Transcription

MEMORIAS DEL XXV CONGRESO INTERNACIONAL ANUAL DE LA SOMIM18 al 20 DE SEPTIEMBRE DE 2019 MAZATLÁN, SINALOA, MÉXICOTema A1 Materiales: (Soldadura láser, Soldadura disímil) Characterization of the dissimilar union of steel 20MnCr5 and ductile iron 65-45-12joined by laser welding process *Mario Alberto Alvarado Veloza, Melvyn Álvarez VeraaaCorporación Mexicana de Investigación en Materiales S.A. de C.V. Calle Ciencia y Tecnología #790 Col. Saltillo 400 C.P. 25290, Saltillo, RESUMENLas propiedades ofrecidas por las uniones disímiles dependen de los componentes utilizados porque combinan lascaracterísticas de los materiales soldados y proporcionan nuevas propiedades en la interfaz cuando se fusionan medianteun proceso de soldadura. Por lo tanto, habrá diferencias microestructurales a través de la unión que afectarán laspropiedades mecánicas a lo largo del elemento soldado. El objetivo de este estudio es la caracterización de una soldaduraa tope unida entre acero 20MnCr5 y hierro dúctil ASTM A536 65-45-12 mediante soldadura láser. Además, la penetracióny la profundidad de la soldadura se predicen mediante un modelo analítico. Se utilizaron técnicas de microscopía óptica,microscopía electrónica de barrido (MEB) y difracción de rayos X (DRX) para identificar y analizar los cambiosmicroestructurales en respuesta al proceso de soldadura. Así mismo, se realizaron perfiles de microdureza para el análisisde las propiedades mecánicas de la soldadura.Palabras Clave: Soldadura láser, Caracterización, Penetración de soldadura.ABSTRACTThe properties offered by the dissimilar joints depends on the components used because they combine the characteristicsof the welded materials as well as provide new properties in the interface when they are fused by a welding process.Therefore, there will be microstrustural differences through the union affecting the mechanical properties along thewelded element. The aim of this study is the characterization of a butt weld joined between 20MnCr5 steel and ASTMA536 65-45-12 ductile iron by laser welding. Moreover, the penetration and depth of the weld is predicted by analyticalmodel. Optical microscopy, scanning electron microscopy (SEM) and X-Ray diffraction (XRD) techniques were used toidentify and analyze the microstructural changes in response to the welding process. In addition microhardness profileswere made for mechanical properties analysis of the weld.Keywords: Laser welding, Characterization, Welding penetration.1. IntroductionLaser welding has been widely used in several industrysectors because of its advantages such as high speed andpower density. Laser welding produces joints with a highaspect ratio (depth) and a narrow heat affected area,compared to conventional welding processes [1]. Althoughthe process have some drawbacks like the high costs,difficulty of fusing high reflectivity and thermalconductivity materials, low tolerance between spacing andcertain tendency to the defect formation in deep penetrationwelding such as porosity [2]; this type of welding has beenrecognized as an advanced joining process, becoming aversatile method of joining components. This process hasreceived attention particularly in the union of metallicdissimilar materials due to the industrial products demand ofquality and performance [3]. On the other hand, defects canbe found in some dissimilar welds like weld bead asymmetryand intermetallic or fragile phases formations such as FeAl3and Fe2Al5 affecting the tensile strength of the joint [4,5],martensite in or near the melting zone [6] and grainrefinement for some cases [7]. These issues are related withthe differences in the mechanical, thermophysical andmetallurgical properties of the alloys, such as thermalconductivity, the specific heat, temperature coefficient ofthe surface tension and thermal expansion coefficient of thesolid and liquid phases [8,9]. Yu et al. [10] carried out aninvestigation about properties such as deformation, torsionand fatigue, analyzing several power and speed of advancelevels in a laser welding process for the union of ductile ironwith a carburized steel. They report that large penetrationsresults in a decrease of mechanical properties because highheat inputs limit the deformation of the joint. Gao et al. [11]allude an effect between the geometry of the weld bead andthe expected mechanical properties. Therefore, it is very

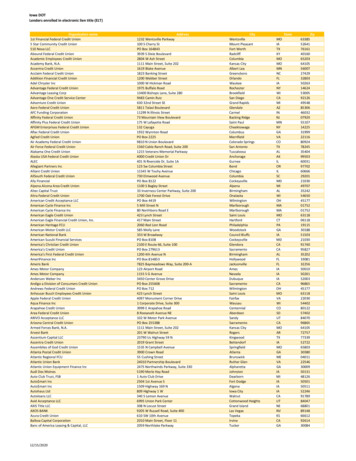

MEMORIAS DEL XXV CONGRESO INTERNACIONAL ANUAL DE LA SOMIM18 al 20 DE SEPTIEMBRE DE 2019 MAZATLÁN, SINALOA, MÉXICOimportant to predict the welding depth with different processconditions. Moreover, it is necessary to predict thepenetration of welding according to the establishedparameters and conditions.Kim [12] reported an analytical solution using the heatflow to predict the geometry and microstructure of the weldbead considering a Gaussian distribution in 316 stainlesssteel with a CO2 laser with 3 kW power per continuouswave. Lankalapalli et al. [13] developed a model to estimatethe penetration of the laser welding process using differentwelding powers and relate with the Peclet number.However, there are also investigations about statisticalpredictions regarding the penetration depth varying processparameters. Bennyounis et al. [14] carried out aninvestigation of the aforementioned by varying the laserpower, welding speed and focal point in medium carbonsteels. Manonmani et al. [15] they also investigatedvariations in laser power, speed of advance and angle ofincidence in stainless steels, both investigations with goodpredictions. Fabbro [16] determined an analytical solution todetermine the depth of welding, relating the power of thelaser, the welding speed and the diameter of the laser beamin stainless steel 304.This research presents a study of dissimilar unionsbetween ductile iron ASTM A536 65-45-12 and a steel20MnCr5 by laser welding process with different laserpower, the analysis of the phases resulting, microhardnessprofiles obtained, the use of analytical model developed byFabbro [16] to determine the depth of the penetration, andexperimental verification of the model.The measurements referring to the depths obtained in thepenetration by the experimentation were made by means ofthe NIKON stereoscope model SMZ-745T. And the analysisof the microstructure was made based on the ASTM E3-11standard.The etch was made with 5% Nital and 2% Picral byimmersion for 5 and 3 seconds, respectively. For theobservation of the fusion zone, the reactive agent Murakamiwas used for 15 seconds. Then, was observed by NIKONoptical microscope model ECLIPSE-MA200 INVERTED at200X.The scanning electron microscope TESCAN MIRA3 wasused for the identification of phases and was used for X-Raydiffraction PANALYTICAL model EMPYREAN 3 forphase identification in the diffractograms according to thepattern charts and the chemical composition (wt. %) wasanalyzed by optical emission spectrometry OXFORDINSTRUMENT model PMI MASTER SMART.The mechanical properties were analyzed bymicrohardness profiles of 18 indentations with 0.5 mmseparation with the WILSON HARDNESS microdurometermodel TUKON 2500 with a preload of 500 g and 10 secondsof maintenance. The microhardness profile in the joint isschematized in Fig. 2.Figure 2 Schematization of the hardness profile.2. Experimental2.1 CharacterizationThe chemical composition of the union between 20MnCr5and ductile iron ASTM A536 65-45-12 was determined byan optical emission spectrometer OXFORD INSTRUMENTmodel PMI MASTER SMART.A butt joint with cylindrical geometries was used with the20MnCr5 steel and the ASTM A536 65-45-12 ductile iron,these components were processed by TruDisk 4002TRUMPF laser equipment. Argon gas was used asprotection gas with a constant flow of 16L / min.Four cross-sectional samples were cut from each weld. Astandard metallography was performed for each transversalspecimen. Fig. 1 schematizes the butt joint of the steel andiron proposed in this investigation joined by laser welding.2.2 MethodologyEqn 1. shows an analytical solution to determine the depthof weld penetration developed by Fabbro [16].e 4 fA0 P DVw(1)Table 1 describes the variables that intervene in Eqn. 1, aswell as the considerations used for them.Table 1 Considerations of the variables of the model developed byFabbro.VariableEFFigure 1 Diagram of the dissi1milar union by the laser process.A0Descriptionpenetrationproportionality factor thatcan also be determinedexperimentally for similarconditions of incident laserintensity; in this case anapproximate value wasused to the resource for astainless steel 304.absorption coefficient [17].Unitsmm3 /JValuesAdimensional 0.75 3 x 10-11

MEMORIAS DEL XXV CONGRESO INTERNACIONAL ANUAL DE LA SOMIM18 al 20 DE SEPTIEMBRE DE 2019 MAZATLÁN, SINALOA, MÉXICOPDVwlaser powerdiameter of the laser beamWelding speedWattsmm/sBased on the analytical solution presented, differentpower levels will be used for the dissimilar union.the result of the prediction calculated from the proposedanalytical model. The maximum relative error between themeasurements obtained experimentally and the resultscalculated by the prediction is less than 6%.Table 3 Measurements of the depths of the experimental data and itserror with respect to the prediction of model for 2.6 kW.2.3 Temperature gradientThe temperature gradients were calculated from theproposed one-dimensional heat transfer equation of AdamsJr. [18]. The equation considers laser power (P), weldingspeed (Vw), thermal conductivity (k), liquid temperature (T)and the ambient temperature (𝑇0 ) where the solution can beexpressed in Eqn. 2:MeasurementNoPower of 2.6kW, mmPrediction ofdepths, mmRelativeerror, 64.5163.02401.08282.71912.91155.76763.2 Characterization of the union 2 kVw (T T0 ) 2 T T x( ) x ( )t ( )T t x tP(2)For this, the powers used were 2.45 kW and 2.6 kW, athermal conductivity (k) of 58 W/m K, the temperature ofthe liquid used was 1723 K and 298 K for the roomtemperature and a welding speed (Vw) of 2.8 m / min.3. Results and discussionTable 4 and 5 show the composition in weight percentage ofsteel and iron, respectively, from the optical emissionspectrometer analysis.Table 4 Chemical composition of 20MnCr5 3.1 Validation of the modelTwo laser power were used for calculations (2.45 kW and2.6 kW), with a laser beam size of 0.333 mm and a weldingspeed of 2.8 m / min. The welding penetration depths weremeasured for the model validation. The results are shown intable 2 and 3.Table 2 shows the results obtained in the measurementsmade in the welding tests for the power of 2.45 kW in turn,also shows the result of the prediction calculated by meansof the proposed analytical model. The maximum relativeerror between the measurements obtained experimentallyand the results calculated by the prediction is less than 7%.Table 5 Chemical composition of ductile iron ASTM A536 65-45-12.FeCSiMnCrMoNiBal. 4.5002.7500.1330.016 0.0050.034CoMgNbTiVSAl 0.0050.050 0.0030.213 0.0500.0040.017The base materials were analyzed by SEM and arepresented in Fig. 3 (a) Lath martensite obtained by heattreatment and (b) graphite nodules distributed in a ferriticmatrix.Table 2 Measurements of the depths of the experimental data and itserror with respect to the prediction of model for 2.45 kW.MeasurementNoPower of 2.45kW, mmPrediction ofdepths, mmRelativeerror, 63.5464.67934.44826.01806.93046.4641Table 3 shows the results obtained in the measurementsmade in the welding tests for the power of 2.6 kW as well asFigure 3 Base materials microstructure. (a) Steel 20MnCr5 and (b)Ductile iron 65-45-12. Observed at 2000X.

MEMORIAS DEL XXV CONGRESO INTERNACIONAL ANUAL DE LA SOMIM18 al 20 DE SEPTIEMBRE DE 2019 MAZATLÁN, SINALOA, MÉXICOThe weld was characterized by optical microscopy andSEM, Fig. 4 (a) schematizes the thermal cycles achievedduring welding and b) shows the microstructure of 20MnCr5steel. In the same figure it is shown grain coarsening, thishas been discussed and observed by Kou [19] and it isexplained in Fig. 4 (a) where the high temperatures werereached near the fusion zone allowing the transformation ofaustenite, nevertheless, close to the melting line (point D)the temperature were high enough to cause the austeniticgrain grow, at point C the temperature reached weresufficient for the partial austenite transformation of themicrostructure which is reflected by a grain refinement ofthe austenite.Figure 6 Effect of thermal cycles in the microstructure by the weldingprocess in ductile iron. (a) Schematization of the thermal cycleachieved in the welding processes and (b) Effect on the microstructurein the partially melted and affected areas by the observed heat at 500XFig. 7 shows microstructure obtained by SEM where theareas mentioned above by the laser welding process areidentifiedFigure 4 Microstructural effect of thermal cycles in the welding processof the steel component. (a) Thermal cycle schematization and (b)Microstructural effect observed at 200X.Fig. 5 SEM image of the aforementioned areas where (a)corresponds to the microstructure close to the fusion line and(b) corresponds to a microstructure farther from the fusionline. Fig. 5 (a) it is shown the microestructure near the limitof the heat affected zone and the base metal, where platemartensite is observed and Fig. 5 (b) corresponds to the heataffected zone close to the fusion zone, where lath martensiteis observed.Figure 5 Effect of thermal cycles on the microstructure in steel. (a)grain refinement and (b) grain coarsening grain refinement. Observedat 2000X.Additionally, the effect of laser welding on the ductileiron was analyzed and shown in Fig. 6. In (a) the thermalcycles are schematized by the laser welding process in theirons. Points C, B and A correspond to areas identified bysaid process.Figure 7 Microstructure by the process of laser welding in ductile iron.Observed at 2000X.Fig. 6 (b) and Fig. 7 shows martensite, as well as retainedaustenite and ledeburite, this was also observed byFernandez - Vicente et al. [20] and Lorella Ceschini et. al.[21], mention that both phases are generated by the greatpower of the laser beam and high advance speeds as well asthe great speed of solidification. During the heating theferritic matrix an inhomogeneous austenite is transformed,then the carbon diffuses from the graphite nodules to theaustenite, this increase only becomes local, thus reducing themelting point around the nodules, resulting in a fusion ofthose areas. But as mentioned above, high cooling speedsled to the formation of iron and martensite carbidemicrostructures. Fig. 7 shows the graphite nodulessurrounded by retained austenite, followed by ledeburite andmartensite. As for the area affected by the heat, it is alsopossible that there is carbon diffusion by the graphitenodules, where the carbon-rich austenite matrix formedmartensite and residual austenite. Finally the austenite withlow carbon is transformed again into ferrite.

MEMORIAS DEL XXV CONGRESO INTERNACIONAL ANUAL DE LA SOMIM18 al 20 DE SEPTIEMBRE DE 2019 MAZATLÁN, SINALOA, MÉXICOFigure 8 Microstructure of the fusion zone. A morphology of skeletaltype at 2000X is observed.The weld zone is observed in Fig. 8, it is composed of theER330 alloy, which has a vermicular or skeletalmicrostructure, this microstructure is commonly observed inaustenitic steels resulting from the controlled diffusion ofthe ferrite solid state transformation into austenite, followedby the solidification of primary ferrite, the ferrite of this typebeing found along the original dendritic nuclei of theprimary ferrite solidification structure. The completesolidification of the ferrite produced with the primarysolidification mode in place is believed to result from aninvariable reaction intervened in the final stages ofsolidification resulting in the formation of austenite withinthe limits of grain, therefore when the solidification hasfinished the predominant microstructure is ferrite withaustenite in the grain boundaries. During the solidifiedphases cooling most of the ferrite transforms to austenitewhich expands from the prior austenite. This type of ferritemorphologies are a function of the composition, but theextent of the transformation is also affected by the coolingrate, which in turn this cooling rate will be a function of thewelding process [22].Figure 10 Microdifraction analysis of 20MnCr5 steel. a) Correspondsto the base metal and b) zone close to the fusion limit.The diffractograms (a) and (b) of Fig. 11 correspond tothat obtained in the base metal and the areas close to themelting limit, respectively3.3 X Ray DifractionX-ray microdiffraction was used in the fusion zones as wellas in the base metals. Fig. 9 shows schematically the locationof the analyzed areas.Figure 11 Microdifraction analysis of ductile iron ASTM A536 65-4512. a) Corresponds to the base metal and b) zone close to the fusionlimit.Figure 9 Diagram of the location of the microdiffraction analysisThe results obtained in the steel 20MnCr5 observed in thediffractograms (a) and (b) of Fig. 10 correspond to thatobtained in the base metal and in the areas close to themelting limit, respectively.Fig. 10 corresponds to an identification of ferrite ormartensite zones, in Fig. 11 (a) the corresponding peaks offerrite or martensite and graphite are shown [23,24] becausethe diffraction was made on the base material, on the otherhand in Fig. 11 (b) the difractrogram shows intensities in theangle Two-theta characteristic of cementite and ferrite ormartensite due to the proximity with the diffraction withrespect to the fusion zone, confirming the microstructurespreviously observed by optical microscopy and SEM.

MEMORIAS DEL XXV CONGRESO INTERNACIONAL ANUAL DE LA SOMIM18 al 20 DE SEPTIEMBRE DE 2019 MAZATLÁN, SINALOA, MÉXICO3.4MicrohardnessThe hardness profiles were made at a depth of 2 mm, takingthe transverse base metal observed as reference and the basemetal near weld bead as starting point. For these tests wereconsidered to evaluate the joints with the identification 1, 3and 5 and are shown in Fig.12 for a power of 2.45 kW. Bythe other hand, the joints 1, 3 and 5 are shown in Fig. 13 fora power of 2.6 kW.By means of the hardness profiles obtained from eachjoint with respect to its power, a subgroup was created foreach indentation. In this way, were presented the averagesand standard deviation of each subgroup for eachindentation for the respective power level. The blue boxesshow the averages and the red lines the standard deviationof each subgroup.Figure 12 Results of the HV microhardness tests for 2.45 kWThe results in the hardness profiles show an appreciabledifference in some of the points. As investigated by Nekouieet. al. [25], where it is argued that the cooling rate has asignificant effect on the high microhardness obtained, aswell as the fact of the chemical composition plays animportant role, this is observed when determining the speedof cooling for the condition of 2.45 kW and 2.6 kW where itwas proposed as a single system obtaining cooling speeds of14095 K / s and 13282 K / s, respectively.Figure 13 Results of the HV microhardness tests for 2.6 kW.In turn, the hardness profile shows five zones shown inFig. 12 and 13; the base metal zone of the steel in both powershown the typical microhardness obtained by quenching andtempering heat treatment, heat affected zone in steel, has anincrease in microhardness compared to base metal, this isrelated to the martensite formation discussed by the authors[26] as well as the mentioned in point 3.2 and his behavioris because in the 6th indentation show a microhardnessincrease which corresponds to the martensite transformationfrom a fine austenite grain. The 7th indentation shows amicrohardness decrease corresponding with the martensitetransformation from a coarse austenite grain, as mentionedabove, this grain growth corresponds to the temperaturesreached near the melting zone. Then, the microhardnessbehavior of the fusion zone is shown which present adecrease in the microhardness, this result is due to the factthat the filler material provides considerable amount nickel,which provides good ductility [27]. The highest peak shownin the test which corresponds to 10th identation is observedin the partially melted zone of ductile iron near the meltingzone and was obtained by melting the material. The hightemperatures reached allowed the migration of carbon fromthe graphite nodules of ductile iron to the matrix and in thisway to reach a high temperature gradient during cooling, ledto the formation of high hardness microstructures inlocalized areas, this was discussed by Hajiannia et. al. [26].Finally the behavior of the microhardness of the base metalin the ductile iron is shown.In addition to the behaviors described above, a higherpeak hardness is observed in the joints where the powercorresponds to 2.6 kW due to the fact that it reaches highertemperature gradients compared to welded joints with 2.45kW of power and this is observed in Fig. 13.

MEMORIAS DEL XXV CONGRESO INTERNACIONAL ANUAL DE LA SOMIM18 al 20 DE SEPTIEMBRE DE 2019 MAZATLÁN, SINALOA, MÉXICO4. ConclusionFrom the results analysis and the previous discussions it isconcluded: The union of steel 20MnCr5 and ductile iron ASTMA36 60-45-12 shows a variety of zones and phasesidentified in the optical microscope, SEM and X-raydiffraction, which differ due to the chemical, thermaland physical characteristics of the materials involved. In steel 20MnCr5 the microstructure near to the meltinglimit was affected by grain coarsing as well as grainrefinement for distant areas with respect to meltinglimit, due to the thermal cycles experienced during thewelding process. Partially melted zone of ductile ironwere observed as well as heat affected zones, it isspeculated that this is due to the carbon diffusion of thenodules towards the ferritic matrix which allowed theiron carbides formation and martensite. The zones mentioned in the previous point showdifferent microhardness due the morphology, chemicalcompositions and the grain size of the steel and ironcomponent. It is possible to determine the weld penetration depthwith the model developed by Fabbro even in thewelding of dissimilar materials, with a relative error 7%.AcknowledgementThis study is supported by the Welding TechnologyPostgraduate program of COMIMSA as well as the doctors,employees and facilitators of the corporation. With specialmention to CONACYT for his contribution on this research.REFERENCES[1] E. W. Reutzel, Advantages and disadvantages of arc andlaser welding (pp. 1-25), Hybrid laser–arc welding,WoodHead Publishing, 1996.[2] S. Katayama, Y. Kawahito and M. Mizutani, Elucidationof laser welding phenomena and factors affecting weldpenetration and welding (pp. 9-17), Phys. Procedia 5,2010.[3] S. Katayama and J.W.R.I., Introduction: fundamentalsof laser welding (pp. 3-7.), in Laser Welding Technology,Cambridge, WOODHEAD PUBLISHING, 2013.[4] P. Wang, X. Chen, Q. Pan and B. Madigan, Laserwelding dissimilar materials of aluminum to steel (p.3081–3090), Int. J. Adv. Manuf. Technol. 87, 2016.[5] S. Katayama, New development in laser welding (pp.158-197), in New developments in advanced welding,Cambridge, Woodhead Publishing, 2005.[6] M. R. N. Esfahani, J. Coupland and S. Marimuthu,Microstructure and mechanical properties of a laserwelded low carbon-stainless steel joint, Journal ofMaterials Processing Technology, 2014.[7] S. Saravanan, K. Raghukandan and N.Sivagurumanikandan, Studies on metallurgical andmechanical properties of laser welded dissimilar gradesteels (3491-3498), J. Braz. Soc. Mech. Sci. Eng. 399,2017.[8] D. Dong, Y. Liu, L. Wang, Y. Yang, D. Jiang, R. Yangand W. Zhang, Microstructure and deformationbehaviour of laser welded dissimilar dual phase steeljoints (pp. 75-82), Science and Technology of Weldingand Joining 21, 2016.[9] Q. Jia, W. Guo, Z. Wan, Y. Peng, G. Zou and Z. Tian,Microstructure and mechanical properties of laserwelded dissimilar joints between QP and boron alloyedmartensitic steels (pp. 59-67), Journal of MaterialsProcessing Tech. 259, 2018.[10] J. Yu, T. Jung, S. Kim and S. Rhee, Laser welding ofcast iron and carburized steel for differential gear (pp.2887-2893), Journal of Mechanical Science andTechnology 25, 2011.[11] Z. Gao, P. Jiang, G. Mi, L. Cao and W. Liu,Investigation on the weld bead profile transformationwith the keyhole and molten pool dynamic behaviorsimulation in high power laser welding (pp. 1304-1313),International Journal of Heat and Mass Transfer 116,2018.[12] J.-D. Kim, Prediction of the penetration depth in laserbeam welding (pp. 32-39), K. S. M. E. Journal 1, 1990.[13] K. N. Lankalapalli, J. F. Tu and M. Gartner, A modelfor estimating penetration depth of laser weldingprocesses (pp. 1831-1841), J. Phys. D: Appl. Phys. 29,1996.[14] K. Benyounis, A. Olabi and M. S. J. Hashmi, Effect oflaser welding parameters on the heat input and weldbead profile (pp. 978-985), Journal of MaterialsProcessing Technology 165, 2005.[15] K. Manonmani, N. Murugan and G. Buvanasekaran,Effects of process parameters on the bead geometry oflaser beam butt welded stainless steel sheets (pp. 11251133), Int. J. Adv. Manuf. Technol. 32, 2007.[16] R. Fabbro, Melt pool and keyhole behaviour analysisfor deep penetration laser welding, Journal of Physics D:Applied Physics 43, 2010.[17] P. Gay, Application of mathematical heat transferanalysis to high-power CO2 (pp. 201-212), in LaserSurface Treatment of Metals, 1986.[18] A. C. Jr, Cooling rates and peak temperatures in fusionwelding (pp. 210-215), Welding J. 37, 1958.[19] S. Kou, Transformation-Hardening Materials: Carbonand Alloy Steels, in Welding Metallurgy, John Wiley &Sons, Inc, 2003.[20] A.Fernández -Vicente, M. Pellizzari and J. L. Arias,Feasibility of laser surface treatment of pearlitic andbainitic ductile irons for hot rolls (pp. 989-1002), J.Mater. Process. Technol. 212, 2012.[21] L. Ceschini, G. Campana, N. Pagano and V. Angelini,Effect of laser surface treatment on the dry slidingbehaviour of the EN-GJS400-12 ductile cast iron (pp.342-351), Tribology International 104, 2016.[22] American Welding Society, Stainless and HeatResistant Steels (pp. 255-334), Materials andapplications, part 1, 2011.[23] J. H. Abboud, Microstructure and erosioncharacteristic of nodular cast iron surface modified (pp.677-684), Materials and Design 35, 2012.

MEMORIAS DEL XXV CONGRESO INTERNACIONAL ANUAL DE LA SOMIM18 al 20 DE SEPTIEMBRE DE 2019 MAZATLÁN, SINALOA, MÉXICO[24] A. Zammit, S. Abela, J. Charles Betts, M. Grech,Discrete laser spot hardening of austempered ductileiron (pp. 143-152), Surface & Coatings Technology 331,2015.[25] M. R. N. Esfahani, J. Coupland and S. Marimuthu,Microstructural and mechanical characterization oflaser-welded high-carbon and stainless steel (pp. 14491456), Int. J. Adv. Manuf. Technol. 80, 2015.[26] I. Hajiannia, M. Shamanian and M. Kasiri,Microstructure and mechanical properties of AISI 347stainless steel/ A335 low alloy steel dissimilar jointproduced by gas tungsten arc (pp. 566-573), Materialsand Design 50, 2013.[27] American Welding Society, Stainless and heat resistantsteels (pp. 289-319), Materials and applications, part 1,2011.

The etch was made with 5% Nital and 2% Picral by immersion for 5 and 3 seconds, respectively. For the observation of the fusion zone, the reactive agent Murakami was used for 15 seconds. Then, was observed by NIKON optical microscope model ECLIPSE-MA200 INVERTED a