Transcription

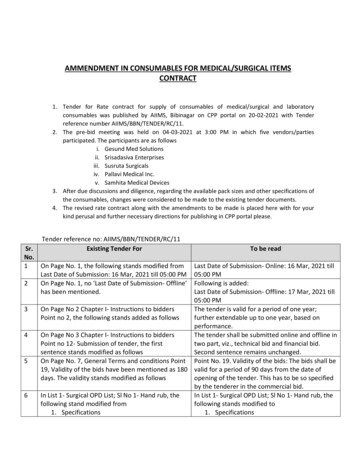

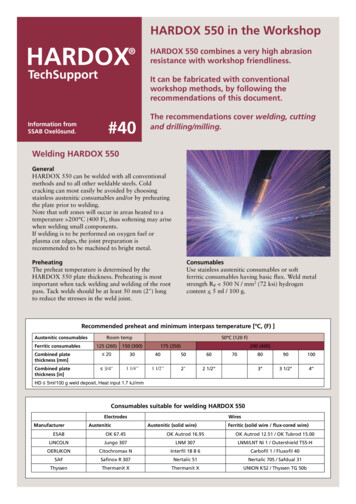

SMAWmetal-coredmig & tigstickCONSUMABLESintroductionSTICKW E L D I N G C O N S U M A B L E S C ATA L O G68281 017 096 ACG.indd 17[17]3/30/10 2:40 PM

Stick (SMAW) ElEctrodESSelection GuideintroductionStick (SMAW) ElectrodeProduct Name& AWS ClassDiameters Availablein (mm)Key Features3/32(2.4)Mild Steel, CellulosicFleetweld 5P(E6010)Fleetweld 5P (E6010)Pipeliner 6P (E6010)stickFleetweld 180(E6011)Fleetweld 35(E6011)Fleetweld 35LS(E6011)mig & tig(E6013)Fleetweld 22(E6022)Fleetweld 4(6.4) High operator appeal and control Easy slag removal Standard in the pipe welding industry High operator appeal and control Easy slag removal Q2 Lot - Certificate showing actual deposit chemistryavailable online AC polarity welding Performs on low amperages and OCV Easy to strike arc Stable arc performance High operator appeal DC and AC welding (1) Use for tack welds under Innershield deposits Light, easy to remove slag DC and AC welding Operable with low amperages on sheet metal Excellent bead appearance Slag control accommodates vertical down welding .6) Deep penetration Optimized for burn-through spot welding Little slag interference in arc High deposition rates Excellent operator appeal Easy to use 3/32(2.4)Mild Steel, High DepositionJetweld 25/32(4.0) Deep arc penetration Light slag with minimal arc interference Excellent vertical and overhead capabilityMild Steel, RutileFleetweld 371/8(3.2) High deposition rates Smooth bead appearance Shallow penetration for minimal dilution1/8(3.2)5/32(4.0)3/16(4.8) 7/32(5.6)1/4(6.4) Manufactured to 2.5 mm diameter.[18]68281 017 096 ACG.indd 18THE LINCOLN ELECTRIC COMPANY3/30/10 2:40 PM

Stick (SMAW) ElEctrodESSelection Guide High deposition rates Smooth bead appearance Minimal spatter(E7024-1)Mild Steel, Low HydrogenPipeliner 16P(E7016 H4)Excalibur 7018 MR(E7018 H4R)Jetweld LH-70(E7018 H4R)Jet-LH 78 MR (E7018 H4R)Lincoln 7018AC(E7018 H8)Excalibur 7018-1 MR(E7018-1 H4R)Excalibur 7028 Premium arc performance Square coating burn-off Easy strike and re-strike Low hydrogen Smooth arc performance Low hydrogen Smooth arc performance AC polarity welding Capable of cold re-strikes Minimal spatter Premium arc performance Square coating burn-off Effortless slag removal Low Alloy, CellulosicShield-Arc HYP (E7010-P1)Pipeliner 7P (E7010-P1)Shield-Arc 85Manufactured to 2.5 mm diameter.(2) 3/32 1/8 5/32 3/16 7/32 1/4(2.4) (3.2) (4.0) (4.8) (5.6) (6.4) High productivity in vertical down and out-of-positionpipe welding Q2 Lot - Certificate showing actual deposit chemistryavailable online (2) Manufactured to a 5.0 mm diameter.W E L D I N G C O N S U M A B L E S C ATA L O G68281 017 096 ACG.indd 19(1) Light slag for minimal arc interference Deep penetration Clean, visible weld puddle For welding 0.50% molybdenum steel Light slag for minimal arc interference Deep penetration and superior puddle control(E7010-A1)3/32 1/8 5/32 3/16 7/32 1/4(2.4) (3.2) (4.0) (4.8) (5.6) (6.4) Low hydrogen, vertical up capability on X60 grade pipe Q2 Lot - Certificate showing actual deposit chemistryavailable online High deposition rates Premium arc performance High speed(E7028 H8) stickJetweld 13/32 1/8 5/32 3/16 7/32 1/4(2.4) (3.2) (4.0) (4.8) (5.6) (6.4)mig & tigMild Steel, High Deposition(1)Diameters Availablein (mm)Key Featuresmetal-coredProduct Name& AWS ClassintroductionStick (SMAW) Electrode[19]3/30/10 2:40 PM

STICK (SMAW) ELECTRODESSelection GuideINTRODUCTIONStick (SMAW) ElectrodeProduct Name& AWS ClassDiameters Availablein (mm)Key Features3/32 1/8 5/32 3/16 7/32 1/4(2.4) (3.2) (4.0) (4.8) (5.6) (6.4)Low Alloy, CellulosicShield-Arc 70 (E8010-P1)Pipeliner 8P (E8010-P1)Shield-Arc 90STICK(E9010-G) Light slag for minimal arc interference Deep penetration Clean, visible weld puddle High productivity in vertical down andout-of-position pipe welding Q2 Lot - Certificate showing actual depositchemistry available online Light slag for minimal arc interference Deep penetration Clean, visible weld puddle (E7018-A1 H4R)Excalibur 8018-B2 MR(E8018-B2 H4R) Designed for welding 0.50% molybdenum steel Premium arc performance Square coating burn-off Designed for welding 1.25% chromium, 0.50%molybdenum steel Premium arc performance Square coating burn-off MIG & TIGExcalibur 8018-B2 XF MR X-Factor 15 ppm(E8018-B2 H4R) Premium arc performance and strikeability Q2 Lot - Certificate showing actual depositchemistry available onlineExcalibur 8018-C1 MR(E8018-C1 H4R)Excalibur 8018-C3 MR(E8018-C3 H4R)METAL-COREDPipeliner 18P(E8018-G H4)(1)[20](1)3/32 1/8 5/32 3/16 7/32 1/4(2.4) (3.2) (4.0) (4.8) (5.6) (6.4)Low Alloy, Low HydrogenExcalibur 7018-A1 MR(1) Designed to produce a nominal 2-1/4% nickeldeposit Premium arc performance Square coating burn-off Designed to produce a 1% nickel deposit Premium arc performance Square coating burn-off Low hydrogen, vertical up capability on X70grade pipe Charpy V-Notch impact toughness tested to-46 C (-50 F) Q2 Lot - Certificate showing actual depositchemistry available online Manufactured to 5.0 mm diameter.THE LINCOLN ELECTRIC COMPANY

Stick (SMAW) ElEctrodESSelection GuideLow Alloy, Low Hydrogen(E9018-B3 H4R)Excalibur 9018M MR(E9018M H4R)Excalibur 10018-D2 MR(E10018-D2 H4R)Excalibur 11018M MR(E11018M H4R)Pipeliner LH-D80(E8045-P2 H4R)Pipeliner LH-D90(E9045-P2 H4R)Pipeliner 19P(E10018-G H4R)Pipeliner LH-D100(E10045-P2 H4R)(1)3/32 1/8 5/32 3/16 7/32 1/4(2.4) (3.2) (4.0) (4.8) (5.6) (6.4) Designed for all-position welding of 2.25%chromium, 1% molybdenum low alloy steels Premium arc performance Square coating burn-off Designed to produce weld deposits with620 MPa (90 ksi) tensile strength Premium arc performance Square coating burn-off Capable of exceeding 690 MPa (100 ksi) yieldstrength after 12 hours at 635 C (1175 F) Premium arc performance Q2 Lot - Certificate showing actual depositchemistry available online Capable of producing weld deposits with760 MPa (110 ksi) tensile strength Premium arc performance Square coating burn-off Low hydrogen, vertical down capability on upto X70 pipe High productivity Q2 Lot - Certificate showing actual depositchemistry available online Low hydrogen, vertical down capability on upto X80 pipe High productivity Q2 Lot - Certificate showing actual depositchemistry available online Low hydrogen, vertical up capability on X80grade pipe Charpy V-Notch impact toughness tested to-46 C (-50 F) Q2 Lot - Certificate showing actual depositchemistry available online Low hydrogen, vertical down capability on upto X90 pipe High productivity Q2 Lot - Certificate showing actual depositchemistry available onlinestickExcalibur 9018-B3 MRDiameters Availablein (mm) (1)mig & tigKey Features (1) metal-coredProduct Name& AWS ClassintroductionStick (SMAW) Electrode (1)Manufactured to 4.5 mm diameter.W E L D I N G C O N S U M A B L E S C ATA L O G68281 017 096 ACG.indd 21[21]3/30/10 2:40 PM

Stick (SMAW) ElEctrodEFleetweld 5P Mild Steel, CellulosicAWS E6010introductionKey FeaturesWelding Positions Deep arc penetration Light slag with minimal arc interference Excellent vertical and overhead capabilityAllConformancesTypical Applicationsstick Steel with moderate surface contaminants Cross country and in-plant pipe welding Square edge butt weldsAWS A5.1/A5.1M: 2004ASME SFA-A5.1:ABS:Lloyd’s Register:CWB/CSA W48-06:TUV:E6010E6010E60103ME4310EN ISO 2560-A:E 42 3 C25mig & tigDIAMETERS / PACKAGINGDiameterin 0)(4.8)(5.6)(6.4)[22]68281 017 096 ACG.indd 22Lengthin (mm)121414141414(300)(350)(350)(350)(350)(350)5 lb (2.3 kg) Plastic Tube20 lb (9.1 kg) Carton10 lb (4.5 kg) EO Can30 lb (13.6 kg) Carton50 lb (22.7kg)Easy Open HE LINCOLN ELECTRIC COMPANY3/30/10 2:40 PM

STICK (SMAW) ELECTRODEFleetweld 5P (AWS E6010)Yield Strength(2)MPa (ksi)Tensile StrengthMPa (ksi)Elongation%Charpy V-NotchJ (ft lbf)@-29 C (-20 F)330 (48) min.430 (60) min.22 min.27 (20) min.515 - 570 (75-83)25 - 3141 - 68 (30 - 50)RequirementsAWS E6010Typical PerformanceAs-WeldedINTRODUCTIONMECHANICAL PROPERTIES (1) – As Required per AWS A5.1/A5.1M: 2004(3)420 - 475 (61 - 69)RequirementsAWS E6010Typical Performance(3)As-WeldedTypical all weld metal.(2)%Si%P%S0.20 max.1.20 max.1.00 max.Not SpecifiedNot Specified0.09 - 0.170.40 - 0.630.09 - 0.430.005 - 0.0170.005 - 0.014%Ni%Cr%Mo%V0.30 max.0.20 max.0.30 max.0.08 max.0.01 - 0.050.01 - 0.05 0.03 0.01(3)RequirementsAWS E6010(1)%MnMeasured with 0.2% offset.(3)MIG & TIGTypical PerformanceAs-Welded%CSTICKDEPOSIT COMPOSITION(1) – As Required per AWS A5.1/A5.1M: 2004See test results disclaimer on pg. 9.TYPICAL OPERATING PROCEDURESPolarity3/32 in(2.4 mm)1/8 in(3.2 mm)5/32 in(4.0 mm)3/16 in(4.8 mm)7/32 in(5.6 mm)1/4 in(6.4 mm)DC 40 - 8070 - 13090 - 165140 - 225200 - 275220 - 325W E L D I N G C O N S U M A B L E S C ATA L O GMETAL-COREDCurrent (Amps)[23]

Stick (SMAW) ElEctrodEFleetweld 5P Mild Steel, CellulosicAWS E6010introductionKey FeaturesWelding Positions High operator appeal and control Easy slag removal Standard in the pipe welding industryAllConformancesAWS A5.1/A5.1M: 2004ASME SFA-A5.1:ABS:CWB/CSA W48-06:TUV:Typical Applicationsstick Cross country and in-plant pipe welding Steel with moderate surface contaminants Repair weldingE6010E6010E6010E4310EN ISO 2560-A:E 42 3 C25mig & tigDIAMETERS / PACKAGINGDiameterin [24]68281 017 096 ACG.indd 24Lengthin (mm)12141414(300)(350)(350)(350)10 lb (4.5 kg) Easy Open Can30 lb (13.6 kg) Carton50 lb (22.7kg)Easy Open 5ED010281THE LINCOLN ELECTRIC COMPANY3/30/10 2:40 PM

STICK (SMAW) ELECTRODEFleetweld 5P (AWS E6010)Yield Strength(2)MPa (ksi)Tensile StrengthMPa (ksi)Elongation%Charpy V-NotchJ (ft lbf)@-29 C (-20 F)330 (48) min.430 (60) min.22 min.27 (20) min.22 - 2951 - 93 (38 - 69)RequirementsAWS E6010Typical PerformanceAs-WeldedINTRODUCTIONMECHANICAL PROPERTIES (1) – As Required per AWS A5.1/A5.1M: 2004(3)415 - 500 (60 - 73)500 - 610 (73 - 88)RequirementsAWS E6010%Mn%Si%P%S0.20 max.1.20 max.1.00 max.Not SpecifiedNot Specified0.09 - 0.200.46 - 0.790.10 - 0.320.005 - 0.0170.004 - 0.014%Ni%Cr%Mo%V0.30 max.0.20 max.0.30 max.0.08 max. 0.04 0.04 0.02 0.01(3)RequirementsAWS E6010Typical PerformanceAs-WeldedMIG & TIGTypical PerformanceAs-Welded%CSTICKDEPOSIT COMPOSITION(1) – As Required per AWS A5.1/A5.1M: 2004(3)(1)Typical all weld metal.(2)Measured with 0.2% offset.(3)See test results disclaimer on pg. 9.TYPICAL OPERATING PROCEDURES1/8 in(3.2 mm)5/32 in(4.0 mm)3/16 in(4.8 mm)DC 50 - 8575 - 135100 - 175140 - 225DC-50 - 8575 - 135100 - 175–PolarityW E L D I N G C O N S U M A B L E S C ATA L O GMETAL-COREDCurrent (Amps)3/32 in(2.4 mm)[25]

STICK (SMAW) ELECTRODEPipeliner 6P Mild Steel, CellulosicAWS E6010INTRODUCTIONKey FeaturesWelding Positions High operator appeal and control Easy slag removal Q2 Lot - Certificate showing actual depositAllchemistry available onlineConformances Standard in the pipe welding industryAWS A5.1/A5.1M: 2004ASME SFA-A5.1:ABS:CWB/CSA W48-06:STICKTypical ApplicationsE6010E6010E6010E4310 Cross country and in-plant pipe welding Root pass on up to X80 grade pipe Hot, fill and cap pass on up to X60 grade pipeMIG & TIGDIAMETERS / PACKAGINGMETAL-CORED[26]Diametermm (in)Lengthin (mm)10 lb (4.5 kg) Easy Open Can30 lb (13.6 kg) Master Carton50 lb (22.7 kg)Easy Open Can2.5 (3/32)3.2 (1/8)4.0 (5/32)12 (300)14 (350)18 (450)ED032609ED032610ED032611ED030848ED030849THE LINCOLN ELECTRIC COMPANY

STICK (SMAW) ELECTRODEPipeliner 6P (AWS E6010)Yield Strength(2)MPa (ksi)Tensile StrengthMPa (ksi)Elongation%Charpy V-NotchJ (ft lbf)@-29 C (-20 F)330 (48) min.430 (60) min.22 min.27 (20) min.22 - 3627 - 85 (20 - 63)RequirementsAWS E6010Typical PerformanceAs-WeldedINTRODUCTIONMECHANICAL PROPERTIES (1) – As Required per AWS A5.1/A5.1M: 2004(3)405 - 515 (59 - 75)495 - 620 (72 - 90)RequirementsAWS E6010Typical Performance(3)As-WeldedTypical all weld metal.(2)%Si%P%S0.20 max.1.20 max.1.00 max.Not SpecifiedNot Specified0.11 - 0.200.51 - 0.770.15 - 0.320.006 - 0.0160.005 - 0.011%Ni%Cr%Mo%V0.30 max.0.20 max.0.30 max.0.08 max.0.01 - 0.040.01 - 0.040.01 - 0.02 0.01(3)RequirementsAWS E6010(1)%MnMeasured with 0.2% offset.(3)MIG & TIGTypical PerformanceAs-Welded%CSTICKDEPOSIT COMPOSITION(1) – As Required per AWS A5.1/A5.1M: 2004See test results disclaimer on pg. 9.TYPICAL OPERATING PROCEDURESPolarity2.5 mm(3/32)3.2 mm(1/8)4.0 mm(5/32)DC 50 - 8575 - 135100 - 175DC-50 - 8575 - 135100 - 175METAL-COREDCurrent (Amps)Preferred polarity is listed first.W E L D I N G C O N S U M A B L E S C ATA L O G[27]

Stick (SMAW) ElEctrodEFleetweld 180 Mild Steel, CellulosicAWS E6011introductionKey FeaturesWelding Positions AC polarity welding Performs on low amperages and OCV Easy to strike arcAllConformancesAWS A5.1/A5.1M: 2004ASME SFA-A5.1:CWB/CSA W48-06:Typical Applicationsstick Small AC welders Sheet metal Edge, corner and butt jointsE6011E6011E4311mig & tigDIAMETERS / PACKAGINGmetal-coredDiameterin (mm)Lengthin (mm)1 lb (0.5 kg) Plastic Tube6 lb (3.6 kg) Carton5 lb (2.3 kg) Plastic Tube20 lb (9.1 kg) Carton50 lb (22.7 kg)Easy Open Can3/32 (2.4)1/8 (3.2)5/32 (4.0)12 (300)14 (350)14 110ED010105ED010114[28]68281 017 096 ACG.indd 28THE LINCOLN ELECTRIC COMPANY3/30/10 2:40 PM

Stick (SMAW) ElEctrodEFleetweld 180 (AWS E6011)Yield Strength(2)MPa (ksi)Tensile StrengthMPa (ksi)Elongation%Charpy V-NotchJ (ft lbf)@-29 C (-20 F)330 (48) min.430 (60) min.22 min.27 (20) min.22 - 3235 - 72 (26 - 53)RequirementsAWS E6011Typical Performance(3)As-Welded460 - 490 (67 - 71)570 - 590 (83 - 86)introductionMECHANICAL PROPERTIES (1) – As Required per AWS A5.1/A5.1M: 2004stickDEPOSIT COMPOSITION(1) – As Required per AWS A5.1/A5.1M: 2004%Mn%Si%P%SRequirementsAWS E60110.20 max.1.20 max.1.00 max.Not SpecifiedNot SpecifiedTypical Performance(3)As-Welded0.13 - 0.200.44 - 0.710.23 - 0.450.009 - 0.0140.005 - 0.008%Ni%Cr%Mo%V0.30 max.0.20 max.0.30 max.0.08 max. 0.03 0.03 0.01 0.01RequirementsAWS E6011Typical PerformanceAs-Weldedmig & tig%C(3)(1)Typical all weld metal.(2)Measured with 0.2% offset.(3)See test results disclaimer on pg. 9.TYPICAL OPERATING PROCEDURESPolarity1/8 in(3.2 mm)5/32 in(4.0 mm)AC40 - 9065 - 120115 - 150DC 40 - 8060 - 110105 - 135metal-coredCurrent (Amps)3/32 in(2.4 mm)Preferred polarity is listed first.W E L D I N G C O N S U M A B L E S C ATA L O G68281 017 096 ACG.indd 29[29]3/30/10 2:40 PM

Stick (SMAW) ElEctrodEFleetweld 35 Mild Steel, CellulosicAWS E6011introductionKey FeaturesWelding Positions Stable arc performance High operator appeal AC and DC weldingAllConformancesTypical Applicationsstick Sheet metal In-plant pipe welding Steel with moderate surface contaminantsAWS A5.1/A5.1M: 2004ASME SFA-A5.1:ABS:Lloyd’s Register:E6011E6011E60113Mmig & tigDIAMETERS / PACKAGINGDiameterin 0)(4.8)(5.6)(6.4)[30]68281 017 096 ACG.indd 30Lengthin (mm)141414141818(350)(350)(350)(350)(450)(450)50 lb (22.7 D028157THE LINCOLN ELECTRIC COMPANY3/30/10 2:40 PM

Stick (SMAW) ElEctrodEFleetweld 35 (AWS E6011)Yield Strength(2)MPa (ksi)Tensile StrengthMPa (ksi)Elongation%Charpy V-NotchJ (ft lbf)@-29 C (-20 F)330 (48) min.430 (60) min.22 min.27 (20) min.RequirementsAWS E6011Typical Performance(3)As-Welded385 - 415 (56 - 60)470 - 510 (68 - 74)26 - 33introductionMECHANICAL PROPERTIES (1) – As Required per AWS A5.1/A5.1M: 200456 - 101 (42 - 75)stickDEPOSIT COMPOSITION(1) – As Required per AWS A5.1/A5.1M: 2004%Mn%Si%P%SRequirementsAWS E60110.20 max.1.20 max.1.00 max.Not SpecifiedNot SpecifiedTypical Performance(3)As-Welded0.11 - 0.160.32 - 0.600.09 - 0.280.006 - 0.0110.004 - 0.013%Ni%Cr%Mo%V0.30 max.0.20 max.0.30 max.0.08 max. 0.060.01 - 0.04 0.02 0.01RequirementsAWS E6011Typical PerformanceAs-Weldedmig & tig%C(3)(1)Typical all weld metal.(2)Measured with 0.2% offset.(3)See test results disclaimer on pg. 9.TYPICAL OPERATING PROCEDURESPolarity1/8 in(3.2 mm)5/32 in(4.0 mm)3/16 in(4.8 mm)7/32 in(5.6 mm)1/4 in(6.4 mm)AC50 - 8575 - 12090 - 160120 - 200150 - 260190 - 300DC 40 - 7570 - 11080 - 145110 - 180135 - 235170 - 270metal-coredCurrent (Amps)3/32 in(2.4 mm)Preferred polarity is listed first.W E L D I N G C O N S U M A B L E S C ATA L O G68281 017 096 ACG.indd 31[31]3/30/10 2:40 PM

Stick (SMAW) ElEctrodEFleetweld 35LS Mild Steel, CellulosicAWS E6011introductionWelding PositionsKey Features Use for tack welds under InnershieldAll Light, easy to remove slag AC and DC weldingConformances depositsAWS A5.1/A5.1M: 2004ASME SFA-A5.1:CWB/CSA W48-06:Typical ApplicationsE6011E6011E4311stick Tack welding Steel with moderate surface contaminantsmig & tigDIAMETERS / PACKAGINGDiameterin (mm)Lengthin (mm)50 lb (22.7 kg)Carton1/8 (3.2)5/32 (4.0)14 (350)14 (350)ED028158ED028159metal-cored[32]68281 017 096 ACG.indd 32THE LINCOLN ELECTRIC COMPANY3/30/10 2:40 PM

Stick (SMAW) ElEctrodEFleetweld 35LS (AWS E6011)Yield Strength(2)MPa (ksi)Tensile StrengthMPa (ksi)Elongation%Charpy V-NotchJ (ft lbf)@-29 C (-20 F)330 (48) min.430 (60) min.22 min.27 (20) min.22 - 3129 - 64 (22 - 47)RequirementsAWS E6011Typical Performance(3)As-Welded400 - 435 (58 - 63)495 - 560 (72 - 81)introductionMECHANICAL PROPERTIES (1) – As Required per AWS A5.1/A5.1M: 2004stickDEPOSIT COMPOSITION(1) – As Required per AWS A5.1/A5.1M: 2004%Mn%Si%P%SRequirementsAWS E60110.20 max.1.20 max.1.00 max.Not SpecifiedNot SpecifiedTypical Performance(3)As-Welded0.09 - 0.190.32 - 0.900.03 - 0.130.007 - 0.0170.005 - 0.011%Ni%Cr%Mo%V0.30 max.0.20 max.0.30 max.0.08 max. 0.060.01 - 0.04 0.020.01 max.RequirementsAWS E6011Typical PerformanceAs-Weldedmig & tig%C(3)(1)Typical all weld metal.(2)Measured with 0.2% offset.(3)See test results disclaimer on pg. 9.TYPICAL OPERATING PROCEDURESPolarity5/32 in(4.0 mm)AC80 - 130120 - 160DC 70 - 120110 - 150metal-coredCurrent (Amps)1/8 in(3.2 mm)Preferred polarity is listed first.W E L D I N G C O N S U M A B L E S C ATA L O G68281 017 096 ACG.indd 33[33]3/30/10 2:40 PM

Stick (SMAW) ElEctrodEFleetweld 37 Mild Steel, RutileAWS E6013introductionKey FeaturesWelding Positions Operable with low amperages on sheet metal Excellent bead appearance Slag control accommodates vertical downAllweldingConformancesAWS A5.1/A5.1M: 2004ASME SFA-A5.1:ABS:Lloyd’s Register:DNV Grade:GL:BV Grade:CWB/CSA W48-06:Typical Applicationsstick Sheet metal Irregular short welds that change positions Maintenance or repair welding For use with small AC welders with low OCVE6013E6013E60133M111E4313mig & tigDIAMETERS / PACKAGINGDiameterin 4.0)(4.8)[34]68281 017 096 ACG.indd 34Lengthin (mm)1212141414(300)(300)(350)(350)(350)1 lb (0.5 kg) Plastic Tube6 lb (3.6 kg) Carton5 lb (2.3 kg) Plastic Tube20 lb (9.1 kg) Carton50 lb (22.7 D010170ED010161ED010153ED010165ED010156THE LINCOLN ELECTRIC COMPANY3/30/10 2:40 PM

Stick (SMAW) ElEctrodEFleetweld 37 (AWS E6013)Yield Strength(2)MPa (ksi)Tensile StrengthMPa (ksi)Elongation%Charpy V-NotchJ (ft lbf)@-29 C (-20 F)330 (48) min.430 (60) min.17 min.Not Specified20 - 3137 - 76 (27 - 56)RequirementsAWS E6013Typical Performance(3)As-Welded400 - 440 (58 - 64)460 - 515 (67 - 75)introductionMECHANICAL PROPERTIES (1) – As Required per AWS A5.1/A5.1M: 2004stickDEPOSIT COMPOSITION(1) – As Required per AWS A5.1/A5.1M: 2004%Mn%Si%P%SRequirementsAWS E60130.20 max.1.20 max.1.00 max.Not SpecifiedNot SpecifiedTypical Performance(3)As-Welded0.04 - 0.070.32 - 0.450.16 - 0.240.01 - 0.020.01 - 0.02%Ni%Cr%Mo%V0.30 max.0.20 max.0.30 max.0.08 max. 0.070.02 - 0.04 0.020.01 - 0.02RequirementsAWS E6013Typical PerformanceAs-Weldedmig & tig%C(3)(1)Typical all weld metal.(2)Measured with 0.2% offset.(3)See test results disclaimer on pg. 9.TYPICAL OPERATING PROCEDURESPolarity3/32 in(2.4 mm)1/8 in(3.2 mm)5/32 in(4.0 mm)3/16 in(4.8 mm)AC50 - 8075 - 105110 - 140160 - 200205 - 260DC 45 - 7570 - 95100 - 135145 - 180190 - 235metal-coredCurrent (Amps)5/64 in(2.0 mm)Preferred polarity is listed first.W E L D I N G C O N S U M A B L E S C ATA L O G68281 017 096 ACG.indd 35[35]3/30/10 2:40 PM

STICK (SMAW) ELECTRODESSelection GuideINTRODUCTIONStick (SMAW) ElectrodeProduct Name& AWS ClassDiameters Availablein (mm)Key Features3/32 1/8 5/32 3/16 7/32 1/4(2.4) (3.2) (4.0) (4.8) (5.6) (6.4)Low Alloy, CellulosicShield-Arc 70 (E8010-G)Pipeliner 8P (E8010-P1)Shield-Arc 90STICK(E9010-G) Light slag for minimal arc interference Deep penetration Clean, visible weld puddle High productivity in vertical down andout-of-position pipe welding Q2 Lot - Certificate showing actual depositchemistry available online Light slag for minimal arc interference Deep penetration Clean, visible weld puddle (E7018-A1 H4R)Excalibur 8018-B2 MR(E8018-B2 H4R) Designed for welding 0.50% molybdenum steel Premium arc performance Square coating burn-off Designed for welding 1.25% chromium, 0.50%molybdenum steel Premium arc performance Square coating burn-off MIG & TIGExcalibur 8018-B2 XF MR X-Factor 15 ppm(E8018-B2 H4R) Premium arc performance and strikeability Q2 Lot - Certificate showing actual depositchemistry available onlineExcalibur 8018-C1 MR(E8018-C1 H4R)Excalibur 8018-C3 MR(E8018-C3 H4R)METAL-COREDPipeliner 18P(E8018-G H4)(1)[20](1)3/32 1/8 5/32 3/16 7/32 1/4(2.4) (3.2) (4.0) (4.8) (5.6) (6.4)Low Alloy, Low HydrogenExcalibur 7018-A1 MR(1) Designed to produce a nominal 2-1/4% nickeldeposit Premium arc performance Square coating burn-off Designed to produce a 1% nickel deposit Premium arc performance Square coating burn-off Low hydrogen, vertical up capability on X70grade pipe Charpy V-Notch impact toughness tested to-46 C (-50 F) Q2 Lot - Certificate showing actual depositchemistry available online Manufactured to 5.0 mm diameter.THE LINCOLN ELECTRIC COMPANY

Stick (SMAW) ElEctrodEFleetweld 47 Mild Steel, RutileKey FeaturesWelding Positions High deposition rates Excellent operator appeal Easy to use Operates on low amperagesAllintroductionAWS E7014Conformances Maintenance and repair welding Sheet metal and fillet welds Heavy sectionsstickTypical ApplicationsE7014E7014E70141M111E4914mig & tigAWS A5.1/A5.1M: 2004ASME SFA-A5.1:ABS:Lloyd’s Register:DNV Grade:GL:BV Grade:CWB:Diameterin (mm)3/321/85/323/16(2.4)(3.2)(4.0)(4.8)Lengthin (mm)14141414(350)(350)(350)(350)1 lb (0.5 kg) Plastic Tube6 lb (3.6 kg) Carton5 lb (2.3 kg) Plastic Tube20 lb (9.1 kg) Carton50 lb 2430ED010189ED010183ED010193ED010186W E L D I N G C O N S U M A B L E S C ATA L O G68281 017 096 ACG.indd 37metal-coredDIAMETERS / PACKAGING[37]3/30/10 2:40 PM

Stick (SMAW) ElEctrodEFleetweld 47 (AWS E7014)introductionMECHANICAL PROPERTIES (1) – As Required per AWS A5.1/A5.1M: 2004Yield Strength(2)MPa (ksi)Tensile StrengthMPa (ksi)Elongation%Charpy V-NotchJ (ft lbf)@ -29 C (-20 F)400 (58) min.490 (70) min.17 min.Not SpecifiedRequirementsAWS E7014Typical Performance(3)As-Welded400 - 510 (58 - 74)490 - 585 (70 - 85)17 - 2945 - 103 (33 - 76)DEPOSIT COMPOSITION(1) – As Required per AWS A5.1/A5.1M: 2004stickRequirementsAWS E7014Typical PerformanceAs-Weldedmig & tigTypical Performance(3)As-WeldedTypical all weld metal.(2)%Mn%Si%P%S0.15 max.1.25 max.0.90 max.0.035 max.0.035 max.0.06 - 0.100.25 - 0.670.04 - 0.690.01 - 0.02 0.02(3)RequirementsAWS E7014(1)%C%Ni%Cr%Mo%V%Mn Ni Cr Mo V0.30 max.0.20 max.0.30 max.0.08 max.1.50 max.0.02 - 0.090.01 - 0.05 0.02 0.020.37Measured with 0.2% offset.(3)See test results disclaimer on pg. 9.TYPICAL OPERATING PROCEDURESCurrent (Amps)metal-coredPolarity3/32 in(2.4 mm)1/8 in(3.2 mm)5/32 in(4.0 mm)3/16 in(4.8 mm)AC80 - 100110 - 155150 - 225200 - 285DC 75 - 95100 - 145135 - 200185 - 235Preferred polarity is listed first.[38]68281 017 096 ACG.indd 38THE LINCOLN ELECTRIC COMPANY3/30/10 2:40 PM

Stick (SMAW) ElEctrodEJetweld 2 Mild Steel, High DepositionKey FeaturesWelding Positions High deposition rates Smooth bead appearance Shallow penetration for minimal dilutionFlat & HorizontalintroductionAWS E6027Conformances Multiple pass welding Fast-fill single pass welds Fillet and lap weldsstickTypical ApplicationsE6027E6027E60273M333E4327mig & tigAWS A5.1/A5.1M: 2004ASME SFA-A5.1:ABS:Lloyd’s Register:DNV Grade:GL:BV Grade:CWB/CSA W48-06:DIAMETERS / PACKAGINGLengthin (mm)50 lb (22.7 kg)Carton3/16 (3.2)1/4 (4.0)18 (450)18 (450)ED010501ED010500metal-coredDiameterin (mm)W E L D I N G C O N S U M A B L E S C ATA L O G68281 017 096 ACG.indd 39[39]3/30/10 2:40 PM

Stick (SMAW) ElEctrodEJetweld 2 (AWS E6027)introductionMECHANICAL PROPERTIES (1) – As Required per AWS A5.1/A5.1M: 2004Yield Strength(2)MPa (ksi)Tensile StrengthMPa (ksi)Elongation%Charpy V-NotchJ (ft lbf)@ -29 C (-20 F)330 (48) min.430 (60) min.22 min.27 (20) min.26 - 3453 - 80 (39 - 60)RequirementsAWS E6027Typical Performance(3)As-Welded365 - 395 (53 - 57)435 - 470 (63 - 68)DEPOSIT COMPOSITION(1) – As Required per AWS A5.1/A5.1M: 2004stick%C%Mn%Si%P%SRequirementsAWS E60270.20 max.1.20 max.1.00 max.Not SpecifiedNot SpecifiedTypical Performance(3)As-Welded0.02 - 0.050.56 - 0.960.12 - 0.410.016 - 0.0240.005 - 0.013%Ni%Cr%Mo%V0.30 max.0.20 max.0.30 max.0.08 max.0.03 - 0.070.02 - 0.050.01 - 0.04 0.002RequirementsAWS E6027mig & tigTypical PerformanceAs-Welded(3)(1)Typical all weld metal.(2)Measured with 0.2% offset.(3)See test results disclaimer on pg. 9.TYPICAL OPERATING PROCEDURESCurrent (Amps)metal-coredPolarity3/16 in(4.8 mm)1/4 in(6.4 mm)AC250 - 300350 - 450DC 230 - 270315 - 405Preferred polarity is listed first.[40]68281 017 096 ACG.indd 40THE LINCOLN ELECTRIC COMPANY3/30/10 2:40 PM

Stick (SMAW) ElEctrodEJetweld 1 Mild Steel, High DepositionKey FeaturesWelding Positions High deposition rates Smooth bead appearance Minimal spatter Shallow penetrationFlat & HorizontalintroductionAWS E7024-1Conformancesstick Large welds Slightly downhill (15 max) positions Multiple pass weldingE7024-1E7024-1E7024-11M111E4924-1mig & tigTypical ApplicationsAWS A5.1/A5.1M: 2004ASME SFA-A5.1:ABS:Lloyd’s Register:DNV Grade:GL:BV Grade:CWB/CSA W48-06:DIAMETERS / 4)Lengthin (mm)1414181818(350)(350)(450)(450)(450)W E L D I N G C O N S U M A B L E S C ATA L O G68281 017 096 ACG.indd 4150 lb (22.7 etal-coredDiameterin (mm)[41]3/30/10 2:40 PM

Stick (SMAW) ElEctrodEJetweld 1 (AWS E7024-1)introductionMECHANICAL PROPERTIES (1) – As Required per AWS A5.1/A5.1M: 2004Yield Strength(2)MPa (ksi)Tensile StrengthMPa (ksi)Elongation%Charpy V-NotchJ (ft lbf)@ -18 C (0 F)400 (58) min.490 (70) min.22 min.27 (20) min.22 - 3127 - 60 (20 - 44)RequirementsAWS E7024-1Typical Performance(3)As-Welded455 - 490 (66 - 71)530 - 565 (77 - 82)DEPOSIT COMPOSITION(1) – As Required per AWS A5.1/A5.1M: 2004stick%C%Mn%Si%P%SRequirementsAWS E7024-10.15 max.1.21 max.0.90 max.0.035 max.0.035 max.Typical Performance(3)As-Welded0.03 - 0.060.63 - 1.020.13 - 0.680.010 - 0.0220.005 - 0.011%Ni%Cr%Mo%V%Mn Ni Cr Mo V0.30 max.0.20 max.0.30 max.0.08 max.1.50 max. 0.060.01 - 0.04 0.020.01 max.0.75RequirementsAWS E7024-1mig & tigTypical PerformanceAs-Welded(1)Typical all weld metal.(2)(3)Measured with 0.2% offset.(3)See test results disclaimer on pg. 9.TYPICAL OPERATING PROCEDURESCurrent (Amps)metal-coredPolarity1/8 in(3.2 mm)5/32 in(4.0 mm)3/16 in(4.8 mm)7/32 in(5.6 mm)1/4 in(6.4 mm)AC115 - 175180 - 240240 - 300300 - 380340 - 440DC 100 - 160160 - 215220 - 280270 - 340320 - 400Preferred polarity is listed first.[42]68281 017 096 ACG.indd 42THE LINCOLN ELECTRIC COMPANY3/30/10 2:40 PM

Stick (SMAW) ElEctrodEPipeliner 16P Mild Steel, Low HydrogenKey FeaturesWelding Positions Hot, fill and cap pass welding up to X60 Low hydrogen, vertical up capability onAll Q2 Lot - Certificate showing actual depositConformances Charpy V-Notch impact toughness testedAWS A5.1/A5.1M: 2004ASME SFA-A5.1:introductionAWS E7016 H4X60 grade pipechemistry available onlinestickto -46 C (-50 F)E7016 H4E7016 H4Typical Applicationsmig & tig Root pass welding of up to X100 grade pipeDiametermm (in)Lengthin (mm)50 lb (22.7 kg)Easy Open Can2.5 (3/32)3.2 (1/8)4.0 (5/32)14 (350)14 (350)18 (450)ED030916ED030917ED030918W E L D I N G C O N S U M A B L E S C ATA L O G68281 017 096 ACG.indd 43metal-coredDIAMETERS / PACKAGING[43]3/30/10 2:40 PM

Stick (SMAW) ElEctrodEPipeliner 16P (AWS E7016 H4)introductionMECHANICAL PROPERTIES (1) – As Required per AWS A5.1/A5.1M: 2004RequirementsAWS E7016 H4Typical Performance(3)As-WeldedCharpy V-NotchJ (ft lbf)@ -29 C (-20 F)@ -40 C (-40 F)Yield Strength(2)MPa (ksi)Tensile StrengthMPa (ksi)Elongation%400 (58) min.490 (70) min.22 min.27 (20) min.Not Specified435 - 545 (63 - 79)550 - 640 (80 - 93)23 - 3484 - 161 (62 - 119)65 - 129 (48 - 95)DEPOSIT COMPOSITION(1) – As Required per AWS A5.1/A5.1M: 2004stickRequirementsAWS E7016 H4Typical PerformanceAs-Welded%C%Mn%Si%P%S%Ni0.15 max.1.60 max.0.75 max.0.035 max.0.035 max.0.30 max.0.04 - 0.081.10 - 1.600.39 - 0.670.005 - 0.0200.004 - 0.012 0.07%Cr%Mo%V%Mn Ni Cr Mo VDiffusible HydrogenmL/100g weld metal0.20 max.0.30 max.0.08 max.1.75 max.4.0 max.0.01 - 0.030.01 - 0.021.14 - 1.711-4(3)RequirementsAWS E7016 H4Typical PerformanceAs-Weldedmig

WELDING CONSUMABLES CATALOG [19] introduction stick mig & tig metal-cored (1) Manufactured to 2.5 mm diameter.(2) Manufactured to a 5.0 mm diameter. Selection Guide Stick (SMAW) ElEctrodES Stic