Transcription

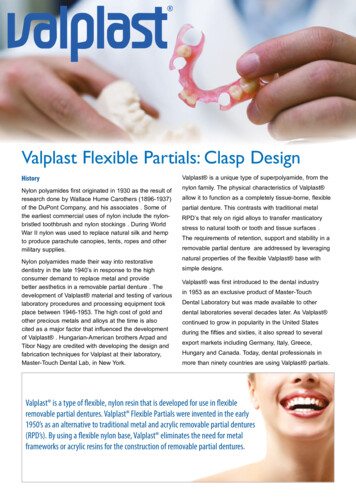

Valplast Flexible Partials: Clasp DesignHistoryNylon polyamides first originated in 1930 as the result ofresearch done by Wallace Hume Carothers (1896-1937)of the DuPont Company, and his associates . Some ofthe earliest commercial uses of nylon include the nylonbristled toothbrush and nylon stockings . During WorldWar II nylon was used to replace natural silk and hempto produce parachute canopies, tents, ropes and othermilitary supplies.Nylon polyamides made their way into restorativedentistry in the late 1940’s in response to the highconsumer demand to replace metal and providebetter aesthetics in a removable partial denture . Thedevelopment of Valplast material and testing of variouslaboratory procedures and processing equipment tookplace between 1946-1953. The high cost of gold andother precious metals and alloys at the time is alsocited as a major factor that influenced the developmentof Valplast . Hungarian-American brothers Arpad andTibor Nagy are credited with developing the design andfabrication techniques for Valplast at their laboratory,Master-Touch Dental Lab, in New York.Valplast is a unique type of superpolyamide, from thenylon family. The physical characteristics of Valplast allow it to function as a completely tissue-borne, flexiblepartial denture. This contrasts with traditional metalRPD’s that rely on rigid alloys to transfer masticatorystress to natural tooth or tooth and tissue surfaces .The requirements of retention, support and stability in aremovable partial denture are addressed by leveragingnatural properties of the flexible Valplast base withsimple designs.Valplast was first introduced to the dental industryin 1953 as an exclusive product of Master-TouchDental Laboratory but was made available to otherdental laboratories several decades later. As Valplast continued to grow in popularity in the United Statesduring the fifties and sixties, it also spread to severalexport markets including Germany, Italy, Greece,Hungary and Canada. Today, dental professionals inmore than ninety countries are using Valplast partials.Valplast is a type of flexible, nylon resin that is developed for use in flexibleremovable partial dentures. Valplast Flexible Partials were invented in the early1950’s as an alternative to traditional metal and acrylic removable partial dentures(RPD’s). By using a flexible nylon base, Valplast eliminates the need for metalframeworks or acrylic resins for the construction of removable partial dentures.

History of Valplast Case DesignsClasps are the retentive arms that are used to hold apartial denture in place and help promote stabilizationof the denture. Valplast clasp design differs significantlyfrom that of metal frame RPD clasp design. Instead ofutilizing tooth borne clasps, Valplast partials rely mainlyon flexible, dentoalveolar clasps that rest on the tissuesurface. When designed and processed correctly, theseclasps are capable of providing excellent comfort andaesthetics to the patient.Valplast clasps, in conjunction with other importantelements of design (material thickness, palatal-lingualcoverage, etc.) also address the requirement ofstability by acting to inhibit anterior-posterior and lateralmovements of the replacement teeth under mastication.Stress is supported by the alveolar ridge, with theflexibility of the Valplast base resin acting as a built-instressbreaker, allowing for equal distribution of stressover the edentulous areas.Most of the conceptual designs for Valplast claspswere based on early dentoalveolar clasp designs byHungarian dentist Dr. Imre Kemény from his book “Afoghiányok klinikuma és a lemezes fogpótlás.” TheKemény clasp designs failed in clinical usage becausethey were fabricated with conventional heat-cureacrylic. The clasps were rigid and failed to withstandthe stresses involved in insertion and removal of thesetypes of appliances. Also, because of the rigidity of theacrylic, the clasps were unforgiving in their interactionwith mucous membranes. When Dr. Kemény wasintroduced to the Valplast material, he noted favorablythat the inadequacies of rigid materials previously athis disposal were fully overcome by the ideal flexibilityof the Valplast resin. His ideas were improved uponby Arpad Nagy and his colleagues as they continuedto develop and refine the Valplast material and casedesigns in the late 1940’s and early 50’s.Mr. Arpad F. Nagy, co-inventor of the Valplast Flexible Partial DentureDr. Kemény DesignsThe early dentoalveolar claspdesigns by Dr. Kemeny would havebeen ideal for removable partialdentures had the material (acrylic)been stronger, more flexible, andbeen able to resist breakage anddeformation. These challengeswere overcome with the arrivalof Valplast, an unbreakable nylonresin for flexible partial denturesin the early 1950’s.Page 2Valplast Function & Design

Clasp Designs & FormationThere are generally four main types of clasp used forretention in a Valplast partial denture. They are theWrap-Around, High Spur, Low Spur, and Split Clasp.Wrap-Around ClaspThe Valplast wrap aroundclasp is a type of retainerthat rests on the surfacesof the natural gum tissuesin order to hold a Valplastflexible partial dentureFigure 1in place. It is the mostcommon type of claspused for Valplast partials.The wrap-around clasporiginates from the buccalor labial flange of thedenture base and traverses Figure 2soft tissue to approachthe abutment tooth froma gingival direction. Foraesthetic purposes,this type of clasp oftenterminates 1mm ontoFigure 3the abutment tooth from agingival direction, the tip ofwhich falls into the embrasure between the abutmenttooth and the next proximal tooth to it. The ideal shapeand position of a wrap-around clasp is shown in Figure1. It is essential to recognize incorrect clasp designand placement to understand better how a correctlydesigned clasp will provide predictable results andproper function. This type of clasp is very retentive asit makes use of both tooth and tissue undercuts. It isa good choice for retaining distal extensions and longspans of replacement teeth. In order to ensure patientcomfort, it is important to note that these clasps do notactually compress the tissues for retention, but shouldalways be resting in direct contact with tissue whilein a relaxed position. If a gap is created by over-reliefbetween the clasp and tissue, irritation could develop.Figure 2 illustrates a wrap-around clasp that is placedtoo high on the natural tooth surface, compromisingaesthetics and failing to make use of tissue undercuts.Figure 3 demonstrates a wrap-around clasp that isoverextended into the tissue undercut area, which maycause irritation to the patient, particularly upon insertionand removal of the denture as the clasp passes overhigh points of the tissue surface.High SpurIn cases where the abutment tooth tilts to createa severe undercut making a wrap around claspunfeasible, a high spur may be placed on the naturaltooth. As this is not ideal for aesthetic considerations,it is used mainly inposterior regions. Thehigh spur is a commonretainer for KennedyClass III cases andmodifications wherenatural posterior teethbound the edentulousspan. The high spurshould be placed so thatit enters along the heightof contour and terminatesin the infrabulge area ofthe abutment tooth.Low SpurLow spurs are placed on thenatural abutment tooth next tothe replacement and positionedclose to the neckline in aroughly triangular form so as toappear as natural interproximalpapillae. As they are more aesthetic than high spurs,they are mainly used in anterior areas. Because theyare placed so low on the labial surface of the naturalabutment teeth they are seldom used in cases wherethe abutment teeth are tilted or flared to create severeundercuts.Split ClaspThe split clasp is usedwhenever the suprabulgeportion of the abutment toothis very wide and narrowssubstantially towards theinfrabulge area, or when aflared or tilted condition of theabutment tooth requires thatthe retentive arm pass over avery severe high point beforeengaging undercuts. Thesplit clasp resembles a roachclasp (from metal frame RPDdesign) in concept and basic design structure, withflexibility along both the vertical and horizontal axes ofthe junction.Valplast Function & DesignPage 3

Clasp Variations & Alternate RetentionAnchor ClaspLabial StrapA seldom used butoccasionally useful designis the labial or buccalanchor clasp. This clasptype is used mainly onmaxillary full dentures inthe labial region whenlarge undercuts arepresent. These shouldextend a two-tooth lengthfrom the junction pointwhere the clasp meets theadjoining buccal or labialflange.In cases where abutment teeth exhibit a high degree ofmobility, they may be splinted by use of a thin, flexiblelabial (or buccal) strap. As demonstrated by the casein the photos below, the labial strap may be fabricatedwith what is essentially a series of continued split claspsso as to avoid placing excessive strain on the abutmentteeth upon insertion and removal of the denture.Split Flange RetentionIn cases with largeprotuberant structuresalong the alveolar ridge,the buccal flange may be“split” along the heightof contour to create aflexible, retentive arm outof the lower half of thesplit flange (along theperipheral border.)Page 4Circumferential ClaspCombination ClaspThe circumferencial claspwas first suggested byDr. Paul Kaplan, a U.S.Army Prosthodontist inhis 2008 article “FlexibleRemovable PartialDentures: Clasp & DesignConcepts.” This type ofclasp completely encirclesan abutment tooth forretention - ideal for freestanding distal abutments.Another Kaplan design,this clasp is a combinationof wrap-around andcircumferential clasps thatconnect palatal/lingualand buccal componentsby crossing the occlusaltable. This clasp mayprovide more retention ofthe denture and stabilityof free end saddles thana standard wrap-aroundclasp, but does requiresome tooth preparation inorder to be placed correctly.Valplast Function & DesignImplant RetainedOverdenture with BarAttachmentBeing a flexible nylonresin, it is possible tofabricate retention clipsfor implant bars directlyinto the Valplast materialwithout the need foradditional components ormetal housings.Friction Fit DentureComplete maxillarydentures fabricated inValplast may have limitedsuccess as the flexibilityof the material mightcomprise the integrityof the post palatal seal.However, a friction fitoverdenture may befabricated for use overtelescopic attachmentswhich would address therequirement of retentionwithout the need forretentive suction.

ReferencesLiterature1. Chemical Heritage Foundation. “Wallace Hume /chemach/plastics/carothers.html2. Wikipedia. “Nylon,” http://en.wikipedia.org/wiki/Nylon3. Dr. Maurice Stern, DDS. “Esthetic retention for modern dental prosthesis,” New York State Dental Journal, February1964.4. Alan B. Carr, Glen P. McGivney, David T. Brown. “Removable Partial Prosthodontics,” 11th Edition, 2005.5. Dr. Imre Kemény. “A foghiányok klinikuma és a lemezes fogpótlás” Hungary, 1959.6. Dr. Paul Kaplan, DDS. “Flexible Removable Partial Dentures: Design and Clasp Concepts,” Dentistry Today,December 2008.7. Valplast International Corporation. “Valplast Processing Technique,” 2006 Edition.8. Dr. Edward Kennedy, DDS. “Partial Denture Construction,” Brooklyn Dental Items of Interest Publishing, 1928.9. Dr. Jacob Schwartz, DDS. “Modern Methods of Tooth Replacement,” Dental Items of Interest Publishing, 1948Photography Credits Title image courtesy of Johannes Weithas KG - Lutjenberg, GermanyImages of Dr. Kemény clasp designs taken from “A foghiányok klinikuma és a lemezes fogpótlás”Labial strap images courtesy of Advanced Technologies - Moscow, RussiaCircumferential clasp and combination clasp images courtesy of Dr. Paul Kaplan, DDSImplant retained overdenture image courtesy of Val-Tech Laboratory - Napoli, ItalyAll other images courtesy of Valplast Interntional CorporationProvided by:Valplast International Corporation200 Shames DriveWestbury, NY 11590(516) 442-3923www.valplast.comValplast Function & DesignPage 5

removable partial dentures. Valplast Flexible Partials were invented in the early 1950’s as an alternative to traditional metal and acrylic removable partial dentures (RPD’s). By using a exible nylon base, Valplast eliminates the need for metal frameworks or acrylic resins for the con