Transcription

Fundamentals of CNCMachiningA Practical Guide for BeginnersCompliments of NexGenCAM, Inc.

Fundamentals of CNC MachiningDesk CopyCompliments of NexGenCAM

Copyright 2012 HSMWorks, ApSAll Rights Reserved.Reproduction or translation of any part of this work beyond that permitted by Sections 107 and 108 of the 1976 United StatesCopyright Act without the expressed written permission of the copyright owner is unlawful. Request for permission or furtherinformation should be addressed to HSMWorks, ApSDisclaimer of LiabilityThe material in this manual was checked and deemed to be accurate. The entire risk as to its accuracy and quality is with the reader.In no event shall NexGen Manufacturing Systems, Inc. be liable for direct, indirect, or consequential damages resulting from anydefect in this material.TrademarksAll brands are the trademark of their respective owners.Printed in the United States of AmericaRegistered with the Library of CongressFundamentals of CNC MachiningDesk CopyDocument Number: 060711ISBN-13: 978-0-615-50059-1ISBN-10: 0615500595

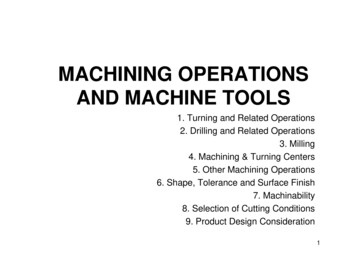

Fundamentals of CNC MachiningTable of ContentsChapter 1:Introduction& CNC ProcessOverviewChapter 2:ShopSafetyChapter3:CNC ToolsDescription . 1-3Prerequisites . 1-3Audience . 1-3Course Design . 1-3SRP vs. RP . 1-4Prototype vs. Production Machining. 1-4Required Tools and Equipment . 1-4Lessons and Appendices . 1-5InstructionalResources . 1-5Recommended Use . 1-6Overview of CAD/CAM Process . 1-6Overview . 2-3SafetyAwareness . 2-3PersonalConduct& Shop Etiquette. 2-4Shop Clothing . 2-4Proper Shop Attire Illustration . 2-5General Safety Practices. 2-6CNC Safety Practices . 2-6SafetyContract. 2-7SafetyContractForm . 2-8Overview . 3-3End Mills . 3-3Face Mill . 3-4Corner Radius Mill . 3-5Slot Mill/SlottingSaw . 3-5Center-Spot Drill . 3-5Twist Drill. 3-6Tap. 3-6Reamer . 3-7Counterbore . 3-8CuttingTool Fundamentals . 3-8Rotational Direction . 3-8Chip Formation . 3-8Chip Load . 3-9Climb vs. ConventionalMilling . 3-9Cutting Speeds and Feeds Formulas . 3-10Speed Formula . 3-11Feed Formula . 3-12TapFeed Formula . 3-12Speed/FeedExamples . 3-13Milling Speed/FeedExample . 3-13Drill Speed/FeedExample . 3-14i

Fundamentals of CNC MachiningContentsTap Speed/FeedExample . 3-15Maximum Spindle Speed Example. 3-16Cutting Data . 3-17Best Practices MachiningParameters . 3-18Troubleshooting Speed/FeedProblems . 3-19Chapter4:CoordinateSystemsChapter5:CNC ProgrammingLanguageChapter6:CNC OperationOverview . 4-3CartesianCoordinate System . 4-3Number Line . 4-33D CartesianCoordinate System . 4-3Quadrants . 4-4Units . 4-5Vertical Machining Center (VMC) Motion . 4-5CNC Motion Control. 4-6CNC Machine Coordinates . 4-6About Machine Home Position . 4-7WorkCoordinate System (WCS) . 4-8WCS Example-1 . 4-9WCS Example-2 . 4-10WCS Example-3 . 4-11Machine and Tool Offsets . 4-12Machine Offset XY . 4-12Machine Offset Z. 4-13ToolLenght Offset (TLO) . 4-13Overview . 5-3CNC Language and Structure. 5-3Program Format . 5-4CNC Editor . 5-4Alphabetic&SpecialCharacterAddress Codes . 5-5AlphabeticAddress Code Definitions . 5-5G&M Codes . 5-8G-Codes. 5-8M-Codes . 5-8Select G-Code Definitions (Expanded) . 5-9Canned Cycles . 5-10Overview of CNC Setup and Operation . 6-3Machine and Tool Offsets . 6-5Fixture Offset XY . 6-5Fixture Offset Z . 6-6ToolLength Offset (TLO) . 6-7Haas Control Face. 6-8Haas Keyboard . 6-9Start/Home Machine. 6-10Load Tools . 6-11Set ToolLength Offset (TLO) . 6-13Set Fixture Offset XY. 6-17ii

ContentsFundamentals of CNC MachiningSet Fixture Offset Z . 6-21Load CNC Program . 6-24Run CNC Program . 6-26AdjustingDiameter (CDC) Offsets . 6-27Shut Down CNC . 6-29Chapter7:2D MillingToolpathsChapter8:CNC TurningOverview . 7-32D/3D/4X/5X Defined . 7-32D (Prismatic) Parts . 7-33D Parts. 7-44-Axis Parts . 7-4Standard CAD Views vs. CAM Views . 7-6CAD Features vs. MachiningFeatures . 7-6Toolpaths by Type and Use . 7-72D MachiningFeaturesExample . 7-82D ToolpathTerminology. 7-9Facing . 7-102D Contouring . 7-11Cutter Diameter Compensation. 7-12Pocketing . 7-13Slot Milling . 7-14ChamferMilling . 7-15Radius (Corner-Round) Milling . 7-16Center Drill . 7-17Drilling . 7-18Tapping . 7-19Overview . 8-3Lathe Components . 8-4Spindle . 8-5Turret . 8-6LatheCoordinate System . 8-8Driven (Live) Tools . 8-9ImaginaryTool Tip . 8-10Part Datum . 8-11Tools and ToolHolders. 8-12Chip Breaker . 8-12Relief Angle . 8-13ToolCutting Angles . 8-13Rake Angle . 8-14Insert Designations . 8-15LatheTool Types . 8-17Face/Turn Tools . 8-17Groove Tool . 8-18Bore Tool. 8-19Thread Tool . 8-20CutoffTool . 8-21Cutting Speeds and Feeds . 8-22Speed/FeedExample . 8-23CuttingFeedExample . 8-24Lathe Setup and ProgrammingExample . 8-25Setup . 8-26iii

Fundamentals of CNC MachiningContentsFace . 8-27Rough . 8-28Finish . 8-29Groove . 8-30Thread . 8-31Drill. 8-32Bore . 8-33Cutoff . 8-34Chapter9:3D ToolpathsChapter10:Milling SetupsOverview . 9-33D Cutter Compensation . 9-3Tolerances . 9-43D Toolpath Setups . 9-63D Roughing . 9-6Parallel Finish . 9-7ScallopHeight . 9-83D Scallop . 9-9REST Milling . 9-10PencilToolpaths . 9-11Conceptualizing 3D Toolpaths . 9-12Overview . 10-3Fixture Components . 10-3Subplates and Angle Plates . 10-3Clamps . 10-4ShoulderBolts and Dowel Pins . 10-5Vise Accessories . 10-5Hard Jaws . 10-6Soft Jaws . 10-6Appendix A:CNC MillingWork-Holding ExamplesProject 1 : Install Vise . A-2Project 2 : Install Vise Jaws. A-4Project 3 : Square Block. A-5Project 4 : Contour Square Step . A-13Project 5 : Base . A-16Project 6 : Housing . A-21Project 7 : Fan Blades .

CNC Machining is a very broad subject and there are many ways to do most things. Covering all options would fill volumes and isbeyond the scope of any one book or course. The goal of this course is not to turn and engineer into a journeyman machinist. Rather,