Transcription

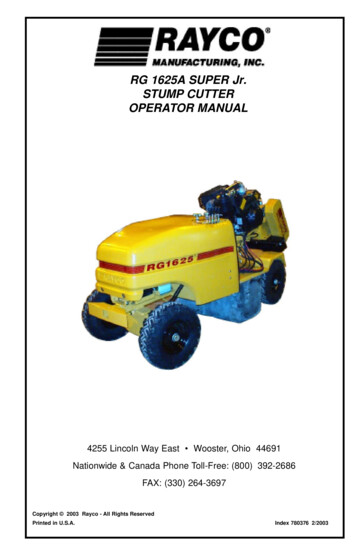

RG 1625A SUPER Jr.STUMP CUTTEROPERATOR MANUAL4255 Lincoln Way East Wooster, Ohio 44691Nationwide & Canada Phone Toll-Free: (800) 392-2686FAX: (330) 264-3697Copyright 2003 Rayco - All Rights ReservedPrinted in U.S.A.Index 780376 2/2003

This Manual is published by Rayco Manufacturing, Inc. for the benefit of the users of RAYCO products.Rayco Manufacturing, Inc. has made every effort to ensure that this manual is correct and up to date at thetime of publication. However, due to continuous improvements, Rayco Manufacturing, Inc. reserves theright to make changes in the contents, at any time, without notice or obligation.Each machine shipped contains an Operator & Parts Manual to familiarize the operator with the properoperating, lubricating, and maintenance instructions. This helps to ensure the best possible performanceand service from the machine. Read and understand all instructions before attempting to operate thismachine. This manual should be readily available for reference at all times. Additional copies of thismanual may be purchased from RAYCO.This RAYCO Stump Cutter was designed and manufactured by Rayco Manufacturing, Inc., Wooster, Ohio.Due to continuous improvements, RAYCO reserves the right to make changes in engineering, design, andspecifications, or discontinue manufacture, at any time, without notice or obligation.Always have a record of the model numbers and serial numbers for your machine to specify when orderingparts. Record your machine model and serial numbers below for your personal records.IDENTIFICATION NUMBERSModel NumberStump CutterEngineSerial Number

3RAYCO Table ofContentsForewordAbout This Manual . . . . . . . . . . . . . . . . . . . . . . .4A Description of the MachineDesign . . . . . . . . . . . . . . . . . . . . . . . . . . . .5How it works . . . . . . . . . . . . . . . . . . . . . . .5Serial Numbers . . . . . . . . . . . . . . . . . . . . .5SafetyGeneral Hazard InformationPressure Air . . . . . . . . . . . . . . . . . . . . . . .7Fluid Penetration . . . . . . . . . . . . . . . . . . . .7Crushing, Cutting Prevention . . . . . . . . . . . . . . .8Burn, Explosion Prevention . . . . . . . . . . . . . . . .8Oils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9Battery Acid . . . . . . . . . . . . . . . . . . . . . . . .9Starting Fluid . . . . . . . . . . . . . . . . . . . . . . .9Lines, Tubes, and Hoses . . . . . . . . . . . . .9Before Starting the Engine . . . . . . . . . . . . . . . .10While in Operation . . . . . . . . . . . . . . . . . . . . . .11Normal Shutdown Procedure . . . . . . . . . . . . . .12Emergency Shutdown Procedure . . . . . . . . . .12While Servicing and Performing Maintenanceon the Machine . . . . . . . . . . . . . . . . . . . . . . . .13While Transporting the Machine . . . . . . . . . . .13Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . .13OperationKnow Your Machine . . . . . . . . . . . . . . . . . . . . .14Machine Controls . . . . . . . . . . . . . . . . . . . . . . .15Other Machine Components . . . . . . . . . .17Pre-Starting Inspection . . . . . . . . . . . . . . . . . .18Starting the EngineNormal Starting . . . . . . . . . . . . . . . . . . . .18Pre-operation Warm up . . . . . . . . . . . . .18Starting with Jumper Cables . . . . . . . . . .18Transporting the Machine . . . . . . . . . . . . . . . .20Transporting the Machinewith Freewheeling Disconnects . . . . . . . . . .21Removing Stumps . . . . . . . . . . . . . . . . . . . . . .22Normal Procedure forCutting a Stump . . . . . . . . . . . . . . . . . . .23Helpful Tips for Operating Machine . . . . . . . . .25Machine Stopping . . . . . . . . . . . . . . . . . . . . . .25Storing the Machine . . . . . . . . . . . . . . . . . . . . .26Preparing the Machine for Storage . . . . .26Removing the Machinefrom Storage . . . . . . . . . . . . . . . . . . . . . .26Warranty Certificate . . . . . . . . . . . . . . . . . . . . .28Copyright 2003 Rayco - All Rights ReservedPrinted in U.S.A.RG 1625A SUPER Jr.

4RAYCO ForewordAbout These ManualsThese manuals contain safety, operating,lubrication, maintenance, troubleshooting and partsinformation.Read - study - keep them with the machine adhere to all of the recommendations.NOTICEWhere the engine is concerned, this manualmakes frequent reference to the KohlerEngines Owner's Manual, which was packed inyour operator’s kit. Keep it, therefore, withthese RG1625 SUPER Jr. Stump Cutter Manualsso that it may be readily used.Guards and covers may have been removed forillustrative purposes. Some photographs orillustrations in this publication show details orattachments that may be different from yourmachine. Continuing improvement andadvancement of product design may have causedchanges to your machine which are not included inthis publication.Whenever a question arises regarding yourmachine, or this publication, please consultRAYCO for the latest available information.NOTICEWhen the NOTICE heading appears in thispublication, what follows is either aclarification or information that will assist youin avoiding damage to the machine or property.RG 1625A SUPER Jr. Operator ManualSafetyThe "Safety" section lists basic safety precautions.In addition, this section identifies the text andlocations of warning labels used on the machine.Read and understand the basic precautions listedin the "Safety" section beforehand, and apply themalways as you operate, transport, performmaintenance, and repair the product.OperationThe "Operation" section is a reference for the newoperator and a refresher for the experienced one.This section includes a discussion of machinecontrols and how to operate the machine.Photographs and illustrations assist the operator incorrect procedures of checking, starting, operating,and stopping the machine.Operating techniques outlined in this publicationare basic. Skill and techniques develop as theoperator gains knowledge of the machine and itscapabilities.Maintenance ManualMaintenanceThe "Maintenance" section is a guide to equipmentcare. A combination of step-by-step instructionsand helpful illustrations and photographsaccompany maintenance items throughout thissection.Trouble-ShootingPossible symptoms are listed with a description ofassociated problems and solutions. A descriptionof how the hydraulic system works is given, as wellas diagrams of the hydraulic and electrical systemsto assist the intuitive troubleshooter in solvingproblems.Parts ManualParts are readily found through illustrations withaccompanying RAYCO part numbers. The machineis broken down into its basic systems andassemblies to enable ease of finding parts. Aseparate engine Spare Parts Catalog is alsoprovided for the aid in identification and orderingengine parts. Please consult your local Kohlerdealer or your local RAYCO dealer for obtainingengine parts and service.Copyright 2003 Rayco - All Rights ReservedPrinted in U.S.A.

5RAYCO RG 1625A SUPER Jr. FOREWORDA Description of theMachineDesignThe RG1625 SUPER Jr.TM stump cutter isdesigned for your maximum benefit for every dollarspent. The machine is constructed for durabilityand easy maneuvering, for those hard to reachtree stumps and roots. Its 17" diameter cuttingwheel with 18 Rayco Superteeth is powerfullydriven through dual V-belts and a low maintenancePolyChain GT belt with tough Kevlar cords,starting and stopping via an electric clutch, with a25 horsepower Kohler Command 25HP OHVV-TWIN engine at its source. Cutting boom motionand the self-propel drive are entirely hydraulic. Thehydraulic controls each include self-centeringfingertip control levers.The machine chassis features rectangular steeltubing and steel guard construction, mounted onextra gripping deep tread tires. The operatorbenefits from a steel cutting wheel guard andheavy rubber curtains, such that his work may beperformed with safety and efficiency. The RG1625A SUPER Jr. has the unique ability to passthrough a 36" gate under its own power. Otherspecial features of the RG 1625A SUPER Jr.include dual cross travel cylinders, sphericalbearing in the pivot head, hardened replaceablebushing on all cylinder ends, flange type bearingson the axle, 6-1/2 gallon fuel tank, steel belt andPolyChain guards, and an easy access ignitionswitch on the engine control panel. Amongavailable options are dual removable travel wheelsfor increased stability and travel traction, commandcut, and additional chip guards.REARRIGHTLEFTFRONTNOTICEThe hood end is considered to be the front ofthe machine, while the cutting end is the rear.Accordingly, the left and right hand sides of themachine are considered to be the same as theoperator's left and right hand side when hestands at the rear of the machine, facingtowards the front.Copyright 2003 Rayco - All Rights ReservedPrinted in U.S.A.For further design information see the"Specifications" section of the MaintenanceManual.How it worksThe machine removes tree stumps by the repeatedgradual sweeping of a multi-toothed high-speedrotating cutting wheel. The cutting wheel has teethon its side, in a strategic pattern. The rotatingcutting wheel takes a sweep from one side of thestump to the other, each tooth rapidly tearing andstripping away small pieces of stump. After eachsweep of 1/4 to 1/2 inches of depth, the cuttingwheel is advanced 1/4 to 1/2 inches further into thestump, and the procedure is simply repeated againand again, under the precise control of theoperator, until the stump is satisfactorily removed.Serial NumbersWhenever communicating with RAYCO or yourRAYCO dealer, have your machine serial numberhandy, as it can help pinpoint most exactly whatinformation is needed in caring for your machine.It is stamped on the operator's side of the framebehind the bumper. Follow the instructions found inthe Kohler Engine Owner's Manual for locating andrecording the engine identification numbers. Forready reference, record them both in the boxesprovided on the inside front cover of this manual.

6RAYCO RG 1625A SUPER Jr. SafetyTragic accidents involving machinery operation,maintenance, and repair are normally caused byfailure to observe basic safety rules or precautions.A machine designed for powerful benefit canbecome an even more powerful setback whenpotentially hazardous situations go unrecognized.Rayco Manufacturing, Inc. is greatly concernedwith the safety of the operator, as well as all in thevicinity of his work. RAYCO has provided shields,guards, safety decals and other important safetyfeatures to aid in using the machine properly. Inorder to further ensure your safety, therefore, weask that you properly operate and service yourstump cutter.The meaning of this safety alert symbol is:Attention! Become Alert!Your safety is involved!A message, either written or pictorial, follows toexplain the hazard. RAYCO cannot anticipateevery possible circumstance that might involve apotential hazard, however. The warnings in thesepublications and on the product are not allinclusive. If you desire to make use of a tool,procedure, work method, or operating techniquenot specifically outlined by RAYCO, therefore, youmust use it only if you have accurately evaluated itand found that it threatens no one's safety. Youshould also ensure that the product will not bedamaged or made unsafe by the operation,lubrication, maintenance, or repair procedures thatyou choose.The procedures described in this "Safety" sectionmay not be fully explained here, but a morecomplete explanation is given in the "Operation”,section in this manual, or in the "MaintenanceIntervals" or "Troubleshooting" sections of theMaintenance Manual.Improper operation, lubrication, maintenance,or repair of this product can be dangerous andcould result in sudden injury or death tooperator or bystanders!The information, specifications, and illustrations inthis publication were produced on the basis ofinformation available at the time it was written. Thespecifications, torques, pressures, measurements,adjustments, illustrations, and other items maychange at any time. These changes can affect theservice given to the product. Obtain the completeand most current information before starting anyjob. Your RAYCO dealer or RAYCO has the mostcurrent information available.Do not operate or perform any lubrication,maintenance, or repair on this product, untilyou have read, you understand, and you decideto do so in compliance with all of theoperation, lubrication, maintenance, andtroubleshooting information contained in thesestump cutter owner's manuals and thatcontained in the Kohler Engine Owner'sManual, which are included with this machine.Additional manuals are available from RAYCOor your RAYCO dealer.Copyright 2003 Rayco - All Rights ReservedPrinted in U.S.A.

7RAYCO RG 1625A SUPER Jr. SAFETYGeneral HazardInformationWear a protective face shield, protective glasses,hearing protection, and other protective equipmentas required by job conditions.Fluid PenetrationNever allow your hand or other part of the body toget near a pressurized fluid leak. Instead, use aboard or cardboard when checking for a leak.Escaping fluid under pressure, especially aninvisible pinhole sized leak, can harmfullypenetrate body tissue, causing serious injury, andpossible death.Do not wear loose clothing or jewelry that cancatch on controls or other parts of the machine.Make certain all protective guards and covers aresecured in place on the machine.Keep the machine free of foreign material, such asdebris, oil, tools, and other items which are notpart of the machine.Never put maintenance fluids into glass containers.Complete all needed repairs before operation.Do not allow untrained personnel to use themachine.The cutting boom can swing during loading andshipping and cause personal injury if it is notsecured by the cutting boom lock block. Be surethat it is properly secured.Beware of the possibilities of unsafe practices ofothers. Always consider what might have beenneglected by a previous operator so that hispossible oversight could not cause harm duringyour use of the machine.Pressure AirPressure air (i.e. from an air compressor) cancause personal injury.When using pressure air for cleaning, wear aprotective face shield, protective clothing, andprotective shoes.The maximum air pressure used for cleaningpurposes must be less than 30 psi (205 kPa).Copyright 2003 Rayco - All Rights ReservedPrinted in U.S.A.The attention of a physician who is speciallytrained to treat such an injury, must be soughtimmediately if penetration into skin or anymucus membrane occurs. Serious infection orreaction will soon result if such a physician isnot immediately consulted.

8RAYCO RG 1625A SUPER Jr. SAFETYCrushing, CuttingPrevention1.Support the cutting boom and the machinesecurely when working beneath them. Do notdepend on the hydraulic cylinders to hold thecutting wheel up. It can fall if a control ismoved or if a hydraulic line breaks.2.Never attempt adjustments when themachine is moving or the engine runningunless otherwise specified, and if so, onlywith extreme caution.3.Where there are boom linkages, theclearance in the linkage area will increase ordecrease with movement of the boom. Evenwithout the engine running, therefore, ahand, for example could become severelyinjured if it were involved in the linkage whenthe cutting boom is being swung from left toright. Stay clear of linkages when movementis occurring.Burn, Explosion Prevention1.All fuels and most lubricants are flammable.Fuel leaked or spilled onto hot surfaces orelectrical components can cause a fire. Donot smoke while refueling, while in arefueling area, or where flammable materialsare stored. Keep all fuels and lubricantsstored in properly marked containers andaway from all unauthorized persons. Store alloily rags or other flammable material in aprotective container, in a safe place.2.Do not weld or flame-cut on pipes, tubes, ortanks that contain flammable fluids. Cleanthem thoroughly with nonflammable solventbefore welding or flame-cutting on them.Remove all flammable materials such asfuel, oil and other debris before theyaccumulate on the machine.3.Dangerous explosion may occur withimproper use or care of starting fluid! Do not attempt to use starting fluid to helpstart engine when using heating plug.4.Stay clear of all rotating and moving parts! Amoving belt and pulleys or chain andsprocket can suddenly pull a limb into them,causing loss of or severe injury to an arm. Arotating cutting wheel can suddenly cut off anarm or leg. Do not use starting fluid without adispensing apparatus that is approved bythe engine manufacturer. Read and follow starting fluidmanufacturer's instructions when usingstarting fluid to start a machine. Starting fluid is poisonous and flammable.5.Wear protective glasses when striking amachine part, to avoid eye injury. Breathing starting fluid vapors or repeatedcontact of starting fluid with skin can causepersonal injury.6.Consult RAYCO or your RAYCO dealer forlifting instructions. Use starting fluid only in well ventilatedareas.7.When the machine is parked, the wheelsshould be securely chocked to prevent thepossibility of the machine rollinguncontrolled. Do not smoke when using starting fluid. Use starting fluid with care to avoid fires. Do not store replacement starting fluidcylinders in living areas.Copyright 2003 Rayco - All Rights ReservedPrinted in U.S.A.

9RAYCO RG 1625A SUPER Jr. SAFETY Do not store starting fluid in direct sunlightor at temperatures above 102 F (39 C).Starting Fluid Discard cylinders in a safe place. Do notpuncture or burn cylinders.Read and follow the starting fluid manufacturer'sinstructions when using starting fluid to start amachine. Keep starting fluid cylinders out of thereach of unauthorized personnel.Starting fluid is poisonous and flammable.4.5.6.7.Do not expose the machine to flames,burning brush, etc. Shields which protect hotexhaust components from oil or fuel spray inthe event of a fire, tube, or seal failure mustbe installed correctly.Breathing starting fluid vapors or repeated contactof starting fluid with skin can cause personal injury.Use starting fluid only in well ventilated areas.Do not smoke when using starting fluid.Do not smoke in areas where batteries arecharged. When using jumper cables alwaysconnect positive ( ) cable, to positive ( )terminal of battery (the terminal that isconnected to starter solenoid), and negative(-) cable from external source, to ground.Make last connection and first disconnectionat a point away from battery. Always connectnegative (-) cable last, and disconnect it first.See the “Operation” section of this manualfor specific instructions.Use starting fluid with care to avoid fires.Clean and tighten all electrical connections.Check daily for loose or frayed electricalwires. Have all loose or frayed electricalwires tightened, repaired or replaced beforeoperating the machine. Never allow a liveelectrical wire make contact with your bodyor with any metal that is touching your body.Lines, Tubes, and HosesHave a fire extinguisher available and knowhow to use it. Inspect and have it serviced asrecommended on its instruction plate.OilsHot oils and components can cause personalburns. Do not allow hot oil or components tocontact the skin.At operating temperature, the hydraulic tank is hot.Relieve all pressure in hydraulic system before anylines, fittings, or components are loosened ordisconnected.Battery AcidAlways wear protective clothing and eyeglasseswhen working with battery.For further important battery safety information,consult the Kohler Engines Owner's Manual.Copyright 2003 Rayco - All Rights ReservedPrinted in U.S.A.Do not store cans of starting fluid in living areas.Do not store starting fluid in direct sunlight or attemperatures above 102 F (39 C).Discard cans in a safe place. Do not puncture orburn cans.Keep starting fluid cans out of the reach ofchildren.Do not bend or strike high pressure lines. Do notinstall bent or damaged lines,

Parts Manual Parts are readily found through illustrations with accompanying RAYCO part numbers. The machine is broken down into its basic systems and assemblies to enable ease of finding parts. A separate engine Spare Parts Catalog is also provided for the aid in identification and ordering engine parts. Please consult your local Kohler