Transcription

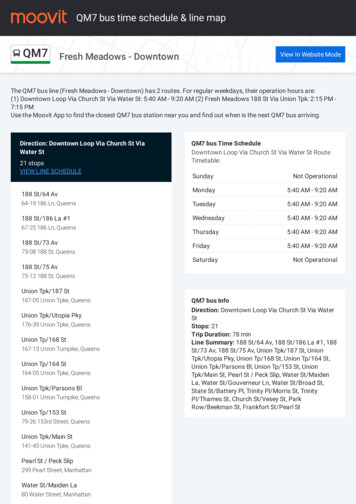

Oil and GasReal-Time On Line Modeling ofUpstream O&G AssetsEng. Luca CadeiAuthors:M. Giuliani, M. Montini,M. Corti, E. Moscinska, C. Bottani,V. La Placa, A. Bianco, P. Fier#PIWorld 2019 OSIsoft, LLC1

AGENDA Project Scope Integrated Production Optimization PI Connection: eDOF Pi Connection: Architecture Field Application Conclusions & Further Developments#PIWorld 2019 OSIsoft, LLC2

Project ScopeBuild integrated production system models fed byreal-time data and able to: represent field operating conditions monitor & optimize asset performances#PIWorld 2019 OSIsoft, LLC3

Project Scope – Main Continuous and Real-time Features1. Monitoring2. Optimization3. Updated Models#PIWorld 2019 OSIsoft, LLC4

AGENDA Project Scope Integrated Production Optimization PI Connection: eDOF Pi Connection: Architecture Field Application Conclusions & Further Developments#PIWorld 2019 OSIsoft, LLC5

Integrated Production Optimization Primary objectives are: Maximise asset value defining best configurationand optimising operating parameters Identify residual potential and bottlenecks Minimise intervention time and costs Minimise/avoid shutdowns Minimise structural interventionsFocus on Production Facilities: from wells tosales point: Reservoir Gathering Network Wells Treatment Plant#PIWorld 2019 OSIsoft, LLC6

Integrated Production Optimization – e-rabbite-rabbit is the in-house developed optimization tool for a multiobjective fitness function: Equity production from wells to stock tank and Operating conditions; Consumptions, emissions, energy efficiency and operating costs;Global maximum identified through the use of an evolutionary algorithm#PIWorld 2019 OSIsoft, LLC7

Integrated Production Optimization – e-rabbit genetic evolutionMethod for solving optimization problems that is based onnatural selection: the process that drives biological evolution.Individuals from the current population are used toproduce children for the next one:Elite childrenCrossover childrenMutation childrenOver successive generations, the population "evolves"toward an optimal solution.#PIWorld 2019 OSIsoft, LLC8

Integrated Production Optimization – Algorithme-rabbit: overcoming relative maximume-rabbit: operating variable exampleAbsolute maximumChoke opening [/64”]Pump speed [rpm]Relative maximumSeparator P [bar]Stabilizer bottom T [ C]Genetic mutation97% of probability success toachieve global maximum#PIWorld 2019 OSIsoft, LLC9

Integrated Production Optimization – Standard Workflow1243#PIWorld 2019 OSIsoft, LLC10

Integrated Production Optimization – Field Data Data Gathering from BU: Activity on demand. Discontinuous dataavailabilitySite survey: Necessary information is collected throughdedicated visits to the plant and meetingswith the operator Real time monitoring - Digital Oil FieldNewdevelopment Field data are available to the HQ in realtime, through PI Potential to extend the study to availablehistorical data, identifying trends andrecurring events, trough PI AF#PIWorld 2019 OSIsoft, LLC11

Integrated Production Optimization – Simulations modelsIntegrated simulationProcess simulationWells/Network simulationReservoirWellsTreatmentPlant Tools: GAP, OLGA, EclipseWells and FlowlinesconfigurationFlow assuranceGathering NetworkAble to capture interactionphenomena among all theasset elements Tools: Hysys (Dynamics) Treatment plant configurationEquipment optimalparameters#PIWorld 2019 OSIsoft, LLC12

Integrated Production Optimization – e-rabbit historical developmentPipeline switch &swing-wellscontrolWHC: ArielIntegrationMulti-objective Target Function Rabbit EnterpriseOn-line Portal2015RabbitDefinition2011Rabbit Parallel SimulationGas lift #PIWorld 2019 OSIsoft, LLC13

Integrated Production Optimization – e-rabbit historical developmentOn-line models &Scheduled SimulationRabbit DynamicGas/Water injectionExploration of newOptimization Algorithms Reservoir integrationAuto-Calibration of modelwith real-time data Speed-up with proxymodels#PIWorld 2019 OSIsoft, LLC14

AGENDA Project Scope Integrated Production Optimization PI Connection: eDOF Pi Connection: Architecture Field Application Conclusions & Further Developments#PIWorld 2019 OSIsoft, LLC15

PI Connection – eDOF Mature technology adopted by O&G Industry various names: Smart Fields , Field of the Future , i-Field , Intelligent Field or Integrated Operations;Based on high frequency data acquired automatically in real time, integrated with lowerfrequency data (daily, monthly ), results of modelling and simulation and manuallycollected data to support better decision making processes;Eni standard configuration is named eDOF: based on configuration of state-of-the artoff-the-shelf components design, implementation and deploymentactivities are performed by Eni people, bothfrom IT and business disciplines,incorporating Eni Intellectual Property. eDOF is actually acquiring/calculating350*106 values every day, with an averagefrequency of 20 sec.#PIWorld 2019 OSIsoft, LLC16

PI Connection – Standard eDOF infrastructureData from theasset arehistoricized at HQGreen Data CenterDevelopment ofthe system fromHQ in tightcollaboration withBU engineersFull support fromEni HQ#PIWorld 2019 OSIsoft, LLC17

PI Connection – eDOF#PIWorld 2019 OSIsoft, LLC18

PI Connection – KPIsDATAINFRASTRUCTUREKPI DEFINITIONKPI MONITORINGMore than 5’000 raw dataper asset per second storedin different TAGsRaw data are elaborated inKPI through application ofinternational standardKPI Implementation andMonitoring(around 100 KPI per asset) PressureTemp.LevelFlowrate APIGPSABest practiceStandards#PIWorld 2019 OSIsoft, LLC19

PI Connection – KPIs top/down logic Overall asset monitoring Fast identification of deviation from normal operation/designNotification/alert to dedicated personwith suggestion to address the issueUser defined dashboardFast troubleshooting Focus on monitoring the entire asset or the digital twinKPI system with Top-Downlogic (from asset to singleequipment)#PIWorld 2019 OSIsoft, LLC20

AGENDA Project Scope Integrated Production Optimization PI Connection: eDOF Pi Connection: Architecture Field Application Conclusions & Further Developments#PIWorld 2019 OSIsoft, LLC21

PI Connection – Architecture General Overview Real-time based application pasteDOFNode 1Manual input ofprocess dataOptimizationAlgorithm SolverPIData feeding onlineand in real-timeModel filesNode 2Node NModel filesModel filesThe new solution ensures data feeding in real-time and lets to use Rabbitfor on-line monitoring and optimization via a user-friendly dashboard22#PIWorld 2019 OSIsoft, LLC21

PI Connection – eDOF to e-rabbit Optimization mode Real-time based application BeforeNode 1Manual inputeDOFPull modePI NowOnline data feedingUser Friendly namingPreprocessed valuesOptimizationAlgorithm SolverModel filesNode 2Node NModel filesModel filesNew real-time connection from eDOF to RabbitEnabler for Rabbit on-line Optimization and Monitoring#PIWorld 2019 OSIsoft, LLC23

PI Connection – eDOF to e-rabbit Monitoring mode Real-time based application BeforeManual Input:NOT usable for automatic executioneDOFMonitoringRunsPull modePI NowNode nPeriodic AutomaticExecutionModel filesOnline data feedingUser Friendly namingPreprocessed valuesNew real-time connection from eDOF to RabbitEnabler for Rabbit on-line Optimization and Monitoring#PIWorld 2019 OSIsoft, LLC24

PI Connection – User Friendly Naming for e-RabbitSiteeDOF (PI)e-rabbitNode 1PI DAPI AFOptimizationAlgorithm SolverModel filesNode 2Node NModel filesModel filesTags881 MFPM 101 FO 031881 U12 105 DPA 031881 U12 114 CVPOrganized byCountry & SiteAF ElementsPhysical Well 01 Oil Flow RateWell 05 Flow Line PressureWell E2 Choke Equivalent OpeningPreprocessed Values#PIWorld 2019 OSIsoft, LLC25

PI Connection – Preprocessing for e-RabbitRaw ValueChecking for: Bad Value Spikes (low and high limits) Stales (standard deviation) Minimum Good Values (percentage)PI AF AnalysesPeriodic execution (5m)Filtered Value and Status ValueAs configured: Noise reduction (moving average) UoM conversion Value Mapping (linear interpolation)toRabbit Value#PIWorld 2019 OSIsoft, LLC26

PI Connection – Central Architecture High Availability Architecturecentred on a couple of servers for each of the 4 main components 2 servers for PI Data Archive2 servers for PI Asset Framework2 servers for PI Vision2 servers for MS SQL(PI Collective)(load balanced)(load balanced)(Always-On) Hosted inside Eni GDC (Green Data Center) in Northern Italy 2 completely separated and independent buildings 3 Data Rooms for each Building For each HA couple, the servers are located in a different GDC buildingsMore details in GothenburgPI World EMEA ?!#PIWorld 2019 OSIsoft, LLC27

AGENDA Project Scope Integrated Production Optimization PI Connection: eDOF Pi Connection: Architecture Field Application Conclusions & Further Developments#PIWorld 2019 OSIsoft, LLC28

Field Application – Operating Advantages of Near Online Models Integrated asset optimization Availability of simulation model up to date: Link of real time data tosimulation models Data reconciliationScheduling of Network and processsimulationIdentify deviation from expectedbehavior#PIWorld 2019 OSIsoft, LLC29

Field Application – Simulation Set upSimulation setupAsset choiceModel inputNotes#PIWorld 2019 OSIsoft, LLC30

Field Application – Mapping of AF elements with GAP input#PIWorld 2019 OSIsoft, LLC31

Field Application – Output Comparison for Monitoring and TuningGAP sim. outputAF element valueThresholddefinitionComparisonSimilarly to the KPI structure,we need to define a newindicator that relates fielddata quality and modeloutputs with the real plantoperating configuration#PIWorld 2019 OSIsoft, LLC32

Field Application – Operating Workflow VIDEO#PIWorld 2019 OSIsoft, LLC33

Operating Workflow – Results ExampleseDOF/PDMSmonitoring systemSurface & Subsurface Sensors Downhole P&T Well Head P&T Multiphase flow meter & ASD Prod. Network P&T Topside process (manifold,separator, compressors) 60% oil rateProductionOptimization(Choke up, gas lift,debottlenecking)#PIWorld 2019 OSIsoft, LLC34

Operating Workflow – User Friendly Interface/Collaborative Environment#PIWorld 2019 OSIsoft, LLC35

AGENDA Project Scope Integrated Production Optimization PI Connection: eDOF Pi Connection: Architecture Field Application Conclusions & Further Developments#PIWorld 2019 OSIsoft, LLC36

ENIReal-Time On Line Modeling of Upstream O&GAssetsThe project has been developed with a team of integrated professionals: HQProcess Engineers, ICT Specialists and Site Engineers. The final frameworkhas been implemented on Eni 4.0 Assets (Digital Lighthouse Project)CHALLENGELack of updated simulationmodels for: Diagnosis/Monitoring of (manifestor possible) production systemSOLUTIONNear on-line digital twin based onadvanced algorithm (e-rabbit, KPIs),simulators and PI (eDOF) system PI tools: PI AF, PI DARESULTSReal-time monitoring of the assetsthrough simulated results based onreal-time data and Updated modelfor scheduled Asset optimization Significant reduction of time duringmodel updating process (2-3 workingdays) Design / verification of particularproduction modes, oftentemporary/transient Simulators: GAP/Prosper, Hysys Check of operating procedures forspecial conditions Test Field: on-shore south Europe,off-shore West-Africa Early and continues support to detectissues, bottlenecks and optimizationopportunities Debottlenecking and productionoptimization new field operatingconditions/constraints Potential application: asset servedby eDOF (PI based system) Licenses optimization and modeltuning standardization Orchestrator: e-rabbit Support to daily and long term assetmanagement#PIWorld 2019 OSIsoft, LLC37

Conclusions – Central & Local SiteseDOF appe-rabbit appGreen Data CenterCentralized system, collecting worldwide data from near to 40 different local data sources#PIWorld 2019 OSIsoft, LLC38

Thank you for the attention Luca Cadei Deputy Plant Manager Eni Southern District luca.cadei@eni.comCo-Authors: Martino Corti, MarcoMontini, Marco Giuliani, ElzbietaMoscinska, Cristina Bottani, VittoriaLa Placa, Amalia Bianco, Piero Fier#PIWorld 2019 OSIsoft, LLC39

Thank You!!#PIWorld 2019 OSIsoft, LLC40

PI Connection – KPIs scope and architectureKPI: Water\Oil droplet diameter 1 and 2 St Nozzles vibration 1 and 2 St#PIWorld 2019 OSIsoft, LLC41

Questions?Please rememberPlease wait forthe microphoneState yourname & companyDOWNLOADTHE MOBILEAPP#PIWorld 2019 OSIsoft, LLC42

#PIWorld 2019 OSIsoft, LLC43

sales point: Reservoir . #PIWorld 2019 OSIsoft, LLC e-rabbit is the in-house developed optimization tool for a multi-objective fitness function: Equity production from wells to stock tank and Operating conditions; . for on-line monitoring and optimization via a user-friendly dashboard