Transcription

The World Leader inCold-Formed Steel TrussesTruss Design Manuala division of ITW Building Components Groupa division of ITW Building Components Group888.565.9181 www.TrusSteel.comTruss Design ManualV2

TRUSS DESIGN MANUALTABLE OF CONTENTS1OVERVIEW4ENGINEERING / SHOP ers & Designers4.03Shop Drawings1.03Contractor & Installer4.04Notes Page1.04Truss Components & Code Recognition1.05Framing & Connections5DETAILS / CONNECTIONS1.06Authorized TrusSteel Fabricators5.01Overview1.07Education & CES5.03Standard Details1.08Notes Page5.04Truss-to-Truss Connections5.06Gable Outlooker Connections2APPLICATIONS5.07Truss-to-Bearing Connections2.01Applications5.13Piggyback and Valley Truss Connections2.02Projects6TRUSS FABRICATION / QUALITY6.01Overview3SPECIFYING / DESIGNING3.01Overview3.02Building Codes & Design Standards7INSTALLATION / BRACING3.03Information Required for Truss Design7.01Site Conditions & Safety3.05TrusSteel System7.02Handling & Storage3.07Wind Loading7.03Lifting & Staging3.10Snow Loading7.04Bracing3.11Seismic Loading7.05Rafting3.13Sound Control3.14Sustainability & LEED8REFERENCES / RESOURCES3.15Fire Resistance & UL8.01Industry Resources3.16Trusses as Building Components8.02Glossary3.17Roof Truss Systems - Framing8.07Weights of Materials3.22Roof Truss Systems - Sample Spans3.23Floor Truss Systems3.26Guide Specifications Copyright 2012 ITW Building Components Group, Inc.This Design Manual is intended as a guide to building professionals for suggested uses of TrusSteel trusses. The building code of jurisdiction and a truss designprofessional should be consulted before incorporating information from this publication into any plan or structure.ITW Building Components Group, Inc., nor any of its divisions or companies, does not warrant the recommendations and information contained herein as properunder all conditions and expressly disclaims any responsibility for damages arising from the use, application or reliance on the recommendations contained herein.1206

NOTES

OVERVIEWUnmatched strength and stiffness in acold-formed steel truss.TrusSteel is the most accepted, most specified coldformed steel (CFS) truss system on the market today. Noother building component combines strength, stiffness, fireresistance, insect resistance and design flexibility so well.The unique, patented truss chord shape and DoubleShearTM fasteners, combined with multiple types of webshapes, make TrusSteel CFS trusses, pound-for-pound, thestrongest and stiffest cold-formed steel trusses on themarket. Not surprisingly, these same characteristicscombine to create a light, economical steel buildingcomponent having exceptional load-span capabilities, withclear spans in excess of 80 ft.Supported by powerful Alpine steelVIEWTM design andanalysis software, TrusSteel CFS trusses provide reliable,economical structural solutions for almost every roof or floorapplication.The Most Trusted Name in CFS TrussesAlpine Engineered Products, Inc. was a drivingforce in the creation of the wood truss industryover forty years ago. Since that beginning, theindustry has consistently recognized Alpine asengineering and innovation leaders. Now, as apart of the ITW Building Components Group, Inc.Alpine provides the same leadership in thefounding and development of the pre-engineeredCFS truss industry.TrusSteel is actively involved in programs withthe International Code Council and UnderwritersLaboratories.Every TrusSteel truss is designed using theindustry-leading Alpine steelVIEW software.steelVIEW is the most accurate truss designsoftware in the industry for a number of reasons,including: True multi-node modeling, not the estimatedThe TrusSteel Division has decades of combinednode modeling used by other CFS truss designexpertise in the truss and CFS building productssoftware packages.industry. The TrusSteel product line combinesover forty years of truss engineering and Multiple load case analysis applied to eachsoftware knowledge with cutting-edgetruss, including gravity, wind, seismic androllforming technology and the proven quality ofunbalanced conditions.in-house truss fabrication. As a result, moreTrusSteel trusses are installed each year than Analysis methodologies derived from the mostany other proprietary CFS truss system.extensive full-scale testing program in theindustry, utilizing the AISI Specification for theTrusSteel provides ongoing leadership to theDesign of Cold-Formed Steel Structuraltruss industry through hands-on participation inMembers.key organizations such as the Cold-Formed SteelAuthorized TrusSteel Fabricators, operatingEngineers Institute (formerly LGSEA), thethe steelVIEW software in-house andAmerican Iron and Steel Institute, the CFSsupported by TrusSteel engineeringCouncil of the SBCA, the AISI Committee onresources, provide solutions for the mostFraming Standards (COFS), and the Center forcomplex truss systems.Cold-Formed Steel Structures.AmericanIron and SteelInstitute12345678This Manual is intended for quick reference only. Drawings and illustrations shown are samples only and are not intended for detailingor construction. Please refer to the TrusSteel Standard Details for technical information on connection design, product use and safety.1.01

OVERVIEWSpecifiers & DesignersDesign FlexibilityOutstanding design flexibilityRecognized fire resistanceTrusSteel CFS trusses provide the same spancapabilities and design flexibilities as woodtrusses. The pre-engineered system allows muchgreater design flexibility than steel “C” trussframing. As a result, you can design in familiarroof lines - pitched or flat, with hips, gables,gambrels, monos, mansards, cantilevers,Project Phoenix-rebuilding the Pentagon after 9-11 overhangs, scissors and floor trusses. Thisdesign flexibility makes TrusSteel trusses idealfor almost any building type: new construction,retrofit, commercial, institutional, military,educational, industrial and municipal structures.Noncombustible TrusSteel trusses provideintegral, recognized fire resistance that does notfade with time. See the following pages for a listof TrusSteel’s useful, cost-saving UL-listed roofand floor assemblies.Assured structural performanceWith over forty years of experience in the trussindustry, you can be assured that TrusSteelunderstands the structural performanceofTMtrusses. The powerful steelVIEW truss designsoftware analyzes each truss individually usingthe latest industry standards, guided by the newEasy to specify and designANSI/AISI/COFS -Standard for Cold-Formed SteelThere is a wealth of information available to help Framing -Truss Design. Finally, each truss designyou specify and design with TrusSteel. A guide is reviewed and sealed by a TrusSteelspecification in CSI format, and standard details Professional Engineer.in DXF and DWG formats, can assure that yourspecs and construction documents are accurate Quality trussesand complete. UL, ICC Legacy report (NER) andFlorida Product Approval are available to assist TrusSteel CFS trusses are built in a shopyou in making design decisions and in working environment with experienced fabricationwith code officials. Local TrusSteel fabricators personnel. TrusSteel endorses industry trusscan aid you in making informed decisions about shop quality control standards as developed bythe Cold-Formed Steel Council.project designs and costs.PGA Headquarters, FLResponsible productsEconomical systemTrusSteel CFS trusses contribute to a safe builtenvironment. They do not emit moisture or fumesduring their life cycle. They are resistant to insectattack, and do not provide a medium for thegrowth of mold. And most of the steel used forCFS framing is recycled steel.Since TrusSteel CFS trusses are the stiffesttrusses in the industry, less permanent bracing istypically required in the truss system. Thisfeature, combined with excellent performance at4 ft. on-center spacings or greater, can reducethe cost of the installed truss system throughreduced labor costs, materials and projectduration. Property insurance premium discountsmay provide long-term savings.Nationwide availabilityTrusSteel supports the largest network ofindependent CFS truss fabricators in theindustry. This nationwide network assures thatTrusSteel trusses are available for your projectsin every region of the United States.The Inn at Biltmore Estate, Asheville, NC11.022345678

OVERVIEWContractor & InstallerContractor-Friendly InstallationSafer to HandleSave Time, Effort and MoneyUnique features of TrusSteel trusses make them TrusSteel trusses streamline the building cyclesafe to handle and install. Stiffer trusses add and save money.handling control and reduce the danger of Timely quotations from local TrusSteelbuckling during lifting and placement. The rolledAuthorized Fabricators provideedges of the chords and webs help protectcompetitive prices and define projectworkers from cuts.costs up front. Sealed engineering drawings and codecompliant components expediteEasier to Installsubmittals. Quickerturn-arounds for revisions.TrusSteel trusses can be as light as one-half the Delivered to the site ready to install, shopweight of similar wood or “C” stud steel trusses.built trusses save days of labor.Unlike some other CFS trusses, laterally stiff Faster truss installation with accurateTrusSteel trusses resist folding or “butterflying”.layouts, extensive details, and a full line ofAnd TrusSteel trusses work exceptionally well ininstallation hardware.rafted installations. Easier site inspections withcomprehensive shop drawings andNo Special Tools Requiredclearly identified components.The tools you are now using to install CFSframing are all you need to install TrusSteeltrusses. A full line of TrusSteel constructionhardware allows you to make connections withstandard screws. Installation details andconstruction hardware are available from yourAuthorized TrusSteel Fabricator.Delivered QualityRoof lines plane accurately, eaves and soffitsalign properly, and interior ceiling lines are flatand true. High-quality TrusSteel trusses help youachieve your quality goals.Delivered ValueReduced CallbacksTrusSteel trusses reduce callbacks because they From bidding to punch list, TrusSteel deliversstart straighter and remain straighter than many value to your project through increased safety,other types of trusses. And the dimensional quality, efficiency and cost-effectiveness.stability of steel reduces drywall fastener pops.Truss Rafting12What is Rafting?Why Raft With TrusSteel?Truss rafting is a framing technique wherecompleted trusses, designed to be rafted, areassembled into an entire roof section on theground and then lifted as an assembly onto thebuilding structure. The assembly can consist ofjust the trusses, or the trusses plus purlins, roofdeck and final roofing which is all installed on theground before the assembly is lifted into place.Employing a rafting technique can save time,increase safety and reduce insurance costs onmany projects.The exceptional strength-to-weight characteristicsand lateral stability of the TrusSteel trusses makethem the ideal truss for use in a rafting process.These characteristics allow an average-sizedcrane to lift the completed truss assembly intoposition. The stiffness and stability of theTrusSteel trusses create an assembly that willsurvive a lift without introducing significantadditional bracing.3456781.03

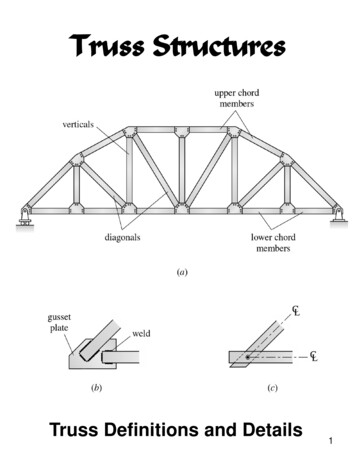

OVERVIEWTruss Components & Code RecognitionTruss ComponentsUnique Chord SectionsPatented FastenersThe symmetrical shape of TrusSteel’s patentedU-shaped chord sections provides nearly equalchord member moment capacity in both in-planedirections. The TrusSteel chord members havesuperior bending strength in out-of-planedirections. These characteristics combine tocreate an efficient truss that is exceptionallystrong and stiff. The recent addition of specialchord sections for short span / low loadconditions and for long span / high lowconditions improves the value engineering of theentire system.TrusSteel is the only CFS truss system in theindustry using Double-ShearTM fastenertechnology. This patented technology provides arigid, bolt-like connection at all chord/webintersections and is specially designed to resistmovement and back-out. Color-coded, markedfasteners create the most dependable, easilyinspected connection available for CFSmaterials.Structural ConnectionsTrusSteel delivers a full line of truss-to-truss andtruss-to-bearing connectors that provideconsistent quality and structural values.WebsTrusSteel utilizes both commercial grade closedtube webs and proprietary roll-formed z-webs todeliver the most cost effective roof system. Bothproducts have unique “double symmetric”properties which contributes to the strength,stiffness and stability of the truss as well asreducing lateral bracing.The industry’s most extensive library of StandardDetails describing our connections, connectors andsection properties is available in various CAD formatson CD or from www.TrusSteel.com.Code RecognitionTrusSteel members are designed and built in compliance with ASTM A370, ASTM A653, ASTM A500,ANSI Standards, and voluntary standards as described in our own reports from UnderwritersLaboratories (UL) and ICC Legacy reports (NER and Florida Product Approval). Visit our web site todownload the complete reports.UL ListingsAssemblies11.0423TrusSteel products qualify for hourly ratings as shown below.45678

OVERVIEWFraming & ConnectionsStandard DetailsHANGER DETAILSTrusSteel ConnectorsUPLIFT ATTACHMENT TO STEELUPLIFT ATTACHMENT TO STEELBottom chord bearing trussto girder trussBottom chord bearing trussto steel beam connectionBottom chord bearing truss toCFS track connectionUPLIFT ATTACHMENTTO CONCRETESPRINKLER PIPE HANGERSPRINKLER PIPE HANGERBottom chord bearing truss toconcrete bearingBottom chord sprinkler pipe hangerusing Sammys x-Press 35 (XP 35)Truss top chord hangerdetailAn extensive set of TrusSteel connectors andapplication details allows a designer to create acomplete truss framing system, whatever theroof type, supporting conditions or other framingmaterials. All TrusSteel connectors are loadrated connectors.Refer to Section 5 of this manual for theengineering values of our full line of connectors(simplified examples are shown here). TrusSteelStandard Details are available for eachconnection application. These Details includeload data as well as installation requirements.Standard Details are available in CAD formatsfrom www.TrusSteel.com and are also containedon the electronic version of this manual.Truss ShopDraw TM and Layout TM InformationSteelDraw Truss Shop Drawings with: All trusses marked and coordinated to layout All truss members clearly identified Complete general notes Fully dimensioned truss profile with bearing elevations,fastener quantities, pitch marks, web bracing locations and more Truss reactions and bearing widths Job-specific loadsLayout Drawings with: Truss marks Key bearing and framing dimensions Truss spacings Connection and bracing details123456781.05

OVERVIEWAuthorized TrusSteel FabricatorsWho is a TrusSteel AuthorizedFabricator?A TrusSteel Authorized Fabricator is anindependently-owned and operated localtruss fabrication shop. Each Fabricatormarkets and services truss projects in their ownregion, backed by over 40 continuous years ofAlpine truss experience. Taken together, the nationwidenetwork of TrusSteel Authorized Fabricators forms a vast repository of truss and framingknowledge at your disposal.What services can an AuthorizedFabricator provide?Knowledge. TrusSteel Authorized Fabricators aretruss experts. They can answer questions abouttruss applications and installations as well asquestions about pricing and delivery. Do youhave questions about truss layouts, spans,spacings, profiles, systems, connections,bracing, overhangs, mechanical chases.andmore? Call your local Authorized Fabricator. Theycan save you money up front in your designdevelopment or structural design process.Engineering. All TrusSteel trusses areengineered trusses. An Authorized Fabricator canprovide not just building components, but canalso provide individually-engineered and sealedtrusses. A staff of over fifty engineers, coveringevery state in the USA, reviews and seals over4,500,000 truss designs each year.and highly accurate cutting/assemblingdrawings created by the steelVIEW software.TrusSteel trusses are built with patented DoubleShearTM fasteners and internal connectors toassure consistently accurate trusses.How can I find local AuthorizedFabricators?You can find a list of Authorized Fabricators onthe TrusSteel Web site at www.TrusSteel.com. Or,you can call the TrusSteel information line at888-565-9181. Wherever your project is located,you can probably find at least two AuthorizedFabricators to provide competitive quotes onyour project.Additional ServicesTrusSteel provides steelVIEWTM software to allAuthorized Fabricators. This powerful proprietarysoftware package includes 3-D modeling andtruss layout, truss engineering and biddingmodules. By-products of these key elements areindustry-best truss layouts, shop drawings andcutting sheets.Quality trusses. Each Authorized Fabricatorbuilds TrusSteel trusses in a plant environment toensure the highest quality components. Trussesare built according to engineered shop drawings11.0623456Structural Services. Through their affiliationwith strategic partner BBD Engineering & DesignFirm, LLC (www.bbdengineering.com), a feebased, full-service consulting engineering firm,TrusSteel Authorized Fabricators can provide fullframing system design services (including thedesign of special connections, bracing, purlins,decks - even entire building framing systems).78

OVERVIEWEducational & CESCold-Formed Steel Trusses 101Attention:Project Architectsand EngineersThe TrusSteel Divisioneducational presentationsmake in your office orchapterofyourorganization.has severalthat we canat the localprofessionalThe “Cold-Formed Steel Trusses 101”and “Bracing for Steel Trusses”presentations are accredited by theAmerican Institute of Architects undertheir Continuing Education System. AIAmembers who participate will receiveone LU Hour of credit, and TrusSteel willfile Form B with the AIA. All otherparticipants will receive a Certificate ofCompletion.Learning ObjectivesLength: One HourCredits: One LU HourHSW: YesCost: NoneAt the end of this program, participants will beable to: Identify the different types of CFS trusssystems, Understand the product capabilities andlimitations of various CFS truss systems, Specify a CFS truss system.DescriptionThis presentation includes a brief history andoverview of the various types of cold-formedsteel (CFS) truss systems on the market, theirphysical and structural characteristics andperformance, common system applications andlimitations, and how to specify these systems.How TaughtUsing a PowerPoint presentation and physicalsamples, the CES facilitator presents informationon the nature and types of CFS truss systems,including basic terminology and applications.Physical samples are used to demonstrate trussterminology.Target AudiencesArchitects, engineers, specifiers andother design professionals in thebuilding market; can be presented toany size audience.AV NeededElectrical power and a screen forPowerPoint (CES facilitator will providethe laptop computer, video projector andsamples).Other PresentationsOther non-accredited presentations areavailable, suitable for various venues.Contact your TrusSteel RegionalManager for details.Facilitator QualificationsTrusSteel facilitators have extensiveexperience in the truss and buildingindustries and are well versed in trussdesign and installation.12Bracing for Steel TrussesLength: One HourCredits: One LU HourHSW: YesCost: NoneLearning ObjectivesDescriptionThis presentation includes an overview of thevarious types of cold-formed steel (CFS) trusssystems on the market, common loadingsituations, structural construction bracing needsand how to specify the bracing for thesesystems.3456At the end of this program, participants will beable to: Identify the different types of CFS trusssystems, Understand common load conditions, Specify the bracing for a CFS trusssystem.How TaughtUsing PowerPoint and physical samples, the CESfacilitator presents information on the nature andtypes of CFS truss systems, including basicterminology and applications. Physical samplesare used to demonstrate truss terminology.781.07

OVERVIEWNotes11.082345678

A P P L I C AT I O N SYour imagination is the only limitTrusSteel Cold-Formed Steel (CFS) trussesare now in service within literally thousandsof buildings, in dozens of buildingapplications.This guide shares only a smallfraction of the total uses of TrusSteel. Youcan view additional information on thesecase studies and other studies on theTrusSteel web site: www.TrusSteel.com.TrusSteel trusses can be used to createroofs and floors of all types (gables, hips,monos, gambrels, etc.). They can be used inmany special applications, including: Re-roofs (over existing structures) Equipment screens Porte cocheres Ag structures Flat roofs Canopies Mansards Shelters FramesInstitutional – Schools – Universities – Churches – Museums – Healthcare – Clinics – Hospitals – Assisted Living Centers – RetirementCenters – Municipal – Community Centers – Town Halls – Hospitality – Hotels – Motels – Commercial – Malls – Banks – Truck StopsTelecommunications – Shopping Centers – Restaurants – Historical Renovation – Industrial – Storage – Roof Refit - CondominiumsMulti-Family – Single-Family – Recreation – Ball Parks – Gaming – Government/Military – Barracks – Depots – Offices123456782.01

A P P L I C AT I O N SMilitaryThe PentagonProject PhoenixArlington, VAReconstruction of the Pentagon began immediately after 9-11, withall parties committed to completing the restoration within 12 months.The Pentagon reopened on-time, on-budget, on the very hard workand cooperation of everyone involved.Davis-Monthan AFBNew DormitoriesTucson, AZSeven entire roofs were built on the ground and lifted into place, completewith trusses, bracing, decking and mechanicals. This installation techniqueis called rafting. See Section 7 for more information.Estimated time savings on the project: two weeks.Fort WainwrightNew Lodging FacilitiesFairbanks, AKRafting (assembling entire sections of the roof system on the groundand lifting into place) allowed this contractor to meet deadlines set bythe short building season in Alaska. Structural design of the trusssystem, lifting bracing, permanent bracing and all connections wasdone by TrusSteel.12.022345678

A P P L I C AT I O N SHospitality / EldercareThe Inn on Biltmore EstateLuxury HotelAsheville,NCOver 35,000 SF of TrusSteel trusses top the new Inn on BiltmoreEstate. Located on a national historic site, quality and ease ofinstallation were of paramount importance to the owner.Unusual framing situations, including radial and conical roof areas,provided challenges met by the truss fabricator and TrusSteelengineering team.Design FlexibilityThe pre-engineered TrusSteel system allows much greater designflexibility than steel “C” truss framing. As a result, you can design infamiliar roof lines - pitched or flat, with hips, gables, gambrels,monos, mansards, cantilevers, overhangs, scissors - as well as floortrusses. This design flexibility makes TrusSteel ideal for almost anybuilding type.Noncombustible TrusSteel trusses provide integral, recognized fireresistance that does not fade with time. Useful, cost-saving ULListed roof and floor assemblies can help you meet the needs ofdemanding building types, owners and codes. For more informationon UL Listed assemblies, see Section 3 of this Manual.The GarlandsAssisted-Living CommunityBarrington, ILOver 150,000 SF of TrusSteel trusses helped to create the “FrenchCountry” style of this campus. One of the many TrusSteel UL Listedassemblies met the architect’s and owner’s requirements for fireprotection.123456782.03

A P P L I C AT I O N SMunicipal / InstitutionalGolden City StationFire StationLouisville, KYThe design of this fire station required long, clear spans andnoncombustible framing. The truck bay areas were covered with 85-footclear span TrusSteel trusses. For ease of shipment,these trusses were shop fabricated in two halves thatwere then connected together in the field by theinstaller.PGA HeadquartersHistorical CenterPort St. Lucie, FLThe new showpiece of the Professional GolfersAssociation headquarters campus is the PGA HistoricalCenter. TrusSteel trusses were selected for their highquality and overall economy of installation.Coral Baptist ChurchNew Church ComplexCoral Springs, FLThe truss systems for the many roofs over this new worship,education and fellowship complex contained just about every typeof truss under the sun. There were piggybacked trusses, flats,drags, hips, commons, monos and radials - with about everybearing condition imaginable, including heavy steel, CFS steel, barjoists and masonry. Because of the design flexibility of TrusSteelCFS trusses, they interfaced well with all these types of framingsystems.12.042345678

A P P L I C AT I O N SIndustrial / Educational / ResidentialFreightliner Research FacilityWind TunnelSwan Island, ORCollaboration between engineers at Freightliner, TrusSteel and the localtruss fabricator resulted in a state-of-the-art design framed completelyfrom TrusSteel products.Alleghany Highlands SchoolsElementary and Middle SchoolsLowmoor, VAThis campus of new elementary and middle schools includedover 112,000 SF of TrusSteel trusses. TrusSteel cold-formedsteel (CFS) trusses offer the features of non-combustibility,UL-Listed assemblies and recycled content demanded on manyschool projects.Schnee ResidenceScottsdale, AZOver 12,000 SF of TrusSteel trusses shelter this new home in thedesert. Fifty-foot trusses framed in a radial pattern created large,open living areas.TrusSteel CFS trusses are among the lightest and strongest steelframing made. They are an excellent alternative to heavier steelframing and trusses, such as “C” stud trusses or stick framing.Because of their superior lateral stiffness and high strength-toweight ratio, TrusSteel common trusses, in short spans, may belifted and installed without the use of a crane. This can provide asignificant benefit on small projects or structures built in areaswith limited access.123456782.05

SPECIFYING / DESIGNINGSpecifications & Design OverviewSpecifying CFS TrussesPre-Engineered TrussesCold-Formed Steel (CFS) trusses should bespecified as “pre-engineered” trusses. The term"pre-engineered" reflects the concept of adesired outcome, where the individual trusseshave been fully analyzed and engineered to meetall specified load conditions. Individual trussdesigns should be sealed by a ProfessionalEngineer who is registered in the state where theproject is located.Pre-Fabricated TrussesCFS trusses should also be specified as “prefabricated cold-formed steel (CFS) trusses”.Trusses should be fabricated in a shopenvironment with experienced fabricationpersonnel. Trusses that are fabricated at the jobsite should not be allowed. TrusSteel endorsesindustry truss shop quality control standards asdeveloped by the SBCA’s Cold-Formed SteelCouncil.several reasons. In the code standards for theseproducts (AISI, COFS, ICC, etc.), these productsare now referred to as cold-formed steel. Inaddition, the gauge system of referencingmaterial thicknesses is becoming obsolete andhas been replaced with mil thicknessdesignations.Industry StandardsThe specifier should assure that all applicableindustry standards are referenced within theproject specification. All applicable loads andload conditions, as well as all other performancecriteria, applicable codes, building use andgeometry, etc. should be clearly defined withinthe specifications and project design drawings.For a further discussion on required information,please see “Information Required for TrussDesign”.The terminology “cold-formed steel” is replacingthe old terminology of “light gauge steel” forDesign and Review ProcessRequirementsTruss Package SubmittalDue to its importance in the overall success of aproject, it is worth repeating that the BuildingDesigner must clearly state, in the plans andspecifications, all specific requirements for thetrusses. This clear and thorough communicationof performance criteria will help truss suppliers,general contractors and truss installers providemore accurate pricing, preliminary designs, andultimately a better product on the project.As a tool for the specifier, a complete GuideSpecification for TrusSteel, written instandard three-part format, is available onthe CD version of this manual.13.012Once the truss designs have been completed andsealed by a professional engineer, the designswill be submitted to the Building Designer forreview and approval. If the Building Designer issatisfied with the truss submittal, then the trussmanufacturer will begin fabricating the trusses. Ifthe Building Designer is not satisfied, the trusssubmittal will be rejected and returned to thetruss manufacturer along with preciseinstructions on corrective action. The trussmanufacturer will make the necessaryTruss Designcorrections and then resubmit the trusses to theProject plans and specifications will eventually Building Designer. This process will continuebe sent for pricing to companies involved in the until the Building Designer approves the trussmanufacture of CFS trusses. After a truss submittal package.manufacturer is awarded the project, the actualdesign of the truss system will begin. The trussmanufacturer will use the plans and Approval, Fabrication and Deliveryspecifications to create an economical truss Once the Building Designer approves the trussframing package.submittal package, the truss manufacturer willbegin the fabrication of the trusses. Afterfabric

design flexibility makes TrusSteel trusses ideal for almost any building type: new construction, retrofit, commercial, institutional, military, educational, industrial and municipal structures. Easy to specify and design There is a wealth of information available to help you sp