Transcription

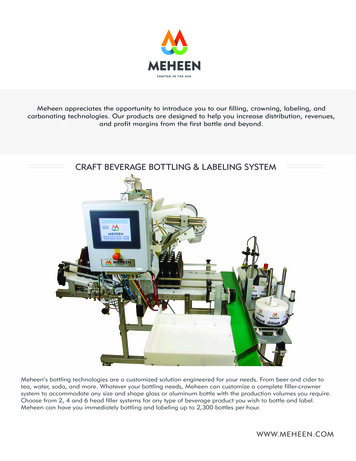

Meheen appreciates the opportunity to introduce you to our filling, crowning, labeling, andcarbonating technologies. Our products are designed to help you increase distribution, revenues,and profit margins from the first bottle and beyond.CRAFT BEVERAGE BOTTLING & LABELING SYSTEMMeheen’s bottling technologies are a customized solution engineered for your needs. From beer and cider totea, water, soda, and more. Whatever your bottling needs, Meheen can customize a complete filler-crownersystem to accommodate any size and shape glass or aluminum bottle with the production volumes you require.Choose from 2, 4 and 6 head filler systems for any type of beverage product you wish to bottle and label.Meheen can have you immediately bottling and labeling up to 2,300 bottles per hour.WWW.MEHEEN.COM

MEHEEN FILLER FEATURESMeheen’s M series fillers are designed to optimize your limited floor space and turn it into a large scaleproduction zone. Meheen fillers are pneumatically powered for long-term reliability. With no motors, gears orbearings to maintain, there is a low cost of ownership. The touch screen operating controls help you monitorand control fill rates, counter pressure, CO2 pulse/fobbing and other aspects of your filling process at the touchof a button. Bottle pre-evacuation, controlled pressures and long fill tubes mean calm pours, low O2 pick-up,and low product loss which provides a consistent, quality product bottle after bottle.Counter pressure fill and advancedsensing control technology ensures cleanand high quality fills while mitigatingunwanted O2.Air operated filling and crowningsystem using high quality pneumaticcomponents. No electric motors orpumps are used in order to deliverrepetitive and reliable performance.Built-in crowning system immediatelyafter the fill station simplifies productpackaging delivering a consumerready product.Give your consumers the best tastingexperience possible by using a Meheenbottle filling system.WWW.MEHEEN.COM

MEHEEN LABELER FEATURESMeheen’s ML bottle labeler is designed to apply labels to a variety of glass, plastic, or aluminum round beveragecontainers. The Meheen ML bottle labeler is extremely versatile with the ability to apply full wrap, front-only,or front-and-back labels at a rate of up to 60 labels per minute. The air assist rotary container guide is uniquein its design and ensures a high quality, consistent application of the labels on dry, moist, and cold substratesurfaces. Additionally, the ultrasonic bottle detection provides reliable bottle sensing regardless of the beveragecontainer, material, or color. Now you can “Label like you Meheen it!”Make your brand pop with theMeheen ML bottle labeler. The MLbottle labeler is available integratedwith the Meheen bottle filler or as astand alone labeling system.Touch screen interface means easysetup of label operation mode andapplication settings.Simple to operate labeler to apply fullwrap, front label, or front and backlabels onto a variety of cylindricalbeverage containers.The air assist rotary container guideensures consistent and smooth labelapplication on dry, moist and coldsubstrate surfaces.Large accumulation tray holdsfinished product for easy unloadinginto the shipping case delivering ashelf ready retail product.WWW.MEHEEN.COM

FILLER & L ABELER TECHNICAL SPECIFICATIONSM6LM4LM2LFilling Heads642Crowners642ML Bottle LabelerIncludedIncludedIncludedFiller Dimensions41” (1066mm) W55” (1676mm) L41” (1066mm) W55” (1676mm) L36” (900mm) W55” (1676mm) LStand with Swivel CastersStand with Swivel CastersStand with Swivel CastersFully AutomatedYesYesYesTouch Screen ControlsYesYesYesAuto Cleaning/SanitizingProduction Rates†YesYesYesUp to 40 BPMUp to 30 BPMUp to 12 BPMRinserYesYesNoLong Tube FillingYesYesYesAuto Crown SorterYesYesYesPre-PurgeYesYesYesSingle & Double Pre-EvacYesYesYesAuto Fill DetectionYesYesYesAuto Leak DetectionYesYesYesManual OverrideYesYesYesCO2 Pulse IntensityYesStandard ConfigurationAir FlowOperating PressureYesYes15 cfm @ 90 psi (25 m /h)15 cfm @ 90 psi (25 m /h)12 cfm @ 90 psi (20 m3/h)95 psi (6.5 bar)95 psi (6.5 bar)80 psi (5.5 bar)33ML BOTTLE LABELERLabel Application RateUp to 60 BPM Depending on Label and Bottle SizeLabel Size Maximum5 inches (125mm) H x 12 inches (304mm) W - Standard Unwind Roll #4Label Spool Diameter9 inches (228mm)Label Core Size (ID)3 inches (76mm)Maximum Bottle Diameter4 inches (101mm)Conveyor Dimensions4 inches (101mm) W x 60 inches (1524mm) LLabeler Dimensions60 inches (1524mm) L x 35 inches (889mm) W x 52 inches (1320mm) HSupply Voltage120 VAC 60 Hz (240 VAC 50 Hz Option)Labeler Air Pressure50 psi (3.5 bar)Labeler Air Flow 1 CFM ( 1 m3//h)FILLER & L ABELER OPTIONSBig ptionML Bottle LabelerLabel Ink-jet Date CoderOptionOptionOption†Beverage product conditions can impact packaging production rates.Meheen Manufacturing, Inc reserves the right to change product design and options.WWW.MEHEEN.COM

CARBONATING TECHNOLOGIESRounding out the complete system is Meheen’s carbonating technology, the Tank Manager. Meheen’stank manager helps you save time and money by reducing manual labor and taking the guesswork outof carbonation management. Carbonation is the most difficult thing for brew masters to control becausetemperature and CO2 absorption are so dynamic. The Meheen Tank Manager helps you achieve consistentquality control while giving you peace of mind that your beverage’s taste profiles are properly managed.TANK 2TANK 1PRESSUREVENT VALVEPRESSUREVENT VALVETANK 1TANK 2TANK 1TANK 2CO2 PRESSUREVALVECO2 SURE VENT VALVEAutomatically vents and relieves CO2 pressure to maintain exact pressure needed for programmed CO2 levels.Relieves head pressure after tank is emptied.CO2 PRESSURE VALVEAutomatically adds precise amounts of CO2 pressure in the head space of the tank. Also used to accuratelymaintain required head space pressures for dispensing to filling equipment.CARBONATION VALVEAutomatically delivers the desired amount of CO2 to the beverage through the carbonation stone.PRESSURE SENSORSenses pressure to automatically calculate carbonation levels and allows for monitoring of head pressure controlto 0.1psi.GLYCOL COOLING CONTROL VALVEUtilizes an RTD to automatically turn on/off the tank’s glycol cooling system, allowing the Tank Manager to coolyour product to specific values.THERMAL PROBEAutomatically and precisely measures tank temperature.Price USD 8,850WWW.MEHEEN.COM

MEHEEN TERMS AND CONDITIONSTRAININGInitial training provided at no cost at Meheen’s facility in Pasco, Washington. Customer to cover all of its costsassociated with training, including airfare, ground transportation, meals and lodging. However, if you attendtraining in Pasco within one hundred twenty (120) days of machine pick-up or delivery, we will reimburse up toUSD 2,000 (for M4L, M4, M6L, and M6 purchases) / USD 1,000 (for M2L and M2 purchases) of your out-ofpocket costs associated with training. Reimbursement does not apply to ML Stand Alone bottle labelers.FILLER / LABELER SHIPPING / DELIVERYAll products are shipped Ex-Works (EXW) Meheen’s facility in Pasco, Washington, USA. The Turnkey Bottle Fillerand Labeler System and Stand Alone Filler requires a deposit of USD 15,000 to begin fabrication. For the StandAlone Bottle Labeler, a deposit of USD 5,000 is required. Fabrication time varies and will be estimated uponexecution of a purchase agreement. Final payment is due upon notification of completion.TANK MANAGER SHIPPING / DELIVERYAll products are shipped Ex-Works (EXW) Meheen’s facility in Pasco, Washington, USA. Final payment is due uponnotification of completion.NOTE: Prices and fabrication times are estimated and subject to change without notice. In the event of anydiscrepancy between this quote and a purchase agreement executed by Meheen and you, the purchaseagreement shall control.If you have any questions, give us a call or send us an email.Meheen Manufacturing, Inc.325 N. Oregon AvenuePasco, WA 99301 USAP: ( 1) 509.547.7029F: ( 1) 509.547.0939Info@meheen.comWWW.MEHEEN.COM

Whatever your bottling needs, Meheen can customize a complete filler-crowner system to accommodate any size and shape glass or aluminum bottle with the production volumes you require. Choose from 2, 4 and 6 head filler systems for any type of beverage product you wish to bottle and label. Meheen can have you