Transcription

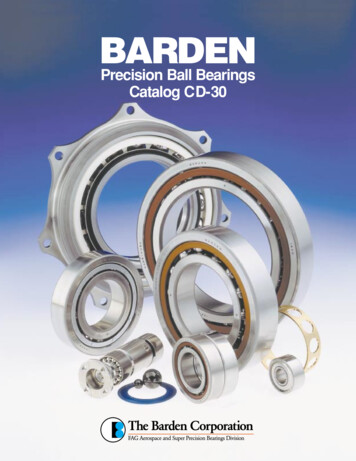

BARDENPrecision Ball BearingsCatalog CD-30

INTRODUCTIONHOW THIS CATALOG IS ORGANIZEDWelcome to the world of Barden Precision Bearings.This catalog contains the most complete list of Bardenprecision bearings currently available.If you have a copy of an earlier Barden catalog, you’llnotice that this version is organized differently. First ofall, the catalog is divided into two primary sections:1) product2) engineeringThe product section is now organized by bearing type: Instrument Bearings (Deep Groove and Angular Contact) Spindle Bearings (Angular Contact) Spindle Bearings (Deep Groove) Ball Screw Support BearingsBarden manufactures super precision spindle bearings and instrument bearings at plantslocated in Danbury, Connecticut (shown above) and the U.K.Bearings are also now listed by bore diameter — fromthe smallest to the largest.Another key change to this catalog is that data onlimiting speeds, ball complement, static capacity, basicdynamic load ratings and standard preloads has beenmoved to the appropriate product page, alongside bearing dimensions and nomenclature. This informationwas previously listed in the engineering section in theback of our older catalogs.Additional relevant data (e.g. on seal and cageoptions, etc) can now be found in the appropriate product sections, instead of appearing in the general engineering reference section, as before.The engineering section also has been reorganized.Much of the specific bearing operating data, as mentioned, can now be found in the appropriate productsection. New material has also been added to the engineering section, particularly on handling and mountingprocedures.One significant new feature, this catalog now hasfour fold-out pages at the beginning of each product section. Each fold-out page contains detailed descriptionsof appropriate bearing nomenclature by type of bearing.We believe that all of these changes will improve thefunctionality —and usefulness— of our primary productcatalog. Finding exactly the right Barden Precision Bearing should now be easier than ever.Finally, we would welcome any comments or suggestions you may have regarding our new format. And, asalways, thank you for choosing Barden.2

TABLE OF CONTENTSCAPABILITIESENGINEERING SECTION, continuedBarden’s Commitment to Excellence.4Barden Products .4Precision Classes.4Going Beyond ABEC Standards.5Sizes and Configurations.5Applications.6Quality Control and Engineering .7Bearing Performance.105–116Bearing Life .105Service Life.105Fatigue Life.106Sample Fatigue Life Calculation .108Miscellaneous Life Considerations .109Equipment Life.110Vibration .110Yield.114Torque.114Measurement and Testing Techniques .114PRODUCT SECTION, PRODUCT TABLESInstrument BearingsDeep Groove and Angular Contact.9Spindle Bearings (Deep Groove).29Spindle Bearings (Angular Contact) .45Ball Screw Support Bearings.67Bearing Application.118–138Mounting and Fitting.118Shaft and Housing Fits.119Shaft and Housing Size Determination.121Shaft and Housing Shoulder Diameters .122Lubrication Windows.130Maximum Fillet Radii .132Nonferrous Bearing Housings .132Random and Selective Fitting .133Calibration .133Axial Location and Control of End Play.135Preload Adjusting Springs .135Clamping Plates and Nuts .135Maintaining Bearing Cleanliness.136Handling Guidelines .138ENGINEERING SECTIONBearing Selection.73–103Selecting the Right Bearing.76Operating Conditions .76Bearing Types .76Bearing Size.77Ball and Ring Materials.78Ceramic Hybrids.78Bearing Capacity.81Bearing Cages.81Bearing Closures .85Selection of Closures.86Attainable Speeds .88Limiting Speed Factors.88Internal Design Parameters .90Preloading.92Lubrication.97Tolerances and Geometric Accuracy .103Barden Warranty .139Index .140The data, specifications and characteristics in this catalog were developed using sound testing and engineering techniques and are believed to be accurate. Every attempt has been made topreclude errors. However, use of this information is the customer’s responsibility. The Barden Corporation’s sole responsibility or liability is contained in the Warranty statement at theend of this catalog.3

CAPABILITIESThe Barden Corporation is a world leader in the engineering, design and manufacture of precision ball bearings and bearing components.In 1991, Barden became affiliated with the FAGKugelfischer Group, and now forms the nucleus of itsAerospace and Super Precision Division along withBarden U.K., a manufacturer of precision ball and spindlebearings, based in Plymouth, England. Also included inthis division are facilities in Stratford, Canada; Schweinfurt,Germany and subsidiary Winsted Precision Ball Company.Aerospace and Super Precision Division customersare served primarily by a staff of Barden Sales Engineers.The replacement market is served by approximately1,000 distributor outlets. Both are supplemented by anetwork of agents and distributors throughout the world.With this global distribution system, Barden can provide bearings of identical quality at any point of need.Present customers include many multinational companies that buy Barden bearings in more than one country.Hybrid bearings utilizing ceramic balls help reduce vibration levels resulting in lower operating temperatures, longer life, greater accuracy and higher running speeds.BARDEN’S COMMITMENTTO EXCELLENCEBARDEN PRODUCTSThe Barden Corporation was originally founded to makeball bearings of exceptional quality requiring rotationalprecision and tolerance control beyond the scope oftechnology then available. Today, over fifty years later,Barden continues to meet the challenge of manufacturing to super-precise/super-critical levels, and is recognizedas an industry leader in this achievement. Excellence inmanufacturing remains our guiding principle.Barden produces thousands of bearing types, sizesand designs for a wide range of precision applicationsserving narrow — but highly demanding — market segments, like spindle and turbine bearings for industrialmachinery and aircraft accessories, as well as instrumentbearings for medical applications and gyroscopes.Barden’s goal remains not only to provide the highest quality, most precise bearings that can be made, butto enable our customers to compete more successfullyin the markets they serve.Regardless of design, all Barden bearings share onething in common: they adhere to the highest standardspossible, with tolerances measured in the millionths ofan inch.The Barden product line encompasses predominantlyradial, single row, super precision angular contact (separable and nonseparable) and deep groove ball bearings.Ball bearings are made to exacting ABEC-7 and ABEC-9specifications, standards which Barden routinely exceeds.Barden super precision bearings come in inch ormetric dimensions with diameters ranging from 3/8"(9.5mm) O.D. up to 111/2" (300mm) O.D. A variety ofseals, shields and metallic/nonmetallic cage designs areavailable to satisfy most requirements. Many Bardenbearings operate comfortably at speeds ranging to 2.0million dN (bore in mm RPM), or above.PRECISION CLASSESPrecision ball bearings are manufactured to tolerancestandards set by the Bearing Engineers Committee(BEC) of the American Bearing Manufacturers Association (ABMA). These standards have been accepted bythe American National Standards Institute (ANSI) andconform essentially with equivalent standards of theInternational Organization for Standardization (ISO).ABEC standards define tolerances for several majorbearing dimensions and characteristics. They are dividedinto mounting dimensions (bore, O.D. and width) andbearing geometry. General-purpose, spindle size ballbearings are manufactured to precision classes ABEC 1,ABEC 3, ABEC 5, ABEC 7 and ABEC 9. The ascend-INTERNATIONAL RECOGNITIONThe Barden name — long synonymous with quality, precision and excellence — is known and respected in virtually every industrialized nation, including the Far East.4

ing numbers indicate increasingly stricter tolerances andadditional requirements. All Barden angular contactmachine tool spindle bearings meet or exceed ABEC 9geometric standards. Bores and O.D.’s are calibrated forgreater mounting flexibility. Barden deep groove spindlebearings meet or exceed ABEC 7.Instrument bearings are produced in comparableclasses, with added refinements designated by suffixes:ABEC 3P, ABEC 5P, ABEC 7P, ABEC 9P, ABEC 5Tand ABEC 7T. Barden bearings in this category aremade to ABEC 7P or better.GOING BEYOND ABEC STANDARDSWhile ABEC classes are very helpful in categorizingbearing precision, they are not all-inclusive. At Barden,we are concerned about total bearing quality and “fitness for use” in critical applications. We often maintaincloser tolerances than specified and we address manyfactors affecting bearing performance and life that arenot covered by ABEC standards.ABEC criteria, for example, do not include functionaltesting of assembled bearings, yet this measure can beextremely important. Barden applies self-establishedstandards, using a number of proprietary tests andinstruments to ensure that we deliver quiet, smooth-running bearings that will perform exceptionally well.Bearing design is also not included in ABEC standards, but it too can make the difference between success and failure in bearing use. Barden design criteria arebased on knowledge of all the factors which are significant for different applications.Thus, a Barden bearing may have specific low torquecharacteristics for a gyro gimbal, extra stiffness for amachine tool spindle, or extremely high reliability for ajet engine application.Because ball quality affects the ability of a bearing torun smoothly, Barden uses both steel and ceramic ballsproduced to its own exacting specifications for ballgeometry, finish and size control.Barden precision bearings are manufactured to ABEC 7 and ABEC 9 tolerances and areavailable in sizes ranging from 3/8" (9.5mm) O.D. to 111/2” (300mm) O.D.CONFIGURATIONSBarden manufactures deep groove and angular contact(separable and nonseparable) bearings, some of whichare available with flanged outer rings.Flanged bearings are especially useful in through-boredhousings. The inboard side of the flange provides anaccurate positioning surface for bearing alignment, eliminating a need for housing shoulders or shoulder rings.Extra wide, or cartridge width, deep groove bearingsare available in Series 9000 for installations requiringlengthy operation without relubrication. Series 9000bearings have more interior free volume and thereforehold more grease.Innovative products include ZSB-series small ballangular contact machine tool spindle bearings, whichfeature integral shields — an industry first — and can beequipped with ceramic balls for increased speedability.Series L and BSB ball screw support bearings consistof angular contact spindle bearings which are speciallydesigned for — and restricted to — specific machinetool applications. Contact angle is unusually high(L 65 , BSB 60 ) to provide axial rigidity and the veryhigh thrust capacity needed in ball screw supports, toolframes, etc.Most Barden bearings are available with a variety ofcage and closure options.SIZESBarden bearings are sized in both inch and metricdimensions. They are categorized as either instrumentor spindle types. This distinction is primarily size-relatedbut is sometimes application-related.5

CAPABILITIESPhoto courtesy of HAAS Automation, Inc. U.S.A.APPLICATIONSMany now-standard bearings featured in this catalogwere once considered “special,” since they offered userssomething new in precision, size or configuration. At anygiven time, Barden has dozens of such new designs anddevelopments being used very successfully in limitedquantities. Current examples of Barden bearing applications include: Turbo molecular pumps Jet engine starters Auxiliary aircraft equipment. Control moment gyroscopes in satellites X-Ray tube anode rotation devices.Barden spindle bearings used in machines like this multi-axis machining center offer the ultimate in precision, speed and accuracy to help optimize cutting tool performance.The precision bearings found in CAT scanner X-ray tubes use a special Barden bearingdesign which must operate in a vacuum under boundary lubrication conditions.Commercial aviation applications include a wide variety of aircraft accessories and criticalcomponents, and comprise a large percentage of Barden’s core business.Photo courtesy of NASA.Photo courtesy of Balzer’s High Vacuum Products.Vacuum pumps place severe demands on spindle bearings which must operate flawlesslyunder grueling conditions and meet long life requirements.The Barden super precision bearings used in NASA’s TIROS weather satellite must meetstringent performance requirements with minimal lubrication.6

QUALITY CONTROLBarden is ISO 9001 certified. The quality controlssystems used at Barden comply fully with MIL-I-45208,Inspection System Requirements; MIL-H-6875, HeatTreat Procedures and ISO 10012-1, Quality AssuranceRequirements for Measuring Equipment (formerly MILSTD-45662). Barden is also certified by The NationalAerospace and Defense Contractors Accreditation Program (NADCAP) for our nondestructive testing processes and is an approved supplier for the Federal AviationAdministration. These controls are coupled with aplanned flexibility which enables Barden to complywith specific requirements of individual customersthrough a system of quality levels, inspections levels andcertification of our product.Quality is built into all Barden products. This thinkingis applied to every aspect of manufacturing, from rawmaterials through packaged assembled bearings.Through the use of Statistical Process Control, theQuality Engineering staff determines and monitors processcapabilities to assure that process tolerances can be maintained. In-process machine control is facilitated using precontrol. These statistical methods are employed as production tools to gain better and more consistent quality.The inspection department is the operating arm ofour quality control organization. Each lot of parts orassembled bearings must conform to quality requirements before it is allowed to move to the next operation. Rather than delay inspection until operations havebeen completed, Barden’s operators are certifiedthrough rigorous training and auditing to performinspection operations during the manufacturingprocess. Our “Certified Supplier” program ensures thatour suppliers are top notch, consistently supplying uswith acceptable product.The Metrology Department of Barden’s quality control organization provides basic standards of reference,using many advanced types of instrumentation. All linearmeasurements are certified to The National Institute ofStandards and Technology.Our Metallurgical and Chemical Laboratories are thesurveillance unit for all incoming bearing steel, lubricants, cage material and other supplies. These laboratories work closely with other laboratories, universities andmanufacturers to develop the highest quality parts, newbearing cleaning equipment, and the most advancedheat treating systems.Barden’s vibration test lab allows engineers to monitor and refine bearing performance in aspindle assembly under “real-world” operating conditions.PRODUCT ENGINEERINGBarden Product Engineering services are available to allcustomers and prospective users of Barden precisionbearings. Our engineers and technicians have capabilities in every area of bearing design, application, testingand development. When bearing performance involvingtorque, vibration or stiffness is an issue, they can perform computer analysis of characteristics and requirements in order to determine a suitable bearing design.If standard cataloged bearings lack the necessary characteristics for a particular application, our Product Engineering Department can design a special bearing to satisfy your need.With over 50 years of specialization in the field ofprecision ball bearings, Barden engineers can draw upona wealth of technical information to aid in failure analysis or troubleshooting of performance problems. Theycan readily identify the contributing causes and recommend solutions to improve bearing performance or life.Our Product Development Laboratory conducts special investigations into new materials, coatings, lubricantsand bearing designs. This laboratory is the center forBarden work on unusual bearing problems, special environmental testing and vibration analysis. Endurance andreliability testing is also performed here.If you have a particular problem that you would likeBarden’s engineers to review, please contact your BardenSales or Application Engineer, or an Authorized BardenDistributor.7

8

INSTRUMENTBEARINGSDeep Groove and Angular Contact

INSTRUMENT BEARINGS (DEEP GROOVE)ENGINEERINGDEEP GROOVE BEARING DESIGNDEEP GROOVE BEARING CAGESDeep groove instrument ball bearings have fullshoulders on both sides of the raceways of theinner and outer rings. They can accept radialloads, thrust loads in either direction, or a combination of loads.The full shouldersand the cages used indeep groove bearings make themsuitable for theaddition of closures. Besides single deep groovebearings with closures, Barden alsooffers duplex pairswith seals or shieldson the outboard faces.Deep groove instrument bearings are available in many sizes, with avariety of cage types. Their versatility makes deepgroove bearings the most widely used type.The principal cage designs for Barden deepgroove instrument bearings are snap-in-types Qand TA; symmetrical types P, W and T. Type Wis a low torque cage developed by Barden, available in many instrument sizes. This two-piece ribbon cage is loosely clinched to prevent cagewindup (a torque-increasing drawback of somecage designs) in sensitive low torque applications.Ribbon cages P and W are used at moderatespeeds and are particularly suited for bearingswith grease lubrication and seals or shields. Forhigher speeds, Barden offers the one-piece phenolic snap-in type TA cage in smaller bearingsizes and the two piece riveted phenolic, aluminum-reinforced T cage for larger sizes. The aluminum reinforcement, a Barden first, providesadditional strength and permits use of this highspeed cage in most standard width sealed orshielded bearings.10

INSTRUMENT BEARINGSBEARING NOMENCLATUREDEEP GROOVEExample: SR4SSWX8K5VKC 0-11CLOSUREFUNCTIONALTESTAbsence of a symbolindicates an open bearing.Shielded bearingsS – Single shield.SS – Double shield.Sealed BearingsF – Single Flexeal. FF – Double Flexeal.CAGEAbsence of a symbolindicates standard cage,which varies with seriesand size. For standardcages see Cage Optionsin the Engineering section, page 81.W – loosely clinchedsteel 2-piece ribbonTA – phenolic 1-piecesnap-inT – phenolic 2-piecerivetedJB – 1-piece bronzeMATERIAL(BALLS & RINGS)Absence of a symbolindicates SAE 52100(chrome) bearing steel.S AISI 440C stainlesssteel.SR438SERIES & SIZEFirst character alwaysdenotes series.R inch series3 metric seriesRemaining characterdenotes bore size.SSWRADIAL PLAYNumeric code indicatesrange of radial play. SeeRadial Play discussionon pages 12 and/or 23.Note: To avoid confusion, radial play codenumber is preceded byseparating letter “K”when previous sectionof bearing number endsin a numeral.X8K5HMost Series R inch deepgroove bearings andSeries 30 metric deepgroove bearings areavailable with low torquecharacteristics. Variationsin torque levels are designated as follows:V – Guaranteed lowmaximum torque level.VK – Very low startingtorque.VM – Very low runningtorque.VT – Actual torque tracefurnished with each VMlevel bearing. ConsultBarden for specific levels.VKCDBTYPEB – Separable angular contactbearing with cutaway innerring shoulder.H– Nonseparable angularcontact bearing with cutawayouter ring shoulder.Absence of a symbol indicatesa deep groove bearing.R2SPECIALFEATURESDUPLEXING ANDPRELOADSLetter “X” followed bynumber(s) indicatesspecial features.Consult BardenEngineering for details.D – Universal mounting.Angular contact duplexsets universally groundhave inner and outerrings of the same widthand can be installed DB,DF or DT.DB – Back-to-backmounting.DF – Face-to-facemounting.DT – Tandem mounting.ANGULAR CONTACTExample: 38HDBR2 G-2LUBRICATIONType of prelubrication is indicated onpackage.O – indicates oilG – indicates greaseNumber code following letter denotesspecific type of lubricant. A discussionof lubricants can be found in theEngineering section, page 97.O-11G-2CALIBRATIONBores and O.D.s aredivided into .0001" or.000050" incrementswithin the tolerancerange.C – .0001" groupsC44 – .000050" groupsRefer to calibration discussion in the Engineering section, page 133.RADIAL RUNOUTA special value of radial runout may be indicated in bearing number by:E – Special radial runout (tighter than standard tolerances). ConsultBarden.The following codes for high point markings may be used with letter“E” (to indicate high points of radial runout for bearings with specialvalues) or separately (to indicate high points for bearings with standard tolerances).R – Inner ring marked for high point of radial runout.R1 – Outer ring marked for high point of radial runout.R2 – Both inner and outer rings marked for high points of radialrunout.11

INSTRUMENT BEARINGS (DEEP GROOVE)ENGINEERINGTable 1. Radial play code selection guide for deep groove instrument bearings.RADIAL PLAYDeep groove bearings are available from Barden in arange of radial play groups. Each group is expressed as aRadial Play Code, representing limits to the range ofradial internal clearance. The code number is used inbearing identification as shown in the Nomenclatureexplanation on overleaf.The available radial play groups listed in Table 1 givethe designer wide latitude in the selection of proper radial internal clearance. Such ranges have nothing to dowith ABEC tolerances or precision classes, hence a bearing with a high value of radial play does not necessarilyhave lower quality or less precision.Specifying a radial code must take into account theinstallation practice. If a bearing is press-fitted onto ashaft or into a housing, its radial internal clearance isreduced by approximately 80% of the interference fit.Thus, an interference fit of .00025” would cause a .0002”decrease in internal clearance.Table 2 is an initial guide for radial play selection.Deep groove bearings with Code 3 and Code 5 radialplay are more readily available than those with othercodes. When performance requirements exceed thestandard radial play codes, consult the Barden ProductEngineering Department. Special ranges of internalclearance can be supplied, but should be avoided unlessthere is a technical justification.Radial Play CodeRadial Play Values23456.0001 to .0003.0002 to .0004.0003 to .0005.0005 to .0008.0008 to .0011All dimensions in inches.Fig. 1. Radial play is a measure of internal clearance and is influenced by measuring loadand installation practices. A high radial play value is not an indication of lower quality orless precision.Table 2. Radial play code selection guide for deep groove instrument bearings.Loads and SpeedsRecommendedRadial PlayCodeMinimum radial clearance without axial adjustment.Light loads, low speeds.3Internal clearance not critical; moderate torqueunder thrust loading.Minimum torque under thrust loading; endurance lifeunder wide temperature range.Specific requirements for axial and radial rigidity; highthrust capacity at extreme speeds and temperatures.Moderate loadsand speeds.Moderate to heavy loads,very low to high speeds.Moderate to heavy loadsat high speeds.3Performance Requirements125ConsultBarden.LimitationsLowest axial load capacity. Highest torque under thrust.Not suitable for hot or cold running applications. Must notbe interference fitted to either shaft or housing.Axial adjustment for very low speed or axial spring loadingfor moderate speed may be necessary.Axial adjustment, spring preloading or fixed preloads usuallyrequired; light interference fits permissible in some cases.Complete analysis of all performance and design factors isessential before radial play specification.

AXIAL PLAYAxial play, also called end play, is the maximum possible movement, parallel to the bearing axis, of the innerring in relation to the outer ring. It is measured under alight reversing axial load.End play is a function of radial internal clearance,thus the nominal end play values given in Table 3 areexpressed for various radial play codes of deep grooveinstrument bearings.End play will increase when a thrust load is imposed,due to axial yield. If this is objectionable, the end playcan be reduced by axial shimming or axial preloading.End play is not a design specification; the BardenProduct Engineering Department should be consulted ifend play modifications are desired in deep grooveinstrument bearings.Table 3. Nominal axial play values of deep groove instrumentbearings for various radial play codes.Basic BearingNomenclatureR2, R2AR3, R4R4AR6R8R1034, 34-535, 3637, .0021Radial Play Codes345Axial Play 91.0045Fig. 2. Axial play, or end play, is defined as the maximum possible movement, parallel to theaxis of the bearing, of the inner ring relative to the outer ring. Axial play, if objectionable, canbe reduced by shimming or preloading.All dimensions in inches.13

INSTRUMENT BEARINGS (DEEP GROOVE)ENGINEERINGTOLERANCESDeep groove instrument bearings are manufactured toABEC 7P tolerances as defined by ABMA Standard 12.Table 4. Tolerances for Series R, FR and 30.INNER RINGBoreMean diameter 1Minimum diameter 2ABEC Class 7P .0000 – .0002– .0002Maximum diameter 2 .0000Out of Round — maximum.0001Taper — maximum.0001Radial runout — maximum.0001Bore runout with side — maximum.0001Raceway runout with side — maximum.0001Width, single bearing — individual ring .0000 – .0010Width, duplex pair — per pair .0000 – .0150Width variation — maximum.0001OUTER RING (Outside cylindrical surface)ABEC Class 7POpen bearingsMean diameter 1 .0000 – .0002Minimum diameter 2–.0002Maximum diameter 2 .0000Out of Round — maximum.0001Taper — maximum.0001Bearings with closuresMean diameter 1 .0000 – .0002Minimum diameter 2–.00024Maximum diameter 2 .000040Out of round — maximum.0002Taper — maximum.0002.00015Radial runout — maximum 3Outside cylindrical surface runout with side — max.00015Raceway runout with side — maximum.0002Width, single bearing — individual ring .0000 – .0010Width, duplex pair — per pair .0000 – .0150Width variation — maximum.0001All tolerances in inches.1Mean diameter 1/2 (maximum diameter minimum diameter).2All diameter measurements are two point measurements.3Radial runout of R10 outer ring is .0002".14

PRODUCT SERIES DESCRIPTIONSAttainable Speeds: Limits given are for lightly loadedsingle bearings. See Engineering section, page 88, forqualifications. For flanged bearings, limiting speeds arethe same as the equivalent size of unflanged bearings.SERIES R, FR AND 30 Deep Groove Open, Shielded and Sealed Series R and FR Inch Instrument Series Series 30 Metric Instrument SeriesMaterials: Series R and FR standard material is AISI440C stainless steel; some sizes are available in SAE52100 bearing steel. Series 30 standard material is SAE52100 bearing steel. Most sizes are also available in AISI440C stainless steel.Series R deep groove bearings have full shoulders onboth sides of the raceways of the inner and outer rings.They can accept radial loads, thrust loads in either direction, or combi

radial, single row, super precision angular contact (sepa-rable and nonseparable) and deep groove ball bearings. Ball bearings are made to exacting ABEC-7 and ABEC-9 specifications, standards which Barden routinely exceeds. Barden super precision bearings come in inch or metric dimensions