Transcription

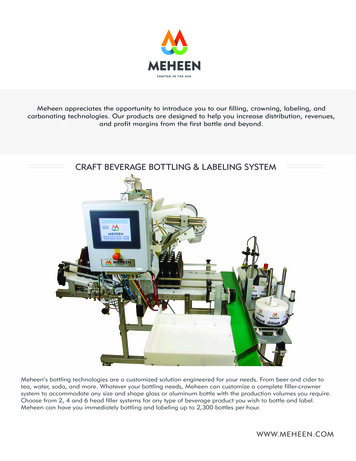

EE-527: MicroFabricationChemical Storage, Labeling, and HandlingR. B. Darling / EE-527 / Winter 2013

Chemical Storage Principles Chemical Storage in the Microfab Lab is based upon:–––––Minimizing risk from chemical incompatibilitiesMaintaining required purity of starting materialsReducing cross-contaminationReducing degradation mechanisms which limit shelf lifeSegregating stock from waste Chemical grades are non-sequential, non-linear, andoverlapping.– Chemical purity is measured by the maximum level of potentialimpurities: Qualitative: which impurities may be present Quantitative: how much of each impurity may be present– Example: 99% is not always more pure than 95% material. It depends upon which impurities are present in the counts.R. B. Darling / EE-527 / Winter 2013

Chemical Grades and Purity - 1 Commercial or Technical Grade– typically 85-90 % purity– rarely used in the laboratory Practical Grade– small step above technical grade– often contain intermediate compounds as part of the preparationprocess United States Pharmacopoeia (USP) Grade– suitable for drug use– generally acceptable for chemistry lab work Chemically Pure (CP) Grade– almost as pure as reagent grade, but application determineswhether purity is adequate for the purposeR. B. Darling / EE-527 / Winter 2013

Chemical Grades and Purity - 2 Spectroscopic Grade– purity determined by optical absorption at particular wavelengths– usually around 99 % purity– used for IR, VIS, & UV spectrophotometry Chromatography Grade– minimum of 99 % purity with no single impurity over 0.2 % Reagent Analyzed or Reagent Grade– certified to have impurities below specific levels set by theCommittee on Analytical Reagents of the American ChemicalSociety (ACS)– bottles are identified by a batch number– minimum standard for any chemical analysis workR. B. Darling / EE-527 / Winter 2013

Chemical Grades and Purity - 3 Electronic or Semiconductor Grade– specified to contain less than set levels of specific impurities: Na, K, Ca, Mg, etc.– common subdivisions are: Low-Sodium MOS Grade Low-Sodium CMOS Grade – If in doubt, order this grade. Primary Standard Grade– at least 99.95 % purity– can serve as reference standards in analytical procedures Ultra-High Purity Grade– usually solids that have been successively refined– expressed as number of nines of purity, e.g. 5-9s 99.999 % purity– often the highest available overall purity of a materialR. B. Darling / EE-527 / Winter 2013

Chemical Labeling Primary Labeling– printed on containers by the manufacturer– specific information is set by Federal Lab Safety Standard (FLSS)– DOT labels are required for transport and storage Secondary Labeling– used for labeling smaller, secondary containers– must be done by user to provide point-of-use information– must contain: common or scientific name of chemicalname of person who is responsible for itdate at which container was filledany specific precautions; minimum is NFPA 704M symbolthe best practice is to add precaution codes (A – Z)R. B. Darling / EE-527 / Winter 2013

DOT/United Nations Hazard ExplosivesCompressed GasesFlammable LiquidsFlammable SolidsOxidizing MaterialsPoisonous MaterialsIrritating MaterialsRadioactive MaterialsCorrosive MaterialsMiscellaneous HazardsClass A, B, CFlammable, NonflammableOxidizers, Organic PeroxidesClass A, BDomestic, Import/ExportClass I, II, III Each has standard international placards that must label any materialfor transportationR. B. Darling / EE-527 / Winter 2013

Common DOT Labels for Microfabricationrare formicrofablaboratoriesR. B. Darling / EE-527 / Winter 2013

NFPA 704M Labeling System National Fire Protection Association (NFPA) Hazard Ratings; 0 to xtreme Example: H2SO4:Some manufacturers, e.g. Baker,use the fourth (white) position toindicate immediate contact hazardFlammability llow)WSpecial Symbols (white)R. B. Darling / EE-527 / Winter 2013

Secondary Labeling Methods in the Lab Solvent wash bottles– Use the pre-labeled polypropylene squirt bottles and just refill thenwhen needed. Glass beakers– For long term use in the same process, use a Sharpie felt-tipmarker on the white labeling area, or create a tape label and applythis to the beaker. Tape labels will resist most chemicals, solventswill dissolve the Sharpie felt tip marks.– For short term use, label a filter paper and place the beaker overtop of it to identify it. (Laboratory version of a glass coaster.) Screw cap chemical bottles– Use a clean, new bottle and put a pressure sensitive label on it, oruse tape labels.R. B. Darling / EE-527 / Winter 2013

Secondary Labeling – Solvent Wash Bottles Use the pre-labeled bottles –nothing to label by hand! Be careful with their use:– Only light pressure willdischarge contents– Heat from a hand will oftencause pressure and dischargevolatile solvents, e.g. acetone– Unscrew the cap slightly tobreak the pressure, but stilllimit the evaporation rate– Lift the bottle by the cap anddischarge tube to avoidsqueezing out the contentsISOPROPANOL310R. B. Darling / EE-527 / Winter 2013

Secondary Labeling – BeakersACETONEACETONEadhesive labellabeled filter paperR. B. Darling / EE-527 / Winter 2013

Secondary Labeling – Glass Jars Necessary elements ofsecondary label:––––Primary compositionPrimary hazardOwnerDate Precaution codes arealso very . B. Darling / EE-527 / Winter 2013

Chemical Precaution Codes for Secondary ophoricDDizziness & DrowsinessQHeat Sensitive (Q ssed GasTToxicHHygroscopicUUltrahigh PurityIIrritantVContents under VacuumJEtiological Agent (Jerms)WWater ReactiveKCarcinogenicXAsphyxiant (hands around neck)LLiquidYVibration SensitiveMLight SensitiveZStatic Sensitive (Zappable)Note that these are specific to the EE Micro Fab Lab and not universal.Spell these out – don’t just use the alphabet letters.R. B. Darling / EE-527 / Winter 2013

Chemical Storage Chemicals must use segregated storage because ofpotential for cross-reactivity and cross-contamination. Chemical Storage Classes for ssed gasesAcids and basesFlammable solventsOxidizers (H2O2, chlorates, phosphates)Photosensitive chemicals (e.g. photoresist)Dry chemicals (powders, granules, shot)Heat sensitive chemicals (thermosetting adhesives, etc.)Hygroscopic materialsUltrahigh purity materials (e.g. wafers)R. B. Darling / EE-527 / Winter 2013

Storage Hazards The biggest and most common hazard is storingincompatible liquid chemicals in the same place: Acids & bases, flammable solvents, and oxidizers musteach be stored separate from the others. Each of these three has their own specific storage space. Misplacing any two of these three together can produce apotentially explosive situation!Acids&BasesFlammableSolventsA non-overlapping Venn diagram !!!OxidizersR. B. Darling / EE-527 / Winter 2013

Laboratory Refrigerators Many microelectronics materials are heat sensitive and need to be stored ina refrigerator.Special designated refrigerators are in the lab for this purpose.– They are NOT for storing any foodstuffs under ANY conditions! Materials that are usually stored under refrigeration:–––––––– Hydrogen peroxide (H2O2) – a strong oxidizer!!!Crystalbond mounting resinApiezon W black mounting waxPolyimide resinsSpin-on glasses (SOG) and spin-on dopants (SOD)Some unusual photoresists, e.g. P2460Thermosetting silver epoxySolder pastesEach of these materials must be warmed back to room temperature beforeuse. Plan ahead since that can often take a few hours.R. B. Darling / EE-527 / Winter 2013

Dry Boxes Used for storing materials underconditions of reduced humidity.Dry nitrogen is used to purge theair from the dry boxes.psidrynitrogenpurge– The dry box is not “dry” unlessthis is done A dry nitrogen purge will usuallyachieve 5 % RH.This is not adequate for trulyhygroscopic materials.This is the most common storagefor wafers, furnace parts, vacuumdeposition parts and materials,and some analytical supplies.R. B. Darling / EE-527 / Winter 2013

Dessicators Used for storing more highly hygroscopic materials.Usually glass construction with a ground sealing flat.Residual moisture is absorbed by CaSO4 crystals (Drierite).Vacuum can be pulled to remove air and water vapor.vacuum valvecoverbaseperforated base plateDrierite is added to thedessicator in an anhydrousform. “Indicating” drierite hasa dye added which turns fromblue to purple when moistureis absorbed. Drierite can berecycled by baking the waterout and restoring it to a white(or blue) color of theanhydrous form.Drierite, CaSO4with moisture indicatorR. B. Darling / EE-527 / Winter 2013

Bottle Residue No bottle cap is ever perfect –some leakage always occurs. Always treat the outside of a bottlewith the same precautions as itscontents! Acid and base bottles very oftenaccumulate crystal growth aroundtheir mouths.– This can be removed by carefulwashing of the bottle, with the cap on!Sulfuric Acid H2SO4032W Always use acid gloves whenhandling acid bottles, even for justmoving them.R. B. Darling / EE-527 / Winter 2013

Returning Material to a Container One Rule: NEVER. What comes out of a stock bottle NEVER goes back.– If too much is poured out, NEVER return the excess back to thestock bottle.– Instead, just pour it into the waste container for that chemical. This is true for all process chemicals, wet or dry, But ABSOLUTELY ESSENTIAL for photoresist.– Dried flakes of material falling back into a photoresist bottle willtotally ruin the entire bottle for any future use!– Returning any material back to a stock container will contaminatethe stock, rendering it useless for any critical work that follows.– Photoresist is always transferred with a pipette, never poured.– The mouth of the bottle and its cap must be kept spotlessly clean.R. B. Darling / EE-527 / Winter 2013

Photosensitive Materials Many photochemicals are used for image transfer or printing inmicrofabrication.Photoresist is by far the most common.These chemicals are sensitive to normal room and outdoor light andmust be kept in bottles which are opaque to their sensitive part of thespectrum.Photoresist is normally kept in brown glass bottles as workingsecondary containers. A 50 mL or 100 mL size is usually best.All photoresist work is performed in the yellow-lightedphotolithography room. The filters on these room lights are designedto produce illumination which does not expose photoresist.Note that inspection microscopes must also use a yellow or orangefilter to keep the illuminator from exposing photoresist that has not yetbeen developed.R. B. Darling / EE-527 / Winter 2013

Bringing New Materials into the MicroFab Lab First check with the laboratory manager to insure that the chemical iscompatible with other processes and equipment in the lab, and that anadequate storage location is available in the lab. Do not just assumethis is the case!Unpack the new material in the gowning room, using the sink to washoff any packing material residue. Dry the container thoroughly beforemoving it further. Do not open the container in the gowning room.Label the container with your name and date.Insure that the laboratory manager logs the new chemical into thelaboratory inventory.Check with the laboratory manager to insure that the necessaryengineering controls and personal protective equipment is available forusing the chemical in the MicroFab Lab.When your use of the new chemical is complete, it is yourresponsibility to arrange for the chemical to be removed or disposedof. Check with the laboratory manager on the specifics for this.R. B. Darling / EE-527 / Winter 2013

Waste Containers When a bottle of a new stock chemical is empty, the bottleis thoroughly washed, dried, and used as a waste containerfor the same type of chemical that it originally held. Waste containers are clearly marked with the word“WASTE” on their labels, along with the composition ofwhat the waste is. Be certain to add waste only to a waste container whosecomposition matches what you are disposing.– This is absolutely critical!– When in doubt, start a new waste container.– Adding random wastes to the same container is the foremost wayto create an unintended chemical reaction, a fire, an explosion, orworse!R. B. Darling / EE-527 / Winter 2013

Sources for Chemical Information Material Safety Data Sheets (MSDS) Chemical Abstracts Services (CAS) HandbooksR. B. Darling / EE-527 / Winter 2013

Material Safety Data Sheets (MSDSs) Material Safety Data Sheets (MSDSs) are a Federally required piece ofdocumentation that must accompany the transport or sale of anysubstance that could contain anything of a hazardous nature.Hard copies will normally be shipped along with the substance, butthey can also be downloaded, usually as PDFs, directly from themanufacturer, who is responsible for making them available.MSDSs contain a lot of boiler plate legalese, and they do not containdetailed chemical property information for using the substance, butthey do contain information on the known hazards of storing orhandling the substance which are important.An important skill is being able to read an MSDS and understand thechemical hazard information that it contains.R. B. Darling / EE-527 / Winter 2013

Organization of an MSDS Product identification (CASRN, mfg. no., etc.)Breakdown of ingredientsPhysical property data (MP, BP, FP, AP, VP, SG, etc.)Shipping description (as applicable)Reactivity data (stability, incompatibilities, etc.)Fire and explosion hazard data (UEL, LEL, fire extinguishants, etc.)Toxicological properties and health

01.04.2009 · Chemical Storage in the Microfab Lab is based upon: – Minimizing risk from chemical incompatibilities – Maintaining required purity of starting materials – Reducing cross-contamination – Reducing degradation mechanisms which limit shelf life – Segregating stock from waste Chemical grades are non-sequential, non-linear, and overlapping. – Chemical purity is measured by the .