Transcription

U. S. DEPARTMENT OF COMMERCEDANIEL C. ROPER, SecretaryNATIONAL BUREAU OF STANDARDSLYMAN J. BRIGGS, DirectorCIRCUUR OF THE NATIONAL BUREAU OF STANDARDS C407[Supersedes Circular C294]AU OF ST AND A pR 19 1935STANDARDSFOR PAPER TOWELSlibrakyByBOURDON W. SCRIBNER and RUSSELL W. CARR[Issued March 21, 1935]UNITED STATESGOVERNMENT PRINTING OFFICEWASHINGTON : 1935For sale by the Superintendent of Documents, Washington, D. C.Price 5 cents

% iriI.' i, t* -ii '

STANDARDS FOR PAPER TOWELSBy Bourdon W. Scribner and Russell W. CarrABSTRACTFurther study relative to Federal specifications for purchase of paper towelsrevealed that the rate at which they absorb water may decrease greatly in 6months. As the decrease was approximated sufficiently well for purchase pur poses, b} heating the towels at 100 C for 1 hour, a test of their absorptivenessafter such treatment is desirable. No constant relation between the initial prop erties of the towels and their absorptiveness after 6 months’ storage was found.The tensile and bursting strengths did not decrease during this period of storage.Tests of water absorptiveness after heat treatment and of tensile strength, to gether with inspection for cleanliness and other visible properties, are recom mended for the evaluation of towels. A discussion of the properties of towelsrelative to their serviceability is included.CONTENTSPageI. IntroductionII. PropertiesIII. TestingIV. Discussion of test data11341. INTRODUCTIONIn 1924, at the request of the chairman of the paper technical com mittee of the Federal Specifications Board, the National Bureau ofStandards made a study of the properties and the testing of papertowels for the purpose of developing a specification to be used for theirpurchase by the Government Departments. A report of the resultsof this investigation was published in 1925 as Bureau of StandardsCircular C294. This revised edition of that circular reports the re sults of a further investigation, which was prompted by the discoverythat the absorptiveness of some towels decreased so much during afew months’ storage as to render them unserviceable. This additionalstudy, like the previous one, was made with the cooperation of papertowel manufacturers.11. PROPERTIESPaper towels are composed of wood fd ers produced by the acidsulphite or the ahialine-sulphate pulping process, by grinding thewood, or by repulping waste paper. Both bleached and unbleachedsulphite and sulphate fibers are used. The unbleached sulphate fibersare commonly termed kraft fibers. The fiber components given intable 2 are quite representative. The best grades of towels are made107029—35I

2Circular of the National Bureau of Standardswholly or largely of virgin wood fibers produced by the chemical puloing processes. The rate of absorption of water by towels is dependentprimarily on the absorptiveness of the fibers and the amount of porespace in the paper, therefore rapid absorption is obtained by specialtreatment of the fibers to make them as absorptive as possible, by theuse of bulky and long fibers to obtain high porosity, and by minimiz ing pressure on the paper to conserve its porosity. Rosin sizing, insmall amount, is used in some toAvels to retard the absorption of watersomewhat and thus prevent excessive localized wetting and conse quent breaking.Paper towels come under the classification of bibulous papers, whichare characterized by absorptiveness, loose formation, and softness.Blotting paper is a well-kno\vn example of a paper in this group.1 owel and blotting papers are similar in their absorptive requirements,but the former must possess much greater strength than blottingpapers. Unlike the latter, they must be comparatively thin to havethe required flexibility, and yet must possess much greater strengththan blotting paper so that they will not break under the severe con- Id.itions of usage. A good grade of paper toweling has two or threetimes the strength of blotting paper of the same fiber composition.'In evaluating paper towels, therefore, the main consideration, in addi- Ition to absorptiveness and softness, is the strength. It is difficult tosecure such a combination of desirable properties in the same sheet ofpaper. IThe natural softness and absorptiveness of wood fiber are consider ably lessened by the usual treatment given to develop its maximumstrength for paper making. Generally, at one extreme, are associatedm paper towels rapid absorption, softness, and weakness, and at theother extreme, slow absorption, hardness, and high strength. Thoseof the first class must be used as a blotter, or they may tear, whilethose of the second class require considerable rubbing to complete thedrying operation. Either extreme is undesirable, as time is an important factor in the use of towels, and the care taken to avoid breaking the very absorbent towels or the prolonged rubbing required bvthe less absorbent but stronger towels may consume more time thanIS desirable. It is true that some towels have the two desirable prop erties of high absorptiveness and strength combined, but they areusually relatively high priced.Cleanliness, of course, is necessary. The use of repulped paperstock is somewhat objectionable from sanitary considerations, andwhile it would seem that the use of miscellaneous waste papers fromunknown sources is undesirable there can be no valid objection to theuse of clean waste papers, such as overruns of newspapers secureddirectly from the publishers. Although a high white color is generallyassociated with purity, from a practical standpoint it is of littleimportance, and any natural fiber color should be acceptable. Towelsare generally creped, and this is desirable because it lends muchadditional resistance to the strains incident to use, and increasesthe bulk.The towels are made in a variety of sizes but mainly about 11inches in width. Folded towels are commonly 13 inches and rolltowels 15 inches in length. No valid reason for this difference insize IS known.I1 i;:'’i

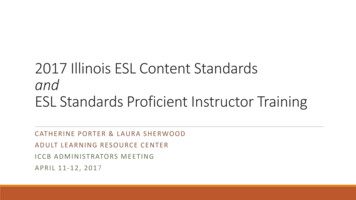

3Standards for Pamper TowelsIII. TESTINGAll known domestic manufacturers of towels were invited to submitsamples representative of their usual products for experimental test ing. From the samples received, 13 were selected as being thorouglilyrepresentative of the various commercial products.The samples were tested for fiber components, weight, burstingstrength, tensile breaking strength, resin, acidity, and rate of absorp tion of water, by the standard methods of the Technical Associationof the Pulp and Paper Industry. Because of the importance of theabsorption test, some representative data are given in table 1, whichshow its reproducibility. It will be noted that the differences be tween the average test values for 10 specimens is usually within 5percent.Table 1.—Maximum deviation of averages of absorptiveness tests made by 2 5151150126CWCWCCW2425262021Average— 127.8 129.6 127.4 124.2 145.2 149.6 135.0 144. 8 189.4 197.8 185.0 191.8 22.0 23.423.423.2120128125139136Deviation (%) ofaverages, 5}samples.Grand av rerage 1Deviation (%) ofaverages, 10 1samples .2. 63. 031491341241281407. 262001821851752052161702101882054. 442071652261711902123212520W2525222520( 1251261111401 137118514021717420971B71A20242527,21Time (in seconds)of absorption of0.1 ml ofwater.12012013612713441B41A3. 686.360.86C 127. 6W 126. 9C 140.1W 147. 2C 187. 2W 194.8C 22.7W 23.30.555. 074. 062. 64Since decrease in rate of absorption of water during storage is avery serious problem, a convenient and reliable method of predictingsuch deterioration was needed. A study was made of heating thesamples in air at a temperature of 100 C ( 1 ) to find if this wouldserve as an accelerated aging test with respect to loss of absorptive ness. Extensive studies made at the Bureau of the aging qualitiesof record papers have indicated that this test is a valuable means ofmeasuring the stability of papers. Absorption tests were madeafter heating for1, 2, and 3 hours, and after storage for 1, 2, 4,and 6 months from date of manufacture. No tests for loss of strengthon aging were made, as preliminary testing had shown that littleloss of strength occurred during a normal storage period. The towelsfor testing the effect of normal aging on their absorptiveness werepacked in cardboard cartons and stored in steel lockers under normalatmospheric conditions.123 Copies can be secured from the association at 122 East 42nd Street, New York, N. Y.BS J.Research 7, 466 (1931) RP352.BS J.Research 11, 727 (1933) RP620.Paper Trade J. 9.5, 28 (July 28, 1932).

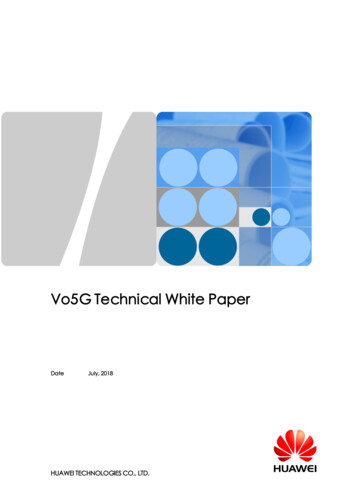

4Circular of the National Bureau of StandardsOther tests mentioned by manufacturers as being used variouslyby tbem are wet tensile breaking strength, softness as indicated byflexibility, pressure absorptiveness by pressing the specimen against a wet screen, stretch, tear, number of dirt particles, lateral absorptionby a strip of the paper, and use of 1.0 ml of water instead of 0.1 ml,the amount specified in the standard method. Considerable effort was imade to develop a suitable procedure for measuring the wet tensilestrength because it is obviously more closely related to the use require ments than testing the paper dry, but the data secured were tooerratic to serve for relative grading of the different types of towels, iThe use of 0.1ml of water appears to be a satisfactoiy test for absorp tiveness. This is more in accordance vrith service conditions than alarger amount because only a little water comes in contact with anysmall area of a towel. The other tests mentioned would seem toneedlessly complicate the evaluation of towels for purchase, althoughthey may be desirable for research and manufacturing control.jIV. DISCUSSION OF TEST DATA Test data for the towels as received and for their absorptivenessafter 6 months of normal aging are given in table 2. These reveal awide range of values in all of the properties and no constant relationbetween any of the properties and the absorptiveness of the towelsafter normal aging. With respect to the fibers, however, clean, longfibers were associated with good quality. The resin contents of thetowels are not an indication that rosin sizing was used, as the resinmay have been derived entirely from the natural resinous matterwhich is normally a component of wood fibers. In figures 1 and 2,the change in rate of absorption of water during natural aging iscompared with the change under the heat test, for each sample. Theidentification numbers of the towels appear at the bottom of eachgraph. In both cases the change in the absorptiveness of most of thetowels is considerable. Because of the extremely variable nature oftowel tissue and the wide differences in the fiber components of thedifferent samples, a regular relation between the change in absorptive ness caused by heating and that which naturally occurred duringstorage could hardly be expected. In most cases, hovrever, the agreement is good and possibly would have been better had the tests beencontinued over longer periods of time. As a practical matter, theresults show that the heat test will foretell whether a towel is likelyto lose much of its absorptiveness during storage, and therefore thistest is considered suitable for inclusion in purchase specifications.A heating period of 1 hour, at a temperature of 100 C, appears to besufficient.'For some tissue products having a slow rate of absorption, the use of as little as 0.01 ml of water has beenfound desirable. Carson and Worthington have described a special pipette device for accurate delivery ofa very small amount of water in making absorption tests. See Paper Trade J. 95, 59 (Oct 20,1932)' :ii1ijjI ' i

ABSORPTIONTIME - SECONDSStandards for Paper TowelsHOURS HEAT TREATED0Vz0)Figure 1.—Change\2 3 0 /21230/21230/2!25MONTHS STORAGE2460124-601 2460124 6in absorptiveness of paper towels on heating and on normal aging.Samples 11, 21, 22, 24, 25, 31, 32, and 41.

6Circular of the National Bureau of Standards300002000015000100008000ABSORPTION TIME - SECONDS6000CDQZ4000o3000ou(D1yEhHOURS HEAT TREATED0I 2 3 0 ‘/2 I 2 31 MONTHS STOf AGE I0 1 24601 246z0Haa0(0CD 200015001000900800700600500300200100 HEATEDO STOREDFigure 2.—Change6HOURS0 /a 1 2 3IMONTHSI0 12 4 6I-I I I {in ah sorptiveness of paper towels on heating and on normal aging.Samples 42, 43, 51, 61, and 71.

7standards for Paper TowelsTable2.—-Test data for payer towelsTensile break ing strength rst 25 X 40,inginchesstrength500(0sheetsPounds43. 548.044. 444. 046. 043.149. 438.548. 446. 942.545.845. 9Points8. 38. 48.17.89.16. 56.88. 29.17. 57.46. 434. 2Ma chinedirec tionkg1. 61. 61. 81. 61. 61. 41. 51.81. 81. 41.31. 55. 0FibersEesinCrossdirec tionkg1.11.31. 51. 41. 3.8LO1. 21.01.01. 42. 0Acidityas SO3GroundwoodPer cent0. 49.62.81. 69. 66.73. 79. 67. 42. 671. 051. 18. 33Per cent0.021.020. 027.031.029.006. Oil.043. 054. 024.072.054. 006Sul phateSulphitePer cent50Un Un Bleach bleach bleach ededed255030Per cent50ICO7070805075402035354060303020Per centPer cent501050100255100Time ofabsorp tion of0.1 mlofwater 3Sec onds51347117108596262106532768566018’ Bursting pressure in lb/in.2 through a circular orifice 1.2 in. in diameter.2 For test specimen 15 mm wide and 100 mm between jaws.3 After 6 months’ storage.While there was no constant relation between the initial absorp tiveness and the decrease in absorptiveness during normal storage,the greatest decrease was found in the three samples which wereinitially the least absorbent. It may be well to mention here thatthe chemical changes in paper which cause its deterioration aregenerally accelerated by excessive heat and dampness, and by light;therefore stored towels should be protected against such influences.The tensile breaking strength test of towels is a better criterion thanthe bursting strength test as the latter gives erratic

Paper towels are composed of wood fd ers produced by the acid- sulphite or the ahialine-sulphate pulping process, by grinding the wood, or by repulping waste