Transcription

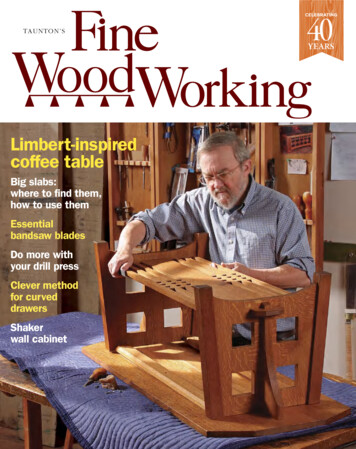

TAUNTON’SLimbert-inspiredcoffee tableBig slabs:where to find them,how to use themEssentialbandsaw bladesDo more withyour drill pressClever methodfor curveddrawersShakerwall cabinet

There are many sides to sanding.We’ve thought of them all.THE PERFECT SYSTEMINTRODUCING THE FIRST BRUSHLESSFESTOOL SANDING SYSTEM.Offering the performance of an air sander without the expense andbulk of an air system, these low-profile, long-life, and low-vibrationsanders can run all day by limiting downtime caused by sleeve orbrush replacements. Pair it with our seamless, integrated system ofaccessories, abrasives, carrying cases and dust extractors, and you’vegot the ultimate sanding system.View our entire line atfestoolusa.com/sanders

WNEFrom CUTTING TOOLSLapped MiterKitchens to Heirlooms.Leigh Jigs Make Dovetails Easy.ROUTER BIT SETMake Perfect Plywood & MDF Joinery! SELF ALIGNING FASTER EASIER STRONGERWATCHVIDEOONLINE!Item: 55-505Only 109.90Leigh Super JigsIncludes Freeood 3/4" Set-Up Block!Make Perfect Plywry!ineJoFD&Mleighjigs.comwww.infinitytools.com 877-USA-BITSFW-FH-FC 1/6v ad 14p3 x 28p6Premium Kits forWoodworkersIgnite YourIMAGINATIONOriginal Designs for You to Create Your Next MasterpieceTo order go to www.bereahardwoods.com or call 1.877.736.5487BereaHardwoods,Co. Inc.SINCE 198018745 Sheldon Rd Middleburg Hts., OH 44130 bereahard@aol.comwww.finewoodworking.comBerea Hardwoods, Co. Inc.January/February 20163

contentsJANUARY/FEBRUARY 201612HASSLE-FREEPANEL GLUE-UPS ISSUE 252features22Limbert-Inspired Coffee TableCOVERSTORYGrids and cutouts define a practical pieceBY KEVIN RODELup front6 On the Web8 Contributors32BY MICHAEL FORTUNE38BY NICK OFFERMAN, ROBERT ORTIZ,AND JOHN STERLING12 Methods of Work Convenient cauls for panel glue-upsSmart jig makes a stackof sanding blocks16 Tools & Materials Miter saw can handle big boardsMiter plane is a versatile trimming tool46Simple Hanging CabinetThe Shakers had this diminutive design peggedBY CHRISTIAN BECKSVOORT52Essential Bandsaw BladesWith this basic kit, your bandsawcan tackle any task20 Designer’s NotebookSplash color on woodDiscover the Beauty of Big SlabsThree experts share their best tipsfor finding and using these natural wonders10 Letters Drill Press Tips and TricksDo more with this tool by improving your basicsetup and adding a few simple accessoriesBY ROLAND JOHNSON58Solid Method for Curved DrawersSmart bent lamination gives the look and feelof solid woodBY STEWART WURTZ16MAKITA’S NEWMITER SAW64Wooden SpoonsA delight to make, they’re also a lastingpleasure to useBY PETER GALBERTCover photo: Michael Pekovich

58CURVEDDRAWERS3878COMPASS ROSEINLAYWORKING WITHBIG SLABSin the back70 Gallery74 HandworkCutting the half-lap78 Master ClassInlay a compass rose84 Looking BackMaking music with a plane90 How They Did ItThe back cover explainedBack CoverMetamorphosisTABLET EDITIONSFREE TO SUBSCRIBERS64HAVE FUNCARVING A SPOONOur digital editionsinclude all of themagazine’s content,ANIMUSplus searchability andHILLAa host of interactiveextras. Download the app atFineWoodworking.com/apps. Accessis free with your print subscriptionor FineWoodworking.com onlinemembership.00

on the webTHIS MONTH ONFineWoodworking.com/extrasVisit our website to access free web tie-ins, available Dec. 2. While you’re there, don’t miss our collection offree content, including tool reviews, an extensive project gallery, and must-read blogs.CELEBRATINGYEARSEditorThomas McKennaExecutive Art DirectorMichael PekovichTaming Big SlabsFlattening massive boards (p. 38) can be achallenge, but Nick Offerman has a simplesolution. Read about his clever router sledin a free online article.Special Projects EditorSenior EditorsAssistant EditorSenior Copy/Production EditorDeputy Art DirectorAdministrative AssistantShop ManagerContributing EditorsThe Simple Art of Spoon CarvingWindsor chairmaker Peter Galbert blows off steam bypicking up a carving knife and whittling spoons (p. 64).See how he creates his elegantly simple designs fromstart to finish in an online video.Methods of WorkSenior Editor, BooksWin Free Woodworking Tools!Fine Woodworking is giving away 40 great prizes tocelebrate our 40th anniversary. Prizes will be rolled outthroughout the year, so check back often to enter foryour chance to win each prize. For details, and to enter,go to finewoodworking.com/40sweeps.Free eLetterBecome an online memberGet free plans, videos, and articlesby signing up for our FREE eLetterat FineWoodworking.com/newsletter.Access more than 1,000 exclusive project and technique videos by subscribing to FineWoodworking.com. You’ll also get 40 years of magazine archives at your fingertips, including 1,400-plus articlesand project plans.VIDEO WORKSHOPBeefy Bench with StorageWhen building a new workbench for theFWW shop, staffers Matt Kenney and MikePekovich turned to the Shakers for guidance.Follow along from start to finish for tips on: Building a rock-solid post-and-beam base Adding drawers to a workbench Installing a twin-screw vise6FINE WOODWORKINGAsa ChristianaMatthew KenneyJonathan BinzenDillon RyanElizabeth HealyJohn TetreaultBetsy EngelWilliam PeckChristian BecksvoortGarrett HackRoland JohnsonSteve LattaMichael FortuneChris GochnourJim RicheyPeter ChapmanFineWoodworking.comVideo DirectorWeb Design DirectorColin RussellJodie DeloheryFine Woodworking: (ISSN: 0361-3453) is publishedbimonthly, with a special seventh issue in the winter, byThe Taunton Press, Inc., Newtown, CT 06470-5506.Telephone 203-426-8171. Periodicals postage paid atNewtown, CT 06470 and at additional mailing offices.GST paid registration #123210981.Subscription Rates: U.S., 34.95 for one year, 59.95for two years, 83.95 for three years. Canada, 36.95for one year, 63.95 for two years, 89.95 for threeyears (GST included, payable in U.S. funds). Outsidethe U.S./Canada: 41.95 for one year, 73.95 for twoyears, 104.95 for three years (payable in U.S. funds).Single copy U.S., 7.99. Single copy Canada, 8.99.Postmaster: Send address changes to Fine Woodworking,The Taunton Press, Inc., 63 S. Main St., PO Box 5506,Newtown, CT 06470-5506.Canada Post: Return undeliverable Canadian addressesto Fine Woodworking, c/o Worldwide Mailers, Inc.,2835 Kew Drive, Windsor, ON N8T 3B7, or email tomnfa@taunton.com.Printed in the USA

For building cabinets and finefurniture, nothing beats Forrestsaw blades.Craftsmen appreciate the way ourblades deliver smooth, quiet cutswithout splintering, scratching, ortearouts. They know our uniquegrade C-4 micrograin carbide,proprietary manufacturingprocess, and hand straighteningproduce exceptional results. Infact, independent tests rate us #1for rip cuts and crosscuts.Woodworker II—Best rated,all-purpose blade for rips n NJ, call 973-473-5236)Chop Master—Perfect for tight,perfectly cut miter joints withoutsplinters.Woodworker IIFine WoodworkingChop MasterWoodshop NewsDuraline Hi-ATWoodshop NewsFW-FH-FC 1/8 ad 22p1.5 x 13p6 2015 Forrest ManufacturingForrest Quality ShowsCode FWOrder from any Forrest dealer orretailer, online, or by calling directly.Our blades are manufactured in theU.S.A. and backed by our 30-day,money-back guarantee.“From the first cut on, I realizedthat this blade was a bargain atany price! Nothing else I havecuts comparably.”Calvin Brodie, Spanaway, WADado KingWOOD MagazineFW-FH-FC 1/4 ad 22p1.5 x 28p6Timeless ClassicsNow Back in PrintEach book in the Fine Woodworking on. series was treasured forits in-depth look at a specific aspect of woodworking. To celebrateour 40th anniversary, we are making a set of these respected titlesavailable again for a limited time.Only at www.tauntonstore.com/timelessCELEBRATINGand VeneerWorkshopBeautiful wood is precious and has to be used sparingly. Hence the art ofveneering, in which rare woods are sliced or sawn into thin leaves andthen glued onto a substructure of more common material. The allied art ofmarquetry consists of making pictures—often to adorn elegant, veneeredfurniture—from a palette of colorful wood veneers. In this collection of 38articles from Fine Woodworking magazine, skilled craftsmen explain howveneer is manufactured and how you can saw your own. They show youhow to lay it using simple equipment and how to design furniture basedon veneer panels. And they demonstrate the methods of marquetry, payingparticular attention to shop-built saws for cutting the most intricate details.wow to Dry ItThe Small WorkshopWood and How to Dry ItMarquetry and VeneerUS 17.95The really hard problem in woodworking is making strong cornerswith nothing but flat sticks. The trees have the answer: they just grow abranch. The cabinetmaker has to fake it, by cutting and neatly fitting ajoint. This book is largely about how to make the sturdy workhorse of thecabinetmaking art, the mortise and tenon joint. In 36 articles from FineWoodworking magazine, experienced craftsmen explain how they choose,make, and use the mortise and tenon and its many variations for paneledwalls and doors, cabinets, tables, and chairs. You’ll also learn about gluesfor wood.Look for other Taunton Press bookswherever books are sold or visit ourwebsite at www.tauntonstore.comPpwwon JoineryCRAFTS & HOBBIESon Planesand ChiselsWell-sharpened planes and chisels may be the most important tools inthe woodworking shop. They can be used to make a rough board flatand smooth, to cut slickly fitting joints, or to shape a delicate edge. Inthis collection of 29 articles from Fine Woodworking magazine, expertcraftsmen explain how they choose, sharpen, and use every kind of planeand chisel. There’s advice on tool maintenance, plus plans for making yourown wooden-bodied planes, and a thorough discussion of sharpening.won Planesand ChiselsFine Woodworking magazine has been the most trusted resource forwoodworkers since 1975. To celebrate the 40th anniversary of Fine Woodworking, The Taunton Press is re-releasing a number of classic titles fromthe early days of the magazine. Long out of print, the books are filled withexpert information that’s as timeless now as when it was first published.wTheon series:Bending WoodPlanes and ChiselsHand ToolsThe Small WorkshopJoineryWood and How to Dry Itwon series:TheUS 17.95ISBN 978-0-91880-474-7517959 780918 804747Taunton Product # 070059SThe Taunton Press63 South Main StreetP.O. Box 5506Newtown, CT 06470 5506www.taunton.comLook for other Taunton Press bookswherever books are sold or visit ourwebsite at www.tauntonstore.comBending WoodPlanes and ChiselsHand ToolsThe Small WorkshopWood and How to Dry ItJoineryWood and How to Dry ItPpThe Taunton Press63 South Main StreetP.O. Box 5506Newtown, CT 06470-5506www.taunton.comUS 17.95ISBN 978-0-91880-453-251795Taunton Product # 070051Son series:Planes and ChiselsThe Small WorkshopJoineryMarquetry and Veneer9 780918 804532wBending WoodHand ToolsMarquetry and VeneerLook for other Taunton Press bookswherever books are sold or visit ourwebsite at www.tauntonstore.comPpUS 17.95ISBN 978-0-91880-425-9517959 780918 804259Taunton Product # 070031SThe Taunton Press63 South Main StreetP.O. Box 5506Newtown, CT 06470-5506www.taunton.comLook for other Taunton Press bookswherever books are sold or visit ourwebsite at www.tauntonstore.comPpUS 17.95ISBN 978-0-91880-428-0517959 780918 804280Taunton Product # 070034TauntonSon JoineryFine Woodworking magazine has been the most trusted resource forwoodworkers since 1975. To celebrate the 40th anniversary of Fine Woodworking, The Taunton Press is re-releasing a number of classic titles fromthe early days of the magazine. Long out of print, the books are filled withexpert information that’s as timeless now as when it was first published.TauntonTauntonTaunton Product # 070033The Taunton Press63 South Main StreetP.O. Box 5506Newtown, CT 06470-5506www.taunton.comCRAFTS & HOBBIESMarquetry and VeneerTaunton51795Sophisticated new power tools come and go, but fundamental wood working skill begins and ends with hand tools. No matter how cleveryou are with jigs for the radial arm saw or router, you almost alwayscome back to planes, chisels, and saws for some aspect of the job. Thisvolume of 38 articles from Fine Woodworking magazine offers a wealthof information on all phases of hand tool use, from basic sawing andchiseling to understanding the finer points of how a plane cuts andwhy it leaves a shimmery surface you can’t get with sandpaper.wwon Hand ToolsTauntonISBN 978-0-91880-427-39 780918 804273and VeneerThePlanes and ChiselsHand ToolsJoineryon Hand ToolsYEARS“These profoundly illustrated volumes make up an excellent andeconomical encyclopedia of woodworking.” —Los Angeles Timeson series:Bending WoodChiselsWorkshopCRAFTS & HOBBIESFine Woodworking magazine has been the most trusted resource forwoodworkers since 1975. To celebrate the 40th anniversary of Fine Woodworking, The Taunton Press is re releasing a number of classic titles fromthe early days of the magazine. Long out of print, the books are filled withexpert information that’s as timeless now as when it was first published.Fine Woodworking magazine has been the most trusted resource forwoodworkers since 1975. To celebrate the 40th anniversary of Fine Woodworking, The Taunton Press is re-releasing a number of classic titles fromthe early days of the magazine. Long out of print, the books are filled withexpert information that’s as timeless now as when it was first published.Thewwon MarquetryFine Woodworking on Planes and Chiselson MarquetryFine Woodworking on Joineryhe most trusted resource fore 40th anniversary of Fine Woodng a number of classic titles fromof print, the books are filled withw as when it was first published.CRAFTS & HOBBIESFine Woodworking on Hand Toolsa place to get the work done.and consideration as the workated the place where you doome new ideas on shop setupWoodworking magazine.outs, plans for building andn storing tools, methods ofcontrolling dust and keepingwwon The SmallFine Woodworking on Marquetry and VeneerFine Woodworking on The Small WorkshopSmallkshopnton Press bookse sold or visit ouruntonstore.comNEWWebsite!MoreBlades!S 2015 The Taunton Presswww.finewoodworking.comJanuary/February 20167

contributorsKevin Rodel (Limbert-InspiredCoffee Table) has been makingcustom furniture in Maine since1979, when he joined the smallcrew of woodworkers at the Thos.Moser Company. Since 1986 hehas run his own shop, focusingat first on furniture inspired byAmerican Arts and Crafts pieces.Over the years he has expanded hisdesigns to include influences fromEurope and Asia, and increasingly personal interpretations of the style. In 2003, heco-wrote Arts & Crafts Furniture: from Classic to Contemporary (The Taunton Press),which traces the international scope of the Arts and Crafts movement.Peter Galbert (Wooden Spoons), who studied painting andphotography in college, worked with sheet goods in fast-pacedcabinet shops in New York City in the 1990s. Then in 2001,while sharing a very small shop in lower Manhattan with a guitarmaker, Galbert was inspired to look for “something I could makein a tiny space with hand tools and solid wood.” Windsor chairswere the answer, and he’s been making them—and teachingothers how to do so—ever since. In 2015 he put all he knowsabout Windsors into an impressive book, Chairmaker’s Notebook(Lost Art Press), which he both wrote and illustrated.Stewart Wurtz (Solid Method for Curved Drawers) has beenbuilding custom furniture in Seattle since 1986, but he got hisstart on the other side of the country. Living in Maine in the late1970s, he found a job at the Thos. Moser Company. After lookinginto various woodworking traditions on a trip to Europe in 1980,Wurtz returned to the United States and enrolled in the storiedProgram In Artisanry at Boston University, where his teachersincluded Jere Osgood and Alphonse Mattia.The latest addition to contributing editor Michael Fortune’swoodworking homestead is a portable sawmill. After seeing theWoodland Mills HM126 in action, Fortune (Drill Press Tips andTricks) decided that for under 3,000, the machine would pay foritself in a few years. But watching him fire it up on a snowy day,we got the sense that owning this machine is at least half aboutthe fun of it all. Fortune didn’t stop at the basic equipment, ofcourse, but made it permanent on a concrete platform, with atimber platform alongside for rolling logs aboard.For more information on our contributors,go to FineWoodworking.com/authors.8FINE WOODWORKINGWe are a reader-written magazine. Tolearn how to propose an article, go toFineWoodworking.com/submissions.PublisherRenee Jordan203-304-3572rjordan@taunton.comNational Ad Director,Home & ConstructionBrian Quinn203-304-3569bquinn@taunton.comSenior Account Manager/Integrated Media,Southeast, East CentralNoelle Kennedy203-304-3530nkennedy@taunton.comSenior Account Manager/Integrated Media,NortheastKelly Ames Smith203-304-3840ksmith@taunton.comSenior Account Manager/Integrated Media,Midwest, NorthwestKevin Draz708-386-1450kdraz@taunton.comSenior Account Manager/Integrated Media,SouthwestCynthia LapporteCynthia@oakmediagroup.comAdvertising SalesAssistantDiana EdwardsDirector of AdvertisingSales MarketingKaren LutjenSenior AdvertisingMarketing ManagerRobina LewisMarketing ManagerMatthew UllandMember AuditBureau of CirculationSingle Copy SalesIndependent publishers since 1975Founders, Paul & Jan RomanPresident & CEOCFOCTOSVP, Creative & EditorialSVP, Consumer MarketingVP, ControllerVP, Human ResourcesVP, FulfillmentDan McCarthyMark FernbergBrian MagnottaSusan EdelmanPaula BackerWayne ReynoldsCarol MarottiPatricia WilliamsonSVP, Home & ConstructionSVP, Fine CookingPublisher,Taunton BooksRenee JordanJohn BolandMaria TaylorPublishers of magazines, books, videos, and onlineFine Woodworking Fine HomebuildingThreads Fine Gardening Fine Cookingtaunton.com

lettersyears old. The pictures don’t show thedovetails, but they made me very proud.I look forward to doing a lot morework like this when I retire (in aboutseven years I hope) along with somewood turning, blacksmithing, and scrollwork—I love it all.By the way, I keep reminding my wifethat the empty space on the plane till(take a look at the picture) is for mySpotlightISSUE NO. 251Tools & Shops 2016p. 84In the latest edition you featured some of your past articles on shopmade machines.Although you didn’t revisit it, the article I enjoyed the most was “An OscillatingSpindle Sander” by Wesley P. Glewwe (FWW #46).I bought the Bodine gear reduction motor in 1984 but didn’t get around to buildingit until the early 1990s. I was teaching both wood shop and metal shop at GeorgeWashington High School in San Francisco and made the metal parts in the machineshop and the wooden cabinet in the wood shop. I followed the plan in the magazinevery closely. My students were astonished that I could build such a thing, and oneasked why I would put such a thing in myliving room. I guess he thought the finishlevel was high enough to warrant puttingit there. I have been using it for around 25years in my shop.The Surplus Center (surpluscenter.com)still sells the #561 Bodine gear motor for 39.95.— ROD S C HWE I G E R , So u th Sa n Fra n c i sc o , C a l i f.Another beautifulback coverThe back page ofFine Woodworkingalways drawsmy attention. It’susually the writingstyle of JonathanBinzen that createsthe allure. But in a recent issue (#249),Mr. Binzen outdid himself with thatincredible photo. You should continue tostrive for excellence in all aspects of yourpublication.—N OAH ELAN , Beit S hemes h, Is r aelTool cabinet completed at lastAbout a year ago I was thumbingthrough the 2014 Tools & Shops annual10FINE WOODWORKINGissue of Fine Woodworking and I cameacross your project, “A Cabinet for HandTools.” I looked at the plans and hadsome time over the Christmas break toknock this project out. I purchased thebulk of my base material (3 4-in. red oakfrom our local “big box” store) on Dec.31, 2014. Last Saturday, Oct. 15, 2015, Ifinally finished! Clearly I would be thepoorest cabinet maker in the countryand given that I work as a mechanicalengineering consultant, if I multiply thetime it took me to complete this by myhourly rate, this cabinet should sell forhundreds of thousands of dollars!Obviously I’m not the fastestwoodworker in town but I had atremendous amount of fun. I’ve beenworking with wood since I was 11Veritas scrub plane. Maybe it will arriveunder the tree this year.Keep up the great work.—I A N M C DO N ALD, Ta m pa , Fl a .Big fan of the Shaker workbenchI hope this workbench (FWW #251) willbe one of a series of projects you do atHancock Shaker Village (I’m a Hancockmember): trestle tables, stand-alonecabinets, built-ins, and even rockers fromMt. Lebanon.Obviously, I love Shaker. And I likesome Mid-Century Modern Wegner-typestuff. Arts and Crafts—with the exceptionof Mike Pekovich’s Barnsley-inspiredtrestle table and some Greene andGreene—you can keep it.Anyway, keep up the great work, andlet’s have many more from Hancock!—C H R I ST O P H E R H U D SO N , Adi r o n da cks , N .Y.Join Our Ad Sales TeamFine Woodworking, the premier magazineand media portfolio serving passionatewoodworkers and the companieswho support and further the craft ofwoodworking, is seeking a motivated andhigh-energy advertising sales professionalto join our team. If you are a woodworkerwith experience in media sales, this is agreat opportunity to combine the pursuitof your craft with your professionalaspirations. To apply, visit careers.taunton.com.

Featuring hands-onclasses for all skill levelstaught by nationallyknown craftsmen includingWill NeptuneSteve LattaPeter GalbertDarrell PeartChristopher Schwarzand more!To contact us:Fine WoodworkingThe Taunton Press63 South Main StreetPO Box 5506Newtown, CT 06470-5506Tel: 203-426-8171Send an email:fw@taunton.comVisit:finewoodworking.comTo submit an article proposal:Write to Fine Woodworking at the addressabove orCall: 800-309-8955Fax: 203-270-6753Email: fw@taunton.comTo subscribe or place an order:Visit finewoodworking.com/fworderor call: 800-888-82869am-9pm et Mon-Fri;9am-5pm et SatTo find out about Fine Woodworking products:Visit finewoodworking.com/productsTo get help with online member services:Visit finewoodworking.com/customerserviceDO IT ALL WITH A SUPERMAX 19-3819-38 DRUM SANDEREngineered for ease-of-use and maximum functionality,the 19-38 can tackle any sanding job in your shop!MACHINE OVERVIEW Sand 19” in a single pass, 38”in a double pass! Sand as thin as 1/32”, asthick as 4”, as short as 2-1/4”To find answers to frequently asked questions:Visit finewoodworking.com/FAQsTo contact Fine Woodworking customer service:Email us at support@customerservice.taunton.comTo speak directly to a customer service professional:Call 800-477-8727 9am-5pm et Mon-FriTo sell Fine Woodworking in your store:Call us toll-free at 866-452-5179, oremail us at tradecs@taunton.comTo advertise in Fine Woodworking:Call 800-309-8954, oremail us at fwads@taunton.com INTELLISAND Technologyauto-regulates the conveyorspeed, preventing gouging,burning or damaging stock!Award Winning! Power requirements 110 Volt,20 AMP serviceMailing list:We make a portion of our mailing list availableto reputable firms. If you would prefer thatwe not include your name, please visit:finewoodworking.com/privacyor call: 800-477-8727 9am-5pm et Mon-FriFor employment information:Visit careers.taunton.comThe Taunton guarantee:If at any time you’re not completely satisfiedwith Fine Woodworking, you can cancel yoursubscription and receive a full and immediaterefund of the entire subscription price. Noquestions asked.Copyright 2015 by The Taunton Press, Inc. Noreproduction without permission of The TauntonPress, Inc.Visit SuperMaxTools.com for full specs and dealer ruary 201611

methods of workE D I T E D A N D D R AW N B Y J I M R I C H E YWoodwingnutsBest TipCauls, maple, 13 4 in. thickby 3 in. wide by 4 ft. long,tapered 1 4 in. from themiddle to each endThreaded rodBar clampClear packing tape onworking face resists glue.Bill Flather wasintroduced towoodworking in the1960s. Over theyears he has restoredantiques, renovatedtwo 150-year-oldhomes, and madetables, cabinets,boxes, and chairs.The cauls in this tipcame to him whenhe was building anew headboard foran antique fourposter bed he wasconverting to aking-size frame. Hecites Flather’s Lawhere: “The need forclamps will alwaysexceed the quantityavailable.”Wingnut, 3 4 in.thick by 1 in. wideby 4 in. longHex nut, mortisedin tightlyUpper caulPanelboardsThreaded rodNylon-washerlocknut,mortisedin tightlyLower caulA Reward for the Best TipSend your original tips tofwmow@taunton.com orto Methods of Work,Fine Woodworking, P. O. Box5506, Newtown, CT 06470.We pay 100 for a publishedtip with illustration; 50 forone without. The prize for thisissue’s best tip was a 12-voltdrill/driver kit from DeWalt.12FINE WOODWORKINGConvenient caulsfor panel glue-upsLike many woodworkers, I use gently curved cauls on panelglue-ups to put pressure on the middle of the panel so that theboards stay aligned while the glue dries. They work well butcan be difficult to set up during a stressful glue-up, so I cameup with this system.A threaded rod is fixed in the bottom caul, by means of alocknut mortised into the wood. The top caul slides onto therod and then is tightened quickly and easily with a shopmadewingnut, made by mortising a nut into a short length of wood.To use the system I set down two or three of the bottomcauls, apply glue to the edges of the boards, lay them down,and then simply drop the top cauls onto the threaded rodsand spin down the wingnuts to tighten them. Finally, I add barclamps to apply pressure across the panel.—W I L L I A M F L AT H E R, Mi ddl e bu r g , Pa .Quick TipWhen drilling dowel joints with a fractional drill bit, I’ve foundthat dowels made to be the same size often don't fit the holes.If the dowels are too tight, I have to sand them down to makethem smaller. If they are loose, I’m out of luck. The answer wasbuying small sets of bits in number and letter sizes. The numberand letter bits are graduated in extremely small increments,perfect for fitting the arbitrary diameters of store-bought dowels.—DA N MA RTIN , G a l e n a , O h i o

The Country’s Largest Displayof Unique Slabs and BurlsBerkshireProductsSheffield, Mass413-229-7919BerkshireProducts.comFW-FH-FC 1/4 ad 22p1.5 x 28p6Our AnnualWoodworkingCatalog isAvailableOnline.View the full catalog online at www.leevalley.comor download it to the Lee Valley Library app foriPad , iPod , iPhone or AndroidTM devices.1-800-683-8170Find us on:www.leevalley.comFW-FH-FC 1/4 ad 22p1.5 x 28p6www.finewoodworking.comFW-FH-FC 1/2v ad 22p1.5 x 58p6January/February 201613

methods of workTwo layers ofparticleboardor MDF asclamping caulcontinuedHow to true a framing squareHere’s a method for truing a framing squareusing just a hammer and center-punch. Firsttest to determine if your square is true bydrawing a straight line 3 ft. to 4 ft. long. Then,with the tongue on the line, draw a pencil linealongside the blade. Flip the tongue over andbring the square into the corner of the twolines just drawn. If the square is true, the lineswill be right alongside both tongue and blade.But if the lines don’t coincide, here’s howto regain a true 90 . At the heel, draw a linefrom the inside corner to the outside cornerand divide the line into thirds. Place a centerpunch on the line in the center of either theinner third or the outer third. By striking thepunch in the outer third you spread the metaland cause the square to close (decreasingthe angle). By striking the punch in the innerthird you will open the square (increasingthe angle). Rap the punch smartly with ahammer, as you would to leave a starting holefor a drill. Naturally, check the square aftereach adjustment is made.Wedge blockstightly together.One fenceis tapered.Wedge hassame taper.Base,melamineBlocks, MDF or particleboard,each exactly 21 4 in. by 51 2 in.9x11sandpapersheetAttach paperwith yellowglue, not sprayadhesive.Fences, MDFClamp entiresandwich.—RO BERT C. AMIRA ULT, S out h T homas t on, M aineSmart jig makes a stack of sanding blocksClassic TipTo mark FWW’s 40thanniversary year, we arepresenting some classicMethods of Work tips.This tried-and-true tip isfrom FWW #17.I encounter lots of odd smoothing, trimming, and chamfering tasksthat are a challenge for a block plane or a chisel. Also, I don’t liketo slow down to sharpen hand tools. In these situations most folksuse sandpaper wrapped around a block, but I don’t like the waythe sandpaper ripples and tears when used this way. That led me todevelop a better sanding block. The paper is glued on, which keepsit flat and rigid for very accurate use. Also, the blocks have square,smooth edges so I can sand inside corners without damaging theadjacent surface. I make these blocks in several grits, from 80 to 220.I use the blocks for sanding inside edges, smoothing surfaces toosmall for a block plane, making small chamfers on the inside edges ofboxes and frames, sanding edges with difficult grain, cleaning up tenoncheeks, and even leveling and smoothing exotic inlays.You need stacks of these blocks, because they must be discardedwhen dull. So I developed a simple jig that produces eight blocks at atime, perfectly sized to use one sheet of regular 9x11 sandpaper. Afterthe glue cures, remove the blocks from the jig and cutthem apart from the back, using a razor knife.—MI C H A E L F O R T U N E , Wa r sa w, O n t. , C a n a d aTo separateblocks, slicefrom back side.14FINE WOODWORKING

ULTIMATETrim Bits“American Made for theAmerican Woodworker”“ULTIMATE” Flush Trim/Pattern Router Bits“ULTIMATE” Trim Bits are perfect when working withtemplates or when using a router to flush trim matching wood surfaces. Whiteside’s compression spiraldesign, along with a ball bearing

In 36 articles from Fine Woodworking magazine, experienced craftsmen explain how they choose, make, and use the mortise and tenon and its many variations for paneled walls and doors, cabinets, tables, and chairs. You’ll also learn about glues for wood. Fine Woodworking magazine has b

![[Ringle Material] 3rd wave coffee (Philz Coffee and Blue .](/img/22/2592b1ca.jpg)