Transcription

Construction of Asphalt Pavements

TopicsProductionTransportationLaydownSelection of MaterialsPreparing Mix DesignProperly Storing AggregateProperly Drying AggregateAdding Binder and MixingTimely DeliveryMatch Paver SpeedProper Thickness and CrownProper Density at ScreenProper Size and Type of RollersProper Vibration FrequencyProper Rolling PatternCIVL 4155/61552

Asphalt PlantsBatch PlantCIVL 4155/6155Drum Plant3

Material Flow(Taken from The Asphalt Institute Manual ES‐1, Second Edition)LiquidAsphaltCementHeatingDryingCold Feed BinsStockpiledAggregateCIVL 4155/61554

Material StockpilesCIVL 4155/61555

Covered StockpilesCIVL 4155/61556

Mix Production CostsCIVL 4155/61557

Batch PlantHot ElevatorCold ElevatorCIVL 4155/61558

Cold Feed BinsColdElevatorCIVL 4155/615511

Aggregate DryerCIVL 4155/615513

Dryer CutawayCIVL 4155/615514

Mixing Tower Cutaway(Taken from The Asphalt Institute Manual ES‐1, Second Edition)SCREEN DECK & HOT BINSHOT ELEVATORCIVL 4155/615516

Screen Deck & Hot Bins(Taken from The Asphalt Institute Manual ES‐1, Second Edition)CIVL 4155/615517

Pugmill Mixer(Taken from The Asphalt Institute Manual ES‐1, Second Edition)CIVL 4155/615519

Typical Mixing Cycle1.3.CIVL 4155/6155Aggregate and asphaltcement are mixedAggregate enterspugmill from weigh box4.2.Asphalt cement enterspugmill from spraybarFinished mix dischargedthrough pugmill gate5.Pugmill gate closes toreceive the next batch20

StorageSLAT CONVEYORCIVL 4155/615521

Drum PlantStorageSiloCIVL 4155/615524

Batch PlantCIVL 4155/615525

Drum PlantStorageSiloCIVL 4155/615526

Parallel‐Flow Drum Plant(Taken from The U. S. Army Corps of Engineers Hot Mix Paving Handbook)CIVL 4155/615527

Counter‐Flow Drum Plant(Taken from The U. S. Army Corps of Engineers Hot Mix Paving Handbook)CIVL 4155/615528

Double‐Drum Plant(Taken from The U. S. Army Corps of Engineers Hot Mix Paving Handbook)CIVL 4155/615529

Double‐Drum Plant(Taken from The ASTEC Double‐Barrel Brochure)BurnerCombustionZone FlightsCIVL 4155/6155ShoweringFlightsConditioningFlights30

Double‐Drum Plant(Taken from The ASTEC Double‐Barrel Brochure)RAP EntersHereBurnerAC EntersHereCIVL 4155/6155Final ProductExits Here31

Portable Drum PlantCIVL 4155/615532

Hot Mix Asphalt Paving

Paving TrainCIVL 4155/615535

Asphalt PaverHopperScreedSide ArmCIVL 4155/615536

Asphalt PaverHopperScreedSide ArmCIVL 4155/615537

Paving MachineSource: PTC Pavement Guide InteractiveCIVL 4155/615538

Paving MachineSource: PTC Pavement Guide InteractiveCIVL 4155/615539

Paving TrainCIVL 4155/615540

Material Transfer DeviceCIVL 4155/615541

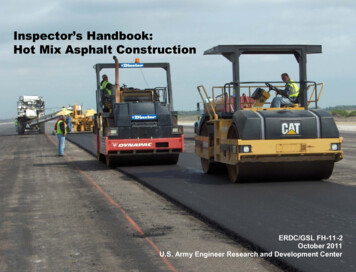

Asphalt CompactionCIVL 4155/615542

Asphalt CompactionScreedBreakdown RollerIntermediate RollerFinish RollerTrafficCIVL 4155/615543

Asphalt CompactionCIVL 4155/615544

Asphalt CompactionCIVL 4155/615545

Asphalt CompactionCIVL 4155/615546

Screen Deck & Hot Bins (Taken from The Asphalt Institute Manual ES‐1, Second Edition) CIVL 4155/6155 17. Pugmill Mixer (Taken from The Asphalt Institute Manual ES‐1, Second Edition) CIVL 4155/6155 19. Typical Mixing Cycle 1. Aggregateenters pugmillfrom pugmillfromweigh box 2. Asphaltcement enters spraybar 3. Aggregate and asphalt cement are mixed 4. Finished mix