Transcription

Air Treatment DivisionDATA & FACTSGEA Close ControlE-Range – Aerial Values Always On The Level

DescriptionGEA Close ControlE RangeThe Range .3Upflow and Downflow VersionsDirect Expansion and Chilled Water Units .3Key to Type Codes .3Energy Saving Options .4Dimensions Downflow Units .5Dimensions Upflow Units . 6Unit Weights / Access / Typical Airflow Arrangements .7Guide Specification .8General Details . 11Cooling Performance: "X" & "A" Versions . 13Cooling Performance: "W" & "F" Versions . 14Cooling Performance: "C" Version . 15Electrical Details . 16"X" and "A" Version .16"W", "F" and "C" Version .17Schematic Diagrams . 18"X" Version.18"A" Version.19"W" Version.20"F" Version.21"C" Version .22Ancillaries and Options . 232PR-2006-0296-GB y Subject to modifications y Status 05/2007

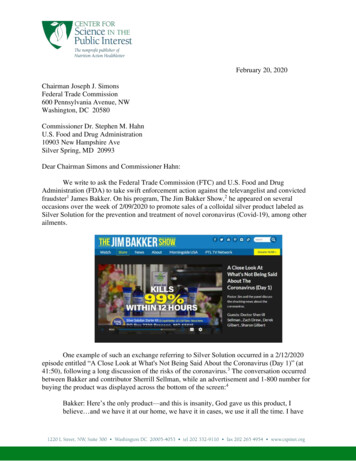

The RangeGEA Close ControlE RangeKey to Type CodesUpflow and Downflow VersionsDirect Expansion and Chilled Water UnitsThe "E" Range of air conditioning units is compact and stylish with the higherperformance and quality demanded by today's close control air conditioning market.These units are designed and built using our unrivalled experience in close controlair conditioning, with extensive testing of components and complete systems. Everyaspect is engineered to ensure maximum reliability, economy of operation and longworking life, together with ease of installation and maintenance.The "E" Range comprises eight (8) models, in four (4) cabinet sizes, with nominalcapacities from 22 kW to 100 kW in the following versions: -X: Split System using Denco Condensing Units.A: Air Cooled DX System with inbuilt compressor(s) and using Denco DCRACondensers.W: Water Cooled DX System with inbuilt compressor(s) and Water CooledCondensers.F: Ambicool System.C: Chilled Water System.D: Combicool SystemKey to Type CodesExample:U 54 A V G HHG VA 54U PR-2006-0296-GB y Subject to modifications y Status 05/2007Humidifier fittedFront Grille Return - U only(as opposed to underfloor return)Variable Refrigerant Flow (VRF)A - Air Cooled SystemX - Split SystemW - Water Cooled SystemF - Ambicool SystemC - Chilled Water SystemD – Combicool SystemUnit Size: 24, 34, 44, 54, 64, 74, 84 and 94Upflow (D Downflow)3

Energy Saving OptionsGEA Close ControlE Range"E" Range air conditioning units incorporate all of the energy / cost saving benefitsfor which Denco products are renowned. These include:Ambicool (Glycol freecooling system) - "F" Version(not available on models 48 – 83)This substantially reduces annual energy consumption, andconsequently costs, by exploiting low average ambienttemperatures to provide partial or full freecooling. It is veryunusual to experience the design summer ambient for anylength of time, and external temperatures are generallyconsiderably less for much of the year. This allows thedrycooler to produce glycol at lower temperatures.When the glycol is colder than the room air, it is passedthrough the economy coil before reaching the condenser,picking up some heat directly from the room rather than viathe refrigeration system. Under conditions such as this, thecompressor run time is reduced, thereby saving energy. Asan example, some degree of freecooling is usuallyavailable for 70 % of the year in northern Europe, givingvery substantial running cost savings.Variable Refrigerant Flow (VRF) - "V" OptionThis provides various compressor options for efficient partload performance, with exceptional economy.Full Cooling LoadBoth compressors running to circulate the full designrefrigerant flow in order to achieve specified maximumcooling capacity. The scroll compressor coefficient ofperformance (COP) is typically 3.5.Part Load OperationLead compressor only running to circulate approximately60% of the refrigerant flow. Evaporator and condenser areboth oversized under this condition, causing increase insuction pressure and a reduction in discharge pressure.Resultant part-load COP increases to typically 5.0.Secondary benefits include reduced temperature swing andincreased compressor reliability caused by reduced cyclingand an optional two-stage high-pressure trip. Lower inrushcurrent and inbuilt redundancy is also provided by dualcompressors and reduced humidifier run time – due to thevery high sensible heat ratio achieved at the higherevaporating temperatures. Payback period is typically lessthan one year.4PR-2006-0296-GB y Subject to modifications y Status 05/2007

GEA Close ControlE RangePR-2006-0296-GB y Subject to modifications y Status 05/2007Dimensions Downflow Units5

Dimensions Upflow Units6GEA Close ControE RangePR-2006-0296-GB y Subject to modifications y Status 05/2007

Unit Weights / Access / Typical Airflow ArrangementsGEA Close ControlE RangeUnit WeightsWeights : (approx.) kgs2434445464748494Version: "X" and "C"345345485485735735795795Version: "A"5205357707951045109012201230Version: "W"5355508608901075113012801305Version: "F"720740116512001480152517051760Unit Access RequirementsThe "E" Range of air conditioning units has been designedto be completely front access for service / maintenance viathe front hinged / removable doors. Therefore, noallowance for access to the ends or back is necessary,although the end panels can be removed in-situ if required.Typical Airflow ArrangementsSection "A" Downflow, into raised floor. Return from room or ceiling.Section "B" Upflow, with horizontal discharge plenum, and front grille return.Section "C" Upflow, with ceiling duct extension and underfloor return.PR-2006-0296-GB y Subject to modifications y Status 05/20077

Guide SpecificationGEA Close ControlE RangeCabinetThe cabinets shall be attractively designed having bevelled corners with flush fittingcurved panels. Units shall have a rigid frame, manufactured from non corrodingAluzink, with hinged curved front panel(s) to provide access for installation andservicing. Panels shall be lined with class "O" non eroding insulation material withboth thermal and acoustic properties. External panels shall be manufactured frompre-coated steel, colour Grey (RAL number 7024).Cooling CoilThe coils shall be multi row constructed from 3/8" O/D copper tubes withmechanically bonded aluminium fins. Direct expansion coils shall have internalgrooving for optimum heat transfer. The coil face area shall be maximised to ensurehigh sensible heat ratio and low airside pressure drop, thereby minimising fan powerand noise level. A stainless steel drain tray shall be included to ensure efficientremoval of the condensate, via a factory fitted trap.--DX: Units shall have one, two or four refrigeration circuits (dependent uponmodel), inclusive of liquid distributor, expansion valve, solenoid valve, sight glassand filter drier, and these components shall be housed in the cabinet.C: Units shall be fitted with a modulating 3 way valve having manual overridefacility with water pressure / temperature test points, and these components shallbe housed in the cabinet.FansLarge, low speed, double inlet, double width fans with forward curved impellers and"sealed for life" ball or roller bearings shall be used to minimise noise levels. Unitsshall have one, two, three or four fans, depending on unit size, each fan to have itsown TEFC motor and speed variation by manually adjustable pulley. Units shallinclude fan fail / airflow alarm which shall in the event of an alarm condition disableall outputs except unit run.8PR-2006-0296-GB y Subject to modifications y Status 05/2007

Guide SpecificationGEA Close ControlE RangeElectric HeatersElectric heaters shall have rigid Incoloy sheathed elements with stainless steelfinning balanced over three phases and rated to operate at black heat. Control shallbe in one or two stages, each stage being protected by a high temperature safetycut-out.FiltrationThe filters shall have an efficiency of 30 % ASHRAE 52/76 Eurovent 4/5 arrestancevalue 90 % (G4). They shall be fitted in the return air stream, held by quick releaseretaining clips, and be accessible from the front of the unit. A differential pressureswitch shall be fitted which, through the alarm facility in the microprocessorcontroller, shall indicate when the filters need changing.CompressorsFully hermetic scroll compressors, one (or two - VRF only) for each refrigerant circuit,shall be located out of the airstream in the services section of the air handling unit for"A", "W" and "F" versions. The compressor(s) shall be located externally in thecondensing unit for "X" versions. When fitted inside the unit, compressor(s) shall beresiliently mounted on a robust frame to minimise noise and vibration transmission tothe structure. Each compressor shall be fitted with back seating isolating valvestogether with crankcase heater ("X" systems only) and on larger models an oil levelsight glass shall be fitted.An external adjustable high pressure cut off switch, with manual reset facility shall beprovided for high pressure protection, in addition to the internal devices. To protectprimarily against loss of refrigerant charge, an adjustable low pressure switch shallalso be provided, which includes an automatic reset facility. On "X" and "A" versionsa LP alarm delay function for temperatures down to -25 C is fitted as standard.Condenser Fan Speed Controllers shall be fitted as standard to units operating withair cooled condensers ("A" version). The controllers, one for each refrigeration circuit,are located within the service section of the Air Handling Unit giving easy access forservicing and adjustment.Note: Where air cooled condenser are not of Denco manufacture, they must besingle phase and have a FLC of less than 5A per circuit to operate with this option.Water Cooled CondensersThe condenser shall be a compact brazed plate heat exchanger having a multiplicityof parallel stainless steel pressed plates. The construction shall give high turbulentflows resulting in a compact heat exchanger form with low pressure drops.HumidifierThe humidifier shall be of the electrode boiler type, located in the bottom of the unit.Features shall include proportional steam output and microprocessor control withalarms and diagnostic facilities. The control system shall allow the use of a widerange of mains water conditions and optimise drain down frequency for maximumoperational economy.DehumidificationThis shall be achieved by switching cooling stages as required, in the case of a VRFsystem this would run both compressors on one of the refrigeration circuits.PR-2006-0296-GB y Subject to modifications y Status 05/20079

Guide SpecificationGEA Close ControlE RangeElectrical PanelThe electrical switchgear shall be contained in a cubicle located in the top of the unit,and shall include:- Controller baseboard and modules (if applicable)- MCB's and contactors for fans, heaters, humidifier and compressors asappropriate- MCB's for remote condensing units (if applicable)- MCB's plus pressure operated on off switches for remote condensers (ifapplicable)Cabling shall be colour coded and numbered, and neatly run in trunking segregatinghigh and low voltages. All wiring shall comply with BS EN 60204 Part 1.Control PanelThe control system and display and push buttons shall be positioned at eye-level inthe front hinged panel of the unit. The door interlocked isolator is positioned in aseparate fixed box behind this panel. The electrical switchgear, contained in ahinged cubicle behind this panel, shall include:-A bottom entry gland plate with grommeted cable entry holesMCB's and contactors for fans, heaters, humidifier and compressors asappropriate- MCB's for remote condensing units (if applicable)- MCB's plus pressure operated controls for remote condensers (if applicable)- Condenser fan speed controllersCabling shall be colour coded and numbered, and neatly run in trunking segregatinghigh and low voltages. All wiring shall comply with BS EN 60204 Part 1.Microprocessor ControlsAll units shall be fitted, as standard, with a C3-05 advanced microprocessor controlssystem, designed by Denco. This shall provide maximum economy of operation, acomprehensive intelligent alarm system and a wide range of information foroperators and service engineers. All information shall be presented in a user friendlyformat with tamper proof setting up arrangements.In addition to precise control of temperature and humidity, the system shall includethe following features:- A liquid crystal semi - graphical display indicating unit function via icons,displaying control conditions and historic logging of temperature and humidityconditions.- Coded security access for set point parameter adjustment- Programmable stage delays, to minimise inrush currents- A comprehensive alarm system. Alarms shall be memorised and displayed in theorder in which they occur in order to aid fault diagnosis- Programmed set points and parameters shall be held in a non volatile memory,therefore being safeguarded upon power failure- Denco Net functions are a standard feature within the controller.- Various third party communication and interface options are available whichconnect direct to the C3-05 controller.10PR-2006-0296-GB y Subject to modifications y Status 05/2007

General DetailsGEA Close ControlE RangeGeneral DetailsD / U - All VersionsCoils:Coil Face AreaFans:No. of FansAir VolumeNoise Level †Fan MotorFan 9837.56139.28Electric Reheat:No. of 251511.251511.25D/U Filters:No. of 40525100PR-2006-0296-GB y Subject to modifications y Status 05/200711

General DetailsGEA Close ControlE RangeD / U - All 35/402"X" VersionsSuction LineLiquid LineHumidifier FeedDraininsinsmmmmStandard C.U.No. C.U.’s fitted-"A" VersionsDischarge LineLiquid LineHumidifier FeedDraininsinsmmmmStandard CompressorNo. Compr. fittedA/C Condenser *No. Condensers fittedDCRA-"W" VersionsCondenser Water InCondenser Water OutHumidifier FeedDrainmmmmmmmmStandard CompressorNo. Compr. fittedW/C CondenserNo. Condensers fittedB-"F" VersionsCoolant InCoolant OutHumidifier FeedDrainmmmmmmmmStandard CompressorNo. Compr. fittedW/C CondenserNo. Condensers fittedB-"C" VersionsChilled Water InChilled Water OutHumidifier alve SizeValve kvinsm3/hr1¼161½25240240Note: 12- Quiet / Residential Condensers are available as an alternative to the Standard versions stated.PR-2006-0296-GB y Subject to modifications y Status 05/2007

Cooling Performance: "X" & "A" VersionsGEA Close ControlE Range“X” Version2434445464748494m /s2.22.63.44.35.66.26.77.521 C, 50 % .869.00.8885.873.40.8722 C, 50 % .270.30.8788.674.80.8623 C, 45 % 45.841.90.9257.549.80.8861.45 8.80.9670.065.40.9482.376.80.9488.781.80.9324 C, 45 % 44.35.66.26.77.521 C, 50 % .068.30.88103.381.00.8022 C, 50 % .369.60.88106.282.30.7923 C, 45 % .476.00.95106.389.30.8524 C, 45 % .777.30.94109.290.70.84Airflow3 “A” VersionAirflow Note:All values are NOMINAL DUTIES (Standard Airflow and Standard Compressor)Cooling performances are NETT, based on Downflow units and:(a) Standard EU4 / G4 filtration and 50 Pa external static.(b) 32 C ambient temperature.(c) Refrigerant: R407C.(d) Standard Condensing Units (alternative combinations available, enquire for details).(e) Standard matching A/C Condensers (alternative combinations available; enquire for details).(f) Suction line loss 1.5K for “X” Version.K(g) Suction line loss 0.5 for “A” Version.PR-2006-0296-GB y Subject to modifications y Status 05/200713

Cooling Performance: "W" & "F" VersionsGEA Close ControlE Range(h) VRF option available on all models.“W” Version2434445464748494m /s2.22.63.44.35.66.26.77.521 C, 50 % .568.10.89108.583.30.7822 C, 50 % .069.40.88111.984.80.7723 C, 45 % .175.80.95112.191.80.8324 C, 45 % .44.25.66.06.77.321 C, 50 % .963.50.9497.277.20.8122 C, 50 % .264.80.93100.478.80.8023 C, 45 % .368.00.97100.585.60.8624 C, 45 % RHT

"E" Range air conditioning units incorporate all of the energy / cost saving benefits for which Denco products are renowned. These include: Ambicool (Glycol freecooling system) - "F" Version (not available on models 48 – 83) This substantially reduces annual energy consumption, and consequently costs, by exploiting low average ambientFile Size: 1MB