearing will becompromised.Stepped housing bores, which make it impossible or verydifficult to maintain accurate alignment of both bearing fits,are no longer necessary. There is also no need for the useof circlips, which create difficulties in small housing bores orthin-walled housings.Proper installation, generalFlanged bearings assembled in narrow housings, such asgearboxes, are particularly effective.Assembly in narrow housingsWith paired bearings, the use of a flanged bearing simplifiesthe proper assembly and alignment of the bearing.Wrong, Shaft radius greater rs minCorrect, Shaft radius smaller than rs minThis allows for the accurate axial positioning of the Duplexbearing pair.Application of a Duplex bearingBearings with extended inner ringsWrong, Shaft shoulder greater than da maxCorrect, Shaft shoulder equal with inner ring shoulderBearings with an extended inner ring simplify designand mounting of various assemblies. Shims, washersand other spacers are not necessary. Stepped shafts arealso redundant.Bearings with extended inner ringBearings with reinforced outer ringWrong, Shaft shoulder smaller than da minCorrect, Support ring in placeNote: Similar examples apply to bearing housings.10 www.grwbearing.comBall bearings whose outer rings are supported by the properhousing fit can withstand the highest loads. To increasethe load capacity of a bearing which is not pressed intoa housing, it takes advantage of a reinforced outer ring.These types of bearings can be used as “rollers“.Bearings with reinforced outer ring 11

HIGH-PRECISION BALL BEARINGSHIGH-PRECISION BALL BEARINGSFitting tolerancesAmong other factors, the fit of the bearing on theshaft and in the housing significantly affects theoperational behavior of miniature ball bearings. Whenselecting fitting tolerances the following criteria should beconsidered:Rotation conditionsRings with circumferential loading should have atighter fit than rings with a single point load.Circumferential loading occurs when the ring isrotating and the load is static, or when the ring is staticand the load is rotating.Point loading occurs when the rings and loads are bothstatic, or when the rings and loads are both rotating in thesame direction with equal speed. Please refer to the table„„Shaft tolerances“ and Housing tolerances“.Running accuracyThe same high standards of accuracy and surfacequality applicable to the bearings must be applied to theshaft and housing bore.LoadingHigher loads require a tighter fit between ball bearing,shaft and housing.TemperatureRecommended fittingsThere may be temperature differences between thebearing and mating components while the bearing is inoperation. Dimensional changes caused by differentialthermal expansion should be considered when selectinga bearing.The recommended fits listed below assume mean tolerances obtained from empirical performance data.With miniature bearings it is very important to select theproper fit for the highest accuracy and reliability, henceonly a close sliding or transition fit is generally required. Inaddition irregularities on the shaft or in the housing boreare transferred to the relatively thin-walled bearing rings.In order to improve the fit, it is possible to classify and sortthe bore and outside diameters into groups (also refer to„the chapter Calibration of bore and outside diameters“).„The values shown in these tables Shaft tolerances“ and„Housing tolerances“ are only valid for materials withthe same expansion coefficient (11 x 10–6 1/K). Fordifferent expansion coefficients, or when there aretemperature differences between the bearing rings andthe shaft or housing, a tolerance should be selected whichensures the appropriate fit at operating temperature.Shaft tolerancesBearing boreQuality Tolerance in µmTolerance in .0001 inch GradingType of ��4–5/–8–2/–3–8/–11–3/–4Slide �6–1.2/–2.5Tight fit 4/–4 1.6/–1.6 4/–2 1.6/–1 4/ 1 1.6/ .4 1/–2 .4/–1Press 5/–5–1/–2 5/–3 2/–1.2 5/–1 2/–.4 5/ 2 2/ 1 2/–1 1/–.4Slide �6–1.2/–2.5Tight /–6–1.2/–2.5–6/–9–2.5/–3.5Press fitOperating conditionsLow loadMedium speedsNo oscillationsLow to medium loadsMedium speedsLow oscillationsHigh loadsHigh speedsOscillations at high frequencySubject to c

the ball bearing but using our expertise to improve, for example, performance levels in terms of running noise, service lifetime and speed! The ball bearing designed by GRW to your individual requirements acquires superior performance due to XTRA. See page 79 o