Transcription

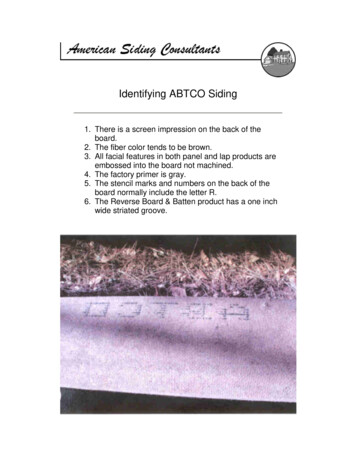

Identifying ABTCO Siding1. There is a screen impression on the back of theboard.2. The fiber color tends to be brown.3. All facial features in both panel and lap products areembossed into the board not machined.4. The factory primer is gray.5. The stencil marks and numbers on the back of theboard normally include the letter R.6. The Reverse Board & Batten product has a one inchwide striated groove.

Identifying Georgia-Pacific Siding BrandsJarratt Siding manufactured by Georgia-Pacific may be identified by oneor more manufacturing stamps or numeric codes like those illustratedbelow:NOTE: If you have the "LWP"stamp, this stamp must reference"MILL NO. 002." If your stamp hasa different mill number, you do nothave Georgia-Pacific Jarratt Siding.A five or six digit numeric code containing the letter "J" may also be used. Forexample:2062J14126J40263J3The back of Jarratt Siding has a screen-like texture or pattern because ofits manufacturing process. This imprint will look similar to one of thefollowing:If the siding sample you remove from the structure has a smooth or nontextured back, you do not have Jarratt Siding. Also, Jarratt Lap Sidingwith a beaded edge may be distinguished from other lap siding byreference to the following:Georgia-Pacific Jarratt Lap Siding

Examples of Lap Siding By Other ManufacturersCatawba Siding manufactured by Georgia-Pacific has a smooth back andmay be identified by one or more manufacturing stamps or numeric codeslike those illustrated below:A numeric code that may contain the letters "GP"or "USP" for example:2 21: 38 257 89 GP13:25 365 96 GP2 21:38 257 87 USP07:11 10 04 96Because stamp and code locations vary with manufacturer, recommendsremoving an entire panel (4'x8') or board (16' length) that shows thecondition at issue. Following removal, locate all legible manufacturer'sstamps and markings. Compare the sample and any markings on thesample to the illustrations provided above.

Identifying Louisiana-Pacific Siding BrandsLouisianaPacificInnerSealexteriorsiding,like many other siding products, is designed to look like solid wood. For thatreason, it is often difficult to tell it apart from other kinds of siding.What is Inner-Seal Siding?Inner-Seal siding (and earlier generations known as Waferwood) is a compositewood product made from wafers of wood that are coated in resin and thenformed into a "mat." A resin-impregnated overlay is placed over the mat, which isthen pressed into panels under heat and pressure. The panels are then cut intoboards to make lap siding or into sheets to make panel siding.There are Two Kinds of Inner Seal-SidingInner-Seal Lap Siding is sold as 16-foot long wood boards. The boards are 7/16inch thick and are either 6, 8, 9 1/2, or 12 inches wide. Lap siding is installedhorizontally with the top portion of each board overlapped by the board above.Most of the Inner-Seal lap siding has a textured surface, designed to look likerough sawn solid wood. Some lap siding was sold with a smooth surface. Thebottom edges of Inner-Seal siding are either slightly beveled or cut at an angle.They are not rounded.Inner-Seal Panel Siding is sold in 4x8, 4x9 or 4x10-foot sheets. The panels areeither 7/16 or 9/16-inch thick. Most of this siding was made with grooves spacedeither 4 inches apart or 8 inches apart, although some siding was made with nogrooves. The grooves are cut square and the bottom of the grooves are flat, withno ribs. Most Inner-Seal panel siding has a textured surface designed to look likerough sawn wood, although some Inner-Seal panel siding was sold with asmooth surface.Other Tips for Identifying Inner-Seal SidingAsk your builderThink back to when the siding was installed. Inner-Seal siding comes from the

An Excellent ClueThe grain pattern on most Inner-Seal siding is embossed using a specially mademetal plate. Engraved on that plate is the distinctive knot shown in this photo.The knot is about 2 1/4 inches high andshould appear on most installations,although not on every board. If you believeyou have Inner-Seal siding, look closely tosee if you can find the knot. If you find theknot, it's a good indication that you mayhave Inner Seal Siding.Click on thumbnail for detail

Identifying Masonite Siding Brands

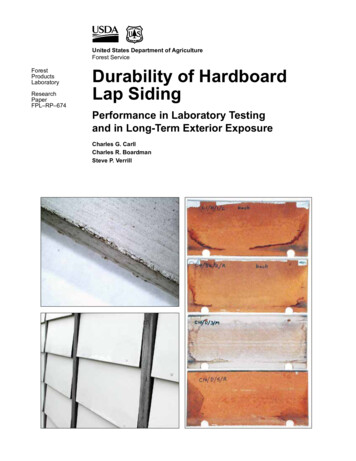

Omni-Board and Omni-Panel are products of the MasoniteCompany. Omni-Board and Omni-panel are essentially thesame product configured for different siding types - lap andpanel.1. Masonite products are typically identified by a stampon the back that says "Masonite" and/or the number"X90"2. The grooves in Omni-Board panels are angled andsealed.3. Omni-Board grooves are cut at a 45 degree anglewhile LP grooves are cut at 90 degrees to the face ofthe panel.4. There are ridges on the back of Omni-Board.5. The wood chips used in Omni-Board Panel siding aresmaller than the wood chips used in Louisiana Pacificsiding.6. The surface of Omni-Board is relatively smooth anddoesn't produce slivers when you run your hand overit.Masonite HardboardMasonite Hardboard siding is a separate product fromOmni-Board, and the process for filing claims for failingHardboard siding is different than for Omni-Board.1. There is a "waffle iron" type pattern on the back of theHardboard product.2. Masonite products are typically identified by a stampon the back that says "Masonite" and/or the number"X90"3. Since there were so many products manufactured atthe same time as Hardboard, sometimes the bestway to identify it is to contact your builder orcontractor.

Identifying Weyerhaeuser SidingWeyerhaeuser siding comes in lap, oversized lap, andpanel siding types.1. When viewed from the back the product is made fromsmall wood fibers - unlike the larger wood chips likeMasonite Omni-Board or Louisiana Pacific Inner-Seal2. Product appears to some people to made from a"cardboard like material".3. Imitation wood details on product surface repeatevery 61 inches.Identifying Boise Cascade Siding Brands

Identifying Stimson Siding BrandsForestex1. Forestex does not crack on the bottom edge like LP siding orOmni-Board2. As Forestex absorbs moisture it swells and causes a "ripple"on the wall as it bows out between the nails.3. The interior material has the feel of cardboard.4. The "wood" patterns on the surface repeat themselves every41 inches.

Identifying Temple-Inland Siding1. Temple-Inland typically has more defined knots thanother manufacturers2. The knots are approx. 52-54 inches apart3. The back of the board doesn't have a screen pattern.4. The color of the back of the board is a dark brown.5. The panel product has a 3/8 inch smooth groove.

Masonite Hardboard Masonite Hardboard siding is a separate product from Omni-Board, and the process for filing claims for failing Hardboard siding is different than for Omni-Board. 1. There is a "waffle iron" type pattern on the back of the Hardboard