Transcription

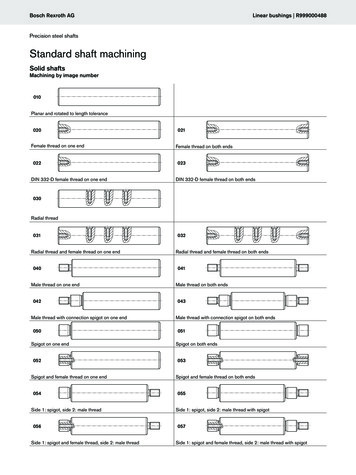

MACHINING OPERATIONSAND MACHINE TOOLS1. Turning and Related Operations2. Drilling and Related Operations3. Milling4. Machining & Turning Centers5. Other Machining Operations6. Shape, Tolerance and Surface Finish7. Machinability8. Selection of Cutting Conditions9. Product Design Consideration1

1. Turning & Related Operations Turning – a machiningvRotational Speed: N process in which aπDosingle-point tool removeDo D f 2dmaterial from theFeed rate: f r Nfsurface of a rotatingLwork piece. (Lathe)Time of machining: Tm Material Removal Rate:DovDffrMRR vfddLf2

Operations related to TurningContour turningFacingTaper turningCutoffThreadingChamferingForm turningBoringDrillingKnurling3

Work Holding Mounting betweentwo centers (Dog &Live center) Chuck Collet Face plate4

Engine Lead Screw5

Other Lathes & Turning Machine Toolroom Lathe and Speed Lathe Turret Lathe– The tailstock is replaced with a turret Chucking Machines – No tailstock Automatic Bar Machine – Similar to chuckmachine but with a collet– A single- and multiple-spindle bar machines NC Lathe6

Boring Machining Boring – Cutting is done inside diameter of the workmaterialHorizontal Boring MachiningVertical Boring Machining7

2. Drilling & Related Operations Geometry of Twist drill– Shank, Neck and Drill body– Helix angle, Point angle, Flute, cuttingedge, Chisel edge, Margin Cutting conditionsv Feed rate: f Nff(in/rev)Spindle: N rπDπD 2 f rMetal Removal Rate: MRR t A 4Machining time: Tm f r For a through holeAdTm For a blind holedtfr8

Twist Drill and Drilling OperationsFrom Kalpakjian and Schmid (2003)9

Machine Tool for drilling Drill press– Upright drill– Bench drill– Radial drill– Gang drill - 2-6 drills together– NC drill Vice, Jig and fixture10

3. Milling MillingUp Milling– A machine operation in which awork part is fed past a rotatingcylindrical tool with multipleedges. (milling machine) TypesDown MillingPartial faceSlab– Peripheral milling Slab, slotting, side andstraddle milling Up Milling (Conventional) &down milling (Climb)– Facing milling Conventional face, Partialface, End, Profile, Pocket &contour millingsConventional ipheral MillingFace Milling11

Cutting conditions Milling cutters– Plain milling cutters– Form milling cutters– Face milling cutters– End milling cuttersRadial RakeAngle Cutting conditionsvN Spindle rotation speed:πDReliefAngleClearanceAngleFeed rate: f r Nnt fMaterial Removal Rate: MRR wdf r12

Milling Machines Knee-and-column MillingMachine– Horizontal and Vertical types– Universal and Ram types Bed-type MillPlaner-type Mills – the largestcategoryTracer (profile) Mill –reproduce an irregular partgeometryCNC Milling machineHorizontalUniversalVerticalRamBed-type mill13

Machining Centers Machining center – highly automatedmachine tool capable of performingmultiple machining operations under CNCcontrol.– Automatic tool changer– Pallet shuttles– Automatic workpart positioning CNC turning center14

A CNC mill-turn centerA series of operations without human interactionsStockTurningMillingDrillingA partFrom a castingFrom a round stockFrom another casting15

5. Other Machining Operations Shaping and planing– A single-point tool moves linearly relative to the work part– Shaping - A tool moves– Planing – A workpart moves Broaching– Performed by a multiple-tooth cutting tool by moving linearlyrelative to the work in the direction of the tool axis. Sawing– Hacksawing, Bandsawing, and Circular sawing16

BroachingSemifinishingteethFinishing teethRoughing teeth17

SawingHacksaw - linear reciprocating motionBandsaw - linear continuous motionSaw Blade (Straight & Undercut toothor Straight & Raker sets)18

1. MACHINING OPERATIONS AND MACHINE TOOLS. 1. Turning and Related Operations. 2. Drilling and Related Operations. 3. Milling. 4. Machining & Turning Centers