Transcription

THE ENGINEER’S CHOICE METRIC ENGINEERING AND PARTSCATALOGREADY TO SHIPOVER 10000 STANDARDSCARBON AND STAINLESS STEELCUSTOM ENGINEERED PRODUCTS5 MM TO 3000 MM,200" TO 120"NO-TOOLING CHARGES smalley.com

READY TO TAKEYOUR DESIGN TOTHE NEXT LEVEL?Ask Smalley. While we offer more than 10,000standard stock products, there’s no guaranteethat one of these will exactly match your specificapplication. We get it. We’re engineers, too. We’realways ready to collaborate with you to designthe unique wave spring, Spirolox Retaining Ringor constant section ring that meets your exactrequirements.If your specifications don’t match a Smalley partnumber, contact a Smalley engineer today to designand prototype a part that fits your needsand gets you to your target applicationperformance.ShelSmalley Engineer2smalley.comNo-Tooling-Charges For Customs

TABLE OF CONTENTSAbout SmalleySmalley Steel Ring Company.4About Wave SpringsGeneral Spring Information/Comparitor. 10Spring Applications. 13Wave SpringsFrom StockSeriesSpring TypeSSBBearing Pre-Load Single Turn. 16Bearing Cross Reference Chart. 18SSRimperial Gap/Overlap Single Turn. 20SSR-Nimperial Narrow Single Turn. 22RWImperial Wavo (Round Wire) Single Turn. 23CM/CMS Crest-to-Crest. 24C/CSimperial Crest-to-Crest/Shim Ends. 31LSLinear. 38SSRSimperial Shim. 40Spring Tester/Fatigue Tester. 41About Retaining RingsGeneral Ring Information. 42Ring Selection Guide/Ring Interchange Listing. 44Ring Applications. 47Assembly/Removal Methods. 50Internal Retaining RingsFrom StockSeriesRating, Ring TypeVHMLight Duty Single Turn, Spirolox. 52EHAerospace, Spirolox. 54DNHDIN, Spirolox. 56FHDIN, Constant Section. 58HHM/HHMU Hoopster. 60HH/HHU imperial Hoopster. 61VHimperial Light Duty Single Turn, Spirolox. 62WHimperial Medium Duty 2-Turn, Spirolox. 64WHWimperial WaveRing, Spirolox. 67WHTimperial Medium Heavy Duty 2-Turn, Spirolox. 68WHMimperial Heavy Duty 2-Turn, Spirolox. 70FHEimperial Heavy Duty Single Turn, Constant Section. 72XAHimperial Constant Section. 74XDHimperial Constant Section. 76ID/OD Lock. 77External Retaining RingsFrom StockSeriesRating, Ring TypeVSMLight Duty Single Turn, Spirolox. 78ESAerospace, Spirolox. 80DNSDIN, Spirolox. 82FSDIN, Constant Section. 84HSMHoopster . 86HSimperial Hoopster. 87VSimperial Light Duty Single Turn, Spirolox. 88WSimperial Medium Duty 2-Turn, Spirolox. 90WSWimperial WaveRing, Spirolox. 93WSTimperial Medium Heavy Duty 2-Turn, Spirolox. 94WSMimperial Heavy Duty 2-Turn, Spirolox. 96FSEimperial Heavy Duty Single Turn, Constant Section. 98XASimperial Constant Section. 100XDSimperial Constant Section. 102Laminar Seal Rings. 103EngineeringMaterials / Finishes. 110Spring Design. 115Ring Design. 121End Configurations. 126Hoopster Design. 127Spring Checklist. 128Ring Checklist. 129Laminar Ring Checklist. 130Sample Request Form. 131How to Order. 132Glossary. 134Copyright 2015 bySmalley Steel Ring CompanyLake Zurich, IL 60047USAAll rights reservedThe following are trademarks of Smalley Steel Ring Company:Gap-Type, No-Tooling-Costs, No-Tooling-Charges, Overlap-Type.The following are registered trademarks of Smalley Steel RingCompany: All Springs Are Not Equal, Circular-Grain, Crest-to-Crest,Edgewound-Coiled, No Ears to Interfere, Quick Ship, Smalley,Spirawave, Spirolox, WaveRing, Wavo, Hoopster.Smalley reserves the right to change dimensions.Smalley 1 847 719 59003

THE ENGINEER’S CHOICE When engineers seek a higher level of precision and performance in retainingrings, wave springs or constant section rings, there’s only one choice: Smalley.From aerospace to automotive, medical, off-highway,oil & gas to industrial, Smalley has built a reputationfor unsurpassed quality and an expert, collaborativeengineering team. For more than 50 years, wehave been the industry leader and technologicalpioneer—working alongside many of the world'smost respected companies to give their products atrue performance edge.What makes Smalley different?Our products—Unlike rings and springs that are diestamped through the metal grain, our proprietaryedgewinding process results in a circumferentialmetal grain structure that gives Smalley rings andsprings exceptional strength, dimensional stabilityand predictable performance characteristics. All ofwhich result in higher quality for your application.Our engineers—At Smalley, we believe that engineersshould work with engineers. So we ensure thatcustomers work directly with our experienced andtalented team. This access to technical expertiseand problem solving, prototyping and collaboration4smalley.comis rare in the industry. But it allows you to take yourdesigns further than you thought possible. And ourNo-Tooling Charges process means cost-effectiveprototyping for you.Our support—Every Smalley ring and spring—whetherit's a unique design or one of our 10000 stockitems—is backed by our legendary customer support.Our commitment to service combined with ournear-perfect record of on-time delivery has earnedus an approved supplier status with leading OEMmanufacturers around the world.We're always looking for ways to expand andimprove our Customer Service and Engineering/Technical Assistance. And with regional offices in theAmericas, Europe and Asia, Smalley provides totalglobal supply chain solutions to meet your worldwidemanufacturing requirements.See for yourself what the Smalley team can bring toyour critical design applications. We look forward toworking with you.No-Tooling-Charges For Customs

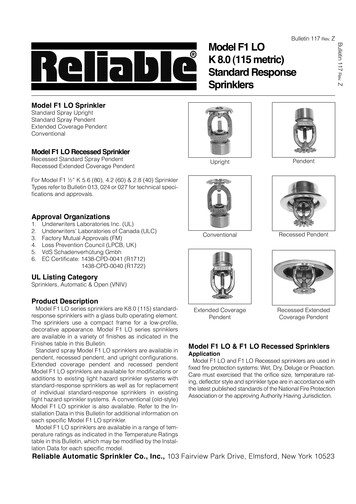

PRECISION PRODUCTSFOR CRITICAL APPLICATIONSAll Smalley retaining rings, wave springs and constant section rings aremanufactured with our unique edgewinding process. This eliminates anytooling charges, greatly increases design flexibility and reduces lead times asdies do not have to be produced.Retaining RingsUnlike die-stamped circlips/retaining rings, Spirolox RetainingRings are coiled to the exactdiameter required. They havea uniform cross-section—or, touse our terminology, “No Ears toInterfere” within an assembly—andare free of burrs. Spirolox RetainingRings meet military and aerospacespecifications and are found inthousands of mechanical productsaround the world.Wave SpringsWave springs are precise flat wirecompression springs that fit intoassemblies where space is at apremium. Since the overall lengthsand operating heights of wavesprings are lower than those ofconventional round wire springs,they will often reduce the size ofthe spring cavity by as much as50%. Of course, this will alsoreduce the weight and rawmaterial cost of the assembly.Constant Section RingsConstant section rings, or snaprings, are often specified forheavy duty or impact-loadingapplications. Produced byedgewinding, theyare fixtures in the automotive andheavy equipment industries astheir larger cross section producesstrength and durability. In addition,a variety of Smalley end types areavailable for easy application in awide range of applications.AutomationSpace ExplorationMedicalEnergyConsumer ProductsHeavy MachineryAerospaceAutomotiveSmalley 1 847 719 59005

ENGINEERING AND DESIGN ASSISTANCE“Ask Smalley” is more than a tagline. For our engineering team, it’s a call toaction. We are always ready to address your application requirements andwork together to take your design to a higher level of performance.Tap Our Knowledge EarlyUsually, the sooner we are able to review yourrequirements, the easier the solution will be. GettingSmalley engineers involved early in your designprocess usually produces the best results.Draw Upon Our Extensive ResourcesOur engineering team has compiled a library of morethan 25000 applications while designing rings andsprings in mechanical components and assemblies.In addition, we offer computer-aided spring-designalternatives to meet your specifications.We also offer additional step-by-step resources. The“Custom Designs” section of this catalog will helpyou determine basic retaining ring and wave springspecifications. Our website offers interactive designguideline and options to help you get the most fromyour application.Put Us On Your TeamThere are many more options we can review withyou once your design criteria are established. Forexample, we can help you with the selection ofa standard part from our vast inventory, or worktogether to modify a standard part to meet yourunique needs.6smalley.comCustomsAt Smalley, customs are standard. It’s easy to get acustom part from our engineers. In most cases wecan manufacture a new ring or spring design in justtwo weeks or work with you to meet your deliveryschedule. Fast, precise and economical—it’s howwe produce rings and springs in short runs or highvolumes, and from 5 mm to 3000 mm in diameter. Ifyou can’t find a standard part to meet your needs inthis catalog, contact our engineering team forimmediate assistance.CAD DownloadsVisit our website for CAD downloads in any nativeor neutral platform. It’s easy to search and select astandard part for a quick upload to your computer.Quality PolicySmalley has established, and is continuouslyimproving upon, a program that is designed tomeet the following objectives: Total product conformance in terms ofdrawings, specifications and contractualrequirements 100% on-time delivery performance Superior products with exceptional value Prompt, professional and courteous responsein every facet of design, manufacturing, salesand customer service Continued development and use of thelatest technologyNo-Tooling-Charges For Customs

MEETING YOUR DEMANDSFOR PRECISION COMPONENTSAt Smalley, we have a single, overriding goal: To supply our customers withuncompromising quality and service. It begins with our raw material andextends through every aspect of our world-class manufacturing process.Raw MaterialPrototypesManufacturingFrom one to one thousand pieces, we can produce,test, modify and reproduce your design as often asnecessary—all without special tooling costs.As demand for more raw material sizes continuesto increase, Smalley has invested heavily in our flatwire rolling mill operation. In addition, we offer avertical integration process that has evolved into theproduction of hundreds of material cross-sections ina wide variety of alloys.Edgewinding, also known as “The No-Tooling CostProcess,” is our precision forming operation thatcoils pre-tempered flat wire on edge to create anear-perfect circle, similar to the famous Slinky coiled metal toy. Circular-Grain metallurgy gives ourproducts key benefits including: Strength and stability that is far superior toconventional retaining rings and washers that aresimply stamped through the metal grain The ability to coil to your exact specification in anydiameter and with any number of turns (layers orcoils), effectively eliminating material waste The flexibility to accommodate your designchanges without the need for additional toolingand die modifications A quicker, more economical ability to produce yourlow-volume custom orders and working prototypesEdgewinding ProcessOur engineers work closely with you to ensure youget the ideal prototype for your design: adjustingdimensions, changing the number of waves or turns,and trying different combinations of variables. Finally,we test for function, before production, so we knowit’s right.WarehousingTo meet our “just in time” (JIT) deliveries and anyimmediate requirement you may have, we maintaina substantial parts inventory of every cataloged/standard retaining ring and wave spring in bothcarbon and stainless steel.Conventional StampingProcessSmalley 1 847 719 59007

DEDICATED TO UNSURPASSEDSERVICE AND SUPPORTSmalley is dedicated to providing the most positive,efficient and economical service possible, eachand every day. We continually train our staff onevery important aspect of keeping you productive.In addition, we can spilt shipments to suit your JITdelivery requirements, and we offer lower pricesfor your annual higher-volume orders. Contact usfor complete details and ideas on how you canpurchase economically.CertificationsStandard Certification of Conformance willbe supplied at no charge. Material and otherCertifications for plating, load, etc. will be furnishedas quoted.TransportationGeneral Sales InformationAs specified by the customer. In the absence ofinstructions, the shipping method will be selectedby Smalley. Insurance will be provided only at thecustomer’s request.DescriptionTermsThe product descriptions in this catalog are intendedto provide practical information for applicationselection. Since it is not possible to include completedetail on all parts, please contact Smalley for anyinformation not included here that may be critical foryour application.QuotationsWe will provide written or verbal quotations asrequested. Requests can be submitted atsmalley.com/rfq, sales@smalley.com or by phone.ReturnsParts not stocked that must be specially manufacturedare not returnable except by special arrangement andwill be subject to cancellation charges. Stocked partsmay be returned for credit at a standard restockingcharge (subject to condition). All returns of stockedparts must be made within 30 days from date ofreceipt of material.1/10/Net 30 on open accounts. For consideration ofan open account, customers are requested to supplybanking information and at least three commercialcredit references. Visit www.smalley.com for Termsand Conditions that apply.F.O.B.Factory, Lake Zurich, Illinois, USAPackagingRings and springs 34 mm in diameter and under arebulk packaged. Rings and springs 35 mm and overin diameter are generally tube (coin) packaged inlengths 250 mm to 450 mm.DeliveryParts carried in stock normally will be shipped within48 hours after receipt of an order. Special parts arenormally delivered in three weeks (if no specialprocesses are required) or as previously arranged.8smalley.comNo-Tooling-Charges For Customs

QUALITY ASSURANCESmalley’s Total Quality Management philosophydictates our commitment to quality and customersatisfaction. While this commitment has earned usofficial certification (ISO 9001, ISO/TS 16949, AS 9100and ISO 14001), quality assurance and customersatisfaction mean much more at Smalley. They aretradition; the very foundation upon which we havebuilt our company. From the beginning, we havenever lost sight of our goal: To supply customers withuncompromising quality and service.Robust Quality TrainingOur entire manufacturing team is committed to aquality policy built around:In fact, our machine capability studies help usidentify sources of variation before they becomea problem. We analyze the capabilities of allproduction machinery in primary and secondaryoperations, heat treating and finishing. We alsofollow our own meticulous procedures to determinethe reproducibility and repeatability of our gaugingsystems. Conformance to specifications with controlled lotvariation about the target Statistical quality control Defect prevention Annual improvement in process and productEvery Smalley employee works toward excellence,individually and cooperatively, to provide superiorproducts and services.Approved Supplier StatusA history of quality and strict compliance with militaryand aerospace standards has earned Smalley anapproved supplier status with many leading OEMsworldwide. In accordance with the requirements ofISO 9001, ISO/TS 16949, AS 9100 and ISO 14001,we have established and continuously improve uponour quality systems. Use of the latest technology,including statistical tools, has helped us achieveand maintain the world-class quality associated withSmalley for more than 50 years.Smalley uses statistical quality control tools to assurethe capability and stability of our coiling process: First, we identify common dimensions to monitorand special causes of variation in the product Then, we collect and analyze data on these criticaldimensions, performing disciplined samplingand taking measurements during in-line andfinal inspection—and yet again during preshipping inspectionIn addition to quality testing, Smalley makes formalSQC in-house training programs mandatory formany employees involved in manufacturing. Thistraining has noticeably developed quality awarenessand responsibility at all levels, giving employees aclear understanding of what is expected, a meansof regulating their processes and checking theiroutput, and statistical tools to ensure optimalmachines performance.Confidence Delivered DailyBased on our careful quality documentation, manySmalley customers have found that they can reduceor even eliminate their incoming inspections of ourproduct. Many have also revised their dual sourcingpolicy and confidently rely on our team as theirsingle source for Spirolox Retaining Rings, wavesprings, constant section rings, linear springs andother wire forms.Defect prevention, o

metric engineering and parts catalog ready to ship over 10000 standards carbon and stainless stee