Transcription

Now with SUPREME FRAMING SYSTEM!PRODUCTTECHNICAL GUIDESteel Stud Manufacturers AssociationI A PM OUNIFORMER# 0313www.SCAFCO.com25073064P

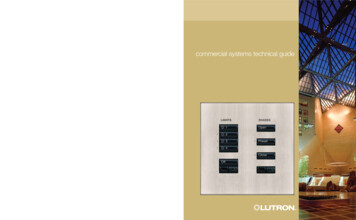

Product Identification"S" and "SFS"- C-STUD/JOISTS and SFS-SECTIONS*"T" and "SFT" - TRACKT and SFT - SECTIONS"U" - CHANNEL "F" - FURRING CHANNELU-SECTIONSF-SECTIONS* For "S" and "SFS" members, see table onpage 5 for stiffening lip length.Nomenclature ExampleProducts have a four-part identification code that identifies the web depth, flange width, style, and mil thickness.Member Web DepthFlange WidthAll member depths are given in 1 100inch.All flange widths are given in 1 100 inch.(Example: 1 5 8" 1.625" 162 1 100 inch)For all "T" sections, member depth is theinside to inside dimension.(Example: 6" 600 1 100 inch)600S54162StyleMil ThicknessNomenclature uses the following fourcharacters to designate the profile:S Stud or Joist SectionsT Track SectionsU Channel SectionsF Furring Channel SectionsSFS Supreme Framing StudSFT Supreme Framing TrackMil thickness is the m inimum base steel thicknessmeasured in 1 1000 inch. Minimum base steelthickness represents 95 percent of the designthickness.(Example: 0.054" 54 mils; 1 mil 1 1000 inch)(Example: Stud or Joist section S)2www.SCAFCO.comCopyright 2015 by the SSMA

Table of ContentsGeneral Product Information4-610 psf Dead Load and 40 psf Live Load56 - 57Mission Statement 410 psf Dead Load and 50 psf Live Load58 - 59Introduction 415 psf Dead Load and 125 psf Live Load60 - 61Technical Assistance 440 psf Dead Load and 125 psf Live Load62 - 63Code Approval 4Floor Joist Web Stiffener Details64Material Specifications 4Header Loads 65 -66Disclaimer 4Web Crippling Loads 67 - 70General Notes for All Tables 5Web Crippling Conditions 67Steel Thickness Table 5Stiffening Lip Length Table 5SSMA Allowable Web Crippling Loads (lbs)Single Members (S-Sections)68Definitions of Structural Property Symbols6SUPREME Allowable Loads (lbs) Single Members69Web Depth-to-Thickness Ratios6SSMA Allowable Web Crippling Loads (lbs)Back-to-Back Members (S-Sections) 70Section Properties 7 - 21SSMA Nonstructural (S) Section Properties7SUPREME Nonstructural (SFS) Section Properties8SSMA Structural (S) Section Properties9 - 12SUPREME Structural (SFS) Section Properties13SSMA Track (T) Section Properties14 - 17SUPREME Track (SFT) Section Properties18 - 19Ceiling Spans 71 - 78Ceiling/Soffit Table Notesand Bracing Details 71Interior Wall Height Tables 20 - 29SSMA Interior Allowable Ceiling/Soffit Spans(S-Sections) - L/240 72SSMA Interior Allowable Ceiling Spans(S-Sections) - L/360 73SSMA Exterior Allowable Ceiling/Soffit Spans(S-Sections) - L/240 74 - 75SSMA Exterior Allowable Celing/Soffit Spans(S-Sections) - L/360 76 - 77SSMA Interior Wall Heights - Composite20SUPREME Interior Wall Heights - Composite21SSMA Interior Wall Limiting HeightsNon-Composite - Fully BracedSUPREME Allowable Ceiling Spans(SFS-Sections) - L/240 7822 - 23SUPREME Interior Wall Limiting HeightsNon-Composite - Fully BracedSUPREME Allowable Ceiling Spans(SFS-Sections) - L/360 7824 - 25SSMA Interior Wall Limiting HeightsNon-Composite Braced 48" oc26 - 27SUPREME Interior Wall Limiting HeightsNon-Composite - Braced 48" oc28 - 29Exterior Wall Height Tables 30 - 36SSMA Curtain Wall Limiting Heights Single Span30 - 32SSMA Curtain Wall Limiting Heights Double Span33 - 35SUPREME Curtain Wall Limiting Heights36SSMA Combined Axial and Lateral Loads5 psf Lateral Load (Interior Walls)37 - 4737 - 3815 psf Lateral Load 38 - 3920 psf Lateral Load 40 - 4125 psf Lateral Load 41 - 42Ceiling Spans - (Hat)Furring Channel (F-Sections)79 - 81SSMA (Hat) Furring ChannelSection Properties (F-Sections)79SUPREME (Hat) Furring ChannelSection Properties (F-Sections)79SSMA (Hat) Furring Channel AllowableCeiling Spans (F-Sections) - L/24080SSMA (Hat) Furring Channel AllowableCeiling Spans (F-Sections) - L/36080SUPREME (Hat) Furring Channel AllowableCeiling Spans (F-Sections) - L/24081SUPREME (Hat) Furring Channel AllowableCeiling Spans (F-Sections) - L/36081Section Properties andCeiling Spans (U-Sections) 8230 psf Lateral Load 42 - 43SSMA U-Channel Section Properties8235 psf Lateral Load 44 - 45SSMA Allowable Ceiling Spans (U-Sections) - L/2408240 psf Lateral Load 45 - 46SSMA Allowable Ceiling Spans (U-Sections) - L/3608250 psf Lateral Load 46 - 47SUPREME Combined Axial and Lateral Loads5 psf Lateral Load (Interior Walls)Screw Capacities 8348 - 50SSMA Allowable Screw Connection Capacity (lbs)8348SUPREME Allowable Screw ConnectionCapacity (Pounds Per Screw)8315 psf Lateral Load 48Weld Capacities 8420 psf Lateral Load 48Typical Details 85 - 8625 psf Lateral Load 4930 psf Lateral Load 49Deflection Track 8535 psf Lateral Load 49Slide Clip Attachment 8540 psf Lateral Load 50U-Channel Lateral Bracing 8650 psf Lateral Load 50Flat Strap Lateral Bracing 86Floor Joist Spans 51 - 64Floor Joist Bridging and Bracing RequirementsWall Stud Web Stiffener 86SCAFCO Locations Map Back Cover51Joist Bridging Detail 5110 psf Dead Load and 20 psf Live Load52 - 5310 psf Dead Load and 30 psf Live Load54 - 55Complies With 2009, 2012 and 2015 IBCwww.SCAFCO.com3

General Product InformationMission StatementThe SSMA's mission is to be the unified voice of the steel framing manufacturing industry, by being the leader in supporting thedevelopment and maintenance of quality product standards and specifications, and by creating growth opportunities for cold-formedsteel through research, marketing, and education.IntroductionTechnical AssistanceThe increasing environmental concerns in the world today havecaused us all to examine the way we live. These issues haveaffected every aspect of our lives, including the materials we usein construction. The use of cold-formed steel members benefitthe environment, contractor, designer, and developer more thanother material.Steel is not only a recyclable product, but also a stronger productthat allows for longer clear-spans. Cold-formed steel is lighter toprovide ease of handling, and is a dimensionally stable product,giving a "straight" wall with which to work. It doesn't sufferfluctuation in price, making it easier to bid a project. Qualitycontrol is stressed in all phases of the manufacturing processso the highest possible quality is delivered to the jobsite. Thestructural shapes manufactured are easily used for nonstructuraland structural wall assemblies, floor and ceiling joist assemblies,trusses, and panelized systems.Professional technical assistance is available through SSMA orindividual manufacturers' technical departments.Code ApprovalSSMA structural and nonstructural cold-formed framing productspecifications meet the stringent requirements of InternationalCode Council Evaluation Services in conjunction with SSMA ICCES evaluation report (ESR-3064P). The product specification anddocumented quality control system & procedures are verifiedduring regular inspections by ICC-ES, the leader in the technicalevaluations for code compliance of the building products.SSMA in collaboration with the American Iron and Steel Institute(AISI) has developed and adopted a standard designator systemfor identifying cold-formed steel framing members. Using astandard system will eliminate the confusion caused by individualmanufacturers' varied designators.Material SpecificationsStructural and nonstructural members are coated to meet the minimum code requirements. Higher corrosion protection coatings suchas G90 are available upon request. Products manufactured by SSMA members are cold-formed from corrosion protected steel coils orsheets and meet the following specifications requirements:Product TypeNonstructural ProductsASTM C645Structural ProductsASTM C955(CP60 Coatings)Material SpecificationsMin YieldMin TensileASTM A653, SS Grade 3333 ksi45 ksiMinimum Metallic Coating DesignationG40ASTM A1003, Grade 33 (NS33)33 ksi. AG40ASTM A653, SS Grade 50, MOD 5757 ksi65 ksiG40ASTM A653 HSLA Grade 50, MOD 5757 ksi65 ksiG40ASTM A653, SS Grade 3333 ksi45 ksiG60ASTM A1003, Grade 33 Type H (ST33H)33 ksi45 ksiG60ASTM A653, SS Grade 50 Class 150 ksi65 ksiG60ASTM A1003, Grade 50 Type H (ST50H)50 ksi65 ksiG60ASTM A653, SS Grade 50, MOD 5757 ksi65 ksiG60ASTM A653 HSLA Grade 50, MOD 5757 ksi65 ksiG60No tensile requirements for nonstructural steel in accordance with ASTM A1003 standardsADisclaimerAll data, specifications, and details contained in this publication are intended as a general guide for using SSMA members' products.These products should not be used in design or construction without an independent evaluation by a qualified engineer or architect toverify the suitability of a particular product for use in a specific application. The SSMA and its members assume no liability for productfailure resulting from the use or misapplication of computations, detail drawings, and specifications contained herein. This publicationcontains the latest information available at the time of printing with respect to the referenced building codes and standards. The SSMAand its members reserve the right to make modifications and/or change materials of any of their products without prior notice orobligation. For the latest information regarding a particular manufacturer's products, contact that manufacturer. All SSMA manufacturersmay not produce all of the products contained in this catalog. Please contact individual manufacturer to verify product availability.4www.SCAFCO.comCopyright 2015 by the SSMA

General Product InformationGeneral Notes for All Tables1. The values in this catalog are based on the North AmericanSpecification for the Design of Cold-Formed Steel StructuralMembers, AISI S100-07 with Supplement S2-10 as referenced by2012 IBC and AISI S100-12 as referenced by 2015 IBC.2. Where AISI S100 is referenced, it is the North AmericanSpecification for the Design of Cold-Formed Steel StructuralMembers, S100-07 and AISI S100-07 with Supplement S2-10 andAISI S100-12, as applicable with U.S. provisions.3. The structural properties included in this catalog have beencomputed based on allowable strength design (ASD) method.4. Distortional buckling calculations are based on Kφ 0.5. The effective moment of inertia for deflection is calculated ata stress that results in a section modulus such that the stresstimes the section modulus at that stress is equal to the allowablemoment. AISI S100 Procedure I for serviceability determinationhas been used.6. Conditions with loads that exceed the 10 psf limit for nonstructuralmembers require an approved G60 coating.7. When provided, factory punchouts will be located along thecenter line of the webs of the stud members and will have aminimum center-to-center spacing of 24". Punchouts for membersgreater than 2 ½" deep are a maximum of 1 ½" wide x 4 ½" long.Members with depths 2 ½" and smaller are maximum ¾" widex 4 ½" long. Any configuration or combination of holes that fitwithin the punchout width and length limitations mentioned aboveshall be permitted; other punchout configurations and locationsnot in compliance with limitations listed above must be approvedby a design professional. Values herein are based on punchoutconfiguration and location as illustrated below.8. The 10" end distance shown may be altered if calculations are inconformance with code.C.L.C.L.10" Min24" Min¾" or 1 ½" TypCenterline of Web4" TypStiffening Lip Length TableSteel Thickness Table180.01790.01880.0843ReferenceOnly Gauge No.25300.02960.03120.078120 – Drywall330.03290.03460.076420 – StructuralS1621 0.05660.084916S2502 .10170.152512S3503 s (mil)MinimumThickness 1 (in)DesignThickness 1 (in)Design InsideCorner Radii 2 (in)StiffeningLip Length (in)MemberFlange WidthS1251 ¼"0.188S1371 ⅜"0.375Minimum thickness represents 95% of the design thickness and is the minimum acceptable thickness delivered to the jobsite based on AISI S100-07 Section A2.4.1The tables in this catalog are calculated based on inside corner radii listed in this table. The inside corner radius is the maximum of 3/32 – t/2 or 1.5t, truncated after the fourthdecimal place (t design thickness). Centerline bend radius is calculated by adding half of the design thickness to listed corner radius.2SUPREME Steel Thickness TableSUPREME Stiffening Lip Length TableDesignationThickness (mil)MinimumThickness 1 (in)DesignThickness 1 (in)Design InsideCorner Radii 2 (in)ReferenceOnly Gauge No.MemberFlange WidthStiffeningLip Length 000.08600.08440.08200.08200.07900.071225 – Drywall20 – Drywall20 – Drywall20 – Drywall20 – Structural18 – StructuralSFS125SFS143SFS162SFS2001 ¼"1 7/ 16"1 ⅝"2"0.3000.3750.5000.625Minimum thickness represents 95% of the design thickness and is the minimum acceptable thickness delivered to the jobsite based on AISI S100-07 Section A2.4.1Complies With 2009, 2012 and 2015 IBCwww.SCAFCO.com5

Definitions of Structural Property SymbolsGross PropertiesI x:Moment of inertia of the cross section about the x-axis.Sx:Section modulus about the x-axis.R x:Radius of gyration of cross section about the x-axis.Iy:Moment of inertia of cross section about the y-axis.Ry:Radius of gyration of cross section about the y-axis.YEffective PropertiesI xe:XXEffective moment of inertia about the x-axis.Sxe:Effective section modulus about the x-axis.Mal:Allowable moment based on local buckling.Mad:Allowable moment based on distortional buckling, assuming Kφ 0.Ma:Allowable moment for track and channel members, based on local buckling only.Vag:Allowable strong axis shear away from punchout, calculated in accordance with AISI S100 Section C3.2.1.Vanet:Allowable strong axis shear at the punchout, calculated in accordance with AISI S100 Section C3.2.2.YTorsional and Other PropertiesJ:St. Venant torsional constant. The numbers shown in the tables for J have been multiplied by 1,000. The actualvalues can be obtained by dividing the listed numbers by 1,000.C w:Torsional warping constant.Xo:Distance from the shear center to the centroid along the principal x-axis.m:Distance from shear center to mid-plane of web.R o:Polar radius of gyration of cross section about the shear center.β:1- (Xo/R o)2L u:Critical unbraced length for lateral-torsional buckling. Members are considered fully braced when unbracedlength is less than L u.KφDistortional buckling moment (Mad) is calculated without the beneficial effect of sheathing to rotational stiffness. Kφ 0.Web Depth (h) to Thickness (t) RatiosMil ThicknessDesignThickness (in)Inside BendRadius (in)Depth (in)1.6252.53.53.62545.56810121416D2518 milD2030EQD/33EQD30 mil33EQS33 mil43EQS43 mil54 mil2,3,468 mil97 mil118 .1863h (in) h/t1.419 752.294 1223.294 1753.419 1823.794 202 15.2945.794-h (in) h/t1.419 752.294 1223.294 1753.419 1823.794 202 15.2945.794-h (in) h/t1.419 752.294 1223.294 1753.419 1813.794 2005.2945.794-h (in) h/t1.414 602.289 973.289 1393.414 1453.789 1615.289 225 15.789 246 17.789-h (in) h/t1.408 472.283 773.283 1113.408 1153.783 1285.283 1795.783 1967.783-h (in) h/t1.403 412.278 663.278 953.403 983.778 1095.278 1535.778 1677.778 225 19.778-h 73105109121169185249 1-h (in) h/t h (in)1.403 35 1.3922.278 56 2.2673.278 81 3.2673.403 85 3.3923.778 94 3.7675.278 131 5.2675.778 144 5.7677.778 194 7.7679.767- 11.767-h/t3150727584117128172217 1-h 1.71713.71715.717h/t243957596692101136172207 1242 1-h 1.64413.64415.644h/t18304446517279107135164192220 1h 1.49213.49215.492h/t h (in) h/t11 1.004 820 1.879 1529 2.879 2331 3.004 2434 3.379 2749 4.879 3954 5.379 4374 7.379 5993 9.379 76113 11.379 92133 13.379 108152 15.379 124h/t exceeds 2001h value used for h/t calculation is the flat width of the web. For S members, this is the out-to-out member size, minus twice the thickness, minus twice the inside bend radius.2h/t values exceeding 260 are marked with a dash ( - ).3h/t values in this table apply to S (studs and joists) members only and do not apply to tracks and channels.46www.SCAFCO.comCopyright 2015 by the SSMA

Nonstructural (S) Section PropertiesTable Notes1. The centerline bend radius is based on inside corner radii shownin the steel thickness table on page 5.2. Effective properties incorporate the strength increase from thecold work of forming as applicable per AISI S100 Section A7.2.3. Tabulated gross properties are based on the full-unreduced crosssection of the studs away from S125-18 8550S125-18 1, 8600S125-18 1, 8800S125-33 1800S125-43800S125-54800S125-68DesignFyThickness 3333333505033335050Gross PropertiesArea WeightlxSxRx2(in ) (lb/ft) (in4)(in3)(in)0.080 0.27 0.038 0.046 0.6860.131 0.45 0.061 0.075 0.6810.145 0.49 0.067 0.083 0.6790.097 0.33 0.099 0.079 1.0140.159 0.54 0.161 0.129 1.0080.176 0.600.178 0.142 1.0060.227 0.77 0.228 0.182 1.0010.280 0.95 0.277 0.222 0.9940.280 0.95 0.277 0.222 0.9940.345 1.18 0.334 0.267 0.9840.345 1.18 0.334 0.267 0.9840.1150.39 0.215 0.123 1.3660.190 0.65 0.351 0.201 1.3590.210 0.72 0.387 0.221 1.3580.272 0.93 0.498 0.284 1.3520.337 1.150.608 0.348 1.3440.4171.42 0.739 0.422 1.3320.1180.40 0.234 0.129 1.4090.194 0.66 0.381 0.210 1.4020.215 0.73 0.421 0.232 1.4000.278 0.95 0.540 0.298 1.3950.344 1.170.661 0.365 1.3860.426 1.45 0.803 0.443 1.3740.125 0.42 0.294 0.147 1.5360.206 0.70 0.481 0.240 1.5290.228 0.77 0.531 0.265 1.5270.295 1.00 0.682 0.341 1.5210.365 1.24 0.835 0.418 1.5120.452 1.541.017 0.509 1.4990.153 0.52 0.630 0.229 2.0290.252 0.86 1.031 0.375 2.0211.139 0.414 2.0190.279 0.950.362 1.23 1.468 0.534 2.0130.450 1.53 1.805 0.656 2.0020.559 1.90 2.209 0.803 1.9870.162 0.55 0.778 0.259 2.1890.268 0.91 1.275 0.425 2.1810.297 1.01 1.409 0.470 2.1790.385 1.311.817 0.606 2.1730.479 1.63 2.236 0.745 2.1610.595 2.02 2.740 0.913 2.1460.366 1.25 2.881 0.720 2.8060.475 1.62 3.721 0.930 2.7990.592 2.01 4.593 1.148 2.7860.738 2.51 5.653 1.413 81.3611.8072.2202.7352.6563.5814.4315.6324. For deflection calculations, use the effective moment of inertia.5. Allowable moment is the lesser of Mal and Mad. Stud distortionalbuckling is based on an assumed Kφ 0.6. See page 5 for additional table notes.Effective PropertiesSxeMalMadVag3(in ) (in-k) (in-k)(lb)0.031 0.610.653020.060 1.191.295430.069 482.419750.1773.493.43126515530.218 4.98 2 5.070.209 6.256.17235318910.266 6.30 2 6.320.262 7.848.0128660.072 1.421.471800.150 2.963.048240.1753.453.5310240.258 5.105.1117390.308 9.229.2533720.400 11.97 12.54 42020.075 1.481.521730.156 3.083.177940.182 3.593.6710240.269 5.315.3317390.321 9.629.6533720.418 12.52 13.11 43700.083 1.641.681560.1743.443.537150.203 4.014.109760.301 5.965.9917390.361 10.81 10.87 33720.474 14.18 14.84 48710.286 5.654.955120.335 6.625.786990.500 9.888.6115500.606 18.13 15.75 30930.791 23.68 21.98 53500.315 6.225.394680.369 7.306.326380.555 10.96 9.4614160.673 20.15 17.34 28230.898 26.88 24.34 53500.507 10.02 8.224740.773 15.27 12.56 10510.942 28.21 23.18 20911.287 38.54 33.22 4221Torsional PropertiesVanet Jx1000 CwXomRo46(lb)(in )(in )(in)(in)(in)1000.009 0.009 -1.029 0.594 1.3151060.043 0.014 -1.014 0.585 1.2981050.058 0.016 -1.010 0.583 1.2941960.011 0.023 -0.904 0.543 1.4273780.052 0.037 -0.889 0.534 1.4123990.070 0.040 -0.885 0.532 1.4083940.154 0.050 -0.873 0.525 1.3963730.299 0.060 -0.859 0.518 1.3795650.299 0.060 -0.859 0.518 1.3793420.585 0.072 -0.839 0.508 1.3565190.585 0.072 -0.839 0.508 1.3561590.014 0.050 -0.797 0.495 1.6374360.062 0.079 -0.784 0.487 1.6244870.084 0.087 -0.780 0.485 1.6206310.184 0.109 -0.769 0.479 1.6099470.360 0.131 -0.755 0.471 1.5938970.706 0.156 -0.737 0.462 1.5711630.014 0.054 -0.786 0.490 1.6674490.063 0.086 -0.773 0.482 1.6545210.086 0.094 -0.769 0.480 1.6506760.188 0.118 -0.758 0.473 1.6391016 0.367 0.142 -0.744 0.466 1.6231004 0.721 0.169 -0.726 0.457 1.6021560.015 0.068 -0.754 0.475 1.7604840.067 0.107 -0.741 0.467 1.7485950.091 0.118 -0.738 0.465 1.7448100.200 0.148 -0.727 0.459 1.7331223 0.390 0.178 -0.713 0.451 1.7181356 0.767 0.213 -0.695 0.442 1.6960.018 0.140 -0.651 0.423 2.1665120.082 0.224 -0.639 0.415 2.1546990.112 0.246 -0.635 0.413 2.1511199 0.246 0.309 -0.625 0.407 2.1411881 0.481 0.374 -0.613 0.401 2.1262532 0.948 0.448 -0.597 0.392 2.1060.019 0.172 -0.623 0.408 2.3084680.087 0.274 -0.611 0.401 2.2966380.118 0.300 -0.608 0.399 2.2931240 0.261 0.378 -0.598 0.393 2.2841947 0.511 0.457 -0.586 0.386 2.2692879 1.008 0.548 -0.570 0.378 2.2484740.146 0.582 -0.519 0.349 2.8751051 0.322 0.735 -0.510 0.344 2.8652091 0.632 0.889 -0.499 0.338 2.8503367 1.250 1.068 -0.485 0.330 .626.626.321.120.8Web height-to-thickness ratio exceeds 200. Web stiffeners are required at all support points and concentrated loads.Allowable moment includes cold work of forming.3Where web height-to-thickness ratio exceeds 260 or flange width-to-thickness ratio exceeds 60, effective properties are not calculated. See AISI S100 Section B1. Application of theseproducts in a non-composite design shall be approved by a design professional.12Complies With 2009, 2012 and 2015 IBCwww.SCAFCO.com7

Nonstructural (S) Section PropertiesSUPREME Nonstructural (SFS) Section 50SFS-33EQD350SFS125-D25 1350SFS-D20350SFS-30EQD350SFS-33EQD362SFS125-D25 1362SFS-D20362SFS-30EQD362SFS-33EQD400SFS125-D25 1400SFS-D20 1400SFS-30EQD400SFS-33EQD550SFS125-D25 2550SFS-D20 2550SFS-30EQD 1550SFS-33EQD 1600SFS125-D25 2600SFS-D20 2600SFS-30EQD 1600SFS-33EQD 1DesignFyThickness 757575757575757575757575757575757Gross PropertiesArea Weight lxSxRx(in2) (lb/ft) (in2)(in³)(in)0.070 0.24 0.033 0.040 0.6820.094 0.32 0.044 0.055 0.6860.117 0.40 0.055 0.068 0.6840.117 0.40 0.055 0.068 0.6840.083 0.28 0.086 0.068 1.0150.111 0.38 0.117 0.093 1.0270.138 0.47 0.145 0.116 1.0250.138 0.47 0.145 0.116 1.0250.099 0.34 0.186 0.106 1.3730.130 0.44 0.252 0.144 1.3950.161 0.55 0.313 0.179 1.3920.161 0.55 0.313 0.179 1.3920.101 0.34 0.202 0.111 1.4160.132 0.45 0.273 0.151 1.4390.164 0.56 0.339 0.187 1.4370.164 0.56 0.339 0.187 1.4370.107 0.36 0.255 0.127 1.5450.139 0.47 0.343 0.172 1.5720.173 0.59 0.427 0.213 1.5690.173 0.59 0.427 0.213 1.5690.130 0.44 0.543 0.198 2.0450.167 0.57 0.726 0.264 2.0840.208 0.71 0.903 0.328 2.0810.208 0.71 0.903 0.328 2.0810.138 0.47 0.670 0.224 2.2070.177 0.60 0.894 0.298 2.2500.220 0.75 1.112 0.371 2.2470.220 0.75 1.112 0.371 0.4170.8960.8960.9760.976Effective PropertiesSxeMalMadVag(in³) (in-k) (in-k) (lb)0.660.730.033 0.951.083970.048 1.631.706210.048 1.631.706211.261.160.060 1.751.722580.090 3.062.685050.090 3.062.685051.751.660.077 2.402.471800.112 3.833.843510.112 3.833.843511.841.720.080 2.522.561730.116 3.973.983380.116 3.973.983382.101.900.087 2.862.841560.129 4.404.413050.129 4.404.413050.204 6.976.092180.204 6.976.092180.219 7.466.602000.219 0380.0380.0110.0210.0410.041Torsional PropertiesCwXomRo(in6)(in)(in)(in)0.011 -1.130 0.650 1.4000.022 -1.365 0.779 1.6220.027 -1.359 0.776 1.6160.027 -1.359 0.776 1.6160.025 -0.990 0.590 1.4900.049 -1.217 0.719 1.6830.060 -1.212 0.716 1.6770.060 -1.212 0.716 1.6770.051 -0.880 0.540 1.6900.097 -1.088 0.662 1.8470.119 -1.083 0.659 1.8420.119 -1.083 0.659 1.8420.055 -0.870 0.540 1.7200.104 -1.074 0.655 1.8730.128 -1.069 0.652 1.8670.128 -1.069 0.652 1.8670.069 -0.830 0.520 1.8100.129 -1.034 0.637 1.9540.159 -1.029 0.634 1.9490.159 -1.029 0.634 1.9490.140 -0.715 0.470 2.2070.259 -0.904 0.574 2.3270.320 -0.900 0.571 2.3220.320 -0.900 0.571 2.3220.170 -0.685 0.450 2.3470.314 -0.869 0.556 2.4620.388 -0.864 0.553 2.4570.388 -0.864 0.553 �Web height-to-thickness ratio exceeds 200. Web stiffeners are required at all support points and concentrated loads.²Web height-to-thickness ratio exceeds 260. Section is not in compliance with AISI S100 Section B1, but may be used in accordance with SSFSA’s published composite wall data forthese members.See Table Notes on page 7.8www.SCAFCO.comCopyright 2015 by the SSMA

Structural (S) Section S162-68400S162-97400S200-33DesignFyThickness 050503333505050333350505033Gross PropertiesArea WeightlxSxRx2(in ) (lb/ft) (in4)(in3)(in)0.197 0.67 0.203 0.163 1.0150.255 0.87 0.261 0.208 1.0100.316 1.070.318 0.255 1.0040.390 1.33 0.386 0.309 0.9940.533 1.81 0.506 0.405 0.9750.223 0.76 0.235 0.188 1.0270.289 0.98 0.302 0.242 1.0220.358 1.22 0.370 0.296 1.0160.443 1.51 0.450 0.360 1.0070.612.07 0.596 0.477 0.9890.258 0.88 0.279 0.223 1.0400.334 1.140.358 0.287 1.0360.4151.41 0.440 0.352 1.0300.5151.75 0.537 0.430 1.0220.7112.420.718 0.575 1.0050.379 1.29 0.426 0.341 1.0600.471 1.60 0.524 0.419 1.0550.586 1.99 0.643 0.514 1.0470.813 2.77 0.864 0.692 1.0310.232 0.79 0.441 0.252 1.3800.300 1.02 0.568 0.324 1.3750.372 1.27 0.696 0.398 1.3670.461 1.57 0.849 0.485 1.3570.635 2.161.130 0.646 1.3340.258 0.88 0.508 0.290 1.4040.334 1.140.654 0.374 1.4000.4151.41 0.804 0.460 1.3920.5151.75 0.985 0.563 1.3830.7112.42 1.320 0.754 1.3620.292 0.99 0.598 0.342 1.4310.379 1.29 0.771 0.441 1.4260.471 1.600.95 0.543 1.4200.586 1.991.167 0.667 1.4110.813 2.77 1.576 0.901 1.3930.424 1.44 0.906 0.518 1.4610.528 1.801.118 0.639 1.4550.657 2.24 1.376 0.787 1.4470.9153.111.870 1.069 1.4300.236 0.80 0.479 0.264 1.4240.306 1.04 0.616 0.340 1.4190.379 1.29 0.756 0.417 1.4110.470 1.60 0.922 0.509 1.4010.648 2.20 1.229 0.678 1.3770.262 0.89 0.551 0.30

in construction. The use of cold-formed steel members benefit the environment, contractor, designer, and developer more than other material. Steel is not only a recyclable product, but also a stronger product that allows for longer clear-spans. Cold-formed steel is lighter to provide