Transcription

By Dr. Jesse YoderWhen evaluating a flow technology, it is natural to consider growth rate as an important criterion. Why invest in productswith a declining market base? It seemsmore logical to invest in growing markets that have increasing demand.Users may also prefer to buy into upand coming technologies, rather thaninto technologies that seem to be ontheir way out.Several recent studies conducted byFlow Research into the worldwidepositive displacement and turbineflowmeter markets suggest a broadergroup of criteria than just growth ratewhen evaluating a flow technologyfor purchase or for product development. These studies suggest that market size and installed base are just asimportant as growth rate.In fact, the results of these studies oftraditional technology flowmeterswere not at all what we expected. Hereare some of the surprising results.The positive displacement and turbine flowmeter markets are far largerthan expected. The two marketstogether total 930 million worldwide.While we did find that some segmentsare declining, we also found that several segments are growing. There arefar more suppliers than anticipated.We identified over 100 suppliers ofpositive displacement flowmeters andover 140 suppliers of turbine flowmeters worldwide.Market size is important becauseeven if the market for a type ofwww.FlowControlNetwork.comflowmeter is declining, that type ofmeter may have much greater marketpenetration than a type of flowmeterwith a slightly declining market. Forexample, our research shows that revenues from positive displacementflowmeters are declining at about a 3percent per year rate. Yet this marketwas valued at over 500 million in2001, on a worldwide basis. Comparethis to vortex meters, which are growing at an average annual rate of 5 percent. Revenues from vortex metersworldwide only totaled 140 millionin 2001. So, vortex meters have lessthan one-third the market penetrationas positive displacement meters, whenrevenues are considered.Installed base is important because,in many cases, when end users replacea flowmeter, they replace it with one ofthe same type. This eliminates theneed to learn a new technology, prevents the loss of auxiliary parts thatmay be required for that type offlowmeter and often makes it possibleto make the replacement from existingstock. Installed base is more difficult toquantify than annual sales, althoughFlow Research does have some dataNew tech meters are fastergrowing, and they incorporatethe latest technical advances. However, traditionaltech meters, while growing slower, or in some casesdeclining, have their use tied more to installed baseand population growth. As a result, growth is morestable than that of new tech meters.November/December, 200231

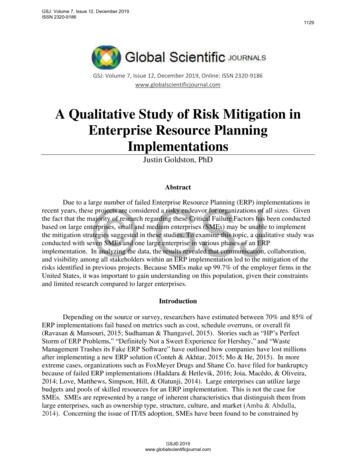

A Two-Track Policy? Flowmeters Manufactured by Leading SuppliersCompanyNew Tech FlowmetersManufacturedCoriolis, magnetic, vortex,MV DPABBActarisControlotronEmerson BrooksUltrasonicCoriolis, magneticEmerson DanielUltrasonicEmerson Micro MotionEmerson RosemountEndress & HauserCoriolisMagnetic, vortex, MV DPCoriolis, magnetic, vortex,ultrasonicFlow TechnologyFluid Components Int’l.FMC Energy SystemsFoxboroGE PanametricsInstrometInvensys Metering SystemsKrohneSiemensCoriolis, ultrasonicCoriolis, magnetic, vortex, MV DPUltrasonicUltrasonicUltrasonicCoriolis, magnetic, ultrasonic,vortexMagnetic, ultrasonicSierra InstrumentsYokogawaVortexMagnetic, ultrasonic, vortexTraditional TechFlowmeters ManufacturedDP, positive displacement,turbine, variable areaPositive displacement, turbinePositive displacement,variable areaDP orifice, positivedisplacement, turbineDPDP, thermalPositive displacement, turbineThermalPositive displacement, turbineDPPositive displacement, turbinePositive displacement, turbineDPDP, open channel, positivedisplacement, variable areaThermalDP, variable area* These are the core flowmeter technologies sold by these companies. Individual companies may have slightly broader product lines.on this. But any type of flowmeterwith a large installed base is prettymuch guaranteed a long lifespan interms of renewed customer orders.It is also important to look at unitnumbers, as well as revenue numbers when evaluating a market.Magnetic flowmeters are high inboth revenues and units, whileultrasonic and Coriolis flowmetersare high in revenues when compared to their units. Both ultrasonic and Coriolis flowmeters have relatively high average selling prices,when compared to other meters, sotheir unit penetration is not asimpressive as their revenue penetration. Positive displacement andturbine flowmeters, by contrast, arevery high in terms of both revenuesand unit numbers.New TechnologyMeter ForecastsLooking at the new technologyflowmeter forecasts, several thingsstand out.1. Ultrasonic and Coriolis are thetwo fastest growing meters.Circle 157 or Request Info Instantly at www.flowcontrolnetwork.com32November/December, 2002Flow Control

However, the Coriolis market issubstantially bigger than the ultrasonic, both in terms of dollars andunits.2. The magnetic flowmeters marketis the largest in terms of dollars,and is far and away the largest interms of units. Even with its slower growth, magnetic flowmetersare still projected to account formore than 50 percent of new technology flowmeters sold in 2005.3. Vortex flowmeters have a relatively small piece of the revenuepie, and also of the unit’s pie.Unlike magnetic flowmeters,which start from a large base, buthave a relatively small growthrate, vortex flowmeters start froma relatively small base, but stillhave only a modest growth rate.Traditional TechMeter ForecastsTo better understand the forecasts forpositive displacement (PD) and turbineflowmeters, it is important to understand that these two markets were divided into the following four segments. Municipal water (commercial andindustrial) Municipal and industrial gas Oil (hydrocarbon measurement) Industrial liquidsNeither the positive displacementnor the turbine studies include the useof PD or turbine meters for residentialapplications. However, they bothinclude the use of PD and turbinemeters for commercial and industrialapplications. This includes the use ofmeters to measure the consumption ofwater or gas at hotels, apartmentbuildings, office complexes andindustrial manufacturing plants. Thenumber of meters sold annually forresidential purposes numbers in themillions, and is a market itself.In terms of revenues, the positivedisplacement flowmeter marketapproaches the magnetic flowmetermarket in size, and is in fact the sec-WILMADTime-Tested Capabilities,Quality SolutionsA LEVEL SENSORSO SIMPLEEVEN YOUR BOSSCOULD INSTALL IT.Introducing Acu-trac ,SSI Technologies new line of ultrasoniclevel sensors. An all-inclusive sensor thatcombines high performance and versatilityin a compact package at an affordableprice. A sensor that’sso simple evenyour bosscould install it.Technicaladvantages include: Highly reliable no moving parts Ranges of 1.5, 3, and 8 meters Minimal Dead ZonesGlass and QuartzPrecision Bore ComponentsWilmad is time-tested in its glass andquartz Precision Bore capabilities.Our technical skills and wellequipped facility assure exacting IDand OD tolerances, with dependableproduction repeatability. We havewide experience in OEM applications. ID tolerances up to .0002” Technical design assistance Glass-to-metal sealing Prototype and productionwww.wilmad.comContact us today with your rough orrefined drawing. We will come upwith the best solution for the job.Typical Applications Electronic and medical components Flow-meter and rotameter tubes Chlorinator flow-tubes Laser cells, bodies, components Syringe barrels and plungers Configurable Analog Outputs– 4-20 mA– 1-10 Vdc Configurable RS485 Digital OutputsCall today – 1-888-477-4320 – formore information on how SSI sensors canmeet your most exacting specifications.Or, simply visit us at:http://ssitechnologies.coman SP Industries CompanyRt. 40 & Oak Rd Buena, NJ 08310 1-800-220-5171 Fax 1-800-220-1081 Email cs@wilmad.comCircle 45 or Request Info Instantly at omCircle 152 or Request Info Instantly atwww.flowcontrolnetwork.comNovember/December, 200233

Circle 156 or Request Info Instantly at www.flowcontrolnetwork.comAUTHORS WANTEDAre You an Expert?Every month, Flow Control publishes adiverse collection of articles from every cornerof the fluid handling universe. The authorswho contribute articles to Flow Control areexperts in their niche who, through years ofexperience, have something valuable toshare with our readers.It’s the expertise and value that anauthor brings to a project that we aremost interested in; we can dot the “i”s andcross the “t”s, if you know what we mean.So, if you’ve got valuable experience that youwish you could share with your colleagues and the fresher faces in the field who are working with fluid handlingequipment, please contact our editors. They’ll gladly takeyour call.Check us out online at:www.flowcontrolnetwork.comContactFlow Control magazine908 788-0343 X141; Fax: 908 ecember, 2002ond largest market in terms of revenues. However, in 2003, worldwidesales of Coriolis meters are projectedto exceed worldwide sales of positivedisplacement flowmeters.In 2001, sales of new technology andtraditional technology flowmeters arefairly close in revenue terms. However,this difference widens as time goes on.In 2005, sales of new technologyflowmeters are projected to exceed 2billion, while the sales of traditionaltechnology meters are projected to be inthe 1.3 billion range. However, whenthe remaining types of traditional technology meters are added, sales of traditional technology meters will most likely be in the range of 1.6 billion for 2005.It is really in the units that the difference is most pronounced. In 2001, therewere more PD units and turbine unitssold than even units of differential pressure flowmeters. And there were almostthree times as many DP, PD and turbinemeters sold as new technology flowmeters. In fact, in 2001, there were more positive displacement and also more turbinemeters sold than the sum total of Coriolis,magnetic, ultrasonic and vortex meters.Even in 2005, projections are that morethan twice as many traditional technology meters will sell as new technologymeters. (See the chart on page 31.)New Tech andTraditional Tech Meters areLike Stocks and BondsIf we compare the flowmeter marketto the stock market, new technologyflowmeters are more like stocks, whiletraditional technology meters are morelike bonds. New tech meters are fastergrowing, and they incorporate the latest technical advances. They are subjectto growth spurts, but sometimes showlittle growth at all for a period of time.Traditional tech meters are slowergrowing, or in some cases declining,but their use is more tied to installedbase and population growth than arenew tech meters. As a result, theirgrowth is more stable than that of newtech meters, even if it is slower. DP, positive displacement and turbine meterswill still be around in 30 years, regardless of what happens with new technol-Flow Control

Now you can get apressure sensor withogy meters because their market size isso large. Like bonds, the yield may belower, but it is more certain.Those in the know about investmentportfolios generally recommend a mixture of stocks and bonds. Likewise, someflowmeter companies have chosen tohave a mixture of new tech and traditional tech meters. One advantage of thisis that whether the customer selects newtech or traditional tech, such a companystill has a product to sell them.Two companies that follow this policy are Emerson Daniel and Instromet.Both companies manufacture bothultrasonic and turbine meters. EmersonRosemount is also the leading supplierof pressure transmitters, including differential pressure flowmeters. EmersonBrooks is a supplier of oval gear andvariable area flowmeters, as well asmagnetic and Coriolis meters.To what extent do the leading sup-pliers of instrumentation follow a twotrack policy when it comes to supplying both new tech and traditional techflowmeters? The chart on page 32answers this question for some of theleading suppliers of flowmeters. FCPERFORMANCETHIS BIG About the AuthorDr. Jesse Yoder is president of FlowResearch, which he founded in 1999. Hehas been a writer and analyst in processcontrol since 1986. Yoder has written over40 market studies and is currently completing a 12-volume series of studies onthe worldwide flowmeter market. Includedin this series is The World Market forTurbine Flowmeters, which was releasedin September of this year. Flow Research(www.flowresearch.com) offers aquarterly update service called theWorldflow Monitoring Service. Youcan contact Dr. Yoder at 781 245-3200, orjesse@flowresearch.com. in aPACKAGE THIS SMALL.King flowmeters performexceptionally well in a widerange of industrial, commercialand specialty applications. That’sbecause we manufacture elevendifferent groups of productswith enough sizes, styles andmaterials of construction tosatisfy almost any rotameterrequirement. That’s how Kingperformance works for you.Next time you need a variablearea flowmeter, basic or withall the options, call the factory.Or visit us at our website.Circle 44 or Request Info Instantly at omSSI Technologies understandsthat compact sensor size should notcompromise optimal performance.That’s why its MediaSensor andMediaNugget sensors aredesigned specifically for whereoptimal performance andcompact size are critical. And atan affordable price.Special Features 0.5% Accuracy Pressure ranges 15 psi through 3,000 psi All laser welded stainless steel designfor media isolation 5 Volt input with 0.5 – 4.5 Volt output 24 Volt input with 4 – 20 mAand 1 – 5 Volt output Integral harness availableCall today – 1-888-477-4320 – for moreinformation on how SSI sensors can meetyour most exacting specifications.Or, simply visit us at: http://ssitechnologies.comCircle 153 or Request Info Instantly atwww.flowcontrolnetwork.comNovember/December, 200235

Controlotron Ultrasonic Emerson Brooks Coriolis, magnetic Positive displacement, variable area Emerson Daniel Ultrasonic DP orifice, positive . * These are the core flowmeter technologies sold by these companies. Indi