Transcription

AN INTRODUCTION TOCOLD-FORMED STEEL FRAMINGSTRONGERT H A N S T E E L.SMINTERIOR FRAMING EXTERIOR FRAMING FLOOR FRAMINGI N T E R IO R F INIS H ING M E TA L L AT H/ACC E S S O R IE S C LIP S/CO N N EC TO R S

ClarkDietrichToday, ClarkDietrich is not only a company of sizeand scope- but one of much broader vision. Beyondthe strength of our steel framing products, we findthat real integrity is found in working with you as aconfident partner who delivers unmatched insight andremarkable perspective.Like you, we look out upon a construction landscapethat’s continually evolving at a rapid pace. Thechallenges are many, but the trends toward higherperformance and greater efficiencies in all aspectsof construction are promising. As the trends takehold and the demands rise, we can truly say walls aregetting smarter.No longer just studs, tracks and headers. No longerjust a division between space. We see what the futurefor walls holds, and we are acting on it with productsthat perform as a system, backed by intelligent designtools and fully capable engineering services.Be assured, we’re always ready to talk about yourspecific needs. Regardless of your project’s size orcomplexity, ClarkDietrich is able to listen, consult anddeliver on all your projects. And we can do it coast tocoast.2

Table of ContentsHow To Use This Book4Benefits of Steel Framing5A Basic Overview101, 2, 3’s of steel framing16Drywall Framing 20Interior Non Load-Bearing WallsStructural Framing 24Load-Bearing and Curtain WallFraming Accessory Products28Head of Wall 33Finishing Accessories 35Metal Corner Beads36Vinyl Beads 37Paper-Faced Beads 38Metal Lath 39Fire-Rated Assemblies 40Residential Applications42TradeReady Floor SystemFasteners 46Selling Metal Framing48ClarkDietrich Locations513

How to use this book.This guide is designed to introduce you toClarkDietrich cold-formed steel framing andits applications. By understanding the variousClarkDietrich products, you can recommendconstruction materials that effectively address theneeds of your customers.Divided into sections that allow you to quickly findinformation about specific ClarkDietrich productsand their applications. It may also be used as a quickreference guide to help answer questions commonlyasked by contractors, builders or do-it-yourselfhomeowners.As the world’s leading producer of cold-formed steelframing, ClarkDietrich manufactures a full range ofproducts for any application. If you have questions orneed additional technical information about a specificproduct, contact us. We’re committed to helping bothyou and your customers.4

The benefits of cold-formedmetal framing.ClarkDietrich cold-formed steel framing offersthe unbeatable combination of durability, strengthand stability. Ideal for use in commercial buildings,houses and schools, steel framing offers the followingbenefits:Corrosion Resistance Steel framing members built into wall cavities, atticspaces or crawl spaces will last over 300 years whennot exposed to water, according to a study conductedin England. Forensic studies conducted on Oahu, HI residencesbuilt over 40 years ago with steel wall studs showedno visible signs of corrosion. Material is compliant with relevant ASTM protectivecoating standards design to resist corrosion.Fire Resistance Steel framing is non-combustible and will notadd fuel to a fire. It actually improves fire safetycompliance with local codes and regulations. Steel framing offers code-approved increases inallowable floor area and/or allowable building heights,compared to conventional wood framing. One-third of all fires start in wall cavities. Actual case studies show steel houses performextremely well in house fires, and experience little orno damage to the structural framing.5

Termites Over 1 billion is spent annually for prevention andcontrol of termites, and to address the damage theycreate. Steel framing provides a termite-proof solution forthe structural integrity of your project. The most ferocious termite is the FormosanSubterranea "Super Termite". An average colony of termites consists ofabout 3 million insects, but can be as large as 10million insects. A single colony normally survivesapproximately 35 years. A well-fed Formosan queen termite can live for 25years and lay 1,000 eggs a day.Mold Steel does not promote the growth of mold andreduces the threat of staggering litigation andexpenses. Mold requires an organic nutrient source andmoisture to grow and flourish. Unlike wood, steel isinorganic and does not contain moisture. Kiln-driedlumber still contains 11-14% residual water content. California has already passed mold-related laws, andnine other states have legislation pending.6

Costs Steel is more economical than traditional masonry,concrete and other types of construction materials. Steel reduces or eliminates callback costs for nailpops, floor squeaks and wall cracks due to shrinkage. Steel lowers construction and homeownersinsurance costs.Environmental Compatibility Steel offers builders an environmentally friendlyalternative to wood. There is little waste when steelframing materials are used. Builders can reduce their disposal costs and divertmaterial from local landfills. Building an average wood-frame home generatesapproximately 50 cubic feet of landfill waste. Acomparable steel-frame home generates about 1.5cubic feet of waste.Pollution Control The American Lung Association encourages the useof steel framing with its Healthy House program.This program recommends steel framing to supportgood indoor air quality. Homeowners sensitive to chemicals, and thosesusceptible to asthma, are exposed to fewer toxins in asteel-framed home. Steel resists mold spores that can lead to chronicillness.7

No pesticides or toxins are required to protect steelframing from termites or vermin. No emissions from resins, adhesives or chemicalsnormally used for wood construction occurs withsteel. Better insulation values can be achieved with acombination of steel and EPS foam to reduce outsidenoise pollution.Recyclability Steel is 100% recyclable and considered to be agreen building material. Steel framing materials contain, on average, 69%recycled steel. Steel can be a significant factor in the LEEDcertification process. It takes 25 old-growth trees to build a 2,500square-foot home, compared with 7 recycledautomobiles for the same home with steel framing. 80 million tons of steel scrap is recycled eachyear – more than paper, aluminum, glass and plasticcombined.Handling Interior non-structural studs are cut easily withmetal snips (aviator snips). They do not require theuse of a circular saw. Metal studs simply twist into place and attach withscrews. Mistakes can be corrected by reversing thescrew gun.8

Steel studs are up to 50% lighter than wood. Pre-punched knock-outs eliminate drilling forelectrical and plumbing lines. Special order cut-to-length material eliminates fieldcutting and waste.Earthquakes and Hurricanes Steel framing can be engineered to meet thehighest seismic and wind loads prescribed by buildingcodes. Steel has the highest strength-to-weight ratioof any framing material – a lighter structure withstronger connections results in less damage fromseismic forces. Steel’s strength and resiliency help it to surviveearthquakes. With a steel structure, there is a smaller probabilityof wind damage due to stronger (screwed vs. nailed)connections. For generations, we have relied on the strengthand durability of steel in our commercial buildings,hospitals and schools.Lightning Resistance Steel buildings are lightning resistant because steelframing provides multiple conductive paths directly tothe ground. Steel skyscrapers have provided occupants withsafe offices and residences for decades. A steel framereduces the likelihood of explosions, secondary fires orpersonal injury.9

A basic overview of metal framing.Metal framing (also referred to as metal or steelstuds) has been used in noncombustible commercialconstruction for more than 50 years. Recently,however, metal framing has become more commonlyused to frame entire structures, including nonstructural interior walls, load-bearing exterior walls,floor joists, curtain walls and roof trusses.Regardless of the application, steel framing offersstrength, quality and performance that is superiorto wood. Those characteristics have broadened thecapabilities of architects, and enabled them to designstructures that are safer, as well as durable anddynamic.The two primary applications for cold-formed metalframing are curtain wall or load bearing framing(structural framing) and interior non-structural(drywall framing).Approximately 60% of metal studs used in the UnitedStates are interior non-structural wall partitions. Thismeans they are not designed to carry a load otherthan wallboard. Unlike conventional wood studs,where 2x4s are used as top and bottom plates, metalframing requires runners or tracks on the top andbottom.10

Lip/returnC-Stud1-1/23/4"2"FlangeWeb2-1/2" widestuds3-5/8"wideCommon steel framing terms.Wooden boards are described as having faces andedges. Steel studs are described differently. Pleasenote the following differences: Instead of a face, a steel stud has a web Instead of edges, steel studs have flanges andreturnsMetal track also has its own terminology. Features ofmetal track are described in the following way: Instead of a face, metal track also has a webdimension. Flanges on metal studs are known as legs for track. Studs are manufactured in multiple lengths.Most building centers commonlystock steel studs in 8’, 10’ and 12’lengths. Track is available only in10’ lengths. Large orders may becut to size at the plant.11

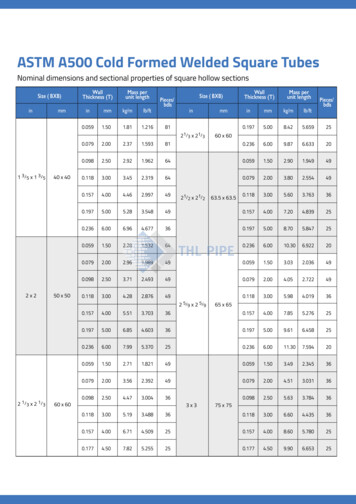

Metal vs. wood sizing.Wood framing is commonly referenced in nominalterms. A 2x4, for example, is really 3-1/2" x 1-1/2".Metal framing, on the other hand, is referenced byactual size. As a result, you will get exactly what youorder. If you request a 3-5/8" stud, you will get a full3-5/8" width. When a contractor asks for a metal2x4, does he or she want an actual 2x4 stud or 3-5/8"metal stud? Be sure to ask for specifics, or call yourClarkDietrich sales representative for assistance.ClarkDietrich interior framing studs are easilydistinguished by their unique ProSTUD diamondpattern. Punch-outs provide mechanical access andreduce or eliminate the need to cut or drill holes.When running wire or pipe through the punch-outs,protection is required to: Avoid damaging wire insulation. Prevent the potential for chemical reactions betweendissimilar metals. Eliminate the potential for components to rattleinside wall. Comply with building codes.Protection for pipe or wire is easily handled with plasticgrommets or sections of pipe insulation.Drywall StudSize (web): 1-5/8", 2-1/2", 3-1/2", 3-5/8", 4", 5-1/2", 6"Gauge: 25EQ, 20EQ DW and 20 STRFlange: 1-1/4"Market Synonyms: Tin Can, Drywall Stud (DWS) SS,Light Gauge Stud (LGS)Applications: Non-structural partition walls, ceilings,column fire proofing. *Not all sizes are available in all markets.12

Drywall TrackSize (web): 1-5/8", 2-1/2", 3-1/2", 3-5/8", 4", 5-1/2", 6"Gauge: 25EQ, 20EQ DW and 20 STRFlange: 1-1/4", 2", 3"Market Synonyms: Runner, Plate, Drywall Track(DWT)Applications: Drywall track is attached to floors andceilings to hold studs in place.The 3-5/8" width is the most common web size usedin interior non-structural wall framing. Matching trackis available for each stud size with 1-1/4", 2" and 3" legheights.Non-structural interior framing (often called drywallframing) is only used for construction of interior wallsthat do not support any load from above and walls thatwill not be exposed to any wind forces.ProSTUD drywall studs are used for non-structuralpartition walls and ceilings. Knockouts (pre-punchedholes) are conveniently placed in the studs to facilitatethe installation of electrical wiring, plumbing, andbridging.At the job site, ProSTUD drywall studs are: Connected to floor and ceiling tracks (runners) withpan head screws. Spaced at either 12", 16" or 24" on-center spacing. Covered with wallboard or other sheathing.Like most products, drywall studs can be purchasedin stock lengths or custom ordered to match specificjob requirements. This flexibility allows the end user tomore efficiently control labor costs at the job site.13

How to build an interior non-structural wall.Interior non-structural walls can be quickly and easilybuilt when the following steps are followed:Calculate the room dimensions: It is recommendedthat you sketch a top view of your project. Measurethe lineal footage of all walls with a tape measure andwrite each wall’s length on the layout.Determine the stud spacing: Based on the roomheight you will space studs on the following guidelines:Interior Partition – Allowable Wall HeightStud Spacing: 12", 16", 24"Calculate the number of studs needed: Basedon spacing requirements, divide the wall length infeet by 1 (12" on-center), 1.3 (16" on-center), or 2(24" on-center) in order to calculate the numberof studs needed. Be sure to add additional studs toaccommodate corners and openings.Calculate the amount of track needed: Take thetotal lineal feet of wall and multiply by 2 to figure theamount of track needed for both the floor and ceiling.Track is only sold in 10' lengths. Add additional trackfor door and window headers and sills.Determine the project layout: According to yourplan, use the plumb bob, a marker, and a chalk line,to establish top and bottom track positions. It is alsobeneficial to mark for door openings at this time.14

Helpful hints.Most wood trim can be attached with adhesive, andmay require temporary screws while the adhesivesets. If mechanical attachment is required, considerinserting sections of wood 2x4 inside the track fornailing.Door-frames may be attached directly to steelframing, but some installers prefer wood 2x4 framingaround the rough opening. If this option is chosen,frame the rough opening 3" wider to allow for woodstuds.If framing is used to support insulation blankets, theinsulation must be ordered to the full 16" or 24" widthdimension.Pictures or artwork can be easily hung with a standarddrywall hanging hardware. Drywall screws arerecommended, however, to attach directly to studs.Extremely heavy shelving and other heavy objectsshould be anticipated and accommodated withinthe wall structure. Cross bracing with C-runners isrecommended.LIMITATION: 25-gauge steel studs are designed onlyfor use in non-structural construction. Check yourlocal building codes before beginning construction.15

The 1 2 3’s of steel framing.161Attach ceiling runner tobottom of joist or truss.2Use plumb line to settop and bottom runners.3Attach floor runnerusing concrete anchors.

4Cut studs and runnerswith tin snips.5Twist studs into place.Make sure studs arelevel and knockouts/punch-outs are aligned.17

The 1 2 3’s of steel framing.186Screw studs to top andbottom runners using7/16" pan screws.7Cut and install runnersand cripples arounddoors and windows.

8Snap in grommets forelectric and plumbing.9Attach drywall. Usecorner bead aroundcorners. Tape, spackleand finish drywall.19

Drywall framing.Interior non load-bearing walls.ProSTUD Drywall Framing System for nonstructural interior walls.The ProSTUD Drywall Framing System can becalled many things. Strong. Versatile. Fast. Andwithout a doubt—revolutionary. But one of thebiggest benefits to keep in mind is this: ProSTUD wasdeveloped, tested and approved by pros in the fieldwho demanded nothing less than achieving absoluteease of use. Its performance has also been proven bythe most extensive laboratory evaluations available.All of which means ProSTUD comes with completeconfidence and no questions about code compliance.The industry’s product of choice.Gauge equivalent (EQ) drywall framing mustmeet the minimum performance requirements ofconventional drywall framing as defined by the SteelFraming Industry Association (SFIA). For interiordrywall framing members, bending strength (orallowable moment) is the criteria most important tothe strength of a wall or ceiling. ProSTUD employsmodern roll-forming and steel-making technologythat enhances the shape and strength with greaterefficiency. ProSTUD—the product of choice—exceedsthe performance of conventional drywall framing forallowable moment and screw connection strength.Life SafetyLife Safety is the primary concern and duty of allconstruction and design professionals. ProSTUDfeatures a number of technological advances to20

enhance its stiffness and strength, contributing to itsallowable moment performance. When it comes tofire-rated systems, ProSTUD is UL-approved for themost common UL design assemblies including V450,U419, V438 and chase wall assemblies.Sound PerformanceProSTUD also has exceptional sound performance inover 50 tested sound assemblies—more testing thanany other manufacturer in the industry.ProSTUD Drywall Framing and ProTRAK DrywallTrack were created specifically to work as a system.This means they work better together for you inachieving strength, fire and sound ratings. It’s also anapproach that leads to enhanced performance on thejob—during installation and long after. High-strength steel combined with low-profileflange stiffening grooves and double offset webplanking increases strength and provides greaterlimiting heights. Diamond embossed web creates stiffness, reducingflange fade and screw spin-out during drywallinstallation. Strong, lightweight stud and track cuts and handleseasier than conventional flat steel studs. Flange grooves provide sight line for drywallalignment and aid in positioning screws at drywalljoints to maintain the 3/8" edge requirement. Web and leg enhancements in ProTRAK providestraight and rigid legs, making it the best choice forframing walls, headers, soffits, and bulkheads.21

5050500.0158600PDS125-152 Ix(in 0180.015Iy(in 0330.033Ae(in2)0.5370.2330.1900.0800.030Ix(in 719Ma(in-lbs)6090100147232Vag(lb)Effective Section Properties at Fy6090100141104Vanet(lb)0.01164 0.1610.00901 0.0640.00852 0.0510.00704 81.7061.4731.369Ro(in)Torsional PropertiesCw(in6)0.00589 0.009Jx1000(in 4.8Lu (in)ClarkDietrich ProSTUD 25 (15mil) physical and structural properties alculated properties are based on AISI S100-12, North American Specification for Design of Cold-Formed Steel Structural Members and AISI S220-15, North American Standard forCCold-Formed Steel Framing—Nonstructural Members. Effective properties incorporate the strength increase from the cold work of forming as applicable per AISI A7.2. Tabulated gross properties, including torsional properties, are based on full-unreduced cross section of the studs, away from punchouts. Tabulated gross properties, including torsional properties, are based on full-unreduced cross section of the tracks. For deflection calculations, use the effective moment of inertia. Allowable moment includes cold work of forming. Allowable moment is taken as the lowest value based on local or distortional buckling. Distortional buckling strength is based on a k-phi 0. Web depth for track sections is equal to the nominal height plus two times the design thickness plus the bend radius. Hems on nonstructural track sections are ignored.Web-height to thickness ratio exceeds 200.Web-height to thickness ratio exceeds 260.Notes:1400PDS125-150.08550250PDS125-15 0.0158362PDS125-151 in)162PDS125-15 0.0158MemberGross Section PropertiesProS T U D 2 5 ( 1 5 M I L ) D R Y W A L L S T U D5-1/2" STUD/TRACK PROPE

0.430.350.29Rx(in)Iy(in 4)Ry(in)Ae(in2)Ix(in 4)Sx(in3)0.855 2.223 0.032 0.431 0.046 0.669 0.1410.321 1.551 0.027 0.453 0.046 0.286 0.0840.254 1.421 0.026 0.456 0.044 0.234 0.0740.107 1.017 0.023 0.470 0.043 0.099 120.012500.01032Jx1000(in l propertiesEffective Section Propertiesat Fy20 (18mil) physicalTorsional0.040 0.685 0.019 0.468 0.039 0.035 0.028Ix(in 4)Gross Section PropertiesArea Weight(in2) (lb/ft)ClarkDietrich ProSTUD 20 (18mil) physical and structural properties alculated properties are based on AISI S100-12, North American Specification for Design of Cold-Formed Steel Structural Members and AISI S220-15, North American Standard forCCold-Formed Steel Framing—Nonstructural Members. Effective properties incorporate the strength increase from the cold work of forming as applicable per AISI A7.2. Tabulated gross properties, including torsional properties, are based on full-unreduced cross section of the studs, away from punchouts. Tabulated gross properties, including torsional properties, are based on full-unreduced cross section of the tracks. For deflection calculations, use the effective moment of inertia. Allowable moment includes cold work of forming. Allowable moment is taken as the lowest value based on local or distortional buckling. Distortional buckling strength is based on a k-phi 0. Web depth for track sections is equal to the nominal height plus two times the design thickness plus the bend radius. Hems on nonstructural track sections are ignored.Web-height to thickness ratio exceeds 200.Web-height to thickness ratio exceeds berPro S T U D 2 0 ( 1 8 M I L ) D R Y W A L L S T U DRTIES

Structural framing.Load bearing and curtain wall applications.ClarkDietrich cold-formed steel framing systemsoffer the most diverse range of framing componentsavailable in the industry. The flexibility to choose froma wide selection of gauges, yield strengths, sizes andflange widths enables building designers to obtainoptimal, cost-effective performance.Structural framing members are used to constructexterior and load-bearing walls for residential orcommercial buildings. They may also be utilized incurtain wall assemblies (the outer skin of commercialbuildings), or for floor and ceiling joists. In addition,structural framing members may be used incombination to create roof trusses and a variety ofsophisticated assemblies. These studs do not supportthe floors and roof of a building.ClarkDietrich curtain wall/cold-formed metalframing systems offer the most diverse range ofproducts available in the industry today. The flexibilityto choose from a wide selection of gauges, yieldstrengths (KSIs), sizes and flanges allows designersto achieve optimal structural performance aseconomically as possible.Cold-formed metal framing is ideal for use in lowrise and mid-rise construction, multifamily housing,and most commercial, institutional and industrialstructures.24

Structural or curtain wall framing is available in avariety of gauges, ranging from 20 to 12 gauge. Thegauge or thickness is determined based on application,load and spacing.Structural GaugesSteel 81.080.05381.370.06771.720.09662.45Proper use of these materials requires evaluationof a number of factors, including end uses and loadcriteria. Load tables, construction details and otherimportant support information for proper selectionand application of these members is available from anyof the ClarkDietrich locations shown at the back ofthis publication, or at www.clarkdietrich.com.ClarkDietrich also provides assistance throughClarkDietrich Engineering Services, our designservices company. Our design group is equipped witha unique computer design aid that is optimized toanalyze construction parameters, and provide criticalcomparisons based on required design criteria. Thesystem will also recommend the most effective andeconomical products from our metal framing productline.ClarkDietrich metal framing components areoptimized for use in prefabricated panel construction,and provide exceptional performance and economy.25

Curtain Wall Framing Systems support the exteriorskin or cladding of commercial and industrial buildings.The studs for these framing systems must be able towithstand: The weight of the cladding material (metal, stone,tile, etc.). The wind loads to which they will be subjected.Structural StudWeb: 2-1/2", 3-1/2", 3-5/8", 4", 5-1/2", 6", 8", 10",12" and 14"Gauge: 20, 18, 16, 14 and 12KSI Rating: 18ga, 20g of 33 KSI16ga and heavier of 50 KSIApplications: Axial and Curtain Wall Framing,Floor Joists, Roof TrussesStructural TrackWeb: 2-1/2" 3-5/8", 4", 6", 8", 10", 12" and 14"Gauge: 20, 18, 16, 14 and 12KSI Rating: 18ga, 20g of 33 KSI16ga and heavier of 50 KSIApplications: Axial Load Bearing Interior Walls,Axial Load Bearing Exterior Walls, Non-AxialInterior & Exterior WallsHole PlacementClarkDietrich studs and joists are made with prepunched 1-1/2" wide holes in the web to accommodateplumbing and electrical installation. Holes are 12" oncenter from each end, with intermediate holes placedat 24" on-center intervals. Webs less than 3-1/2"are punched with a 3/4" wide hole, unless otherwisespecified.26

Flange DimensionsThe key variation among stud styles is in the flangedimension. For most projects, the flange is theattachment surface for cladding materials. It also is akey contributor to the load-bearing capacity of themember.Curtain Wall Studs - (CWN) 1-3/8" flange stud usedin light duty applications.Standard Studs and Joists – (CSJ) Outfitted with a1-5/8" flange, these components are ClarkDietrich’smost popular structural members, and provide thevertical strength necessary for demanding curtain walland load-bearing structural applications.Wide Studs and Joists – (CSW) These members have awide 2" flange dimension that provides a larger bearingsurface for attaching sub flooring or panel materials.Extra Wide Studs and Joist –(CSE) These componentsfeature an extra wide flange of 2-1/2". The additional1/2" makes this member even more rigid in certainapplications.Super Wide Studs and Joist –(CSS) These componentshave the widest flange of 3". The super wide flange isespecially useful for reducing the number of membersneeded for jamb or king stud conditions.Structural Track – Designed to serve as channelrunners at the top and base of curtain wall and loadbearing wall constructions, these members also workas end caps for joists.27

Framing accessory products.ClarkDietrich manufactures a number of accessoriesfor use in a wide variety of framing configurations.Drywall Furring ChannelSize (web): 7/8" and 1-1/2"Gauge: 25, 20, 18, 16Market Synonyms: Hat Channel,DWC, High Hat, Drywall ChannelApplications: Roll formed, hat-shaped sectionavailable in three gauges of galvanized steel. DWC-25channel is used for attachment of: Gypsum panels. Veneer or conventional plaster base in ceilingconstruction. Noncombustible furring for interior or exteriorwalls.Heavier channels permit greater spans and loadcapacity. The channels are available in 7/8" and1-1/2" depths.Z-FurringSize: 1", 1-1/2", 2" and 2-1/2"Gauge: 25, 20Applications: Made of 25 gauge, galvanized steel, isused to attach the following: Rigid foam and other types of insulation Gypsum panels28

Corner AngleSize: 1-1/2" x 1-1/2" , 2" x 2", 3" x 3", 1-3/8" x 7/8"Gauge: 25, 20, 18, and 16Market Synonyms: L-Angle,Utility Angle, AngleApplications: Metal Angle is made of 25 and 20 gauge,galvanized steel. All-purpose metal angle is available inthree common sizes. The 1-3/8" x 7/8" size is used tosecure core board to floors and ceilings in laminateddrywall and veneer plaster systems. Other sizes are usedfor a variety of purposes.Resilient ChannelSize: 1/2" (Single Leg and Double Leg)Gauge: 25 and 20Market Synonyms: RC-1, RC-2,RC ChannelApplications: Resilient channel is one of the mostefficient low-cost methods developed to reducetransmission of airborne sound through partition andceiling assemblies. Dampens sound waves effectively,dissipating the energy and reducing sound transmissionby suspending gypsum wallboard 1/2" from the stud orjoist. Sound absorption can be maximized by utilizingsound attenuation blankets within the wall or floorcavity.29

BridgingThe TradeReady SPAZZER 5400 BarSize: 50"Gauge: 16Market Synonyms: Bridging BarThe TradeReady SPAZZER 5400 bar providesbridging for structural stud systems withoutmechanical attachment (Except in axial load bearingapplications) in much the same way the SPAZZER9200 bar works for drywall partitions. The 5400is galvanized 16-gauge bar that is 50" long and isnotched to rigidly hold studs on 12", 16" or 24"centers.The SPAZZER bar’s slots are engineered to use"shear" to bridge steel studs into a rigid, accuratepattern grid work. The 5400 bar is simply passedthrough the stud punch outs, rotated 90 degrees, andthen the pre-notched slots are seated down over theweb of the stud.The TradeReady SPAZZER 9200 BarSize: 50"Gauge: 20Market Synonyms: Bridging BarThe TradeReady SPAZZER 9200bar provides bridging for drywall stud systems withoutmechanical attachment. The 9200 is a 20-gaugebar that is 50" long and is pre-notched to rigidly holdstuds on 12", 16" and 24" centers. A new concept inbridging, the 9200 bar is simply passed through thestud punch-outs, rotated 90 degrees, and then the

ClarkDietrich cold-formed steel framing offers the unbeatable combination of durability, strength and stability. Ideal for use in commercial buildings, houses and schools, steel framing offers the following benefits: Corrosion Resistance Steel framing members built into wall cavities, a