Transcription

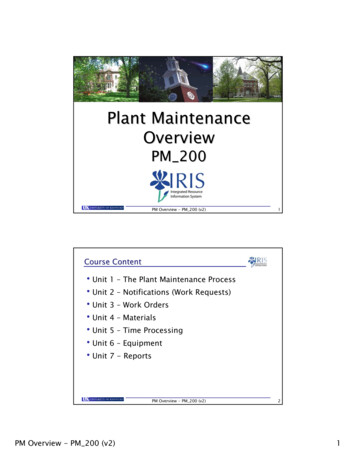

Plant MaintenanceOverviewPM 200PM Overview - PM 200 (v2)1Course Content Unit 1 – The Plant Maintenance Process Unit 2 – Notifications (Work Requests) Unit 3 – Work Orders Unit 4 – Materials Unit 5 – Time Processing Unit 6 – Equipment Unit 7 - ReportsPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)21

Prerequisites and Roles Prerequisites PM UK 100 IRIS/SAP Awareness & Navigation Roles All Plant Maintenance IRIS users will take thisclass Each PM class taken will allow different accessroles for different users, based on each user’sjob and the IRIS functionality needed to performthat job.PM Overview - PM 200 (v2)3Plant Maintenance IRIS Project Goals Integrate Plant Maintenance with Finance, HumanResources, and Materials Allow enhanced scheduling and planning for workassignments Provide work scheduling as well as managementreporting tools Improve automated updates to customers about thestatus of work Implement a Preventive Maintenance system forbuildings, areas, and equipment Use standard SAP functionality to collect utility use andcost information for recharge calculationsPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)42

Integration Across IRIS IRIS data integrationprovides: Data that flowsimmediately throughoutthe systemW(N orkot Reifica quetio stns s) Real-time access ofersIRISDatabasecommon information in PM Virtual elimination ofEquipmetiv ceen nev tenarP inMaentMaterialsduplicate entries and theerrors they can producerWordkOPM Overview - PM 200 (v2)5Unit 1The PlantMaintenance ProcessPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)63

The Plant Maintenance ProcessIdentify the WorkPlan the WorkDo the WorkWeb RequestPriority / DatesParts IssuedPhone CallLabor RequiredPurchase ReqsPartsPreventive MaintenanceHistory/AnalysisTechnical HistoryProceduresSchedulesRecord What was DoneHours WorkedBreakdownsCommentsCostsCodesPM Overview - PM 200 (v2)7The Plant Maintenance Process in IRISIdentify the WorkPlan the WorkNotificationWork OrderDo the WorkGoods IssuePurchase OrderPreventive MaintenanceHistory/AnalysisTask ListRecord What was DoneMaintenance PlanOrder ConfirmationReportsUK BusinessWarehousePM Overview - PM 200 (v2)PM Overview - PM 200 (v2)84

The “Plants” in Plant Maintenance The Maintenance Plant Represents the physical facilityThe entire UK campus: buildings and groundsRepresents the place where maintenance materials are keptAlways UK10 The Planning Plant Organizational in nature Work groups are grouped by plantThere are 3 main Planning Plants:- Main Campus PPD (CPPD),- Medical Center PPD (MPPD), and- Housing (HOUS)PM Overview - PM 200 (v2)9Functional Locations The Functional Location Structure The first level would be the “campus” (LX-) The next level is the building The next level is the floor The next level is the room There is a separate structure for Grounds (exterior space)PM Overview - PM 200 (v2)PM Overview - PM 200 (v2)105

Functional Location Structure The Building:LX-0030Student Center The Floor:LX-0030-02 The Room:LX-0030-02-249Student Center, 2nd floorStudent Center, 2nd floor, room 249 LX-0030-STStairway LX-0030-ELElevatorPM Overview - PM 200 (v2)11Unit 1 – The Plant Maintenance ProcessExercise 1DisplayFunctionalLocationIL03PM Overview - PM 200 (v2)PM Overview - PM 200 (v2)126

Unit 2Notifications(Work Requests)PM Overview - PM 200 (v2)13The Plant Maintenance ProcessIdentify the WorkPlan the WorkNotificationWork OrderDo the WorkGoods IssuePurchase OrderPreventive MaintenanceHistory/AnalysisTask ListMaintenance PlanReportsRecord What was DoneOrder ConfirmationUK BusinessWarehousePM Overview - PM 200 (v2)PM Overview - PM 200 (v2)147

What is a Notification? A Notification is a non-financial transactionthat is used to: Report a problem Request work Record an event or activityIdentify the WorkPM Overview - PM 200 (v2)15How are Notifications Created? Notifications may be created: Via a web form used to report a problem orrequest work Through a phone call to the control desk By a maintenance user, to record a log entry ortechnical observationPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)168

Information Captured on a Notification Description Explanation of the problem or work Examples: Room too cold; Broken window Can include long text for more detail Functional Location – the location of the work LX-0030 is the Student Center LX-0030-02 is Student Center, 2nd floor LX-0030-02-249 is Student Center, 2nd floor, room249 Stairways and elevators are also includedPM Overview - PM 200 (v2)17Information Captured on a Notification Priority indicates when this work should bescheduled. Choices are: Daily Operations Emergency Research FAC Renovations Scheduled Maintenance Elective ImprovementPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)189

Information Captured on a Notification Reported by The person reporting the problem Main Work Center A work group or individual Examples include Electric Shop, Plumbing,Cabinet Shop, Grounds, etc.PM Overview - PM 200 (v2)19Creating a Notification – IW21NotificationType isrequired.Click on thePossibleEntries iconto see options.Double-clickon your choice.Press Enter.PM Overview - PM 200 (v2)PM Overview - PM 200 (v2)2010

Notification TypesCampus PPDMedicalCenter PPDHousingPPDEmergencyCEMEHEFire AlarmCFMFHFLog Entry onlyCLMLHLProblem ReportCPMPHPWork RequestCRMRHRNotification createdby external systemCXMXHXDescriptionResNet NotificationHNPM Overview - PM 200 (v2)21Creating a NotificationOn the next screen,fill in theDescription,Functional Location,Reported by, andPriority fieldsPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)2211

Creating a NotificationSelect thePriority from thedrop-down listPM Overview - PM 200 (v2)23Creating a NotificationAfter entering theinformation, clickon the Save iconPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)2412

Notification NumberThe Notificationnumber isdisplayed in thelower-left cornerof the screenPM Overview - PM 200 (v2)25Unit 2 – Notifications (Work Requests)Exercise 2Display aNotificationIW23PM Overview - PM 200 (v2)PM Overview - PM 200 (v2)2613

Unit 3Work OrdersPM Overview - PM 200 (v2)27The Plant Maintenance ProcessIdentify the WorkPlan the WorkNotificationWork OrderDo the WorkGoods IssuePurchase OrderPreventive MaintenanceHistory/AnalysisTask ListMaintenance PlanReportsRecord What was DoneOrder ConfirmationUK BusinessWarehousePM Overview - PM 200 (v2)PM Overview - PM 200 (v2)2814

What is a Work Order? A financial and work management transaction used toplan and charge labor, stock materials, non-stockpurchases, and services It is integrated with Financials, Materials Management,and Human Resources in the IRIS system It may be created from a Notification or without anexisting Notification. Multiple Notifications can be turned into ONE WorkOrder.Plan the WorkPM Overview - PM 200 (v2)29Why are Work Orders used?Work Orders are used: To plan and schedule work To accumulate charges for work that will be rechargedto others To document the costs of an event For Preventive Maintenance workPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)3015

Who Creates Work Orders? This function will be used primarily by the Dispatcharea (WorkWork Control Centers)Centers to create orders to initiatework to be done. Authorized users responsible for creating orders fortheir area will also have access to create work orders inIRIS.PM Overview - PM 200 (v2)31Information on a Work Ordery Description - includes “long text” which can be ofunlimited lengthy A Priority for the worky An object to be maintained: A Functional Location(building, room) or piece of Equipmenty Contact information for the person reporting theproblem or requesting worky Planned labor and materialsy Actual labor and materials costsPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)3216

Other Work Order Information Person Assigned – This could be an individual witha specialty in a certain area Materials – Parts and supplies needed to performthe work Special Conditions – For example: Patient Rooms,Hazardous Areas These items can be added later as additionalplanning is performed for more complex orders.PM Overview - PM 200 (v2)33Creating a Work Order – IW31There are 3 requiredfields on the first screen: Order Type Priority Functional LocationPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)3417

Work Order TypesClick on the PossibleEntries icon to see thelist of Order Types.Double-click on theone you want to use.PM Overview - PM 200 (v2)35Work Order TypesTypeCASHEVNTPREVRENVREPRNameCash Chargeout OrderExample: Fraternity WorkSpecial EventExample: CommencementPreventive MaintenanceExample: Oil HVAC regularlyRenovation (Charged Out)Example: Install new bathroomCorrective (Repair)Example: Repair hinge on doorPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)3618

PriorityClick on the drop-downicon in the Priority fieldto see the choices.Each priority has a specifiedtime span for the work.PM Overview - PM 200 (v2)37Priority InformationDescriptionStartEndArea(s)Emergency10 Min24 HoursMCPPDEmergency30 Min24 HoursPPD, HousingGeneral Maint.7 Days30 DaysMCPPDScheduleable Maint.7 Days30 DaysPPD, HousingDaily Operations1 Day2 DaysAllResearch Fac. Res.1 Hour4 HoursPPDPriority Maintenance1 Hour4 HoursHousingPatient Care1 Hour4 HoursMCPPDElect. Improv.3 Days10 DaysMCPPDElect. Improv.PPD, HousingRenovationsPPD, MCPPDRenovations/AptChkHousingPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)3819

Functional LocationIf you do not know theFunctional Location code, clickon the Possible Entries iconto search for it.PM Overview - PM 200 (v2)39Functional LocationThe Functional Location searchbox will appear. Navigate tothe Text( Description) tab.Enter your search text in theDescription field. The asteriskis the wildcard character.Example: *mcvey* for McVeyHall.Then press the Enter key.PM Overview - PM 200 (v2)PM Overview - PM 200 (v2)4020

Functional LocationThe Functional Locationmatches will be displayed.Double-click on theappropriate location topopulate the FunctionalLocation field on the Order.PM Overview - PM 200 (v2)41Creating a Work OrderAfter completing the fields,press the Enter key or clickon the Create Order button.PM Overview - PM 200 (v2)PM Overview - PM 200 (v2)4221

Creating a Work OrderThe work order will appear.Enter a description of thework and an estimate oflabor time required.Click on the Save iconPM Overview - PM 200 (v2)43Work Order NumberThe Work Ordernumber isdisplayed in thelower-left cornerof the screenPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)4422

Unit 3 – Work OrdersExercise 3Display aWork OrderIW33PM Overview - PM 200 (v2)45Unit 4MaterialsPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)4623

The Plant Maintenance ProcessIdentify the WorkNotificationPlan the WorkDo the WorkGoods IssueWork OrderPurchase OrderPreventive MaintenanceHistory/AnalysisTask ListMaintenance PlanReportsRecord What was DoneOrder ConfirmationUK BusinessWarehousePM Overview - PM 200 (v2)47Materials and Inventory Materials Management Inventory will be replacingStores Inventory Systems On-shelf inventory will be minimized We are moving toward “just-in-time” inventory (partswill be requisitioned daily) We are moving away from ProCard being used formaterials; instead, contracts will be set up There will be stock, non-stock, and non-file materials Materials may be planned (used on a routine basis) andunplanned Stock and non-stock materials will be identified bynumbers in IRISPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)4824

Stock Materials on a Work Order We are assigning numbers for parts we keep “instock” on campus – called Stock Materials Putting stock material numbers on your work orderwill create a Reservation for you at the Storeroom The Storeroom can then pick, stage, and deliver thematerials as required For example, say next week you plan to replace the air filtersin your building. You can set up the work order and undermaterials needed go ahead and fill out the number for airfilters. If the materials are “stock”, this will reserve thematerials you need. You can pick them up under your WorkOrder number or the Storeroom can deliver the materialswhen needed.PM Overview - PM 200 (v2)49Non-Stock Materials on a Work Order Items that we don’t want to store on campus but rather geton an as-needed basis, these are called non-stock and canalso be assigned material numbers If you need non-stock materials, when they are placed onthe work order the system will automatically generate apurchase requisition that will go thru Purchasing. These areautomated because we have set up contracts withcommonly used Vendors. Purchasing can take a look at these purchase orders on thecomputer and approve them. Much faster process than theold paper days and less paper work. The materials are ordered from the Vendor and delivered toCentral Stores. The Storeroom can then pick, stage, anddeliver the materials as requiredPM Overview - PM 200 (v2)PM Overview - PM 200 (v2)5025

Non-File Materials on a Work Order Not everything will have a material number. We callthese things non-file materials Non-file materials are parts ordered as needed and donot have IRIS material numbers If you have a Work Order where you need to order anon-file material, you will manually create a PurchaseRequisition. The system can’t do these automaticallybecause we probably don’t have contracts set up withthe Vendor This is the process used for those hard-to-find parts.Once you find a supplier for the item, you will proceedwith a Purchase Requisition (as we do currently) or usethe Pro-Card when necessaryPM Overview - PM 200 (v2)51Unplanned Materials on a Work Order If you are on your way to a job and realize you needlight bulbs, you certainly can drop by the Storeroomand pick up the bulbs without having to drive first to acomputer to reserve them! These are called Unplanned Materials

Plant Maintenance IRIS Project Goals Integrate Plant Maintenance with Finance, Human Resources, and Materials Allow enhanced scheduling and planning for work assignments Provide work scheduling as well as management reporting tools Improve automated updates to customers about the status of work Implement a Preventive Maintenance system forFile Size: 1MBPage Count: 47